Define hardware limits in Pannoramic scanners

This chapter

summarizes the knowledge and procedures to define hardware limits for stepper

motor driven moveable parts in Pannoramic scanners in global and detailed aspects; used with the PCON,

P250, SCAN,

Contents

Sensor

“Home1” and hardware limits

The file

“MicroscopeConfiguration.ini”

Techniques

to define hardware limits

Units and

their hardware limits

Requirements

· Service

program “SlideScannerService.exe”

· Diverse hex key bolt drivers

(only for some units, where the bumper position can be adjusted)

The Pannoramic scanner includes hardware units with a stepper

motor driven moveable part.

The Pannoramic scanner includes hardware units with a stepper

motor driven moveable part.

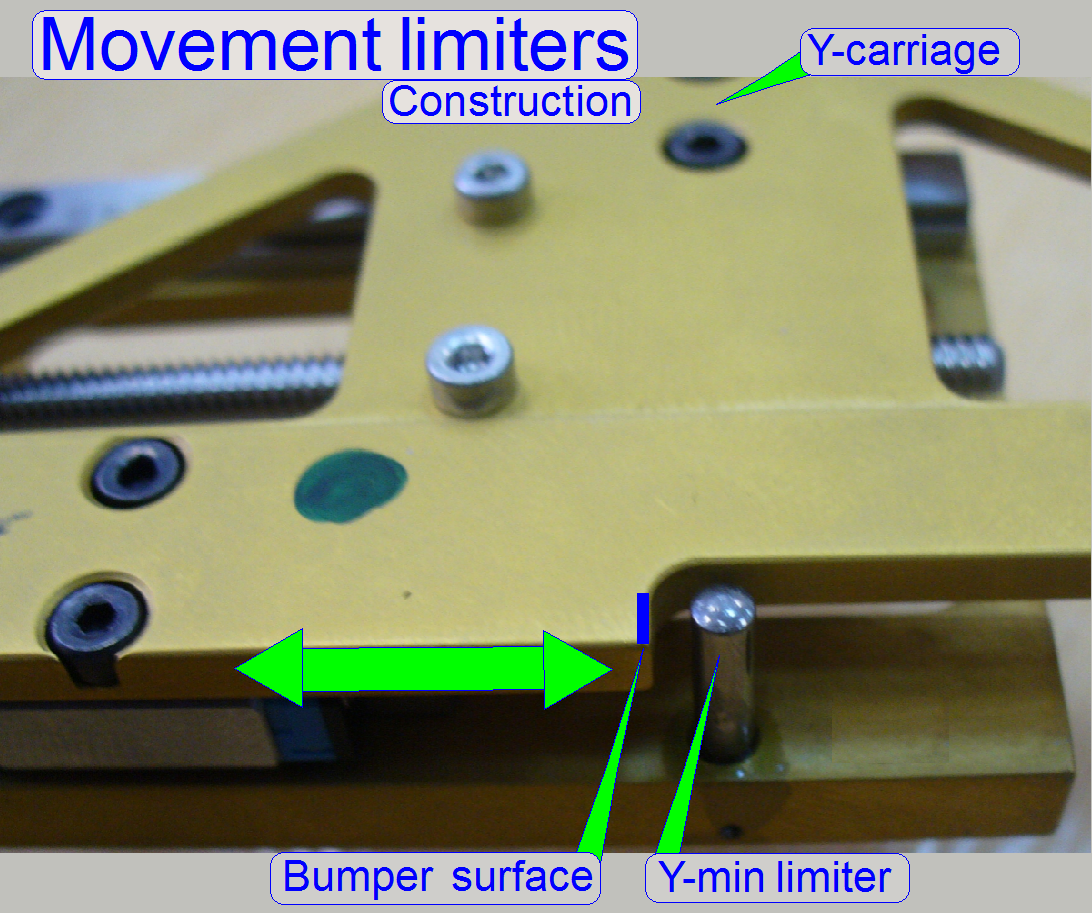

The moveable part, except it can

move endless, needs a start point and an end point as well, so its movement is

limited by the use of a hardware limiter and a bumper surface.

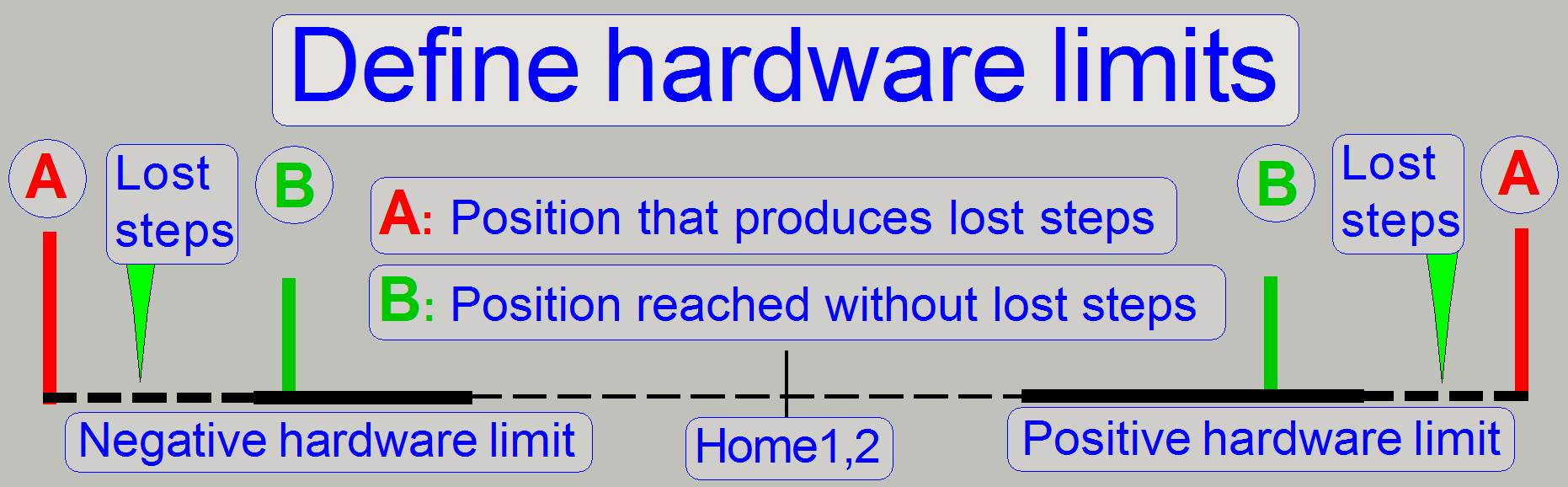

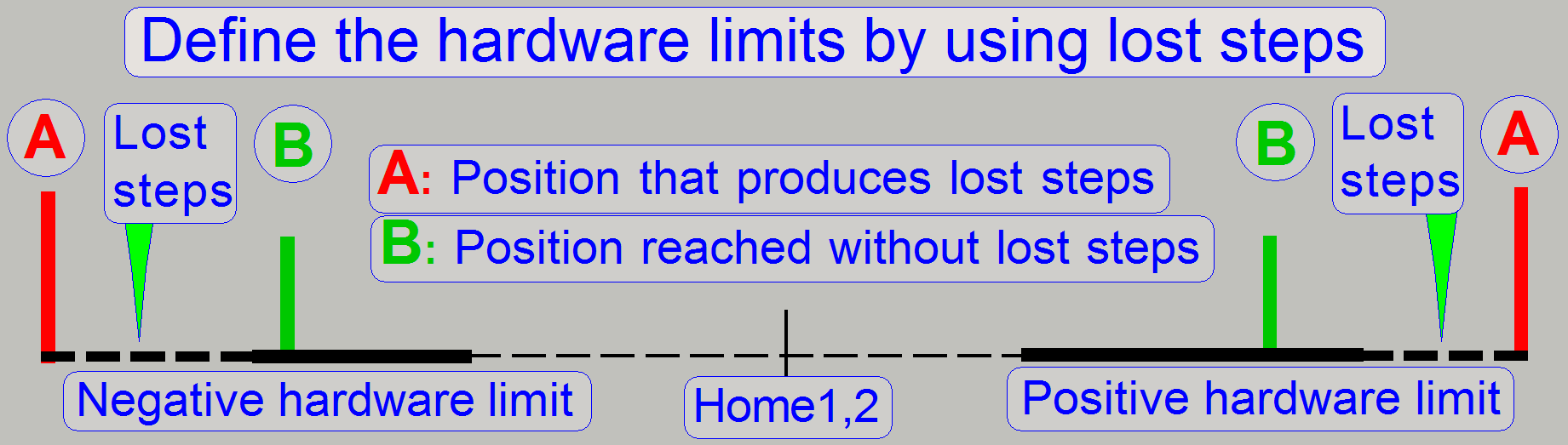

Because lost steps occur, if the

bumper surface bumps against the limiter, the limit positions have to be

defined before the bumper surface reaches the limiter; these are named as lower

and upper hardware limit, negative and positive hardware limit or as hardware

limit “min” and “max”. These defined limit positions are used by the software

to limit the movement of the unit.

Because lost steps are unwanted

during the scan procedure and normal work, the “Hardware limit” position has to be defined before the bumper

surface will reach the hardware limiter; the hardware limit position itself is

a part of the real movement range.

· Usually we can say, the start point of the unit is the

negative limit and the endpoint of the possible movement range is the positive

limit.

Accuracy of the defined

limit

The accuracy of the defined hardware

limit position depends on the unit; in the X-Y-stage unit for example, the

accuracy is 0.1mm (100µ-steps) during

in other units, like the camera changer or the focus unit, the accuracy of the

limit is 10µ-steps.

This means, the distance of the

bumper surface to the limiter is 0.1mm or less, but the bumper surface never

bumps against the limiter; lost steps must not occur.

· The step number

of the hardware limit is always defined before steps are lost!

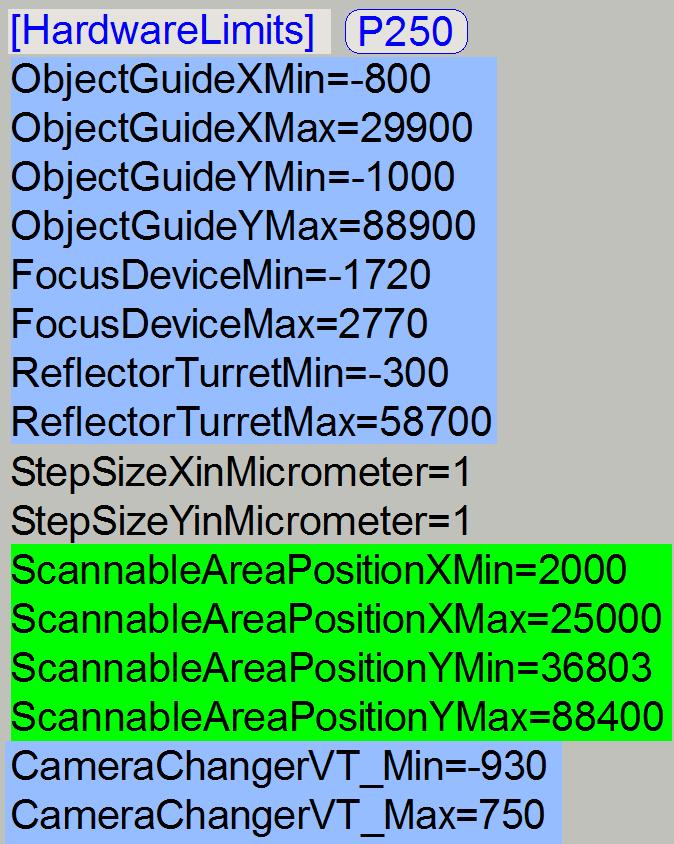

· All the used hardware

limit positions for the units are collected in the section “[HardwareLimits]”

of the file “MicroscopeConfiguration.ini”.

On the other side, to find the

correct hardware limit, we are creating lost steps first (with the service

program), and then we reducing the number of steps by the allowed accuracy

(100steps or 10steps) until lost steps do not occur during the movement of the

unit.

· Check the found

hardware limit by moving the unit more (3) times from the position Home1,2 to

the found limit position and return to Home1,2. During these movements, lost

steps should not be experienced (not more then +-2steps).

· Move also the

mechanical drive against the limiter until lost steps are produced. With the

service program, the unit should be able to leave the jammed position if the

unit is moved some 100 steps in direction to Home1,2. If jamming occurred and

the unit can not be moved away from the limiter, the unit is faulty (or

adjusted wrong). During this check please do not use the button “Home1” because

the timing and control of the motor steps is often different between normal

move and searching for Home1.

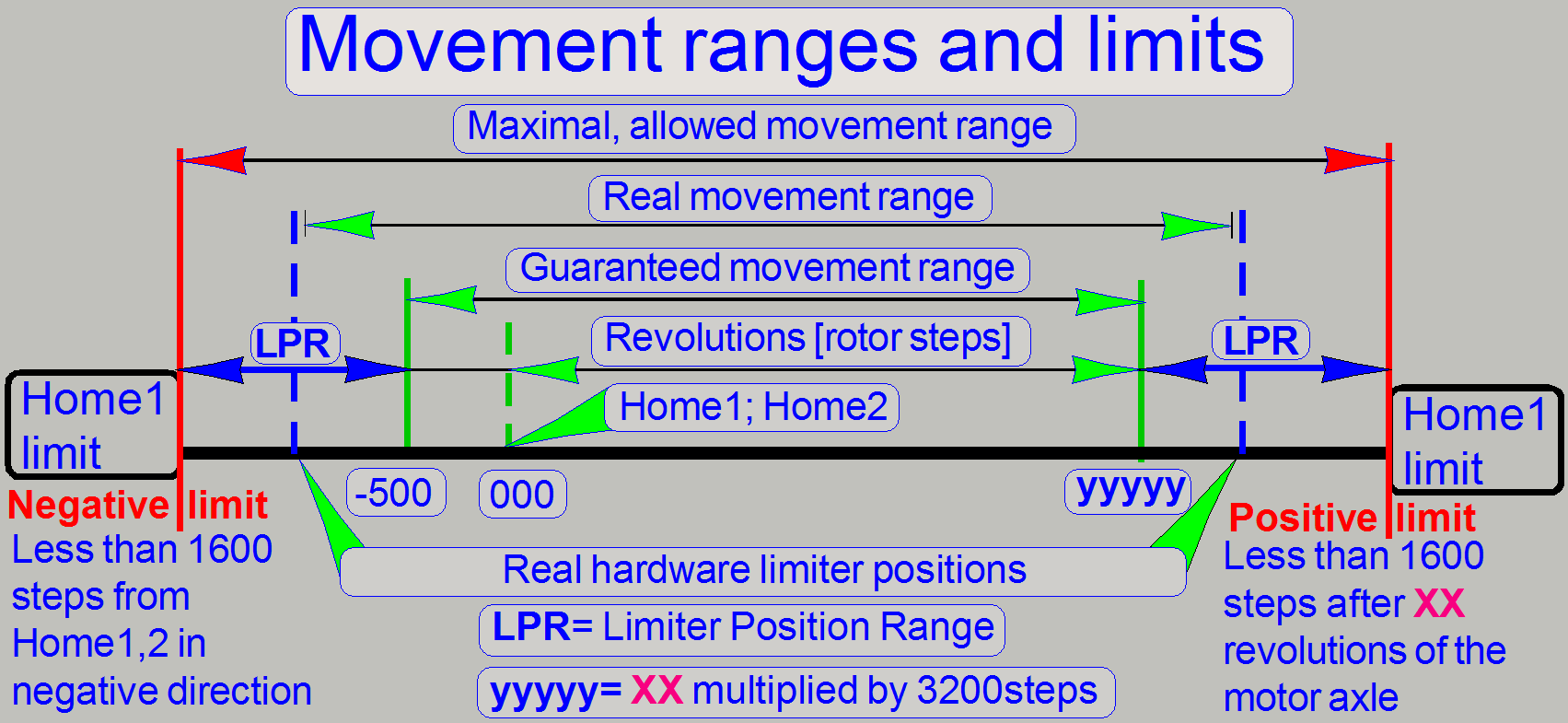

The values, where the limit

positions of the appropriate unit can be found are different from unit to unit

of the same type also, so an interval is defined.

