Adjust the parallelogram

For experienced technicians!

This chapter describes the

adjustment procedure to reach perpendicularity between the objective (optical

axis) and the slide surface (specimen holder).

Because this adjustment needs

special tools and might be time consuming, it should not be done in the field;

an experienced technician may execute these steps in the service center.

The adjustment is based on the

software version 1.15 and the scanner P250, but the principle and almost all

procedures are the same in the scanners S_M_D.

Contents

Prepare the scanner for the

adjustment

Images of the adjustment

steps

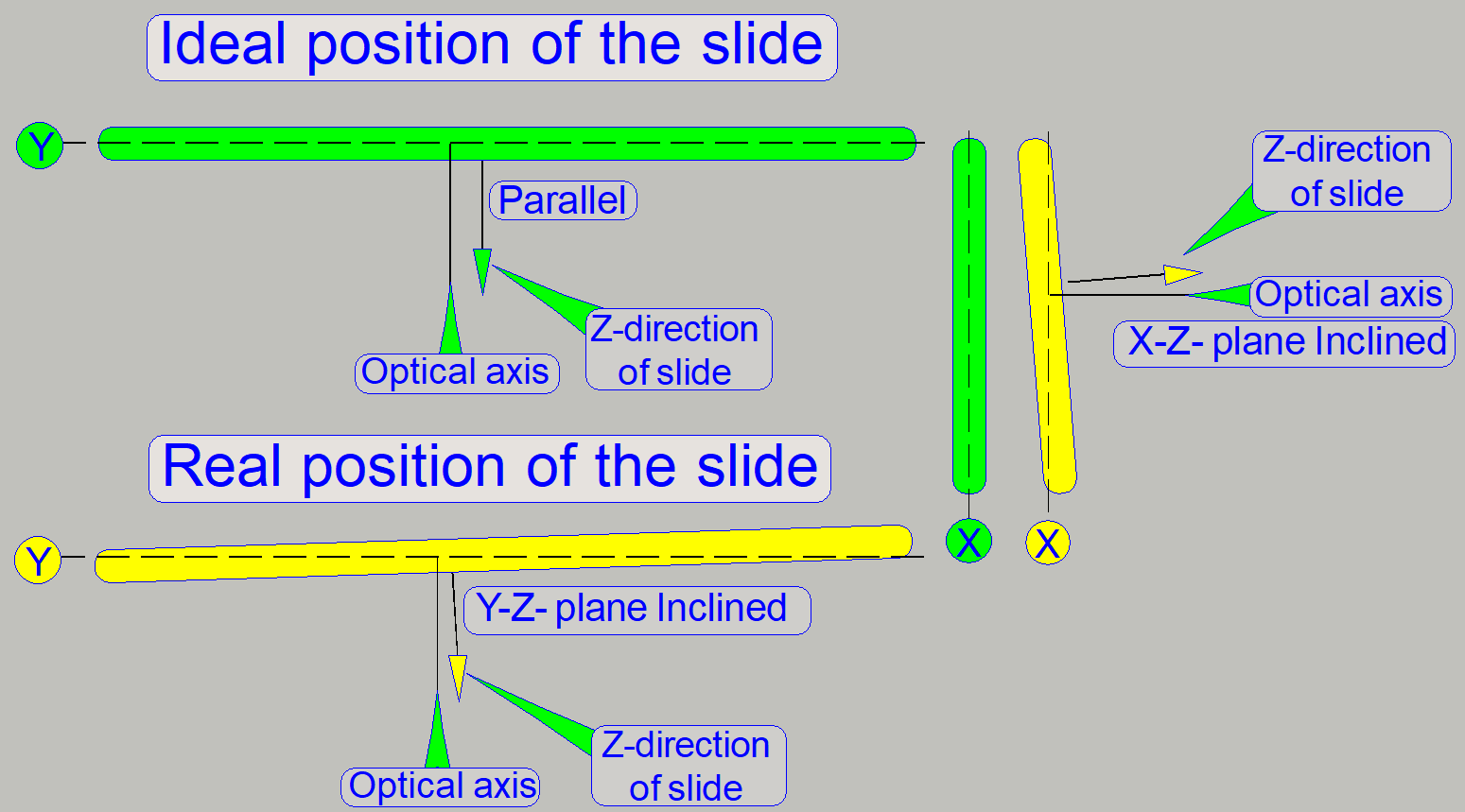

The optical axis of the objective

and the glass slide needs to be perpendicular to avoid tilting and partially

out of focus FOVs on digital slides.

