Handling

the INI files

For

technicians!

The following chapter contains information

about the *.ini-files with explanation of used parameters and their meaning.

The following chapter contains information

about the *.ini-files with explanation of used parameters and their meaning.

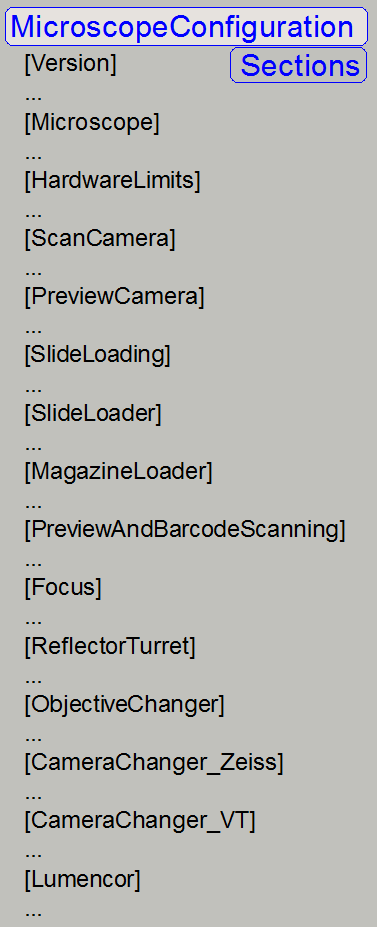

The sample, etalon file “MicroscopeConfiguration.ini”

is stored as “MicroscopeConfiguration.txt” containing all the parameters, used

in the software 1.18 and may be used as starting file for upgrading to the

appropriate software version.

Important

· The scanner specific parameter values of

the etalon ini-file in the sections [HardwareLimits],

[PreviewAndBarcodeScanning] and other sections should not be copied to the

ini-file of the scanner in front of you!!

· The etalon ini-files should be used only

to verify the existence of required parameters; values are mostly unique in

each scanner!

· Please make a security backup of the

existing ini-files before manipulating parameters and values!

·

If modifications are done in the file

“MicroscopeConfiguration.ini”, the scan software “SlideScanner.exe” has to be

started again; only so the modifications take effect (this is true for some

parts of the service program also).

If you working with the service program, please refer

also to “SlideScannerService”

Contents

Construction

of “MicroscopeConfiguration”

Sections

in the file “MicroscopeConfiguration.ini”

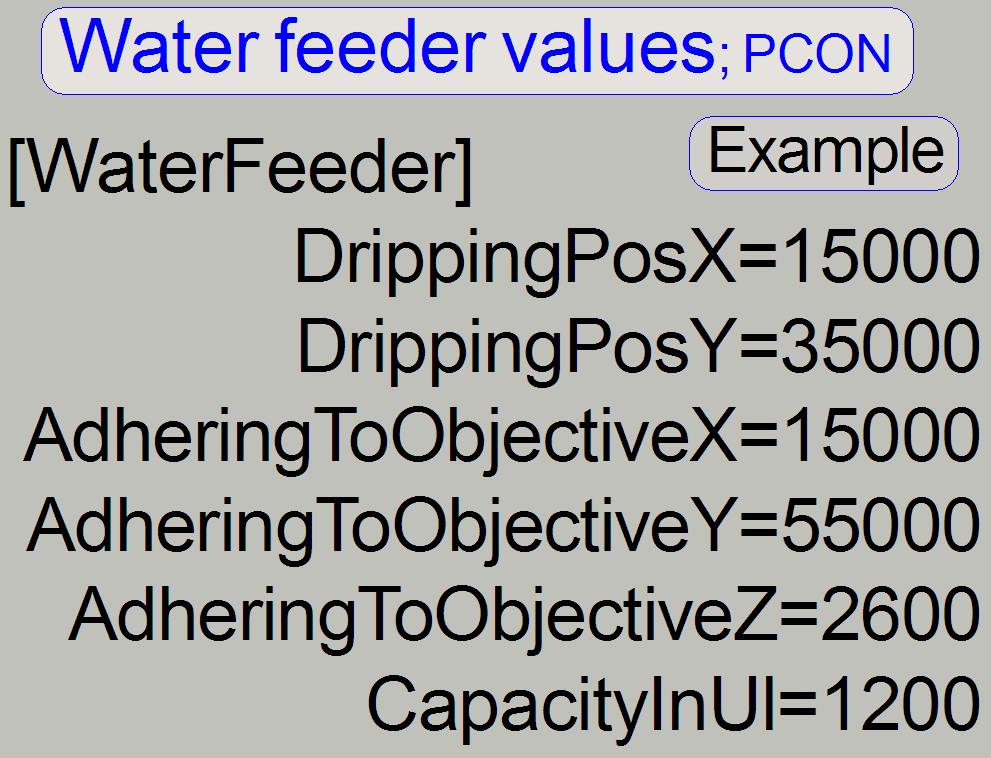

[WaterFeeder]; PCON

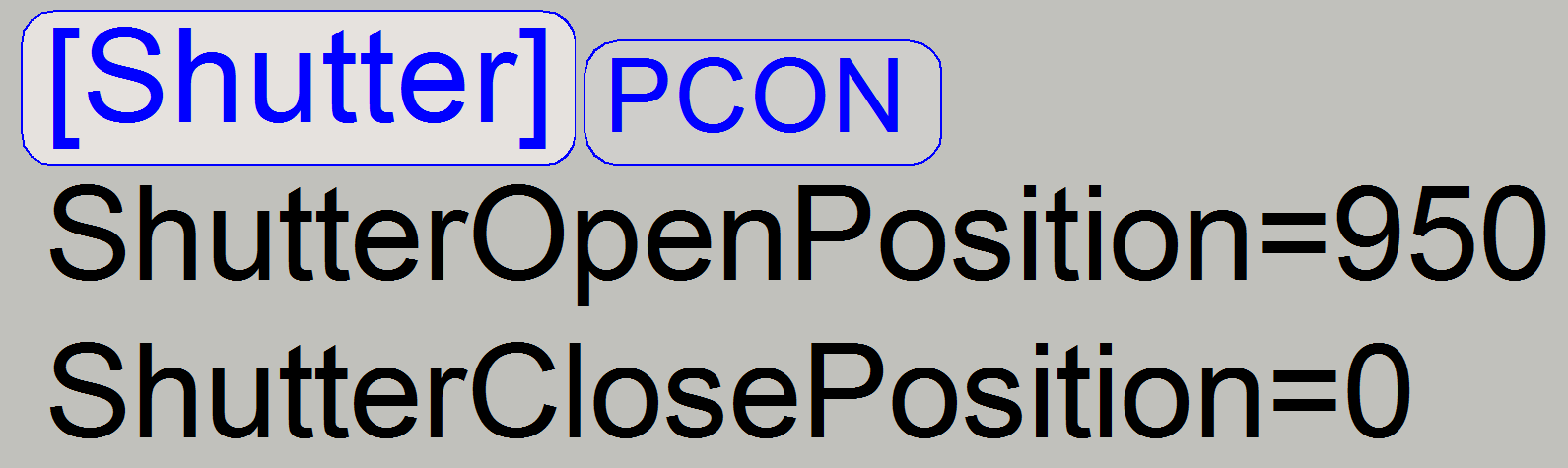

[Shutter]; PCON

As commonly known, the file “MicroscopeConfiguration.ini”

and the file “MicroscopeSettings.ini” contain scanner specific information and

are unique for each scanner.

Before the software version 1.9 these files were

named as “tdhmic_config.ini” and “tdhmic_settings.ini”.

Since the software version 1.9, the files are named

as “MicroscopeConfiguration.ini” and “MicroscopeSettings.ini”.

The file “MicroscopeConfiguration.ini”

contains hardware specific parameters and values concerning the scanner hardware;

these should be modified only during system integration or repair procedures by

a qualified technician!

The file “MicroscopeSettings.ini”

contains settings information concerning the used camera(s), installed

objective type(s) and magnification as well as implemented filters for

fluorescent scan mode. These values are updated during the saving procedure of

the dialogue “Microscope

settings”.

The original versions of the ini-files are stored in

the EEPROM of the Scanner’s USB controller also; please refer to “EEPROM”

· The parameter values of the file

“MicroscopeConfiguration.ini” are not collected in a dialogue, so the technician

has to patch the values by the use of a simple text editor, then the file has

to be saved as a file without formatting information; as a “txt only” type file

with the extension ".ini".

Information about the path of the appropriate

ini-file can be found in the chapter “Paths and locations”

Construction of the file

“MicroscopeConfiguration.ini”

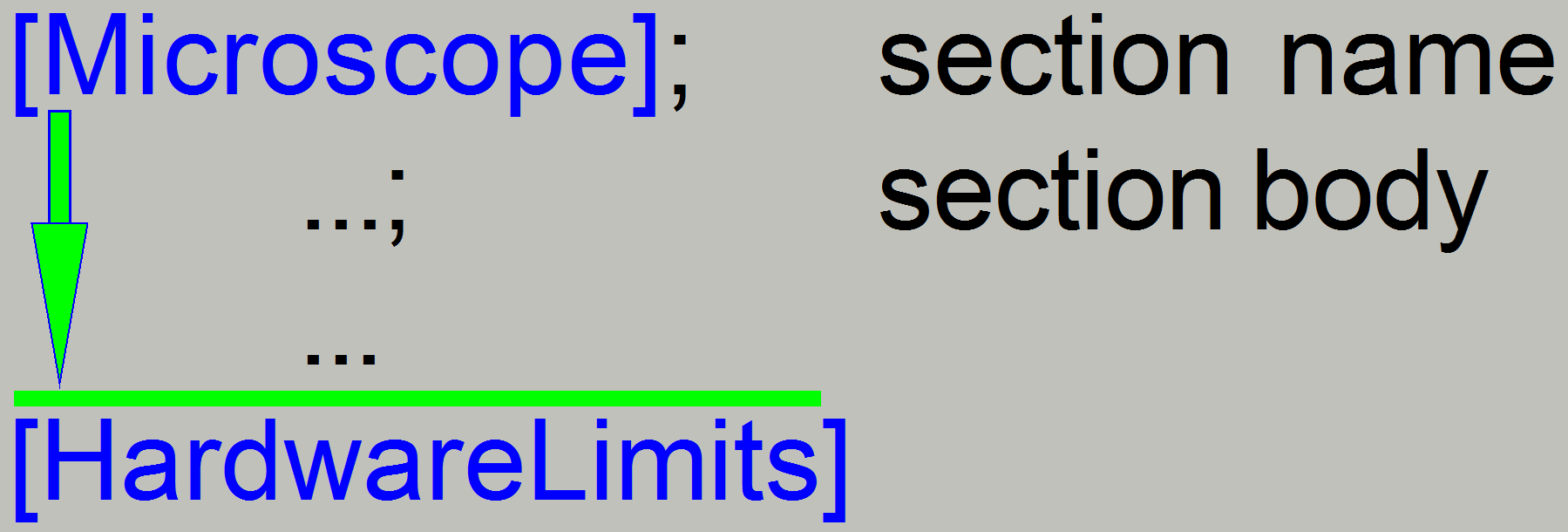

The entire file is divided into sections; the

sections starting with the section name, and this is defined within brackets.