Each unit of the same type has its

limit “min” and “max” in the defined range (the limiter position range, LPR),

outside the guaranteed movement range.

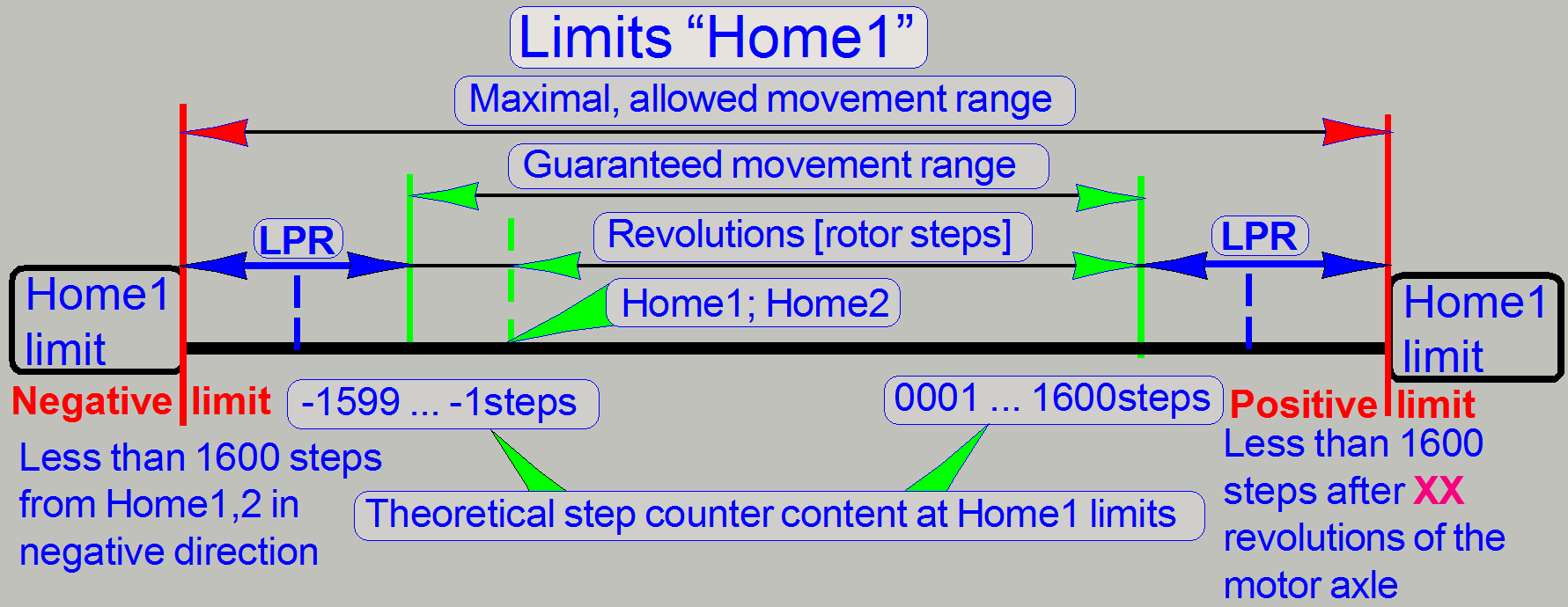

Maximal movement range

The maximal movement range is defined

by the behavior of the sensor “Home

· If the moving part of the unit can be moved behind the

specified value of the maximal movement range (the limit “Home1”), the unit is

faulty.

Guaranteed

movement range

·  The guaranteed movement range is defined by the

requirements of the moveable unit to fulfill its task; it may be 1revolution,

several 10 revolutions until over 200 revolutions of the motor axle.

The guaranteed movement range is defined by the

requirements of the moveable unit to fulfill its task; it may be 1revolution,

several 10 revolutions until over 200 revolutions of the motor axle.

· The guaranteed movement range is defined by the number

of revolutions of the stepper motor axle.

· In exceptions, it is prolonged by some 100 steps in

any direction by shortening the limiter position range (LPR).

· In exceptions the upper limit may be shortened if

collision of components would occur.

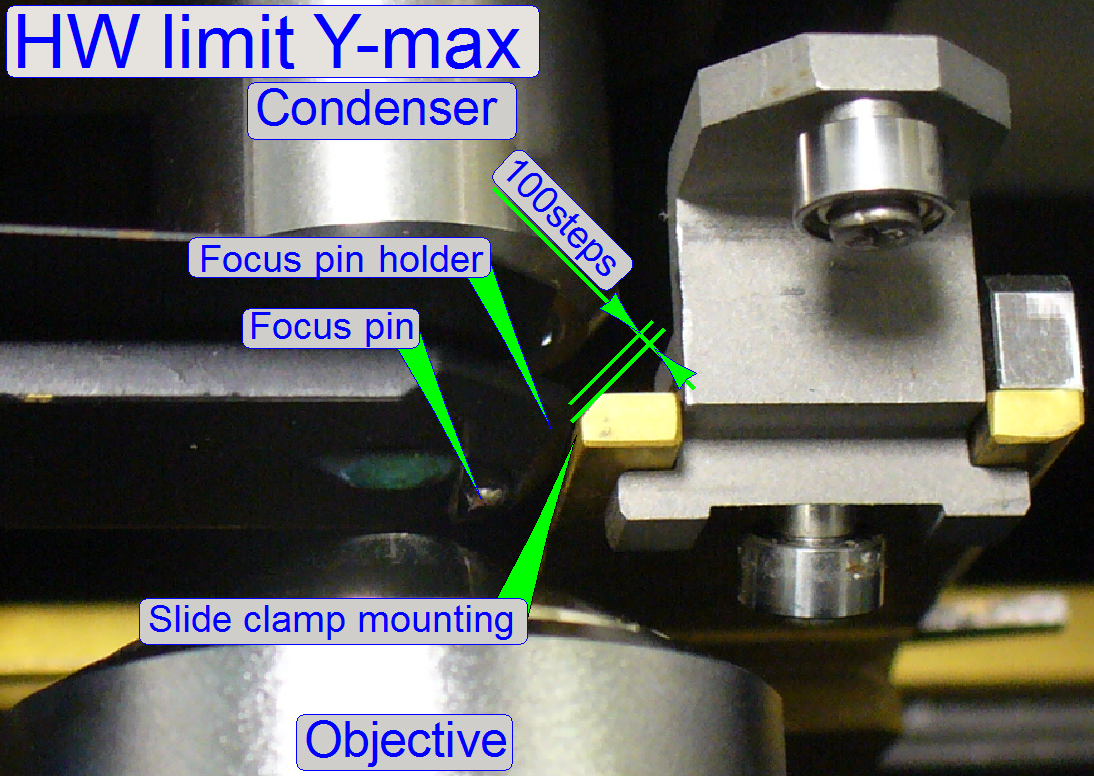

![]() P250 hardware limit

Y-max and SCAN

hardware limit Y-max

P250 hardware limit

Y-max and SCAN

hardware limit Y-max

Position Home1,2

The home position of the entire

mechanical drive, the start position for counting motor steps, is defined

inside the guaranteed movement range. Starting from this position, the rotor

steps are counted in positive or negative direction.

Real movement range

· The real movement range is always larger then the

guaranteed movement range, it is limited by the found hardware limiter

positions; before the bumper surface contacts the limiter; except the camera

changer unit and the focus unit.

· The absolute value of the negative limit of the real

movement range is less than or equal to the negative limit of the maximal

movement range (the limit “Home1”).

· The positive limit of the real movement range is less

than or equal to the positive limit of the maximal movement range (the limit

“Home1”).

The hardware limiters for the positive and the

negative limit of the unit are physically found in this range.

The hardware limiters for the positive and the

negative limit of the unit are physically found in this range.

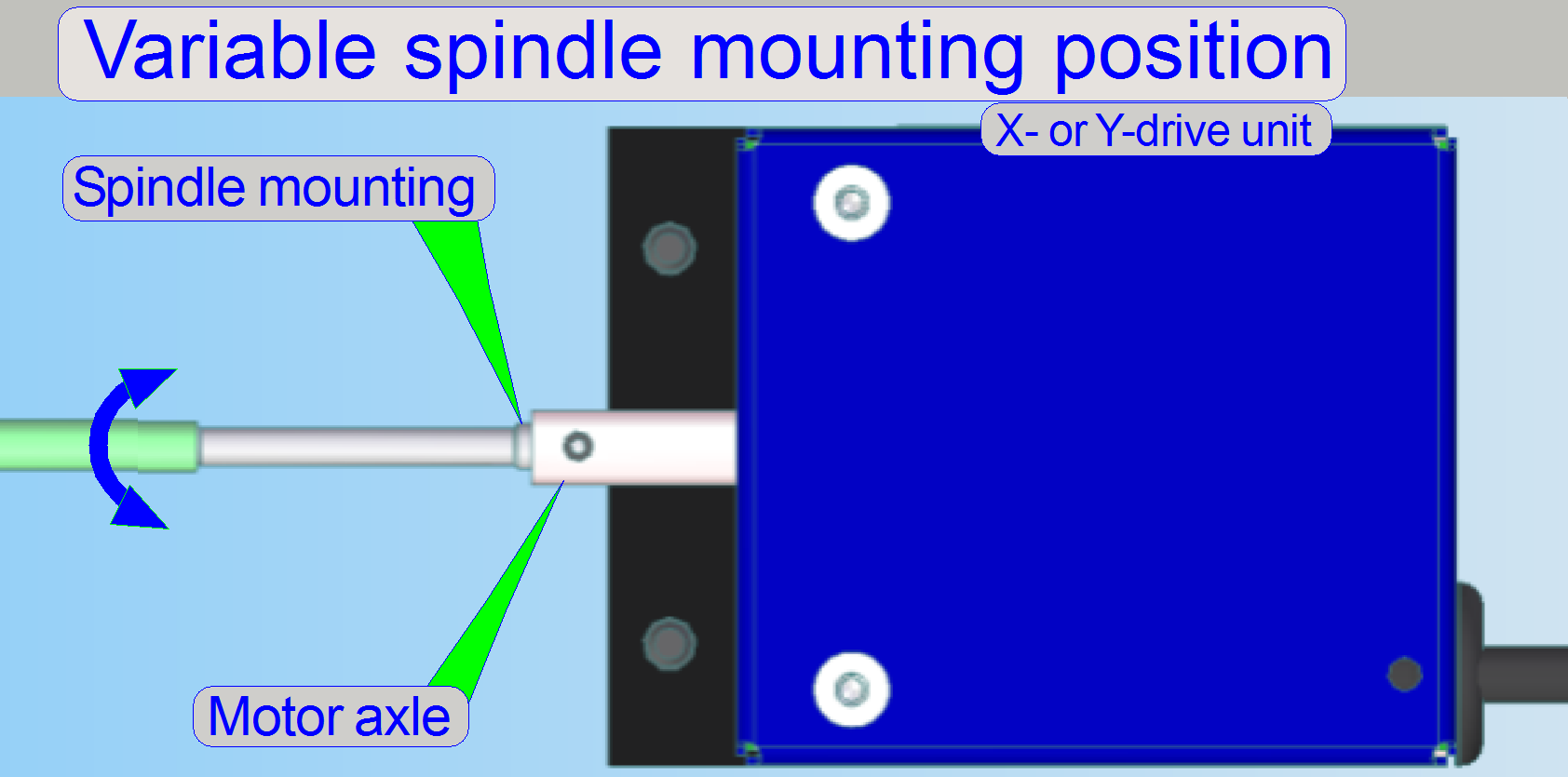

The physical position of the

limiters and the bumper surfaces are always exactly on the same place in the

unit, therefore, if the negative limit is found correctly, the positive limit

will always fulfill the requirement of the limit “Home1”; but because the

mounting position of the spindle in relation to the rotor axle is variable (X-

and Y-drive unit) and the found thread starting position of the transport nut

is defined with an accuracy of 800steps, the real hardware limit value may be

anywhere in this range.

· The found hardware limit values define the real

movement range.