As commonly known, in Pannoramic

scanners, the slide is moved with the focus pin around the nominal focus

position (around the position +500 steps; in S_M_D this position is 1600 steps

nominal) during focusing. To shift the slide in the Z-direction (this means

focusing) and not inclining or tilting the slide during these movements, a

parallelogram is used. The parallelogram is mounted between the Y-carriage and

the specimen holder.

Also important is the position of

the parallelogram in relation to the X-Z-plane and the Y-Z-plane of the slide.

Best scanning results will be

reached if the slide is perpendicular to the optical axis.

· The adjustment, described in this chapter, defines the

position of the parallelogram so, that the inclination of the slide in the

X-Z-plane and the Y-Z-plane will not exceed the allowed limits.

More information can also be found

in the chapters:

·

“Focus unit” and “Scan area”, “Principle of focusing”

·

“X-Y-Stage unit”, “Parallelogram” , “Specimen holder”

·

“Optics

and illumination”, “Stage skew check”

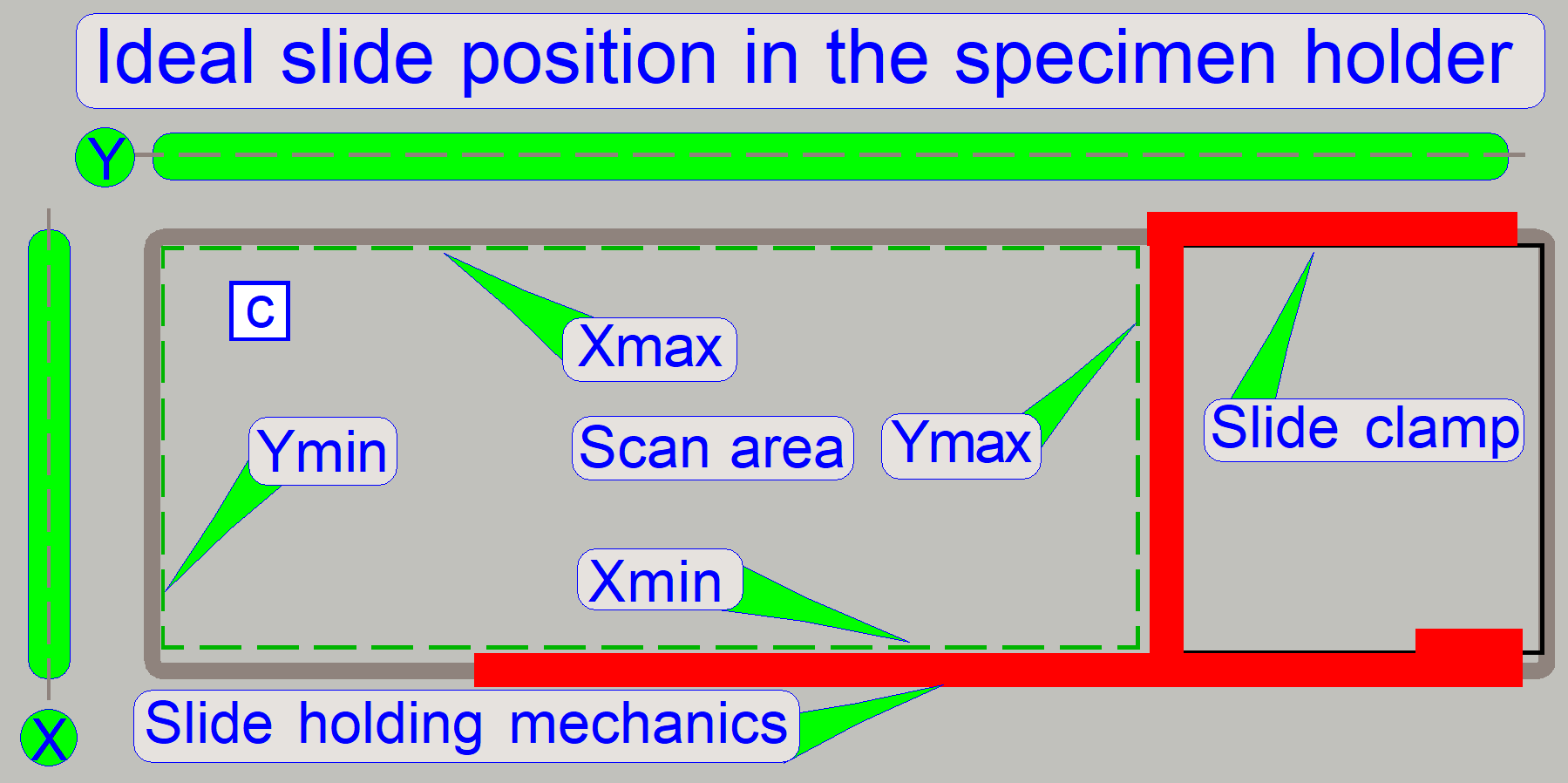

Ideal position of the slide in the specimen holder

In the ideal position of the slide,

the optical axis is perpendicular to the slide surface and by moving the focus

pin in the range of -300 steps to +1300 steps or by selecting any field of view

inside the scan area, this perpendicularity will not be lost; the LASER beam

(reflected by the slide surface) would be always reflected in the same angle

onto the same position of the screen during movements of the slide.