The length of the section, the section body, is defined until the next section

name is found.

[SectionName]

The sections are following each other

sequential in the file.

The sections are following each other

sequential in the file.

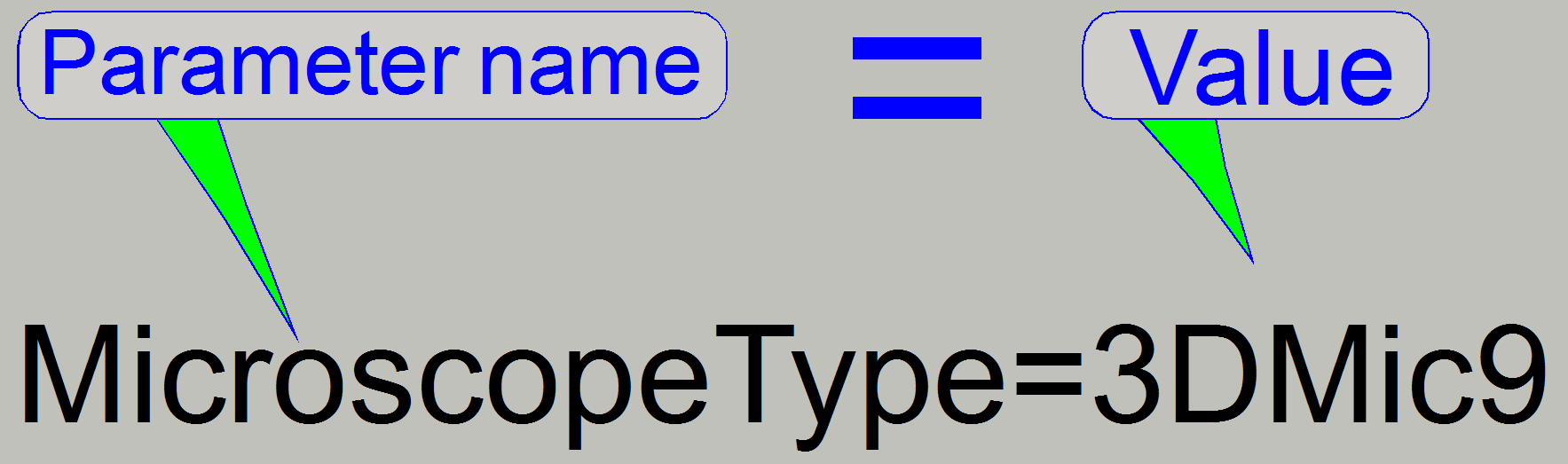

Inside the section body, the parameter value is found

by comparing the parameter name.

· A semicolon “;” behind the value is used

to define comment text in the appropriate line

· If a line starts with a semicolon “;” in

the first character position of the line, the entire line is comment text only.

This is often used to exclude parameters and values from the appropriate

section; so variants of the parameter value can be tested easily and quickly.

·  Each section contains specific parameter

names; the parameter names are unique in the entire file.

Each section contains specific parameter

names; the parameter names are unique in the entire file.

· The value, assigned to the parameter name,

is shown on the right side of the equal sign “=”.

· Negative values starting with a minus (-)

sign!

· Values related to the moving part of the

unit and defined outside the hardware limit are cut to the hardware limit by

the scan software!

Sections in the file

“MicroscopeConfiguration.ini”

It contains information about the construction

of the ini-file; usually the slide scanner software version number is used

since the modification of the ini-file handling is done. This value defines how

to handle the ini-file.

It contains information about the construction

of the ini-file; usually the slide scanner software version number is used

since the modification of the ini-file handling is done. This value defines how

to handle the ini-file.

CurrentInifileVersion=1.8; the

construction is realized in the file “tdhmic_config.ini”

· If the section [Version] or

the parameter “CurrentInifileVersion=” does not exist, the file format is

handled like in the file “tdhmic_config.ini”

Because new parameters are implemented in

the software version 1.9 the construction of the ini-files was modified.

· To decide, how the ini-file

must be handled, the version number was increased.

CurrentInifileVersion=1.9

Since the software version 1.9, the content and the

structure of the files was modified.

The file “MicroscopeConfiguration.ini”

contains hardware specific parameters and values concerning the scanner; these

should be modified only during system integration or repair procedures by a

qualified technician!

The file “MicroscopeSettings.ini”

contains user specific settings concerning the used camera(s), installed

objective type(s) and magnification as well as implemented filters for

fluorescent scan mode. These values are updated during the saving procedure of

the dialogue “Microscope settings”; please see “Setup filters” for

example.

· An example of the sections since the

version 1.9 is shown on the right.

· Not required sections may be left out from

the sequence.

· The sequence of the sections is

unimportant and may vary in the ini-file of the scanner in front of you!

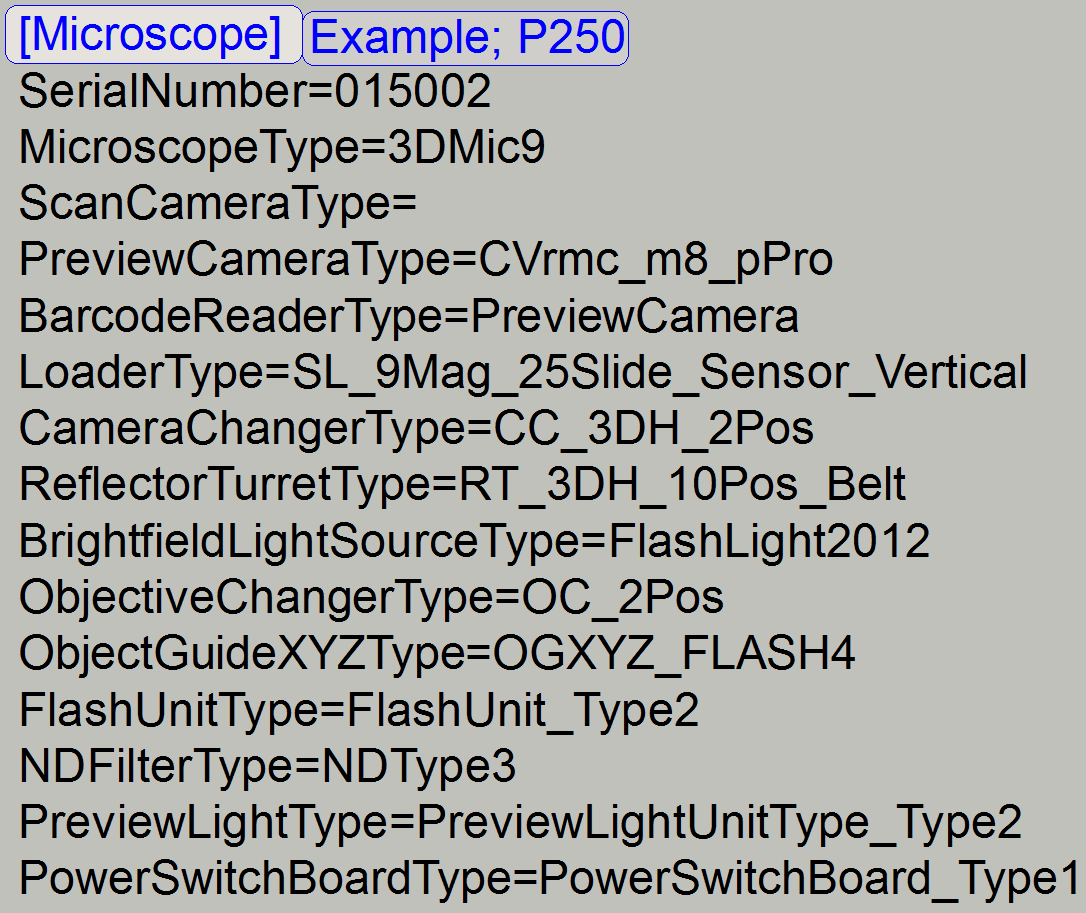

The section [Microscope] contains scanner specific

information concerning the implemented units and components.

An explanation about parameters and values can also

be found in the chapter “Configure …”

of the appropriate unit.

[Microscope]

SerialNumber=xxxxxx; a

six digit number defines the serial number of the P250, so the file MicroscopeConfiguration.ini

is assigned to the hardware. The serial number should be equal (at least

partial) with the serial number on the label of the scanner. The serial number

may contain 15 alphanumerical characters.

SerialNumber=xxxxxx; a

six digit number defines the serial number of the P250, so the file MicroscopeConfiguration.ini

is assigned to the hardware. The serial number should be equal (at least

partial) with the serial number on the label of the scanner. The serial number

may contain 15 alphanumerical characters.