![]() “Exchange

the Y-drive of the X-Y-stage unit”

and “Before we can mount the

drive unit”

“Exchange

the Y-drive of the X-Y-stage unit”

and “Before we can mount the

drive unit”

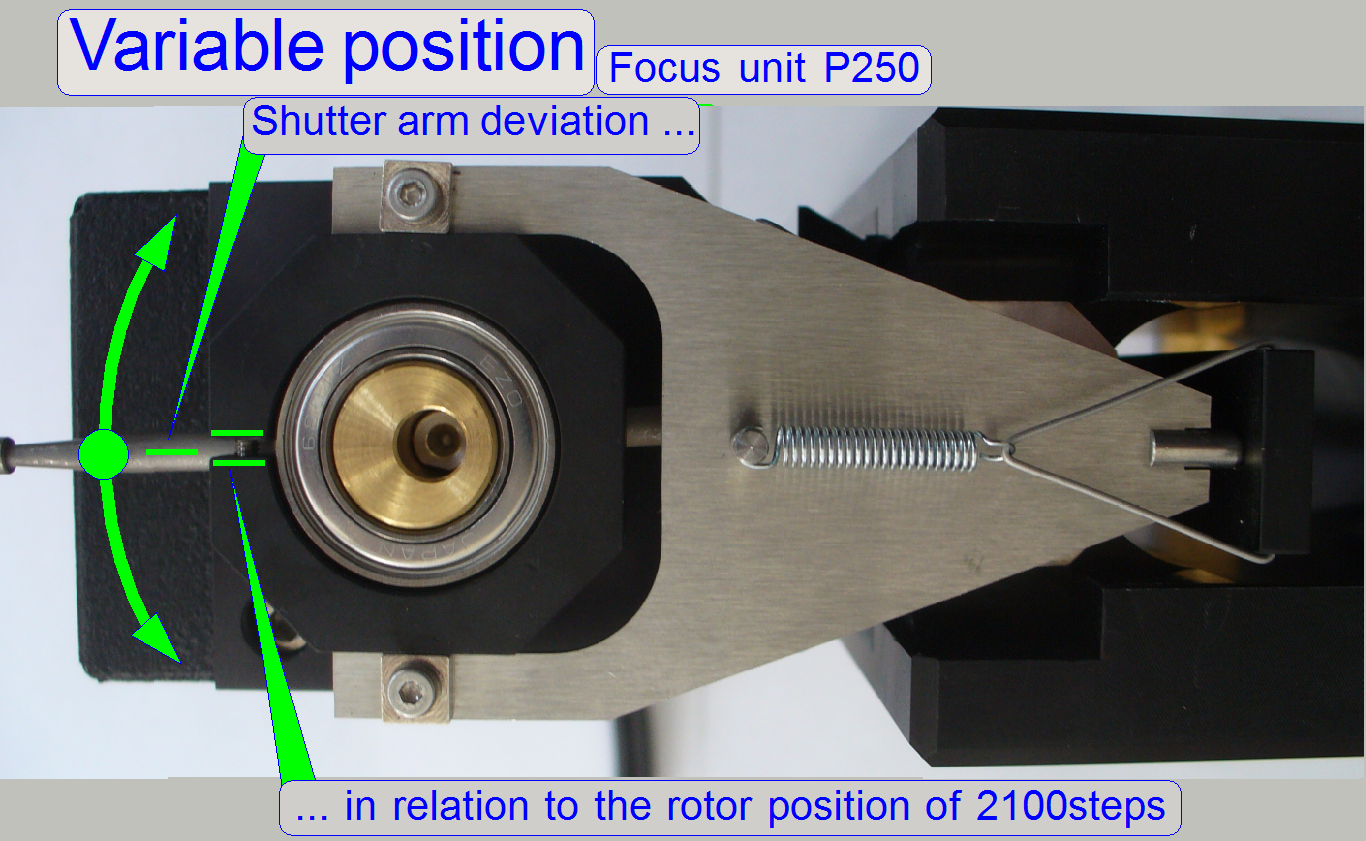

In the focus unit

In the focus unit the hardware limit values depending

highly on the found ex-center position on the motor axle.

In the focus unit the hardware limit values depending

highly on the found ex-center position on the motor axle.

![]() in the P250: “Adjust the ex-center

position”

in the P250: “Adjust the ex-center

position”

SCAN,

· In the SCAN, the

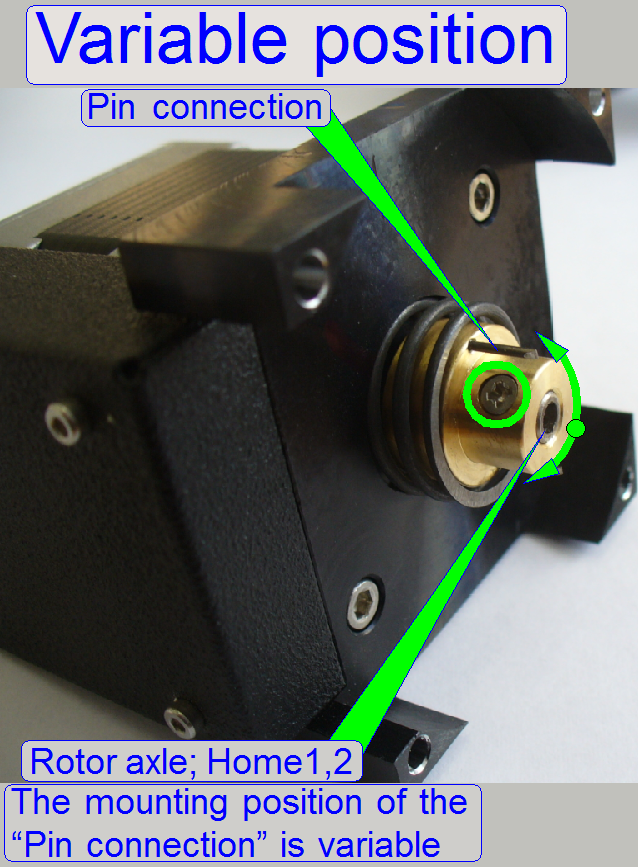

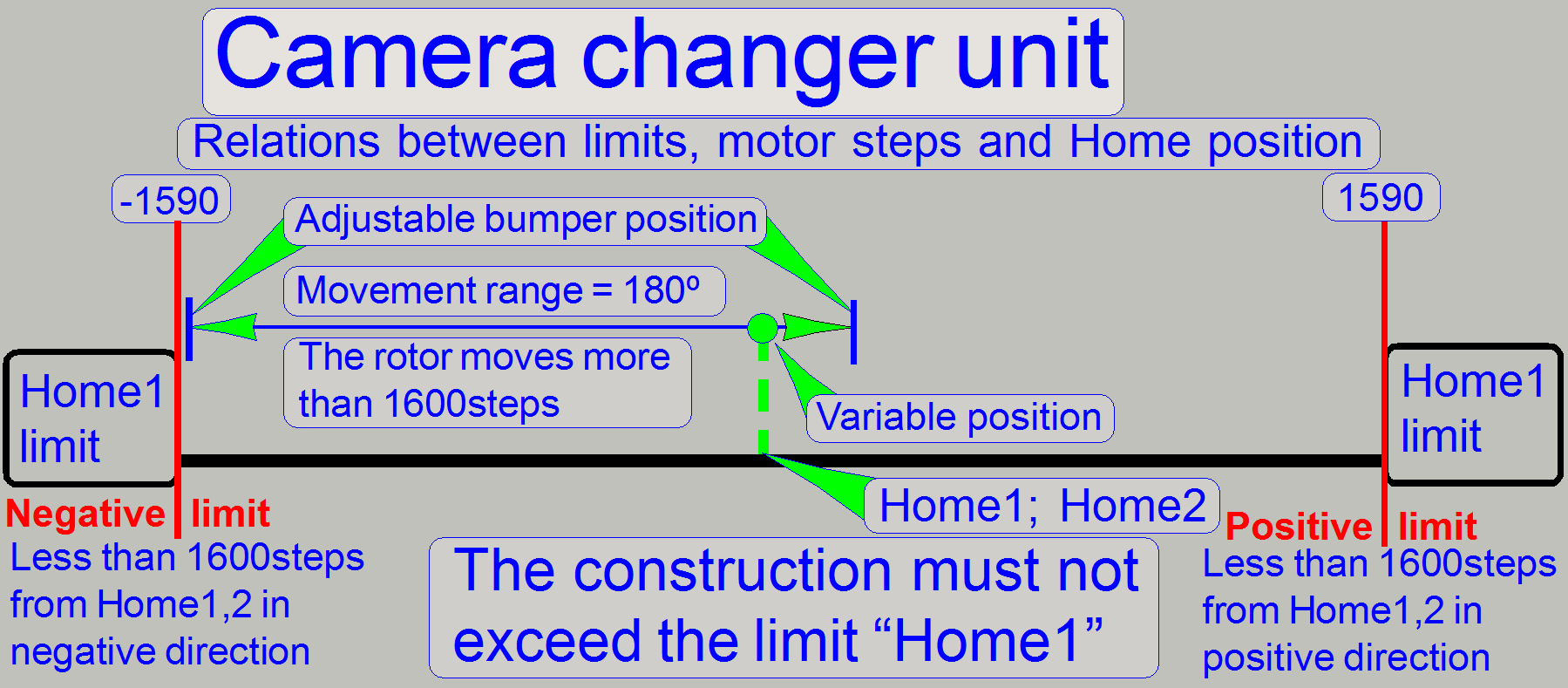

In the camera changer unit the “Variable position” of

the guaranteed movement range depends on the found clutch mounting position on

the motor axle; so the pin connection may be in different positions in relation

to the home position of the rotor. Therefore, the home position Home1,2 will be

only in exceptions in the center of the guaranteed movement range.

In the camera changer unit the “Variable position” of

the guaranteed movement range depends on the found clutch mounting position on

the motor axle; so the pin connection may be in different positions in relation

to the home position of the rotor. Therefore, the home position Home1,2 will be

only in exceptions in the center of the guaranteed movement range.

Sensor “Home1” and hardware limits

This chapter describes the role of the sensor “Home1” during

the definition of the hardware limits.

This chapter describes the role of the sensor “Home1” during

the definition of the hardware limits.

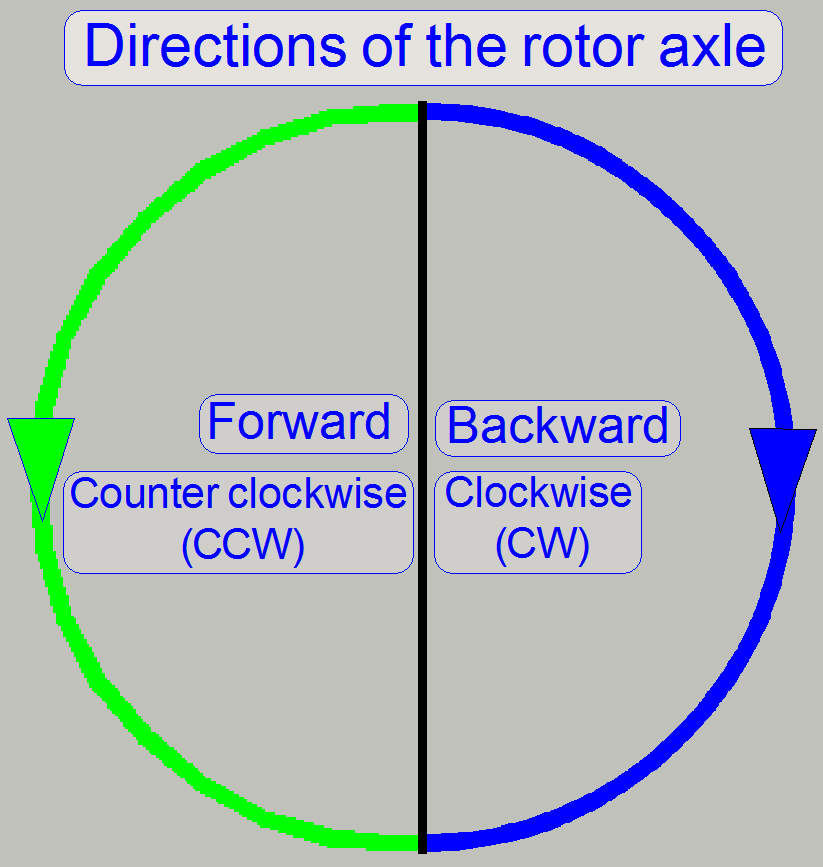

· If the mechanical drive is moved in direction to the

“max” (positive) limit, the rotor of the stepper motor rotates forward (CCW);

the step number of the step counter will be increased.

· If the mechanical drive is moved in direction to the

“min” (negative) limit, the rotor of the stepper motor rotates backward (CW);

the step number of the step counter will be decreased.

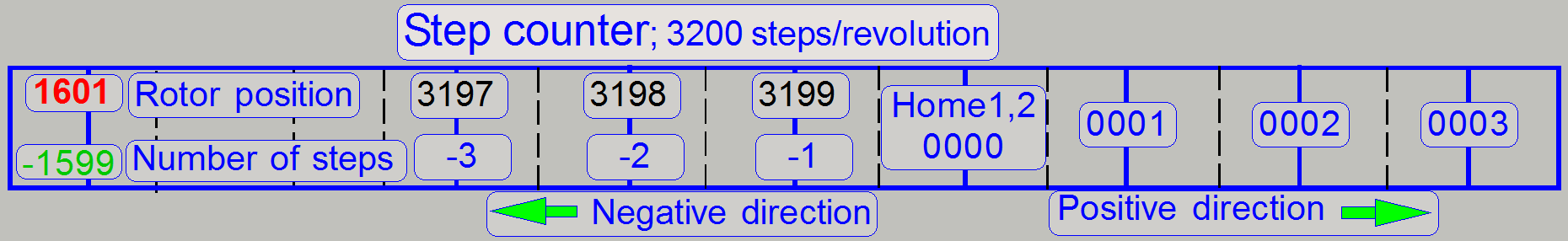

Important remark

The hardware limits are always defined

as a number of steps, done in the positive or negative direction, counted from

Home1,2.

During stepping in positive

direction, the “Rotor position” is identical with the “Number of steps” gone!

· If we are doing steps in negative direction, the “Number

of steps” gone is different from the “Rotor position”!

· The service program shows always the step counter

content, not the rotor position

· The value of the appropriate hardware limit is always

the “Number of steps”; in “our” step counter example above the lowest value would be -1599! And not

1601!

Home sensor “Home1”

The implementation of the sensor “Home1” defines the

main restriction in question of all the hardware limits.

The implementation of the sensor “Home1” defines the

main restriction in question of all the hardware limits.

Depending on the actual step number of

the step counter, the rotor rotates forward (CCW) or backward (CW) respectively

to find the position “Home1”.