1)

The ideal slide

position would be reached if the field of view (FOV), near to the limit Y-min

would be in the same plane as the field of view near to the position Y-max

(shown with the line (Y))

And

2)

The field of

view, near to the limit X-min would be in the same plane as the field of view

near to the position X-max (shown with the line (X)).

· If this requirement is fulfilled, the optical axis is

perpendicular to the slide surface.

This definition assumes also:

· The slide (the glass) itself is flat, and not tilted

or slant in any direction and the slide thickness does not vary.

· The force of the preload spring of the parallelogram

is not much; otherwise, the pressure of the focus pin against the slide may

tilt the slide surface in positions of the field of view, far away from the

holding mechanics (c).

In practice, the ideal position will

not be reached, but the inclination of the slide in X- and Y-direction may be

reduced as much as possible.

· The slide will be inclined in the X-Z-plane, in the

Y-Z-plane or in both planes at the same time, but always inside the allowed

tolerances.

· In these cases, the Z-axis of the slide will be

inclined, in relation to the optical axis.

The LASER beam will be reflected to

a different position onto the screen (in relation to the ideal position of the

slide).

· The inclination of the slide may result in unfocused

parts of the virtual slide and these are best visible on the border of the

actual field of view in relation to the neighbor FOV, if the inclination of any

plane is too much.