MicroscopeType=3DMic9; 3DMic9

means Pannoramic 250, see “ScannerType”

ScanCameraType=; not

used, defined in the “MicroscopeSettings.ini”

see

Scan

cameras

PreviewCameraType=CVrmc_m8_pPro; the

preview camera type; see Configure

preview unit

BarcodeReaderType=PreviewCamera; Barcode

reading is done by the preview camera

LoaderType=SL_9Mag_25Slide_Sensor_Vertical; Magazine unit type, see: Configure

magazine unit

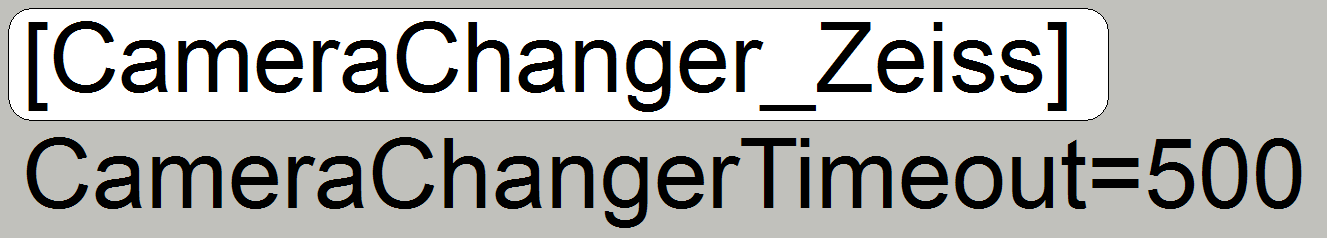

CameraChangerType=CC_3DH_2Pos; see:

Configure

camera changer

ReflectorTurretType=RT_3DH_10Pos_Belt; see: Configure the turret

unit

;BrightfieldLightSourceType=FlashLight2010; see: Configure

brightfield light source

BrightfieldLightSourceType=FlashLight2012; see also: Configure ND filter unit

ObjectiveChangerType=OC_2Pos; see:

Configure objective changer

ObjectGuideXYZType=OGXYZ_FLASH3; see:

Configure

the X-Y-stage unit

FlashUnitType=FlashUnit_Type2; see: Configure electronics components

FlashUnitType=FlashUnit_Type2; see: Configure electronics components

NDFilterType=NDType2; see:

Configure ND-filter

unit

PreviewLightType=PreviewLightUnitType_Type2; see: Configure the preview unit

PowerSwitchBoardType=PowerSwitchBoard_Type1; see: Configure

electronics components

![]() “Focus unit OC” and “Configure the scanner”

“Focus unit OC” and “Configure the scanner”

· Not required parameters may be left out

from the parameter sequence

· Wrongly defined parameter names and values

will be ignored (as it would not be present) or causes a software error

· The sequence of the parameters is

unimportant so it may vary in the ini-file of the scanner in front of you!

Parameter options of the section

· Wrongly defined parameter

names and values will be ignored (as these would not be present) or causes a

software error

MikroscopeSubtype

MicroscopeSubtype=Confocal; modular

MicroscopeSubtype=SCS; modular

Preview Camera

PreviewCameraType=CVrmc_m8_pPro; S_M_D, P250, PCON,

Preview camera for delivered scanners since SW version 1.15

PreviewCameraType=DFK21F04; S_M_D type scanners; Preview camera

for delivered scanners until SW version 1.14

Following

software versions handling the DFK21F04 furthermore!

PreviewCameraSerialNumber=000XXX; SCS; because there are

several VR-magic cameras connected via USB to the same computer, the serial

number is used to distinguish the cameras.

PreviewCameraType =

CVrmc_m8_pPro_Double; DESK_II; the

extension "Double" is used to indicate that the capturing procedure

is done twice.

PreviewCameraType= CVrmc_m8_pPro; the camera VRMC-8+/C is

also recognized by the previously code for delivered scanners since SW version

Preview Illumination type

PreviewLightType=PreviewLightUnitType_Type4;

since SW version 1.20; P250 Flash;

Preview and barcode illumination connected to XYZND controller, SCAN_II

PreviewLightType=PreviewLightUnitType_Type3;

since SW version 1.20; S_M_D,

MIDI_OC; SCAN_OC;Preview and barcode illumination connected to DC-controller,

as usual in MIDI and DESK type scanners.

PreviewLightType=PreviewLightUnitType_Type2; P250 and Flash types; Backgrund and DF

Preview illumination present; BF and FL scan

PreviewLightType=PreviewLightUnitType_Type1; P250 and Flash types; DF preview

illumination removed; BF scan only

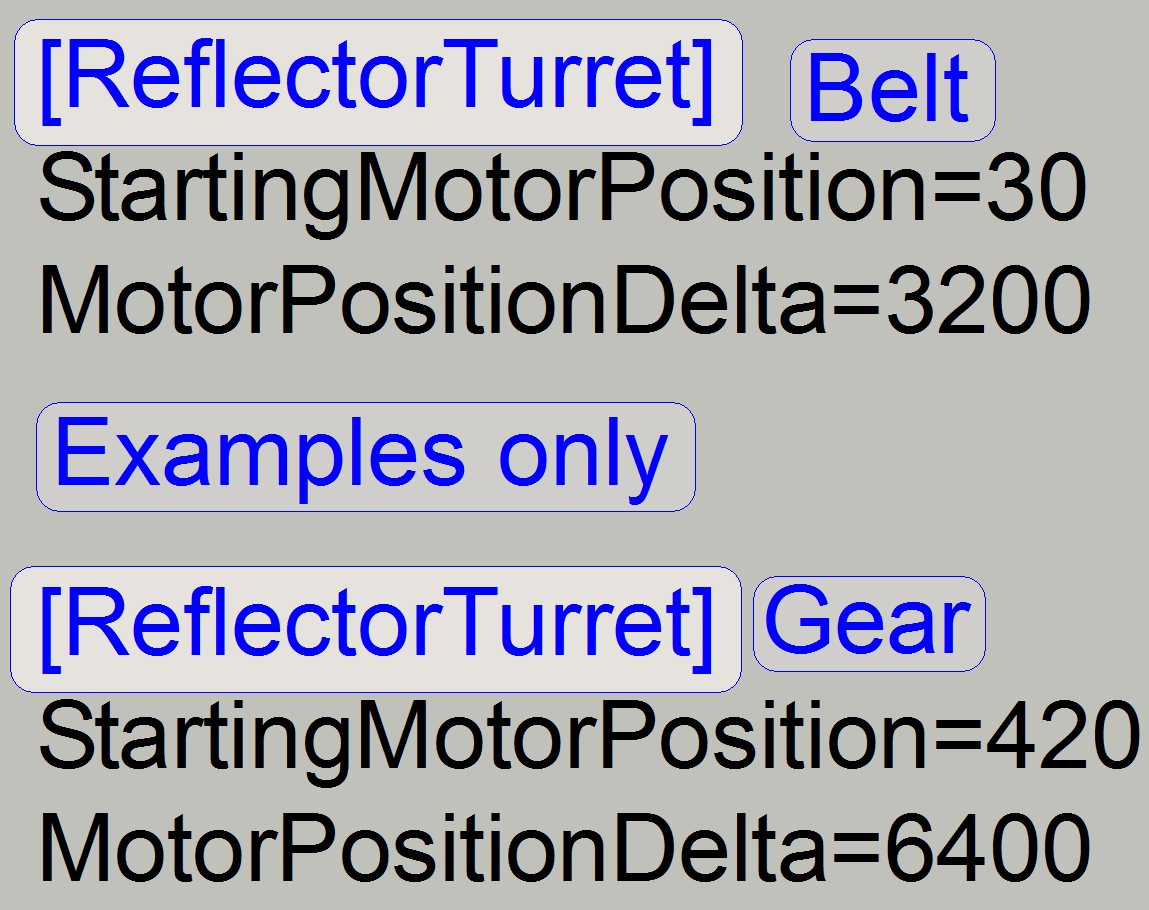

Reflector turret type

ReflectorTurretType=RT_None; any scanner without turret unit mounted;

BF scan only type scanners

ReflectorTurretType=RT_3DH_10Pos_Belt; P250, SCS; S_M_II

ReflectorTurretType=RT_3DH_10Pos_Gears; SCAN and

Camera Changer type

CameraChangerType=CC_None; MIDI_OC; SCAN_OC; PCON, SCS; S_M_D_II, any

scanner without motorized camera changer

CameraChangerType=CC_3DH_2Pos; P250, any scanner with motorized camera changer

mounted

CameraChangerType=CC_3DH_Fix1PosType1; since SW-version 1.18.2; 90° camera tube

present

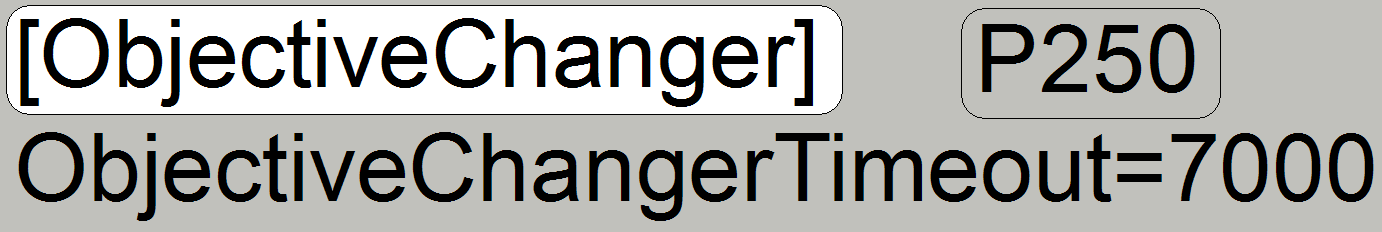

Objective changer type

ObjectiveChangerType=OC_None; S_M_D type scanners

without motorized objective changer or parameter not used

ObjectiveChangerType=OC_2Pos; any scanner with

motorized objective changer

Loader type

LoaderType=SL_9Mag_25Slide_Sensor_Vertical; P250 and Flash types; the magnet

disc stops with the rising edge of the sensor

LoaderType =

SL_6Mag_25Slide_NoSensor_Vertical; SCAN;

the magnet disc stops with the falling edge of the sensor; 3Dmic6 and 3Dmic8

LoaderType =

SL_6Mag_25Slide_NoSensor_Vertical_2; SCAN

150, PSCAN, S_II the magnet disc stops with the rising edge of the sensor;

3Dmic8

LoaderType =

SL_1Mag_12Slide_Sensor_Horizontal;

LoaderType =

SL_1Mag_12Slide_Sensor_Horizontal2; PCON;

LoaderType =

SL_1Mag_12Slide_Sensor_Horizontal_SCS; special

tray for iSaCS; the transporter can reach the tray position 1 of the modular

LoaderType =

SL_1Slide_DoubleWide DESK_II,

single and double width slide

LoaderType =

SL_1Mag_12Slide_Sensor_Horizontal3; MIDI_II

Brightfield scan illumination type

BrightfieldLightSourceType=BLS_Halogen_5W; MIDI_OC; SCAN_OC; S_M_D type scanners

BrightfieldLightSourceType=FlashLight2012; P250 Flash types; BF scan with 40x

magnification possible

BrightfieldLightSourceType=FlashLight2010; P250; BF scan with 40x magnification

impossible

BrightfieldLightSourceType

= RGBLedLight; RGB illumination

unit, PCON, S_M_D_II

Power distribution and switch board type

PowerSwitchBoardType=PowerSwitchBoard_None; MIDI_OC; SCAN_OC; S_M_D type scanners

PowerSwitchBoardType=PowerSwitchBoard_Type1; P250 and Flash type scanners, iSaCS

Object guide type

ObjectGuideXYZType=OGXYZ_1; S_M_D; MIDI_OC;