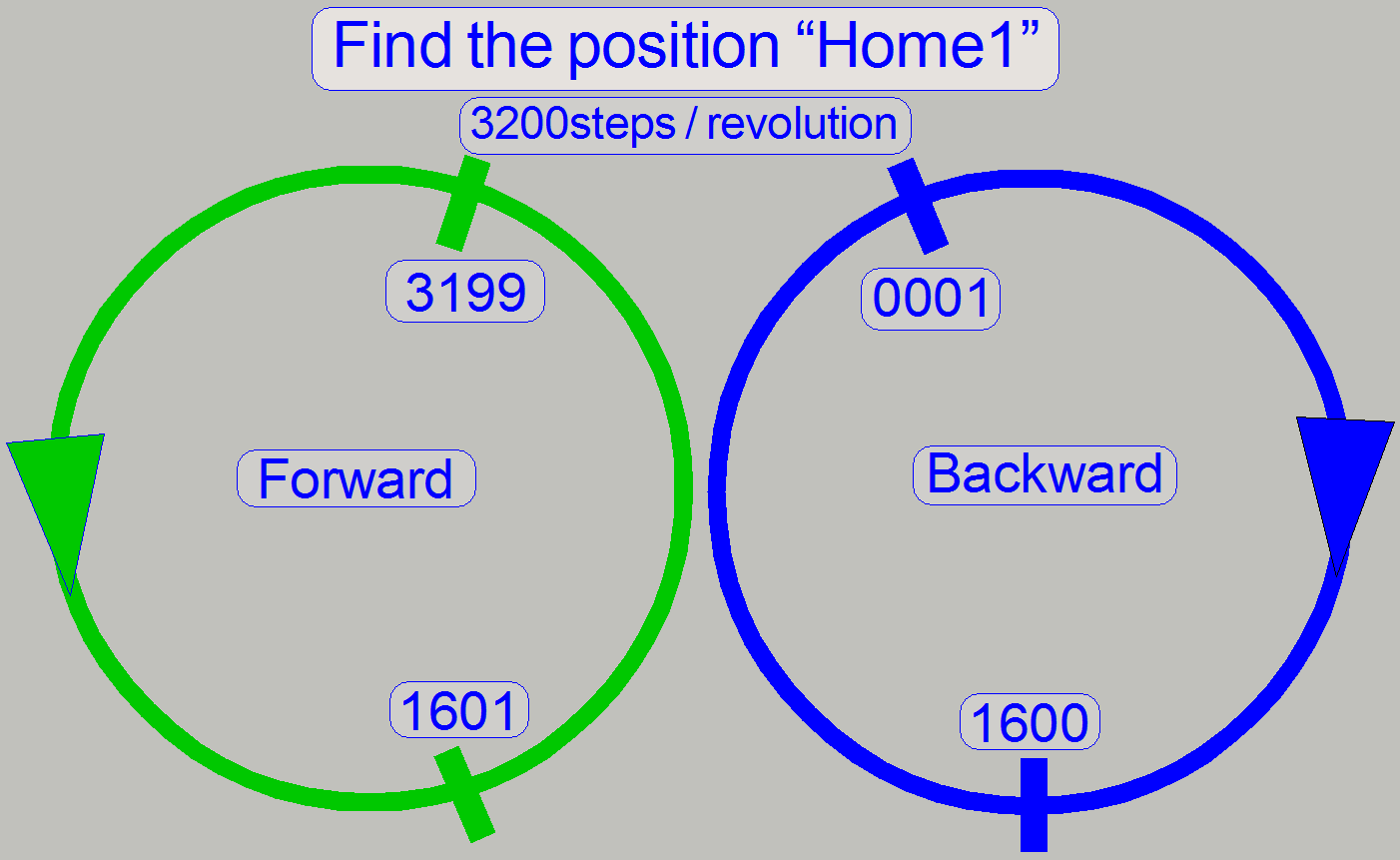

· If the step number of the step counter is in the range

from +0001 to +1600 (or a multiple number of +3200steps) and the command

“Home1” is issued, the rotor is moved backward (CW) to find the position

“Home1”.

· If the step number of the step counter is in the range

from -1 (rotor position 3199) to -1599

(rotor position 1601) (or a multiple number of +3200steps) and the

command “Home1” is issued, the rotor is moved forward (CCW) to find the

position “Home1”.

· If the step number of the step counter stays in the

position “

· Because we allowing a maximal tolerance of +-2steps in

the found home position, and the position 1600steps of the rotor is critical

for the sensor “Home

Remark

The explanation above is true if we

assume that the revolution of the rotor is done in 3200steps; the position of

1600steps defines exact a half revolution. If the revolution is done in

6400steps, the number of steps for a half revolution is also twice, 3200steps.

The sensor “Home1” works always with a half revolution!

![]() “Sensors Home1,2”; and “Sensors”.

“Sensors Home1,2”; and “Sensors”.

Negative limit

The rotor rotates in backward direction (CW), seen

from the state “Home1,2” (the steps are counted in backward direction also; the

step number in the step counter will be decreased) until the rotor position “

The rotor rotates in backward direction (CW), seen

from the state “Home1,2” (the steps are counted in backward direction also; the

step number in the step counter will be decreased) until the rotor position “

If we would allow more steps to go

in backward direction, the construction would overstep the border of the rotor

position of “

· The absolute negative limit (defined by the limiter)

is always less than 1600steps in negative direction, counted from Home1,2 (lost

steps have to be generated before the

rotor position of 1600steps is reached); otherwise the unit is faulty (or

adjusted wrong; please refer to the chapter “Limiter position range”)..

Positive limit

The mechanics moves in direction to the

positive limit, (the rotor moves forward, CCW).

The number of steps in the step

counter will be increased and, if the guaranteed movement range is passed, the

sensor “Home1” defines also the possible number of steps to go; this number is

also less than 1600steps.

The rotor rotates in forward

direction, seen from the state “Home1,2” until the step number “

If we would allow more steps to go

in forward direction, we would overstep the border of 1600 steps (the rotor

position would be higher than 1600 steps) and, if we issuing the command

“Home1” the rotor would move forward to find the position “Home1”, mechanical

jamming of the construction would occur; the moving part would be moved against

the limiter and lost steps occur.

· The absolute positive limit (defined by the sensor

“Home1”) is always less than 1600steps in positive direction after the

guaranteed movement range is passed, counted from Home1,2 (lost steps have to

be generated before the rotor position

of 1600steps is reached); otherwise the unit is faulty (or adjusted wrong;

please refer to the chapter “Limiter

position range”).

Remark

Because we are allowing a tolerance

of 2steps, the hardware limit in the position 1600steps of the sensor “Home1”

is critical and should never be used. In other words, the found hardware limit

position should be always clearly less then 1600steps.

If the resolution of the motor is

6400 steps, the border value of 1600 steps is also changed to the value of

3200steps. In other words, we using always exact a half revolution of the rotor

to define the limit of the sensor “Home1”.

![]() “Sensors Home1,2”; and “Sensors”.

“Sensors Home1,2”; and “Sensors”.

File

“MicroscopeConfiguration.ini”

· Please make a security backup of the file “Microscope

Configuration.ini” before modifying values!

The file “MicroscopeConfiguration.ini”

will be found in the folder:

In the

software version 1.14 (Windows XP): C:\DocumentsAndSettings\AllUsers\ApplicationData\3DHISTECH\SlideScanner\

In the

software version 1.14 (Windows XP): C:\DocumentsAndSettings\AllUsers\ApplicationData\3DHISTECH\SlideScanner\

In the software version 1.15 or

higher (Windows 7): C:\ProgramData\3DHISTECH\SlideScanner\

In earlier

software versions: The file

“MicroscopeConfiguration.ini” or “Config.ini” is situated in the same folder as

the scan program; the filename of the scan program was “Mscan.exe”. Please use

the file search option of Windows and search for the file

MicroscopeConfiguration.ini or “Config.ini”.

![]() SlideScannerSercie.exe and Paths and locations

SlideScannerSercie.exe and Paths and locations

·

To edit the

parameter values of the file “MicroscopeConfiguration.ini” the program

“WordPad” or “Notepad” should be used.

·

Save the file

“MicroscopeConfiguration.ini” without any formatting information, as a

*.txt-type file (text only)!

Section [HardwareLimits]

All the used hardware limit

positions for the units are collected in the section “HardwareLimits” of the

file “MicroscopeConfiguration.ini”.

· Depending on the scanner type and the configuration,

not all the parameter values are used.

· Other sections of the file

“MicroscopeConfiguration.ini” may also be affected by the found hardware limit;

please see the appropriate unit.

Techniques to define hardware limits

Using lost steps

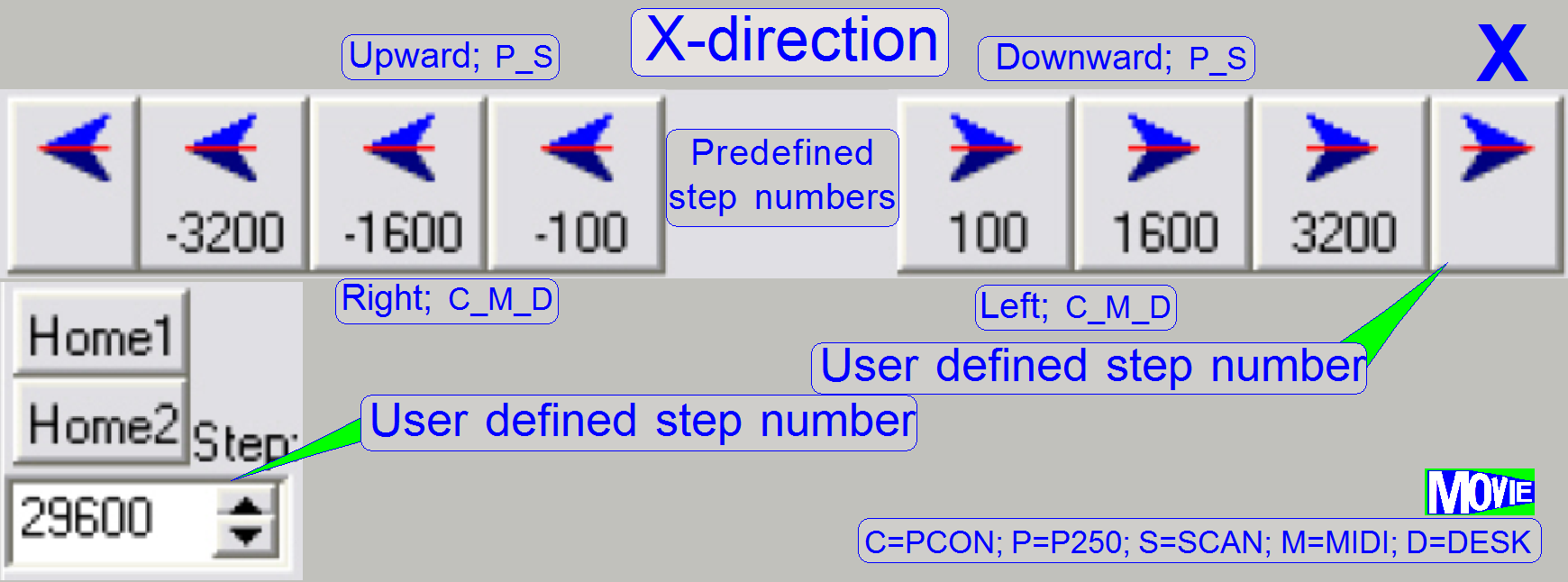

Start the service program and set the appropriate unit

to its home position.

Start the service program and set the appropriate unit

to its home position.

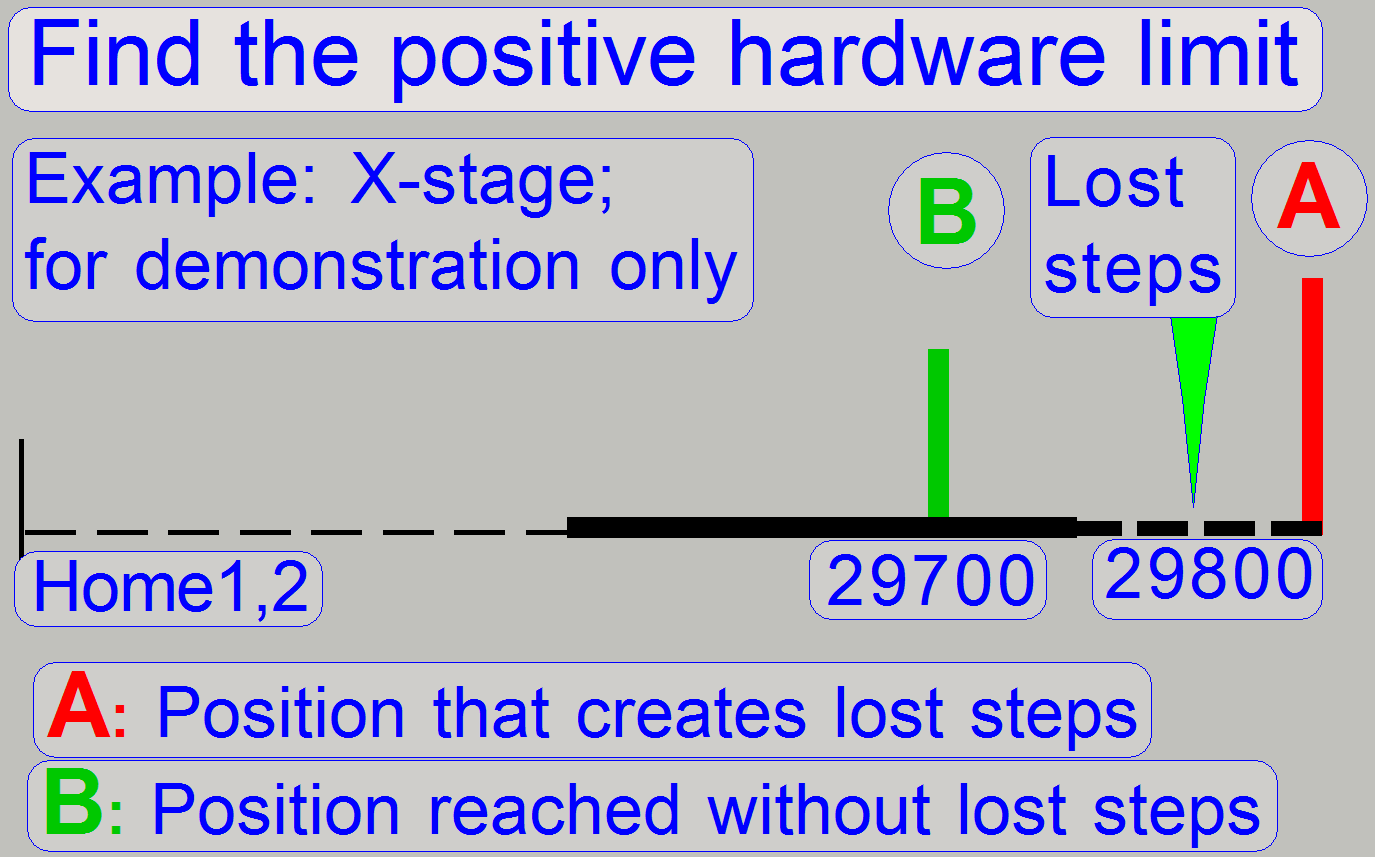

To find the hardware limit of the

unit in question, we always producing lost steps first, then we decreasing the

absolute number of steps to go by the number of steps with the limit accuracy

until lost steps do not occur.