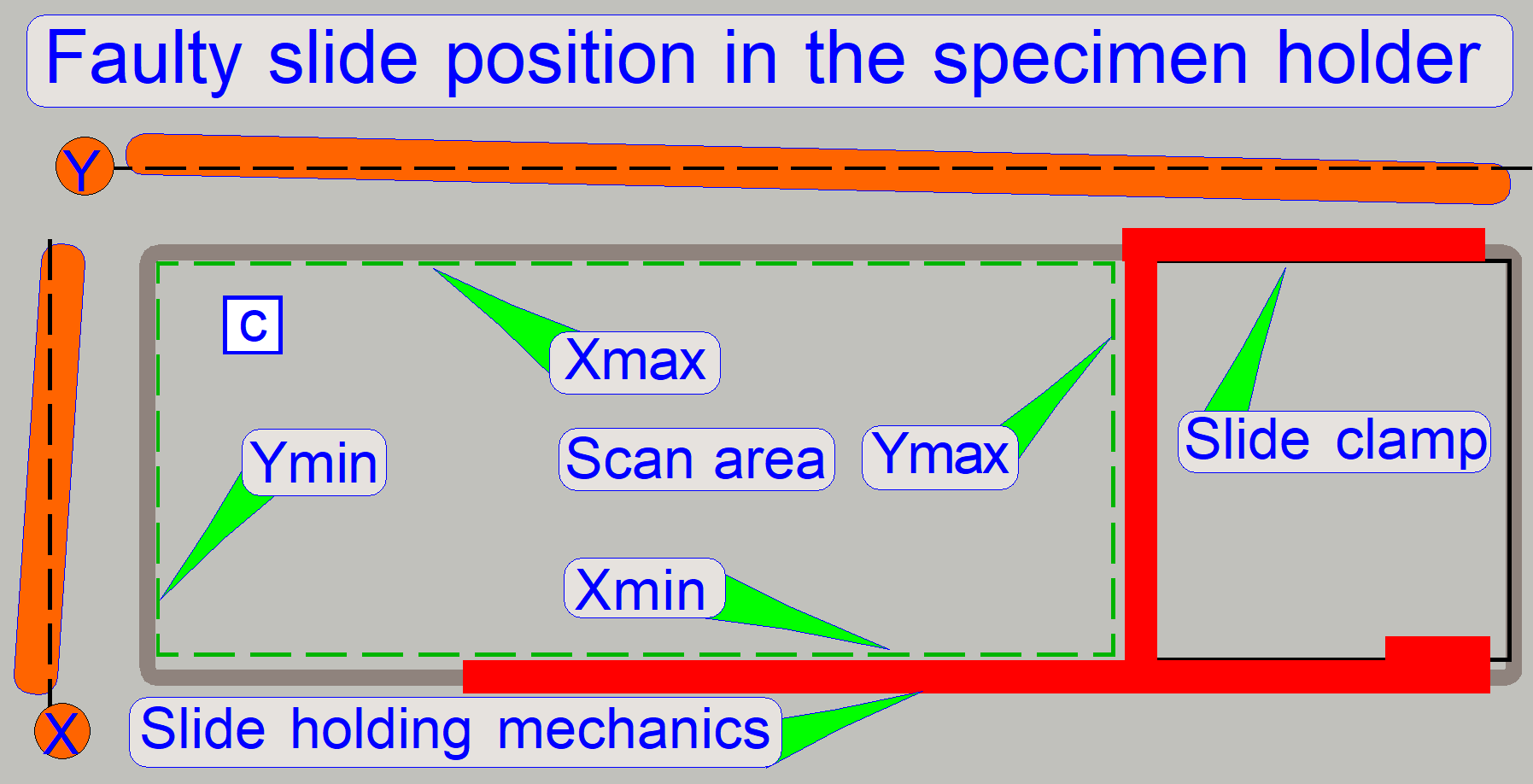

Faulty inclination of the

slide in the specimen holder

The real position of the slide is faulty if:

· The Z-axis of the slide is inclined, in relation to

the optical axis; outside the allowed limits.

The inclination

angle of the slide’s X-Z- or Y-Z-plane is too much, if the focus of the field

of view differs (the focus difference is visible) on the border to the neighbor

field of view in the virtual tissue and:

· The slide is correctly inserted into the specimen

holder

· The slide is held properly in the specimen holder (the

slide does not change its position during scanning)

· This behavior can be detected often on two neighbor

FOV’s on different positions of the scanned tissue; the border of the FOV is

visible (in relation to the focus).

· The neighboring FOV’s are scanned in the same focus

motor step position

· Some parts of the field of view are out of focus while

other parts of the same field of view are in focus

· This behavior can be found on different tissues

(slides) also.