SCAN_OC; 1.0mm slides; Step motor contains control electronics

ObjectGuideXYZType=OGXYZ_FLASH2; Y-stage=89600steps; 1.0mm slides;

step motor control realized in XYZND-controller

ObjectGuideXYZType=OGXYZ_FLASH3; P250, P250 Flash;

Y-stage=89600steps; XYZND-controller; slides 1.2mm

ObjectGuideXYZType=OGXYZ_FLASH4; Flash2; Stepper motor firmware upgraded

ObjectGuideXYZType =

OGXYZ_TypeDouble; D_II

ObjectGuideXYZType =

OGXYZ_1.2mm MIDI_II

Flash unit type

FlashUnitType=NoFlashUnit; MIDI_OC; SCAN_OC;

S_M_D type scanners

FlashUnitType=FlashUnit_Type2 P250; P250 Flash; P250 Flash2;

X-Y-Z-ND Flash-controller present

ND filter type

NDFilterType=ND_None; MIDI_OC;

SCAN_OC; S_M_D type scanners

NDFilterType=NDType3; Motor driver

firmware upgrade to reach the high scan speed in Flash3 type scanners, since

SW-version1.18.2

NDFilterType=NDType2; P250; P250

Flash;

Water

feeder

WaterFeederType =WF_None; PCON; water feeder not

present

WaterFeederType=WaterFeeder_Type1; PCON; water feeder present

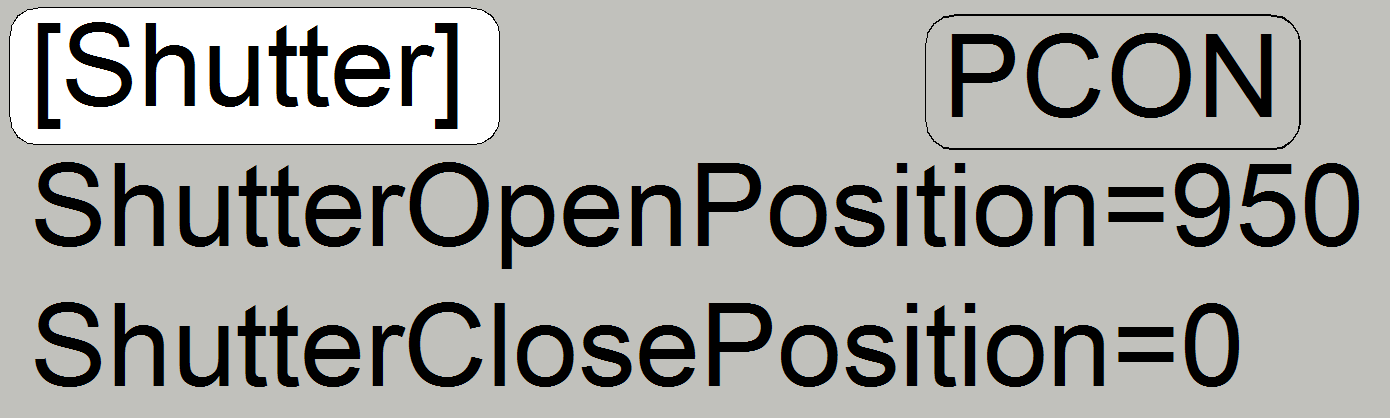

Shutter

motor

ShutterMotorType=Shutter_Motor; PCON; Shutter motor present

ShutterMotorMin= 0

ShutterMotorMax= 300

This section contains the hardware limits of

the moving parts of the units and related values, used in the scanner.

This section contains the hardware limits of

the moving parts of the units and related values, used in the scanner.

· Parameter value “min” is

always less than parameter value “max”!

ObjectGuideXMin=; ObjectGuideXMax=

These values defining the real movement

range of the moving part of the X-stage unit.

![]() “How to define hardware limits”, “X-direction_P250”

and “X-direction_S_M_D”

“How to define hardware limits”, “X-direction_P250”

and “X-direction_S_M_D”

ObjectGuideYMin=; ObjectGuideYMax=

These values defining the real movement

range of the moving part of the Y-stage unit.

![]() “How to define hardware limits”, “Y-direction_P250”

and “Y-direction_S_M_D”

“How to define hardware limits”, “Y-direction_P250”

and “Y-direction_S_M_D”

FocusDeviceMin=; FocusDeviceMax=

FocusDeviceMin=; FocusDeviceMax=

These values defining the real movement

range of the moving part of the Focus unit; the shutter off and shutter on

positions.

![]() “How to define hardware limits”, “Focus unit_P250”

and “Focus unit

_S_M_D”

“How to define hardware limits”, “Focus unit_P250”

and “Focus unit

_S_M_D”

ReflectorTurretMin=; ReflectorTurretMax=

These values defining the real movement

range of the Filter wheel in the reflector turret unit (used in the gear driven

version only).

![]() “How to define hardware limits”, “RTU_P250”

and “RTU_S_M”

“How to define hardware limits”, “RTU_P250”

and “RTU_S_M”

StepSizeXinMicrometer=1; StepSizeYinMicrometer=1; please do not modify

Movement accuracy of the mechanical drive

in X and Y-direction

· These values are constant in all scanner

types.

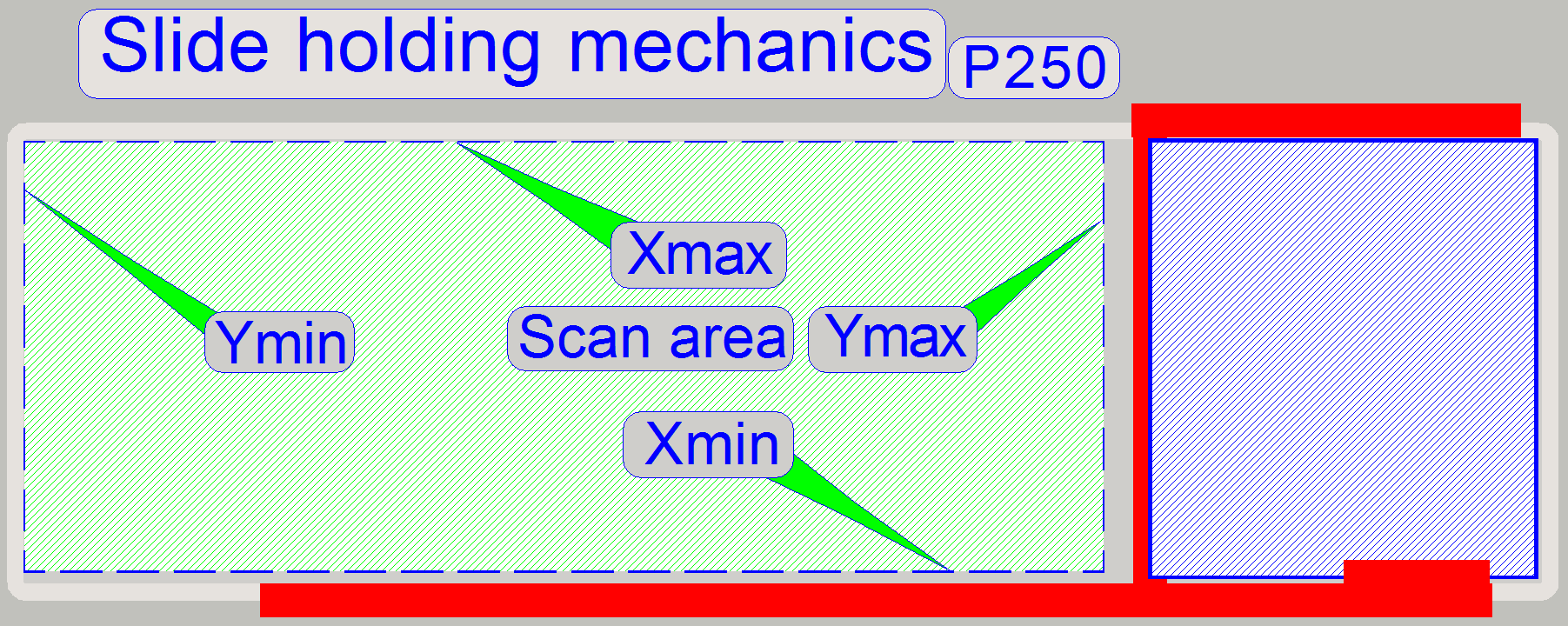

ScannableAreaPositionXMin=; ScannableAreaPositionXMax=

ScannableAreaPositionYMin=; ScannableAreaPositionYMax=

· The scan area is defined just before the

focus pin or the objective touches the specimen holder mechanics of the

scanner.

· The value of the parameter

“ScannableAreaPositionYMin=” will be modified as a result of the preview

calibration procedure.

Detailed information about the scan area

of the appropriate scanner can be found in the chapter:

Physical construction of the specimen

holder “PCON”, “P250”, “SCAN”, “MIDI” and “DESK”

Define

the scan area “PCON”, “P250”, “S_M_D”