· The first number of steps that do not produce lost

steps is used as hardware limit.

· Always check and define the negative limit first, then

the positive limit.

· Limit adjustments are always done with the negative limit

position!

1.

Set the

appropriate unit to its Home1,2 position.

2.

Start with a

step number outside the guaranteed movement range.

3.

Move the unit

to the start position and go backward the same number of steps.

4.

Press Home1

only.

5.

If there are not more than 2 steps difference to

Home1, increase the number of steps by the accuracy of the limit (100 or

10steps) and repeat from step

6.

If there are more than 2 steps difference to Home1,

decrease the number of steps by the accuracy of the limit (100 or 10steps) and

repeat from step

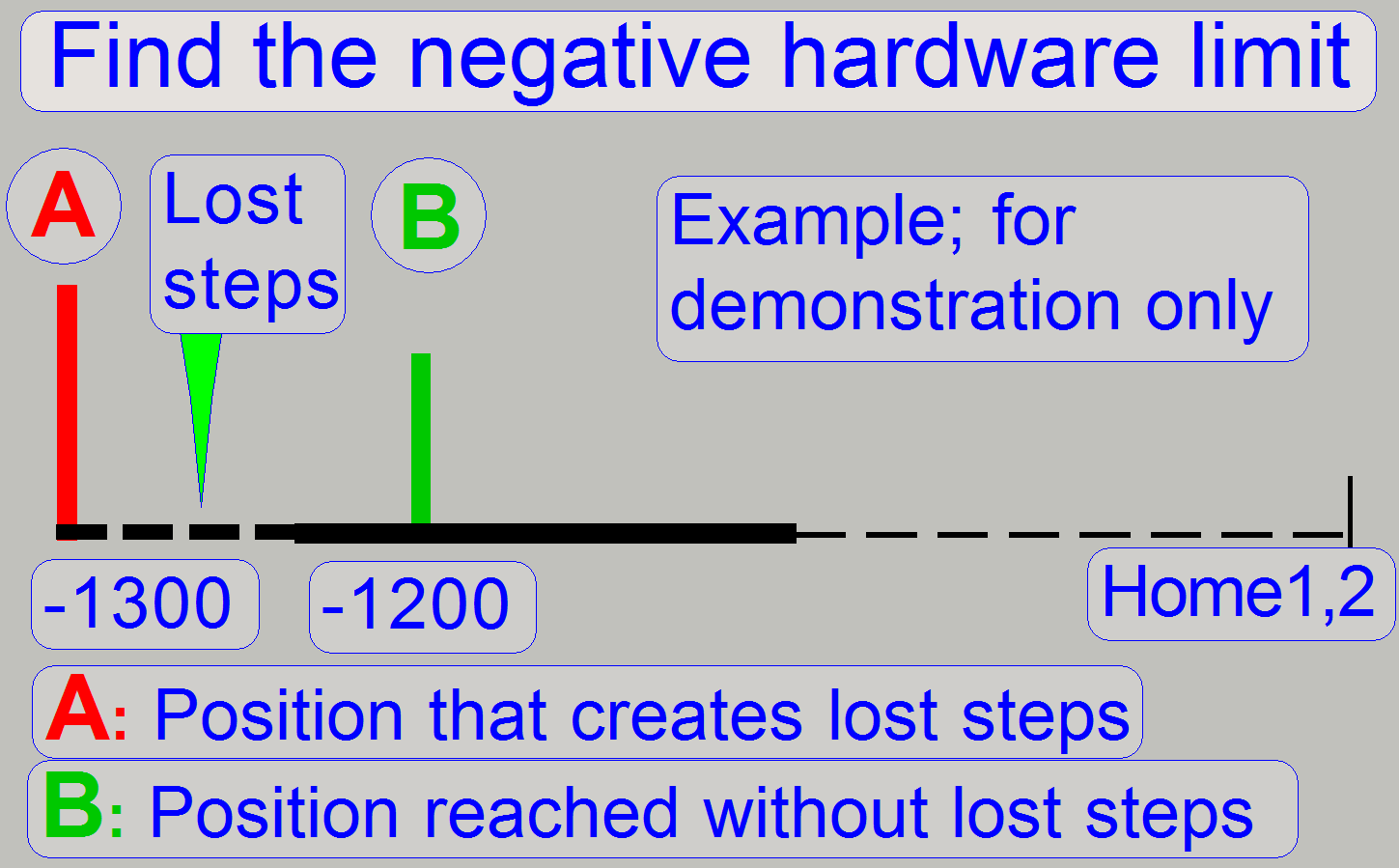

Remark

· The starting number of steps to find the negative

limit is outside of the guaranteed movement range, I prefer the use of

1300steps (X- or Y-stage).

· The starting number of steps to find the positive

limit is also outside of the guaranteed movement range, it should be higher by

some 100steps.

· In all cases, even if the found limit number is in the

near of the maximal movement range, the correct working

of the home sensor “Home1” should be checked painstakingly.

Example to find the negative

limit in -X-direction

1.

With the service

program set the Y-carriage to Home1,2.

With the service

program set the Y-carriage to Home1,2.

2.

Set the X-carriage to Home1,2.

3.

With the service program go forward to the X-motor

position -1300 steps.

4.

Go backward +1300 steps.

5.

Press Home1 (only). There should be not more than +-2

steps difference to Home1. If there are more steps lost, decrease the actual

absolute number of steps by 100 and repeat from step

6.

If there are not more than 2 steps difference to

Home1, increase the number of steps by 100 and repeat from step

7.

The negative limit is found correctly if the motor

movement has no steps lost and the actual absolute number of steps, increased

by 100 would produce lost steps.

8.

Update the value of the parameter “ObjectGuideXMin” in the file “MicroscopeConfiguration.ini” section [HardwareLimits] with the found

number of the actual steps and save the file.

Remark

The found negative limit can differ by more 100steps from unit to unit.

The reason is the spindle fixing position on the motor axle and the found

thread starting position of the spindle in relation to the transport nut.

Example to find the positive limit in +X-direction

9.

With the service program set

the X-carriage unit to Home1,2.

With the service program set

the X-carriage unit to Home1,2.

10.

Go forward to the X-motor position +29700 steps.

11.

Go backward 29700 steps.

12.

Press Home1 (only). There should be not more than +-2 steps

difference to Home1. If there are more steps lost, decrease the actual number

of steps by 100 and repeat from step

13.

If there are not more than 2 steps difference to Home1,

increase the number of steps by 100 and repeat from step

14.

The positive limit is found correctly if the motor

movement has no steps lost (max. 2 steps) and the actual number of steps,

increased by 100 would produce lost steps.

15.

Update the value of the parameter “ObjectGuideXMax” in the file “MicroscopeConfiguration.ini” section [HardwareLimits] with the found

value and save the file.

16.

Check the found limits

by using the number of steps, used as parameter value in the file “MicroscopeConfiguration.ini” section [HardwareLimits]. Lost steps have

not to occur.

Check the found limits

by using the number of steps, used as parameter value in the file “MicroscopeConfiguration.ini” section [HardwareLimits]. Lost steps have

not to occur.

Remark

The found positive limit can differ by more 100steps from unit to unit. The

reason is the spindle fixing position on the motor axle and the found thread

starting position of the spindle in relation to the transport nut.

Units and their hardware limits

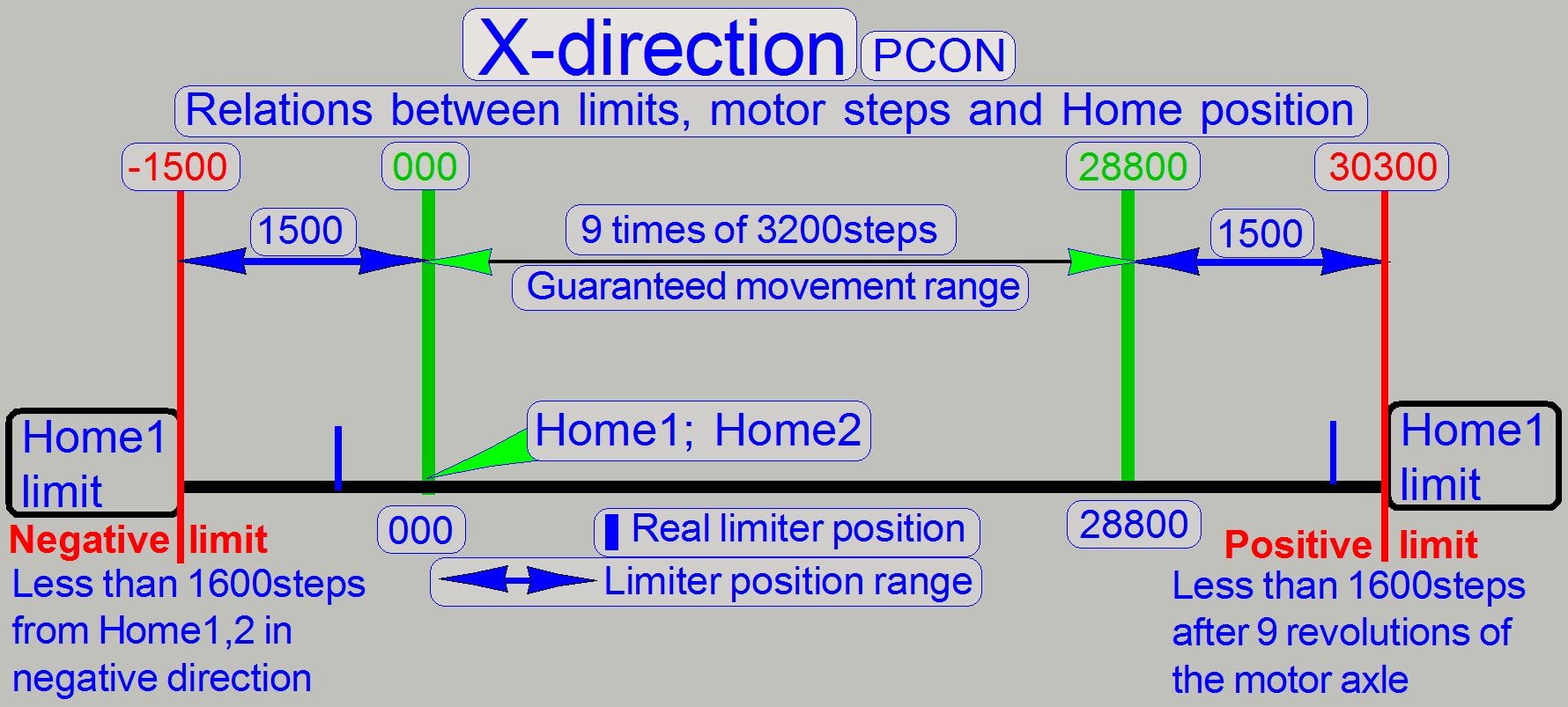

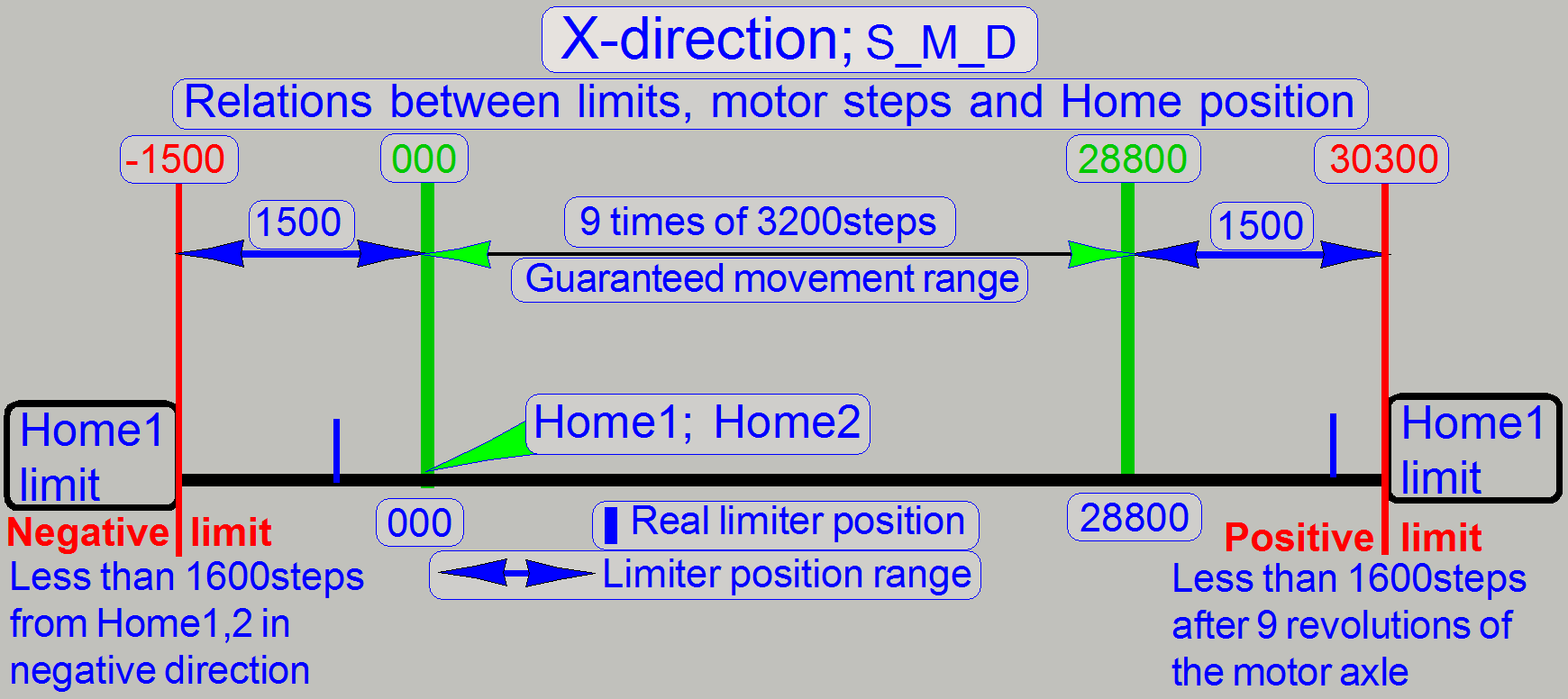

X-direction; PCON

Parameters: [HardwareLimits]

“ObjectGuideXMin”; “ObjectGuideXMax”

· The accuracy= 100steps (0.1mm)