· By adjusting the parallelogram position, the

inclination of the slide in relation to the optical axis will be minimized or

eliminated; this is the task of the adjustment.

Remark

· During

the tissue creation process the thickness of the sample itself may vary on

small spots and this might also be visible as unfocused part of the virtual

tissue. To decide, whether the thickness of the sample is varying or the

inclination of the slide is the cause of the error, please check always the

focus on the border of the FOV in relation to its neighbor FOV on different

tissues also.

· The

inclination of the specimen (holder) may also be checked in the live view and

with a zoom factor of 2.73 of the scan program; see also: “Stage skew check”.

In all cases

If the scanned tissue shows mistakes

or errors, that may occur in conjunction with non perpendicularity of the

objective (Optical axis) and the specimen holder (slide surface) (some parts of

the field of view are out of focus during other parts of the same field of view

are in focus) and this behavior can be detected very often on two neighbor

FOV’s and there is no difference in focus steps, the following checks have to

be done first:

Please do the following checks before you set up the adjustment tools!

- Check the correct tightness of the X-Y-stage unit; loosen it, check the dovetail mounting for unexpected

behavior (smoothness, dust) move it into the correct position again and

tighten the fixing bolt.

- Check the correct tightness of the focus unit; loosen it, check the dovetail mounting for

unexpected behavior (smoothness, dust) move it into the correct position

again and tighten the fixing bolt.

- Check the correct position and the tightness of the scanner plate; loosen it, move it into the correct position

again and tighten the fixing bolts in the right

sequence.

- Check the correct position and the tightness of the turret unit; loosen it,

move it into the correct position again and tighten the fixing bolts in the right

sequence.

- Insert a slide into the specimen holder and check

the correct fixing of the slide in the specimen holder (the slide should not be inserted slanted!)

- Check the hysteresis in X- and Y-direction.

- Check a well visible part of the tissue in the

“Live view” window as described in the chapter “Stage skew check”.

- Scan the tissue of the well inserted slide and

analyze it for slanted field of views.

Any mechanical reason or

incorrectness named above may result in the incorrectness of the optical axis;

if one component is not placed well in the optical axis, the result is the same

as if the parallelogram would be adjusted wrong!!

When shell I check or adjust the

parallelism between the focus- and the X-Y-stage unit?

To check the parallelism, use always the “Stage skew check” first, before you set up the adjustment

tools!

- If the “Stage

skew check” failed or a faulty inclination of the slide in the specimen

holder was detected.

- If the

parallelogram was removed.

- If the

parallelogram or the specimen holder was exchanged.

- If the entire

X-Y-stage unit was changed.

- If the Focus

unit was exchanged.

- If any spare

part was changed and this spare part is in connection with the parallelism

or the straightness of the optical axis.

- If the

mounting bolt positions or the adjustment bolts position of the

parallelogram was altered.

Attention

If the parallelogram or the specimen holder is

deformed (bent) or any spring of the parallelogram is broken or deformed, this

adjustment will not deliver the desired results!

Exchange the

appropriate spare part first before doing the adjustment steps.

Important

If any modification on the parallelogram or the

specimen holder mounting was done, please:

· Check or adjust the magazine unit

position.

· Check or adjust the

correct position of the specimen

holder fixing fork.

·

Check or define the scan area again

before scanning tissues!

·

If the scan area was modified, please

execute the preview

calibration also.

·

Check the darkfield preview.

Requirements

· The

tools, described in the chapter “Tools used for the adjustment”.

· Diverse

hexagon key bolt drivers

· Service

program “SlideScannerService.exe”

· Scan

program (SlideScanner.exe)

· Viewer

program (“SlideViewer.exe”)

· Required

time may be 2 hours or more.

Remark

The required time depends highly on the misalignment

of the parallelogram, the post adjustments and checks that has to be done (see

above “Important”) and, nevertheless, the experience of the technician.