Further parameters can be found in the

file “MicroscopeConfiguration.ini” of the PCON,

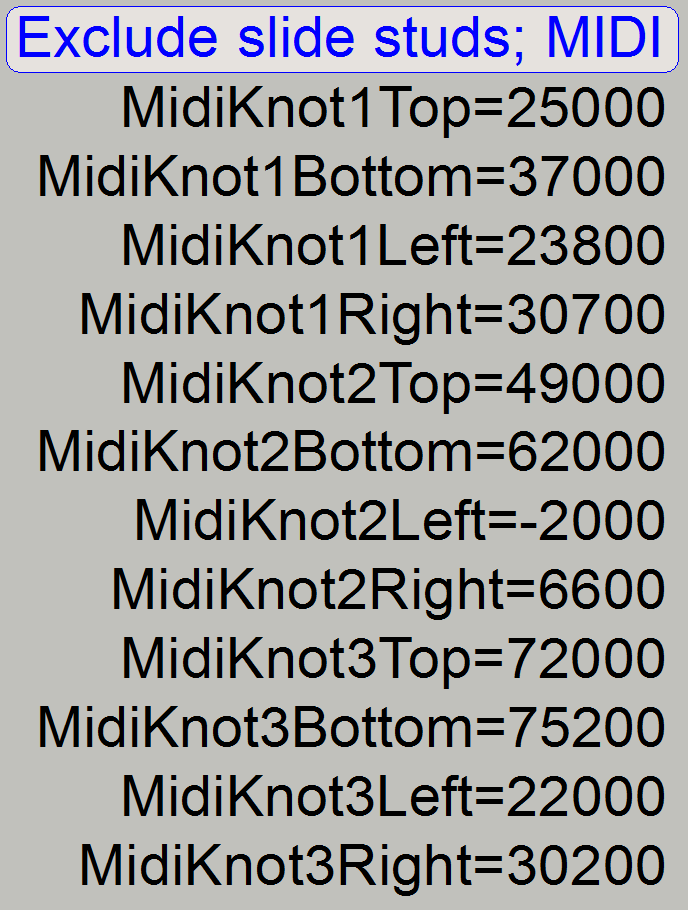

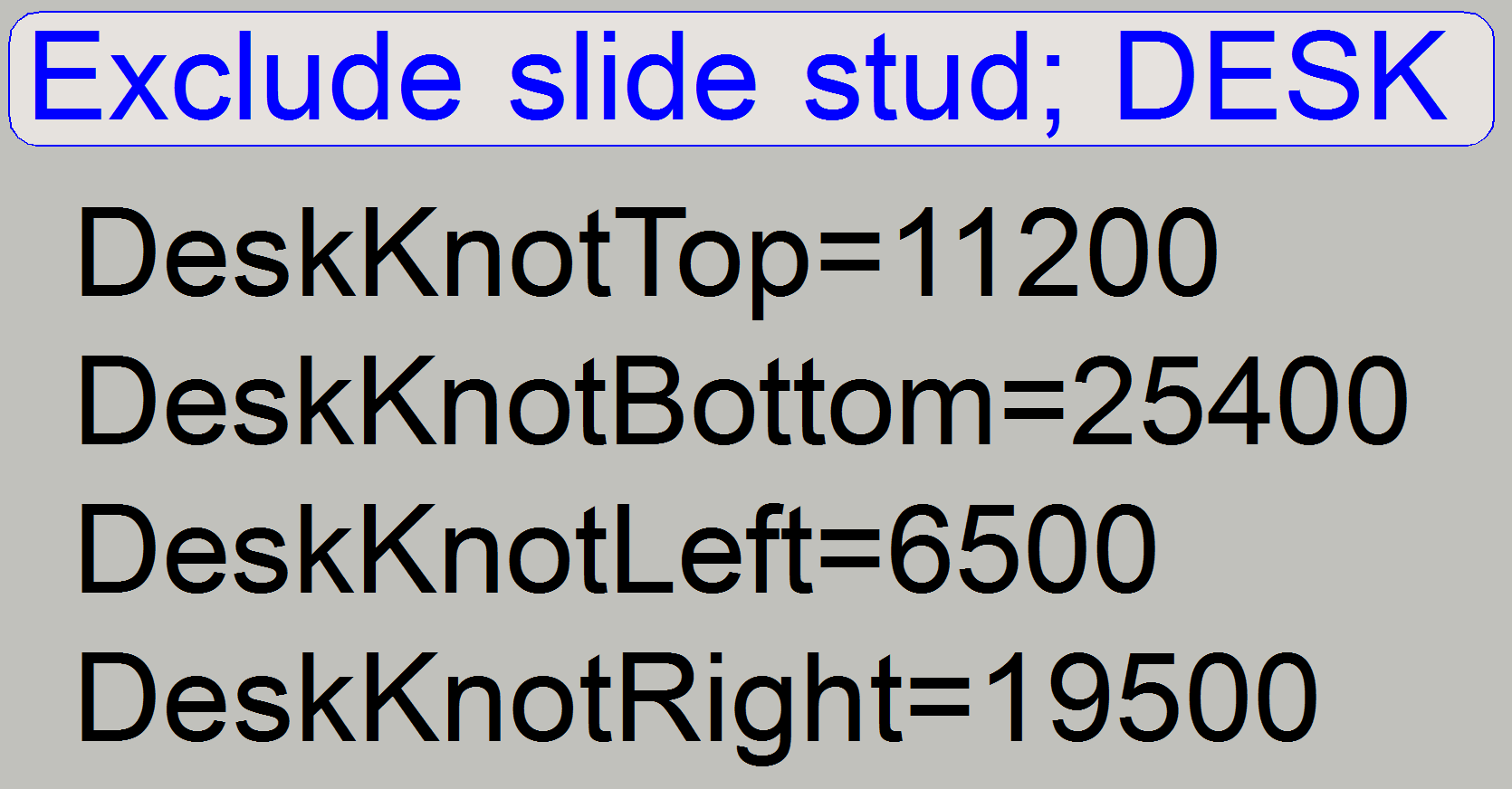

· The area of the slide stud is cut out

explicitly from the scan area of the slide; since the software version 1.16 and higher.

Further information can be found in the chapters:

![]() Scan area

and specimen holder “PCON”, “PMIDI”

and “PDESK”

Scan area

and specimen holder “PCON”, “PMIDI”

and “PDESK”

·  Values on the right are for demonstration only!

Values on the right are for demonstration only!

Remark

· Values, outside the defined hardware

limits are cut to the hardware limit by the scan software!

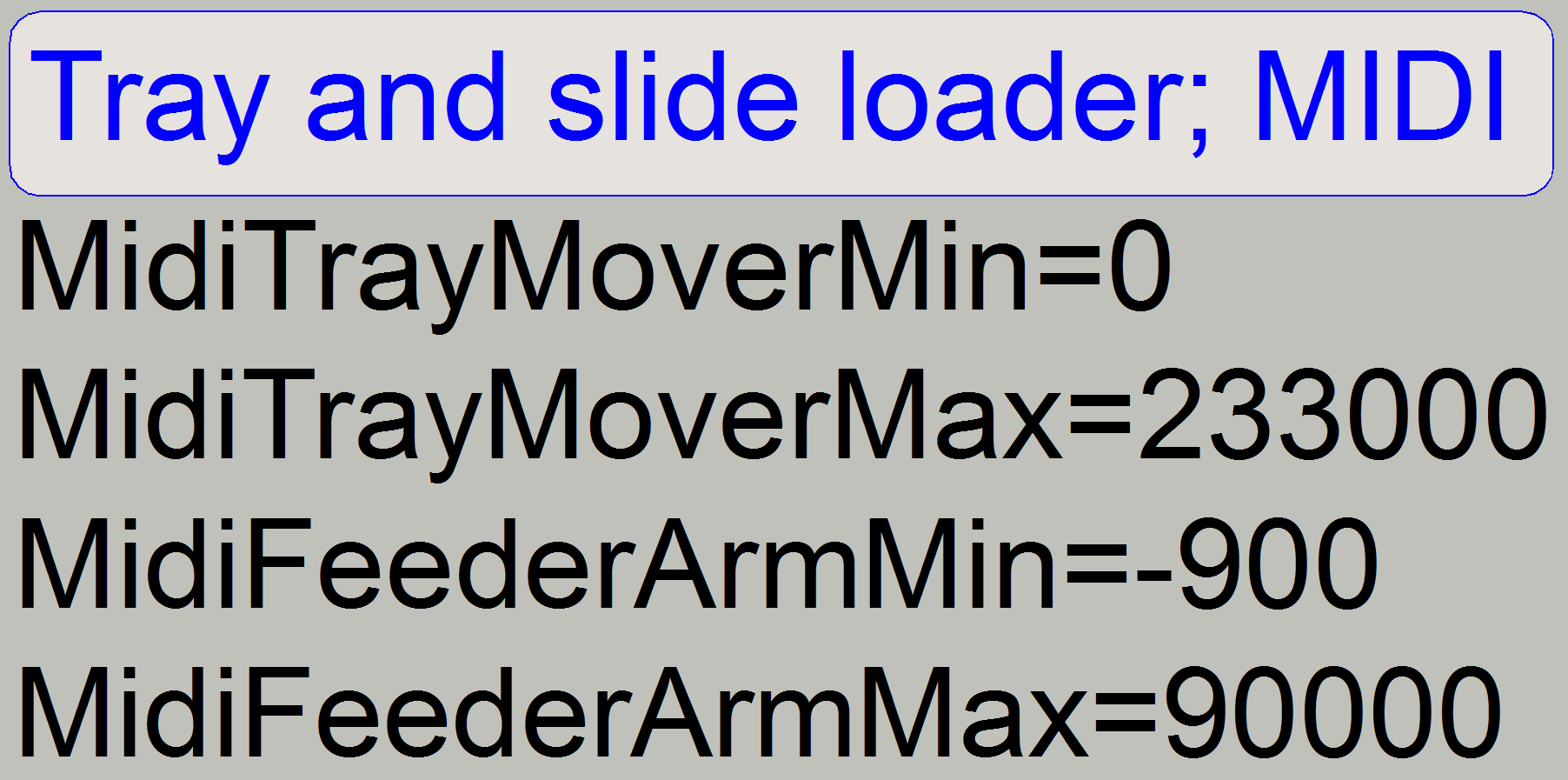

MidiTrayMoverMin=; MidiTrayMoverMax=

The movement range of the tray conveyor

unit is defined with these parameters.

More information about the values can be

found in the chapter:

![]() “Tray- and slide loading”, “Check the physical limits of the tray loader”

“Tray- and slide loading”, “Check the physical limits of the tray loader”

MidiFeederArmMin=; MidiFeederArmMax=

The movement range of the slide loader is

defined with these parameters.