Negative limit

-1500steps ≤ “ObjectGuideXMin” < Home1,2

Positive limit

28800steps < “ObjectGuideXMax” ≤ 30300

Other related or affected sections and parameters: none

![]() “X-Y-stage unit” and “Find the

hardware limits”

“X-Y-stage unit” and “Find the

hardware limits”

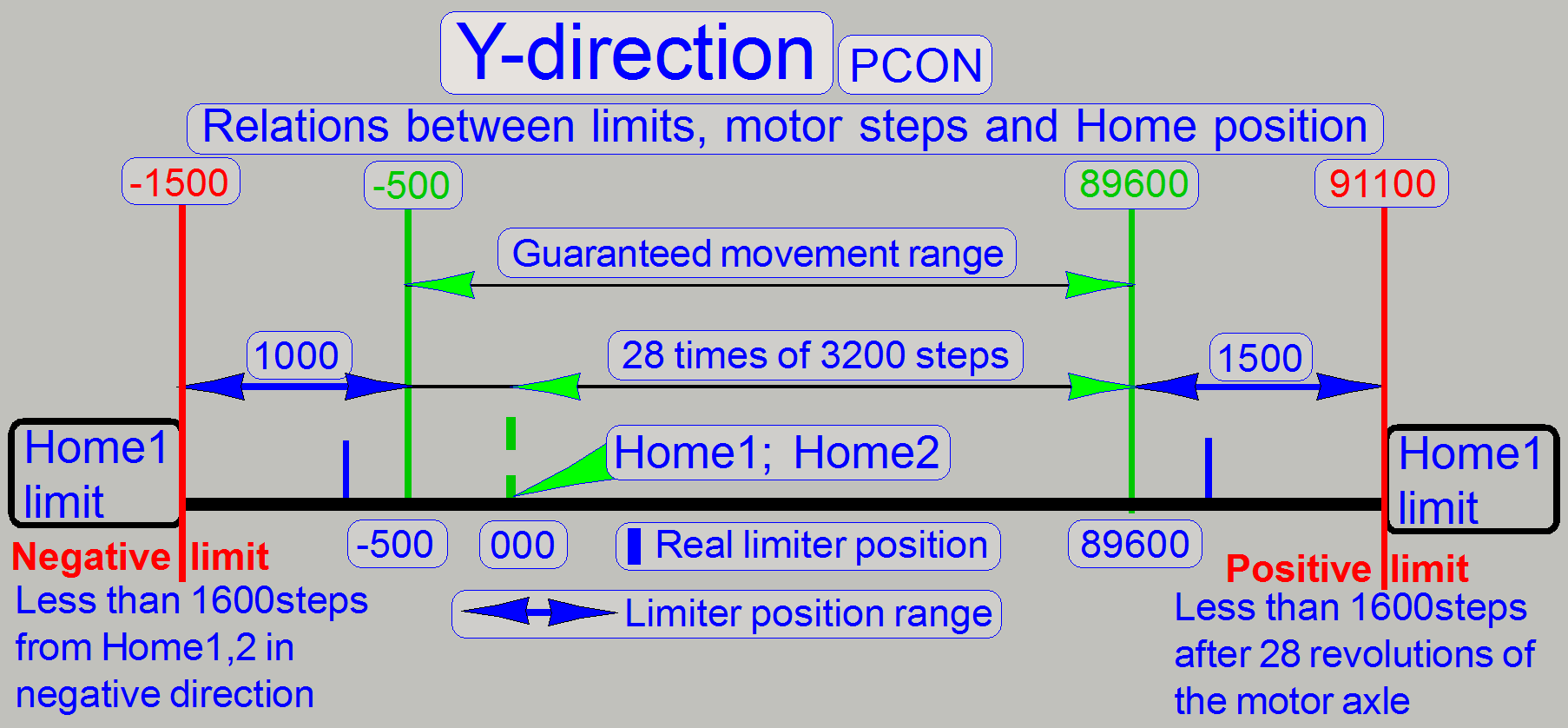

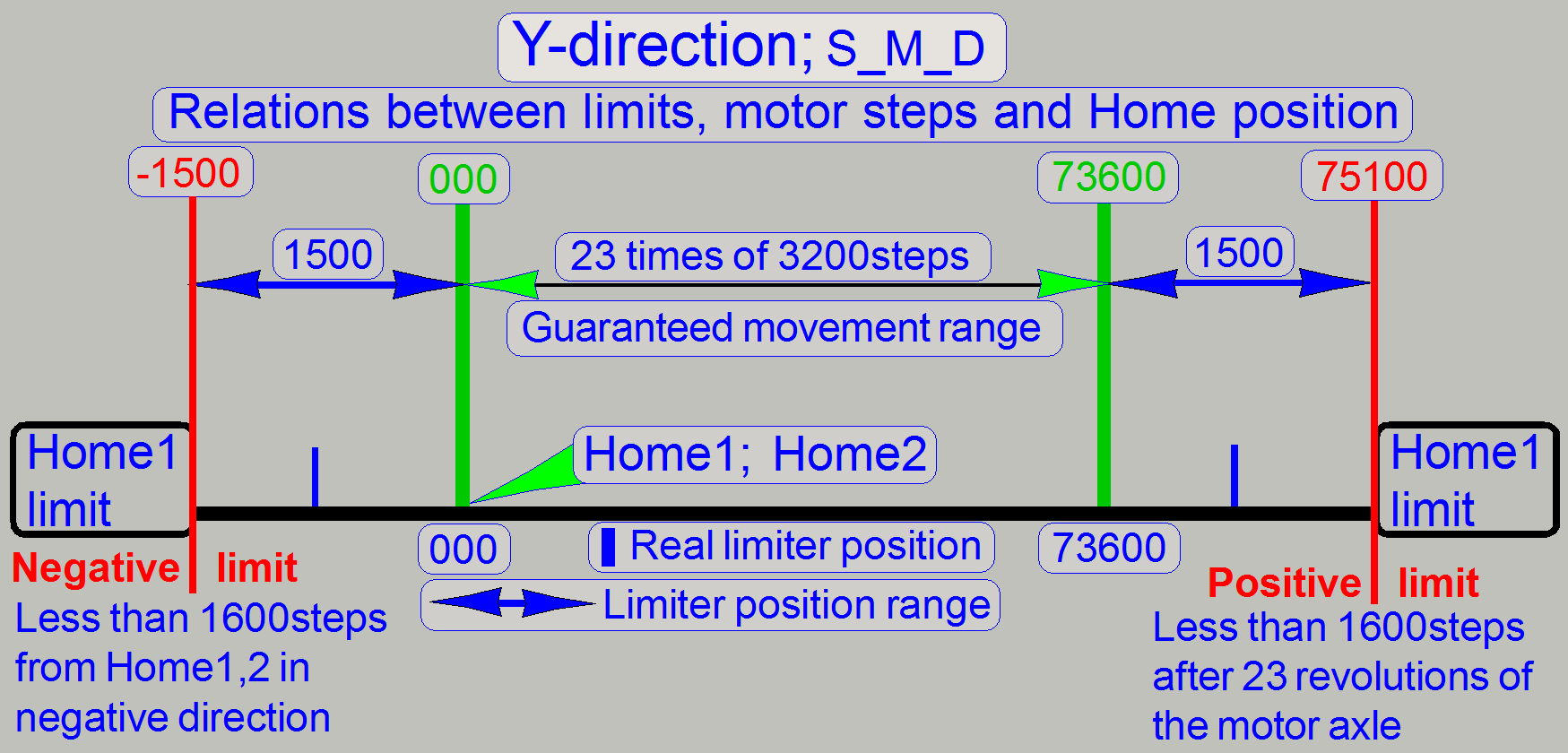

Y-direction; PCON

Parameters: [HardwareLimits]

“ObjectGuideYMin”; “ObjectGuideYMax”

Parameters: [HardwareLimits]

“ObjectGuideYMin”; “ObjectGuideYMax”

· The accuracy= 100steps (0.1mm)

Negative limit

-1500steps ≤

“ObjectGuideYMin” < -500steps

Positive limit

89600steps <

“ObjectGuideYMax” ≤ 91100steps

Other related or affected sections and parameters: none

![]() “X-Y-stage unit” and “Find the

hardware limits”

“X-Y-stage unit” and “Find the

hardware limits”

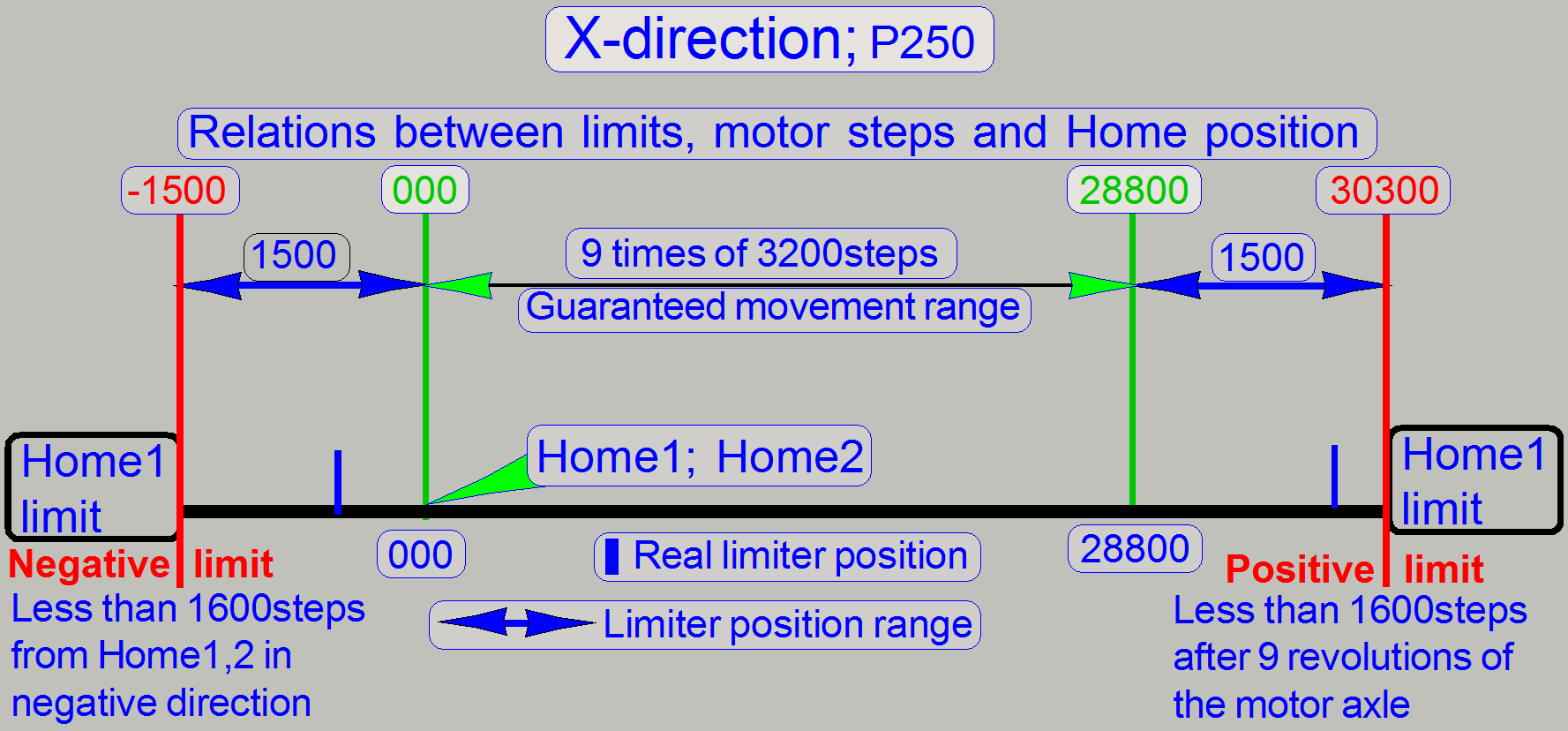

X-direction; P250

X-direction; P250

Parameters: [HardwareLimits] “ObjectGuideXMin”; “ObjectGuideXMax”

· The accuracy= 100steps (0.1mm)

Negative limit

-1500steps ≤

“ObjectGuideXMin” < Home1,2

Positive limit

28800steps <

“ObjectGuideXMax” ≤ 30300

Other related or affected sections and parameters: none

![]() “X-Y-stage unit” and “Find the hardware

limits”

“X-Y-stage unit” and “Find the hardware

limits”

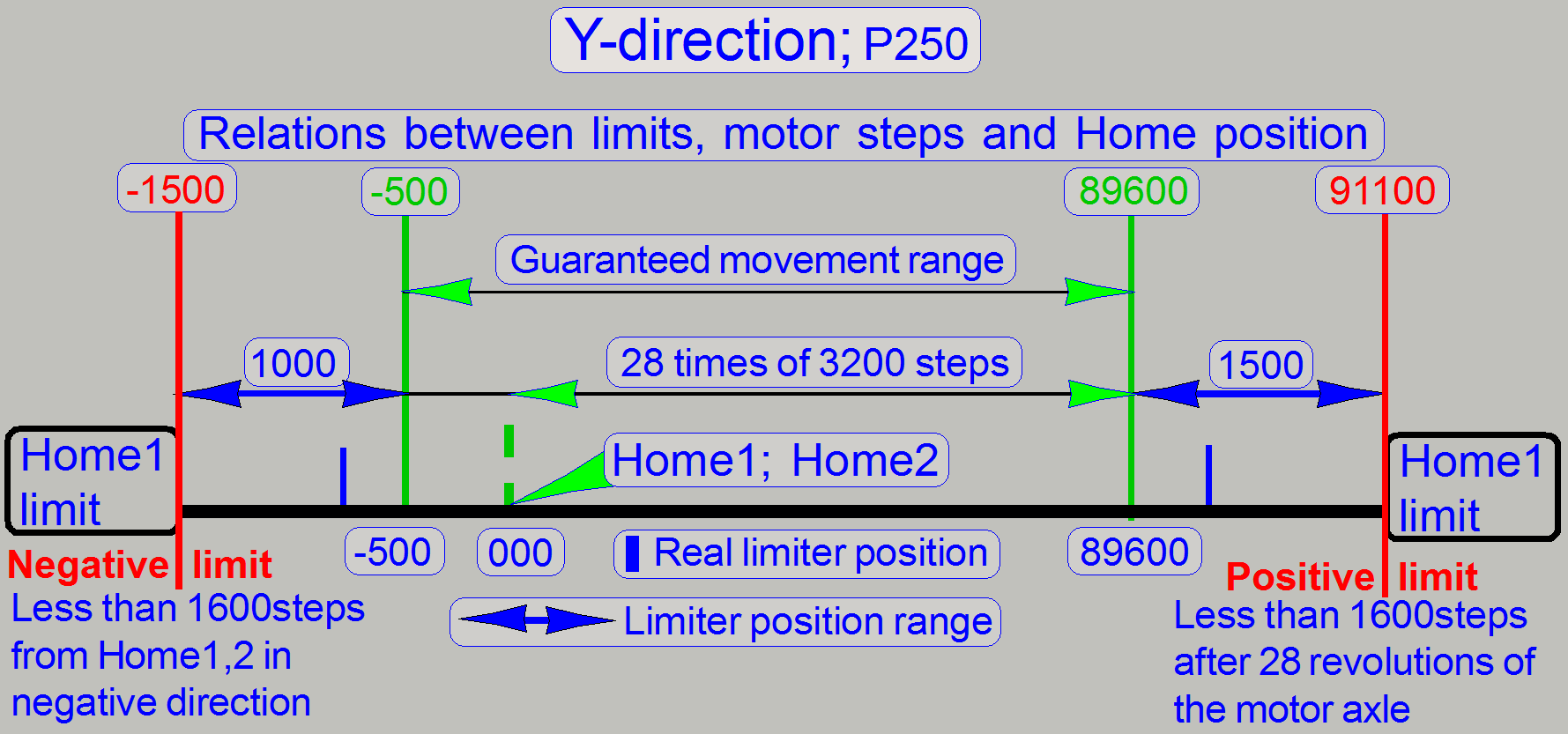

Parameters: [HardwareLimits] “ObjectGuideYMin”; “ObjectGuideYMax”