More information about the values can be

found in the chapter:

![]() “Tray- and slide loading”, Define “MidiFeederArmMin”

and “MidiFeederArmMax”

“Tray- and slide loading”, Define “MidiFeederArmMin”

and “MidiFeederArmMax”

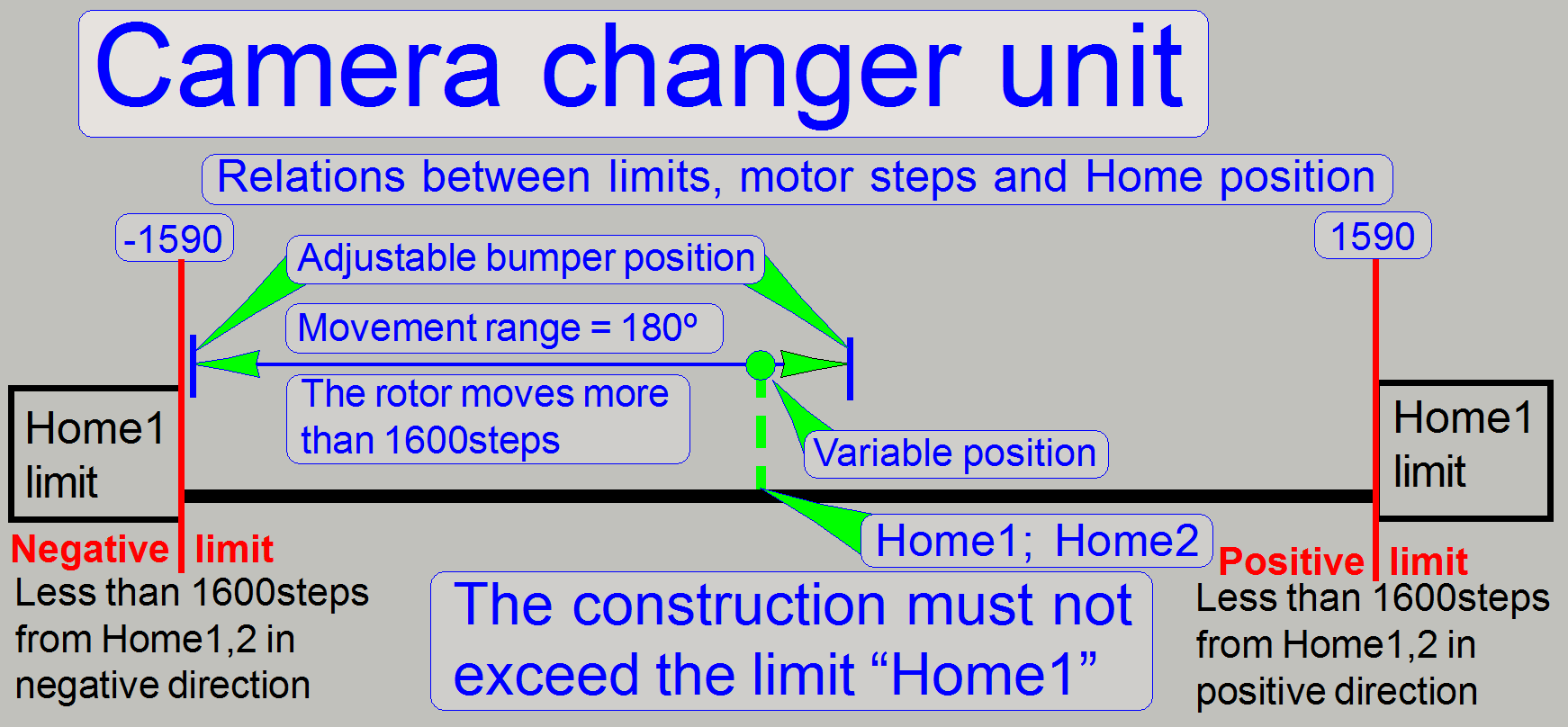

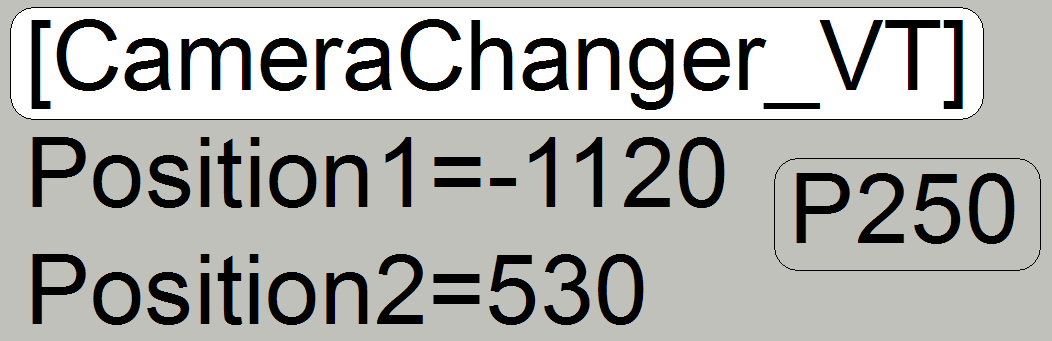

CameraChangerVT_Min=; CameraChangerVT_Max=

These values defining the real movement

range of the camera changer stepper motor’s rotor.

· The sum of both values must exceed the

rotation angle of 180º = 1600rotor steps!

![]() “How to define hardware limits”, “Camera

changer unit” and “Find the

hardware limits”

“How to define hardware limits”, “Camera

changer unit” and “Find the

hardware limits”

PCON, SCAN,

ObjectGuideXYTimeDelayBeforeImageAcquisition=30

This value defines a “pause time” in [ms] between

reaching the desired slide position of the X-Y-stage unit and start of FOV

capturing.

The value is used in the “start-stop” scan mode only

and should help to eliminate vibrations.

· The recommended value is 30ms

· A value of “

· Higher values decreasing the scan speed

(drastically)!

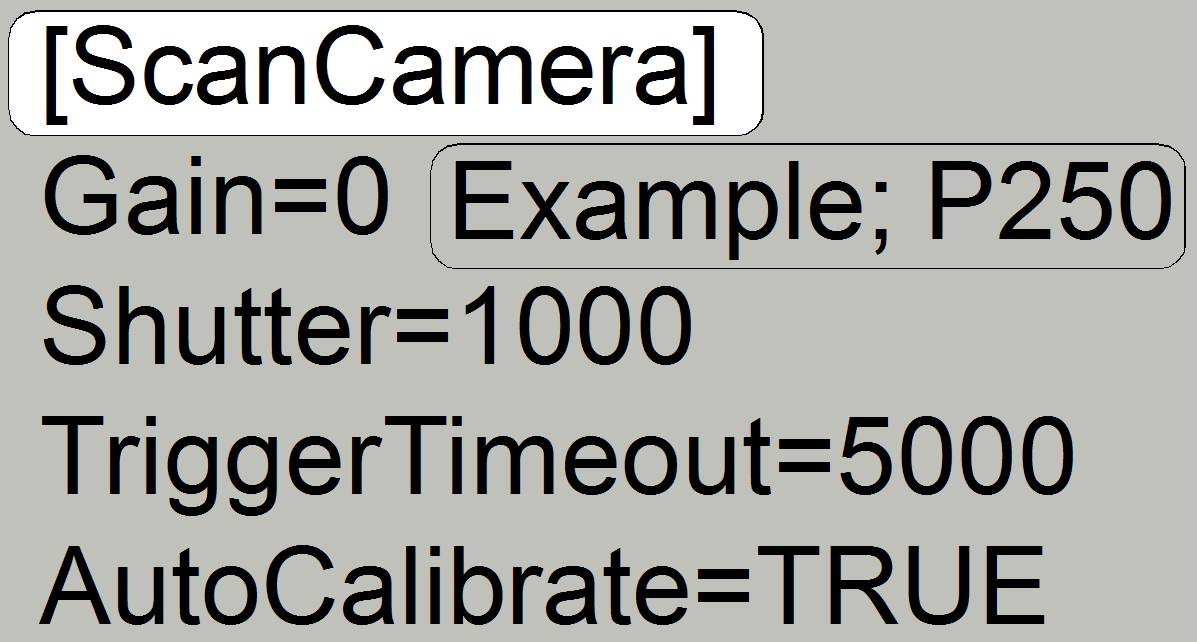

This section contains initial parameter

values for the scan camera; since the software version 1.12 these values are

handled by the scan program SlideScanner.exe; do not modify.

This section contains initial parameter

values for the scan camera; since the software version 1.12 these values are

handled by the scan program SlideScanner.exe; do not modify.

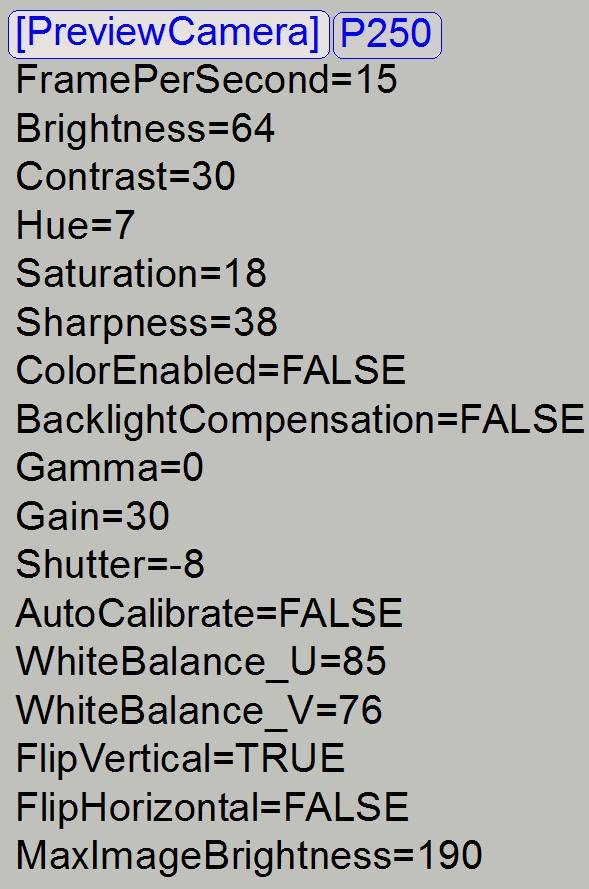

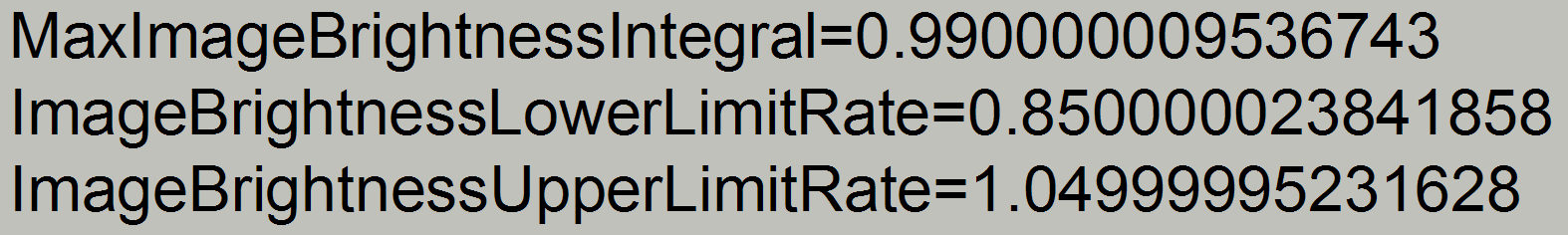

This section contains initial parameter

values for the preview camera; since the software version 1.12 these values are

handled by the scan program SlideScanner.exe; do not modify.

This section contains initial parameter

values for the preview camera; since the software version 1.12 these values are

handled by the scan program SlideScanner.exe; do not modify.

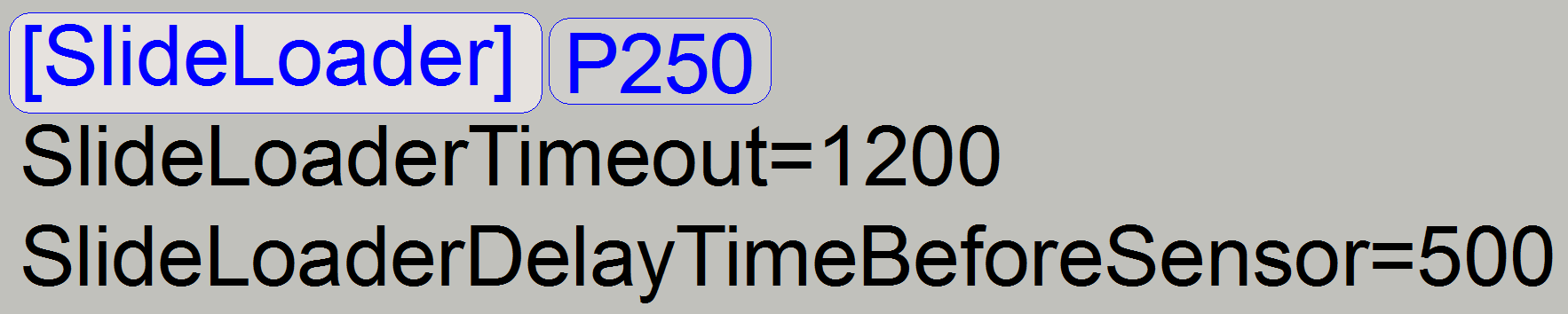

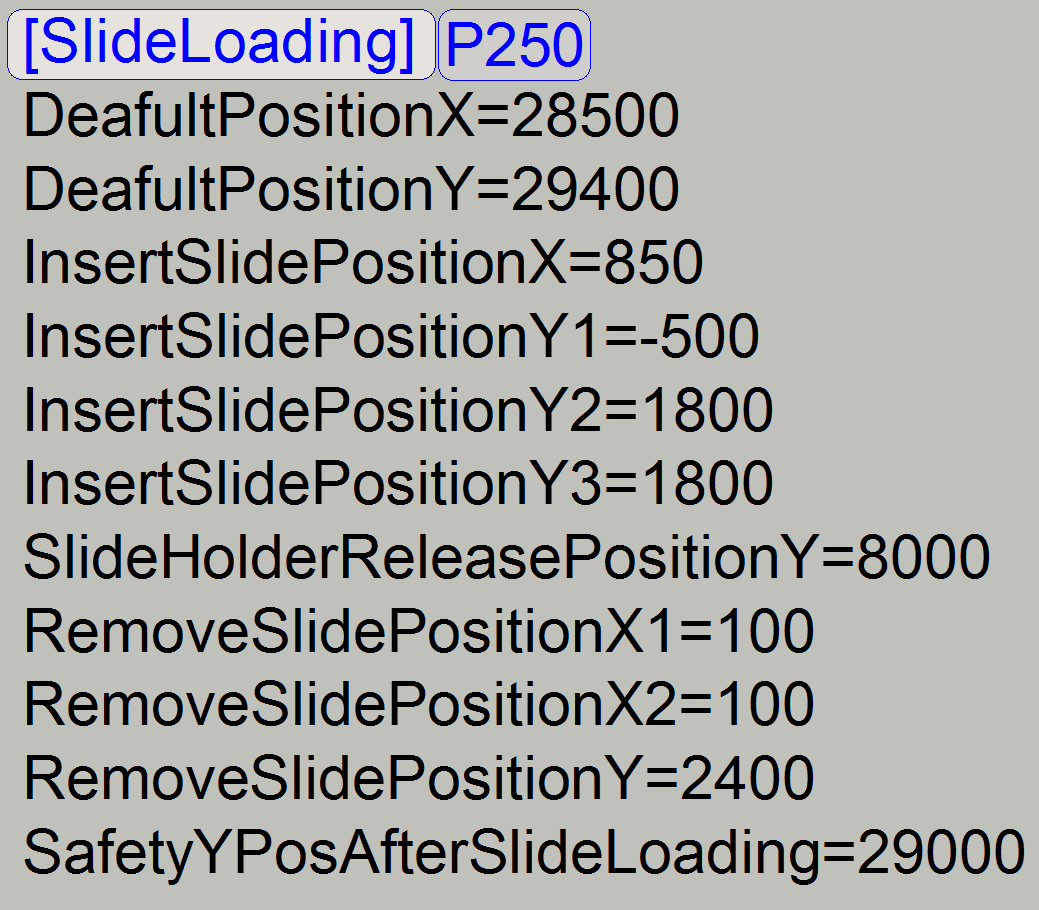

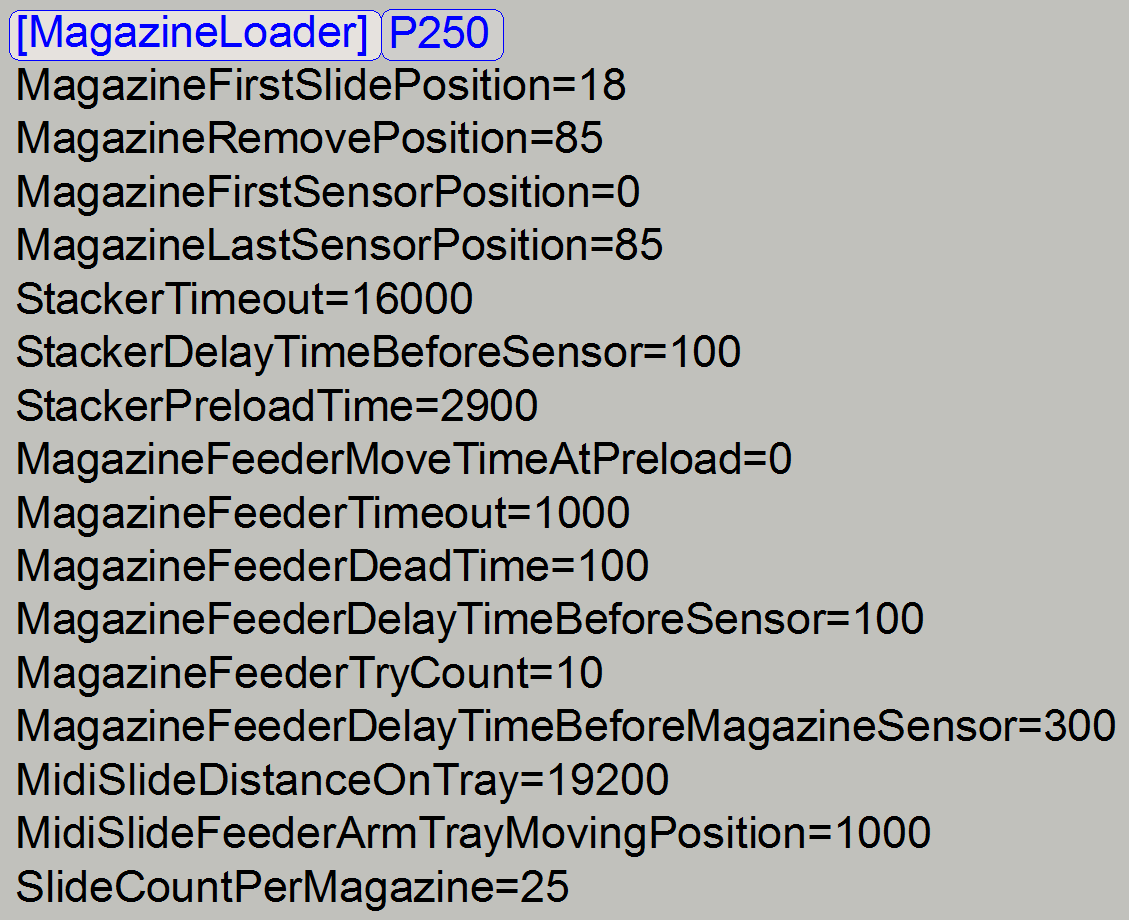

![]() PCON: “Tray_slide_loading”

PCON: “Tray_slide_loading”

P250: “Magazine unit; Slide handling”

SCAN: “Magazine

unit; Slide handling”

DESK: “Define

slide insert and remove parameters”

· Please do not modify these values!

· Please do not modify these values!