· The accuracy= 100steps (0.1mm)

Negative limit

-1500steps ≤

“ObjectGuideYMin” < -500steps

Positive limit

89600steps <

“ObjectGuideYMax” ≤ 91100steps

Other related or affected sections and parameters: none

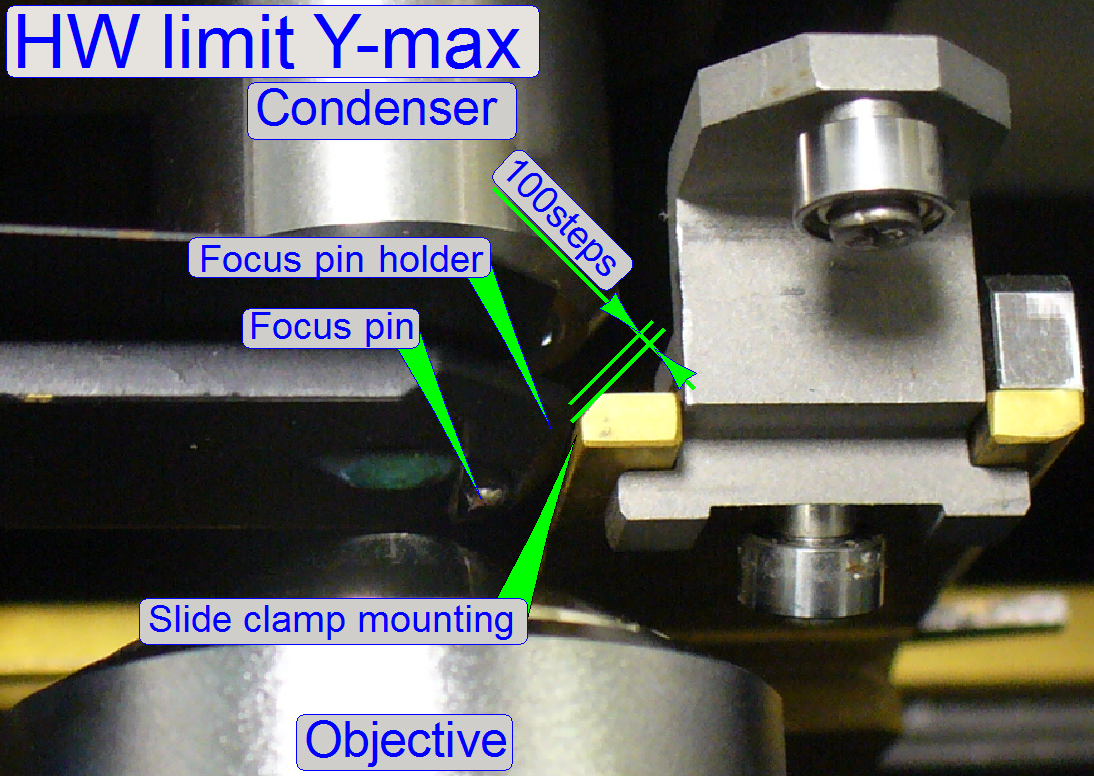

To

avoid collision of the slide clamp with the focus pin holder, the possible

upper limit of the Y-carriage can not be used as hardware limit!

To

avoid collision of the slide clamp with the focus pin holder, the possible

upper limit of the Y-carriage can not be used as hardware limit!

·

Move the Y-carriage in direction to

the limit “Y-max” until a gap of 0.1mm (= 100 steps) exists between the focus

pin holder and the slide clamp (mounting)!

The value is found in the

near of 89000 steps

Other related or affected sections and parameters: none

![]() “X-Y-stage unit” and “Find the hardware

limits”

“X-Y-stage unit” and “Find the hardware

limits”

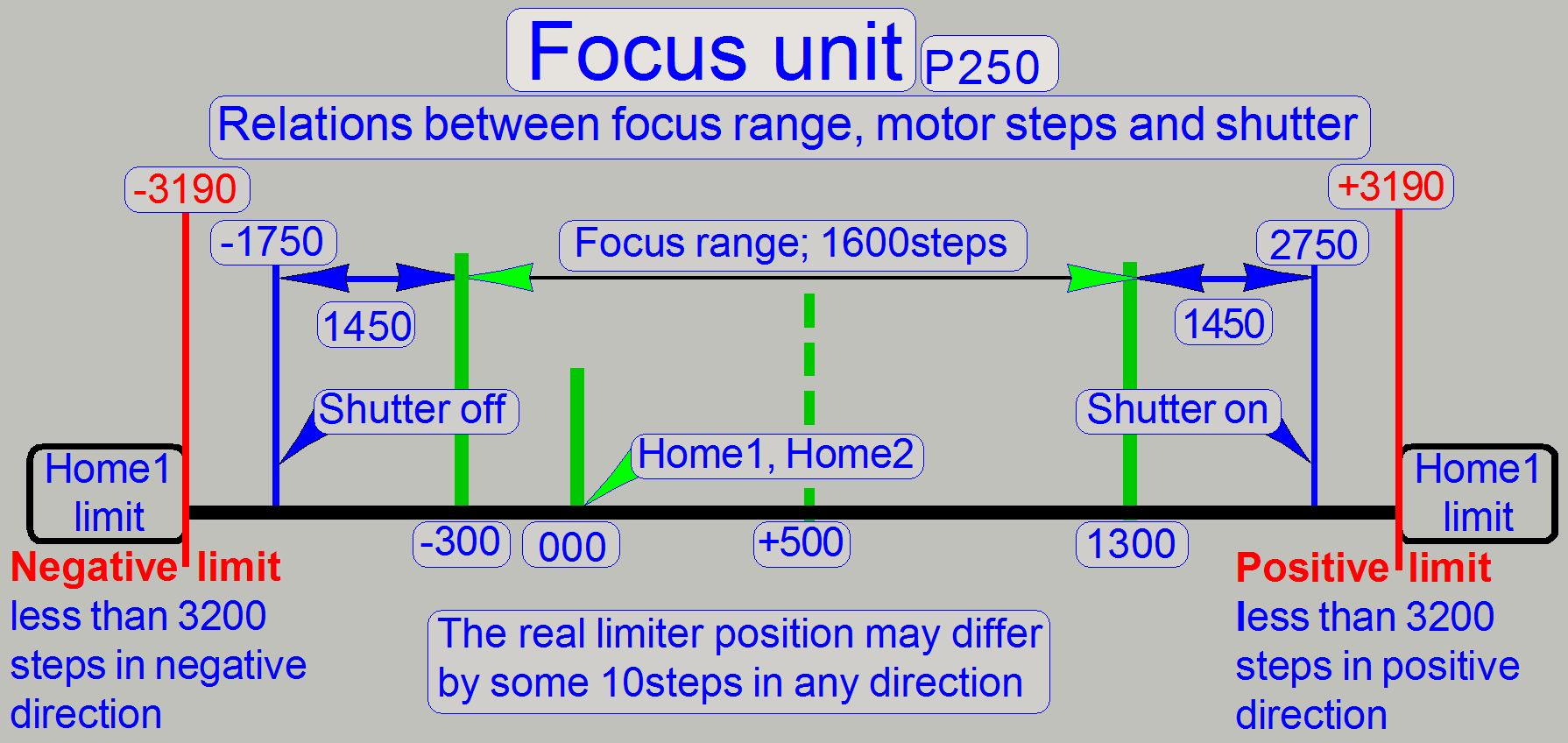

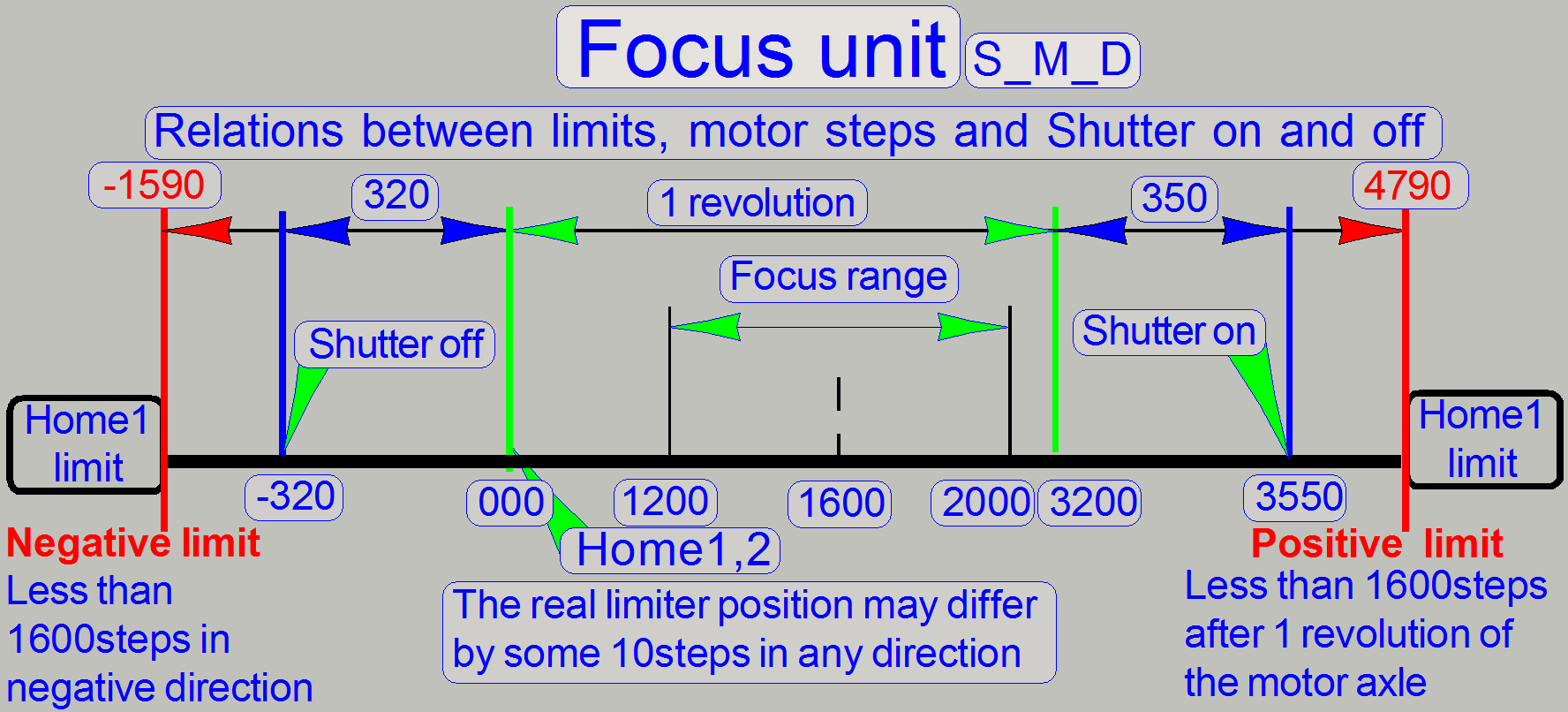

Parameters: [HardwareLimits] “FocusDeviceMin”;

“FocusDeviceMax”

·  The accuracy= 10steps

The accuracy= 10steps

· The hardware limit’s values depending highly on the

found ex-center position on the motor axle.

Negative limit

-3190steps ≤ “FocusDeviceMin” < -300steps

Other related or affected sections and parameters:

[Focus]; CondenserCoverOff

Positive limit

1300steps < “FocusDeviceMax” ≤ 3190steps

Other related or affected sections and parameters:

[Focus]; CondenserCoverOn

![]() “Adjust the ex-center position”

and “Find the

hardware limits for the focus unit”

“Adjust the ex-center position”

and “Find the

hardware limits for the focus unit”

Remarks

The focus motor has a resolution of 6400steps / revolution; so the limit

of “Home1” is defined by 3200steps.

The hardware limit is defined by the shutter wire and the shutter arm.

The real limit position depends on the adjusted ex-center position and

may vary by some 10steps.