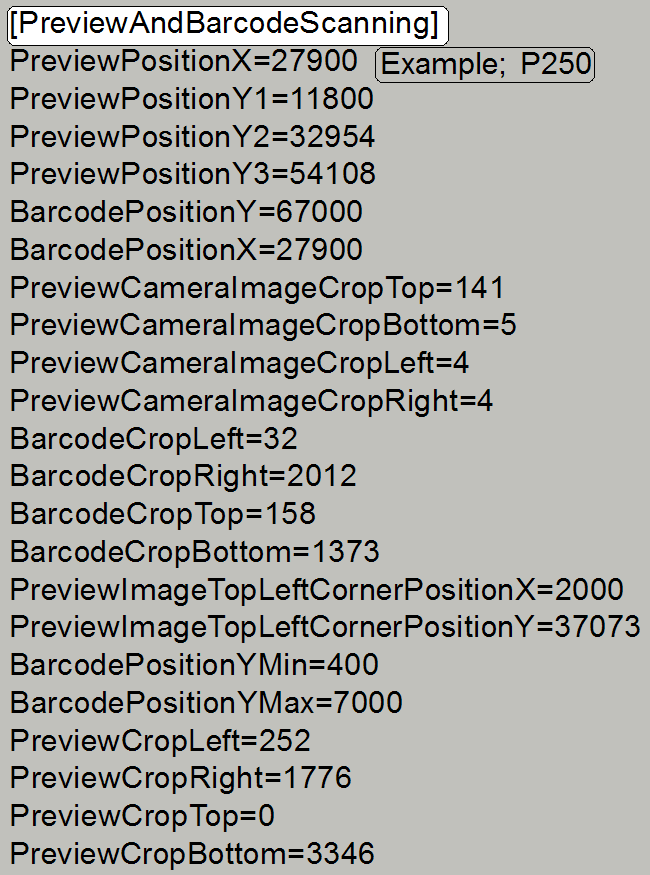

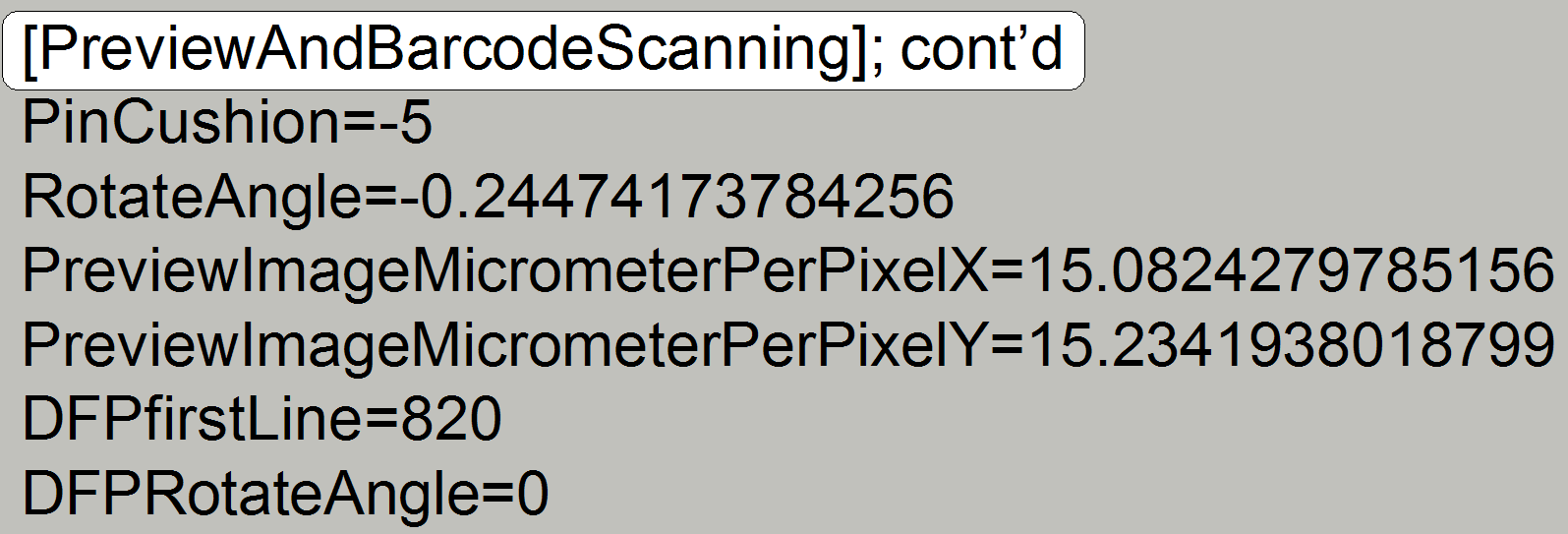

Section

[PreviewAndBarcodeScanning]

![]() “Field of view and Preview Area”

“Field of view and Preview Area”

S_M_D: “Preview

unit”

P250: “Preview

unit” and “Darkfield

preview”

PCON: “Preview”

and “Darkfield

preview”

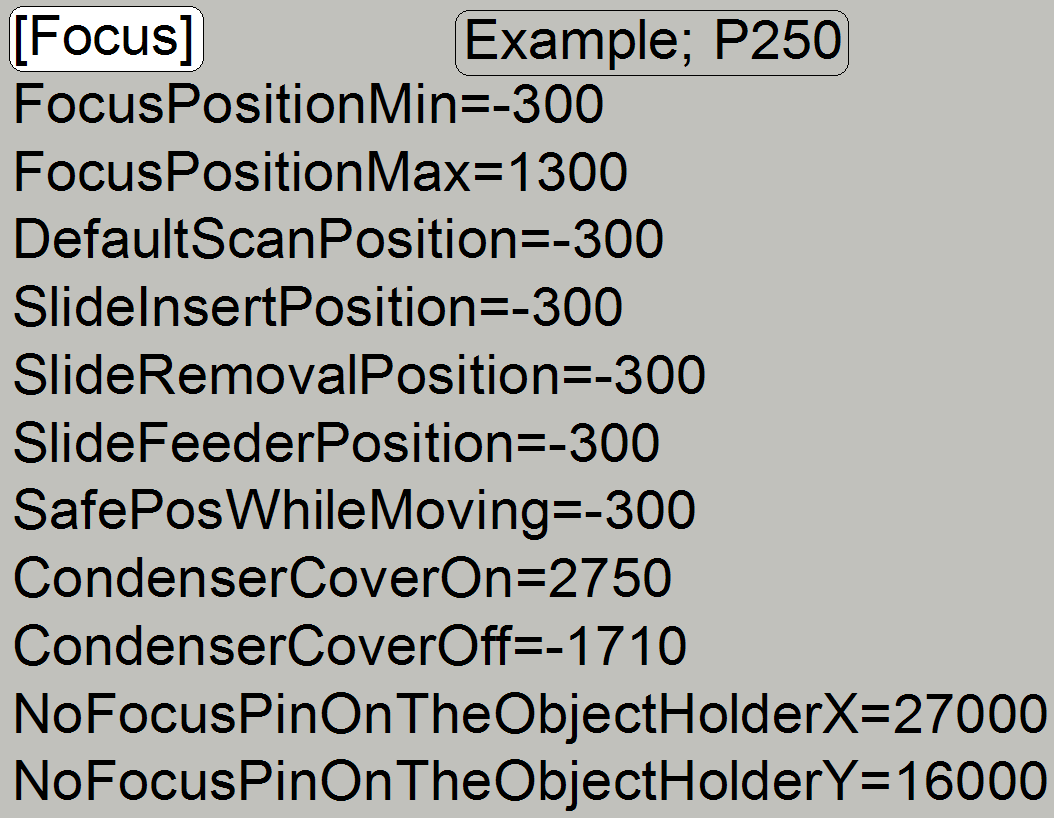

CondenserCoverOn= CondenserCoverOff=

CondenserCoverOn= CondenserCoverOff=

![]() S_M_D: “Focus unit” “Find the hardware limits”

S_M_D: “Focus unit” “Find the hardware limits”

P250: “Objective changer” “Find the hardware limits”

FocusTimeDelayBeforeImageAcquisition=40

Since the SW-version 1.17 defines this value a “pause

time” in [ms] between reaching the desired slide position of the X-Y-stage unit

and start of FOV focusing.

Since the SW-version 1.17 defines this value a “pause

time” in [ms] between reaching the desired slide position of the X-Y-stage unit

and start of FOV focusing.

· The recommended value is 40ms

· A value of “

· Higher values decreasing the scan speed!

![]() “FocusDeviceMin=;

FocusDeviceMax=”

“FocusDeviceMin=;

FocusDeviceMax=”

· Please do not modify not explained parameter values!

![]()

PCON: “Objective changer” “Find the hardware

limits”

PCON: “Objective changer” “Find the hardware

limits”

StartingMotorPosition=

· Defines the correct filter position in

[motor steps] related to the illumination and image path.

· With this value, a deviation to the found

position of Home1,2 is defined, so the next or previous filter position will

fit exactly the image path also.

![]() S_M: “Find the

first filter position”

S_M: “Find the

first filter position”

P250: “Find the first

filter position”

MotorPositionDelta= Do not modify!

MotorPositionDelta= Do not modify!

· Defines the distance between two filter

positions in [motor steps] related to the illumination and image path.

![]() S_M: ”Drive and limits”

S_M: ”Drive and limits”

P250: “Principle of

belt drive”

· Please do not modify these values!

The unit is not implemented

The unit is not implemented

· Please do not modify these values!

Position1= Position2=

Position1= Position2=

·  These parameters defining the mirror working position

in the camera position 1 and 2

These parameters defining the mirror working position

in the camera position 1 and 2

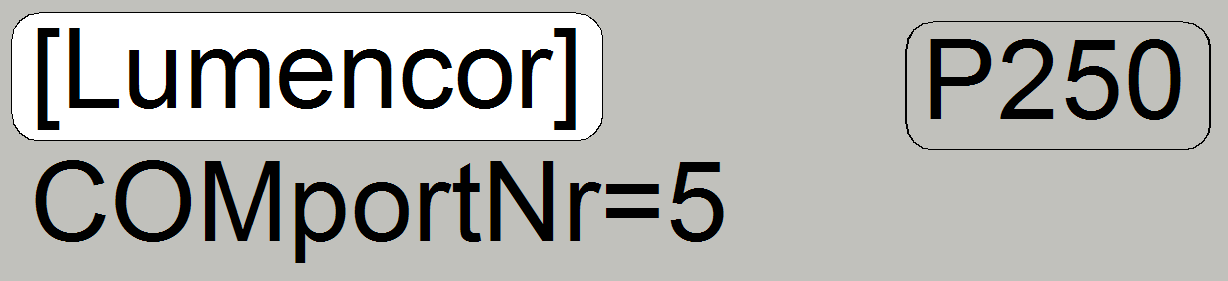

![]() “Lumencor SPECTRA light

engine” and “Check and update the USB port

address”

“Lumencor SPECTRA light

engine” and “Check and update the USB port

address”

Used in PCON only

Used in PCON only

· Values for information only!

[WaterFeeder]

DrippingPosX=15000

DrippingPosY=35000

AdheringToObjectiveX=15000

AdheringToObjectiveY=55000

CapacityInUl=1200

![]() “Immersion liquid feeder_control” and “Immersion

Liquid Feeder_optics”

“Immersion liquid feeder_control” and “Immersion

Liquid Feeder_optics”

Used in PCON only

·  Values for information only!

Values for information only!

Please refer to the chapter “Shutter mechanics” and “Mechanical shutter”

Section

[Confocal]

ConfocalCalibationFilterPosition

= 1; During Start-up the Aurox

unit will be calibrated in the named filter cube position

Possible values are 1 or 2 or 3

ShutterMotorMin= 0

ShutterMotorMax= 300

[Shutter]

ShutterOpenPosition=0

ShutterClosePosition= 200

· The etalon ini-files got the extension

“.txt” to avoid an unwanted overwrite of the original ini-file!

·  Use these ini-files to check the existence of

parameter names in the appropriate sections of your MicroscopeConfiguration.ini

file.

Use these ini-files to check the existence of

parameter names in the appropriate sections of your MicroscopeConfiguration.ini

file.

· Open the file with “NotePad”

· The values, shown in the etalon ini-files

are for information only; please don’t use these without checks!

|

Scanner |

MicroscopeType |

Remark |

Download |

||

|

|

|||||

|

PCON |

Subtype=Confocal |

|

|||

|

P250 |

P250; and Flash types |

|

|||

|

PSCAN |

Without objective changer |

|

|||

|

PSCAN_OC |

SCAN modular; with OC |

|

|||

|

PMIDI |

Without objective changer |

|

|||

|

PMIDI_OC |

|

|

|||

|

DESK |

|

|

|||

|

SCAN_II |

3DMic11 |

|

|

||

|

MIDI_II |

3DMic10 |

|

|

||

|

DESK_II |

|

|

|||

|

|

|

|

|

||