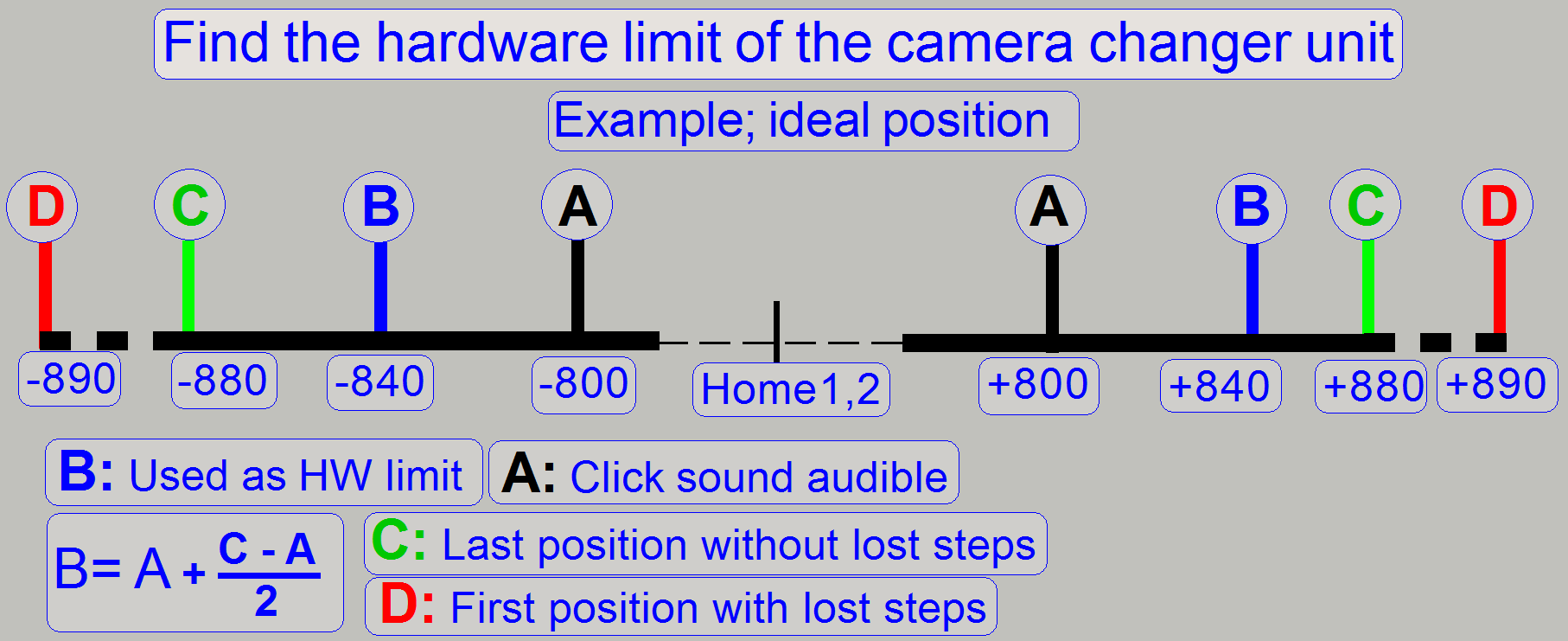

Camera changer

unit; P250

Parameters: [HardwareLimits] “CameraChangerVT_Min”; “CameraChangerVT_Max”

Parameters: [HardwareLimits] “CameraChangerVT_Min”; “CameraChangerVT_Max”

· The accuracy = 10steps

· The hardware limit’s values depending highly on the

found clutch-pin position on the motor axle; see “Variable position”.

Negative limit

-1590steps ≤ “CameraChangerVT_Min”;

“Movement limiters” and “Find the

hardware limits”

Other related or affected sections and parameters:

[CameraChangerVT]; Position1=

![]() “Define the mirror disc working position”

“Define the mirror disc working position”

Positive limit

Positive limit

“CameraChangerVT_Max” ≤ 1590steps;

![]() “Movement limiters” and “Find the hardware limits”

“Movement limiters” and “Find the hardware limits”

Other related or affected sections and parameters:

[CameraChangerVT]; Position2=

![]() “Define the mirror disc working position”

“Define the mirror disc working position”

Remarks

The “Variable position” means,

the position Home1,2 is only in exceptions in the center of the guaranteed

movement range.

On the other side, the construction must be fit always between

the limits Home1!

·

The positions “C”, the last position without lost

steps, must not exceed the limits “Home1”; otherwise, the adjustment is faulty!

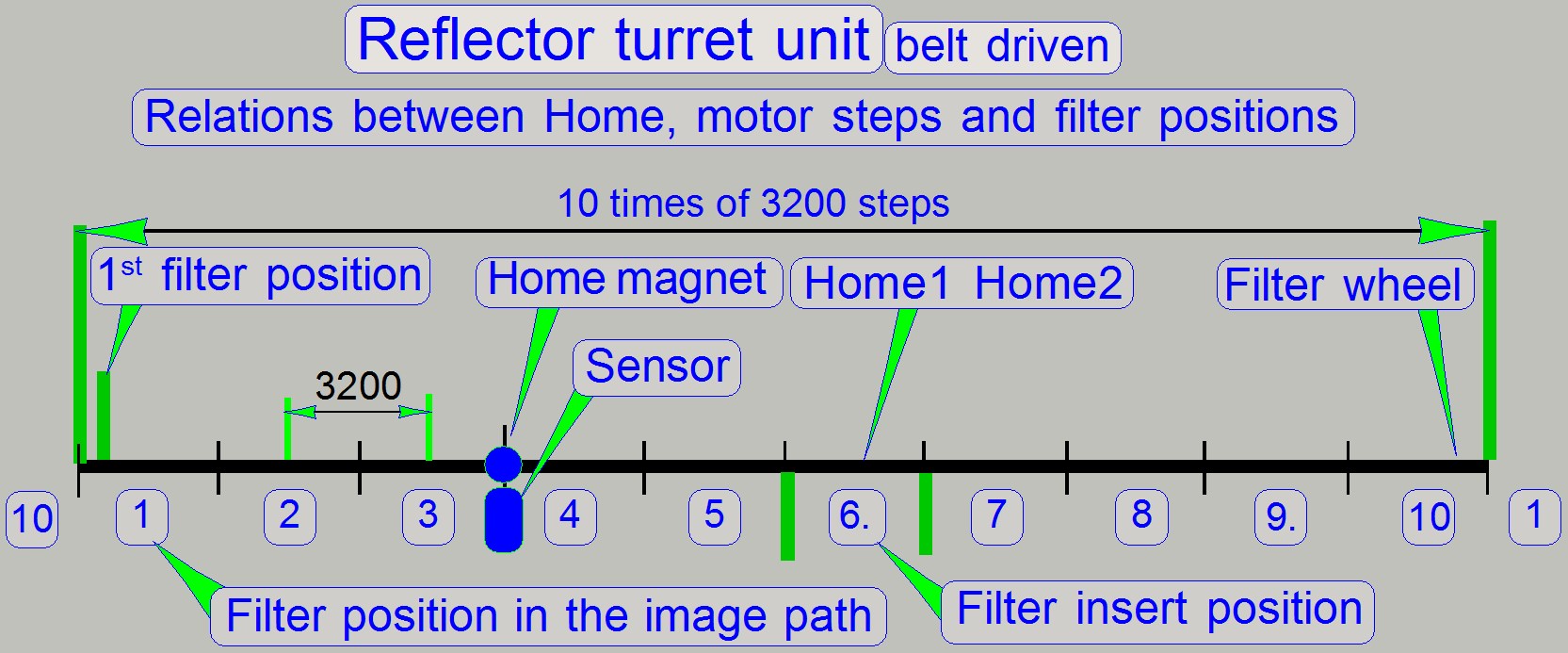

Reflector turret

unit; P250 (belt driven)

Parameters: none

Other related or affected sections and parameters:

[ReflectorTurret];

StartingMotorPosition= see: “Find the first

filter position”

Remark

Parameters: [HardwareLimits] “ReflectorTurretMin”; “ReflectorTurretMax” are not

interpreted if the “ReflectorTurretType”

in the section [Microscope] is set to “RT_3DH_10Pos_Belt”

ReflectorTurretType=

RT_3DH_10Pos_Belt; see: “Configure the belt driven reflector turret unit”

![]() “Find the Home position of the filter wheel” and

“Check

or adjust the external sensor acting range”

“Find the Home position of the filter wheel” and

“Check

or adjust the external sensor acting range”

X-stage unit; SCAN,

Parameters: [HardwareLimits]

“ObjectGuideXMin”; “ObjectGuideXMax”

Parameters: [HardwareLimits]

“ObjectGuideXMin”; “ObjectGuideXMax”

· The accuracy= 100steps (0.1mm)

Negative limit

-1500steps ≤ “ObjectGuideXMin” < Home1,2

Positive limit

28800steps < “ObjectGuideXMax” ≤ 30300

Other related or affected sections and parameters: none

![]() “X-Y-stage unit” and “Find the hardware limits”

“X-Y-stage unit” and “Find the hardware limits”

Y-stage unit; SCAN,

Parameters: [HardwareLimits]

“ObjectGuideYMin”; “ObjectGuideYMax”

Parameters: [HardwareLimits]

“ObjectGuideYMin”; “ObjectGuideYMax”

· The accuracy= 100steps (0.1mm)

Negative limit

-1500steps ≤ “ObjectGuideYMin” < Home1,2

Positive limit

73600steps < “ObjectGuideYMax” ≤ 75100

Pannoramic

SCAN

Important restriction!

To

avoid collision of the slide clamp with the focus pin holder, the possible

upper limit of the Y-carriage can not be used as hardware limit!

To

avoid collision of the slide clamp with the focus pin holder, the possible

upper limit of the Y-carriage can not be used as hardware limit!

·

Move the Y-carriage in direction to

the limit “Y-max” until a gap of 0.1mm (= 100 steps) exists between the focus

pin holder and the slide clamp (mounting)!

The value is found in the

near of 73000 steps

· Use the found

value as hardware limit Y-max!

Other related or affected sections and parameters: none

![]() “X-Y-stage unit” and “Find the hardware limits”

“X-Y-stage unit” and “Find the hardware limits”

Focus unit; DESK,

Parameters: [HardwareLimits] “FocusDeviceMin”; “FocusDeviceMax”

Parameters: [HardwareLimits] “FocusDeviceMin”; “FocusDeviceMax”

· The accuracy= 10steps

Negative limit

-1590steps ≤ “FocusDeviceMin” < Home1,2

Other related or affected sections and parameters:

[Focus]; CondenserCoverOff

Positive limit

3200steps < “FocusDeviceMax” ≤ 3550

Other related or affected sections and parameters:

[Focus];

CondenserCoverOn

![]() “Adjust the ex-center

position” and “Find the

hardware limits”

“Adjust the ex-center

position” and “Find the

hardware limits”

Remarks

· The focus motor

has a resolution of 3200steps / revolution; so the limit of “Home1” is defined less

than 1600steps.

· The hardware limit

is defined by the shutter wire and the shutter arm.

· The real limit

position depends on the adjusted ex-center position and may vary by some

10steps.

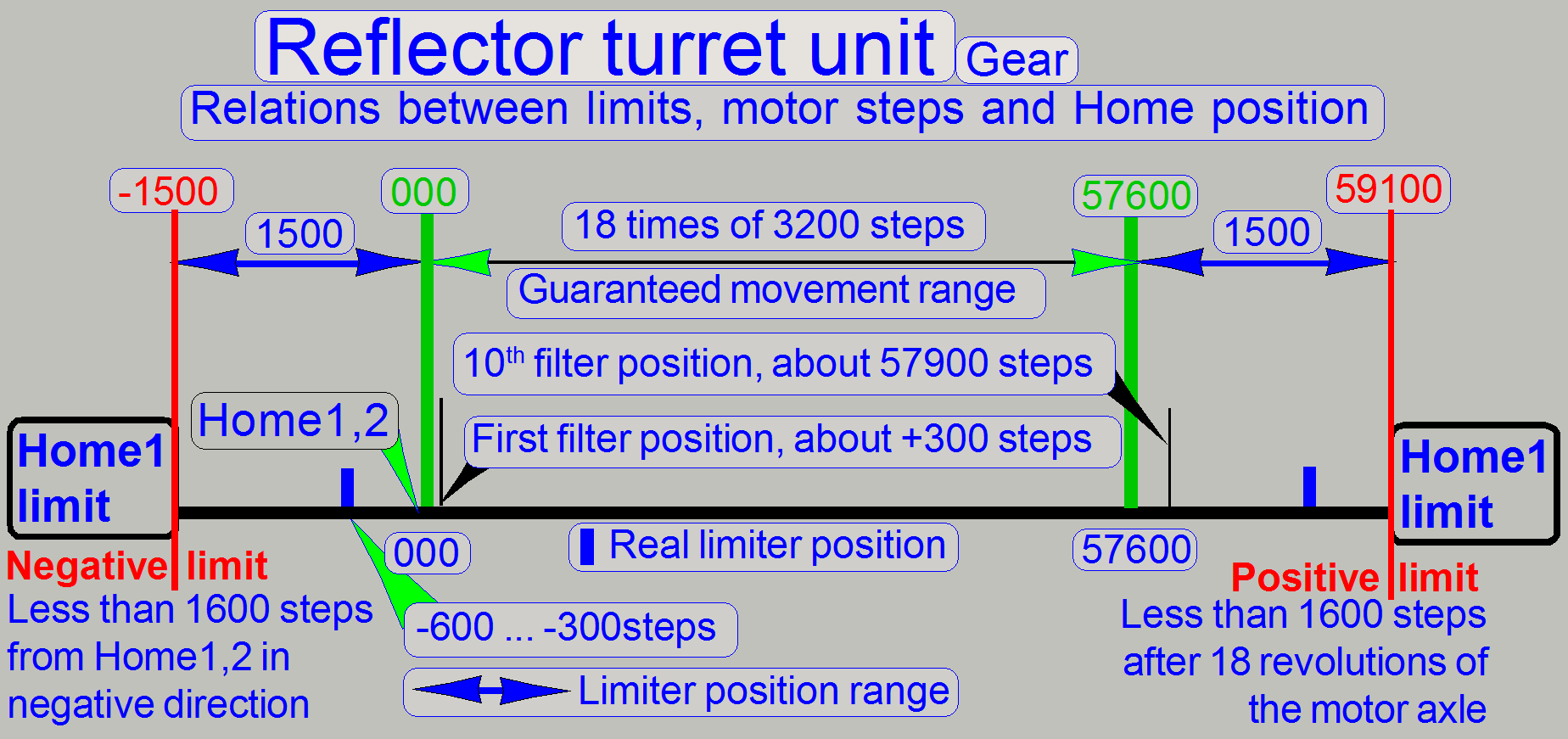

Reflector turret

unit; S_M (gear driven)

Parameters: [HardwareLimits]

“ReflectorTurretMin”; “ReflectorTurretMax”

Parameters: [HardwareLimits]

“ReflectorTurretMin”; “ReflectorTurretMax”

· The accuracy= 100steps

Negative limit

-600steps ≤

“ReflectorTurretMin” ≤ -300steps; see also: “Adjust the negative turret limit”

Positive limit

57600steps < “ReflectorTurretMax” ≤ 59100steps; see also: “Adjust the positive turret limit”

Other related or affected sections and parameters:

[ReflectorTurret]; StartingMotorPosition= see: “Find

the first filter position”

· The accuracy= 10steps

“Hardware construction” and “Adjust the filter selector wheel and the

mechanical drive”

“Hardware construction” and “Adjust the filter selector wheel and the

mechanical drive”

End