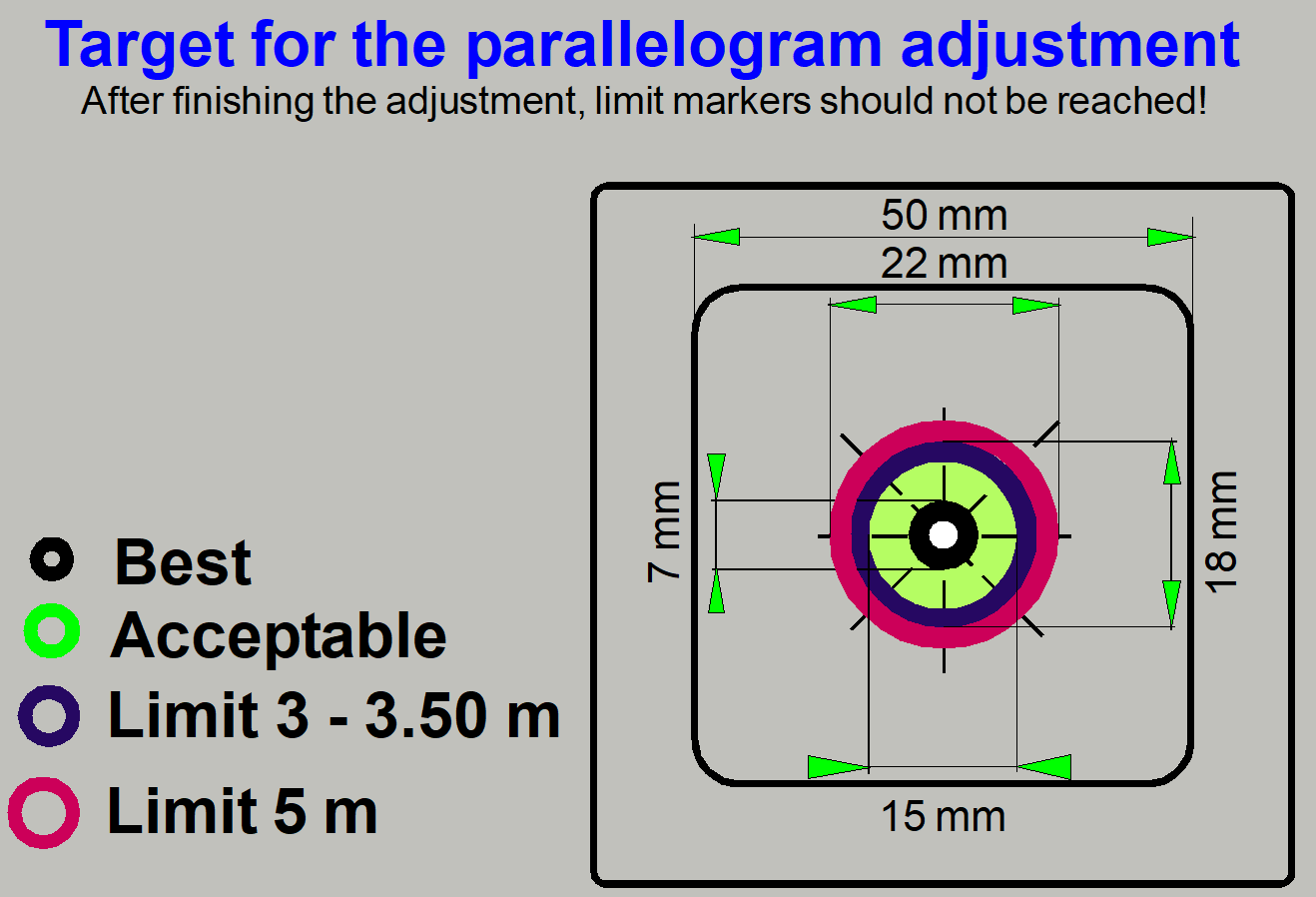

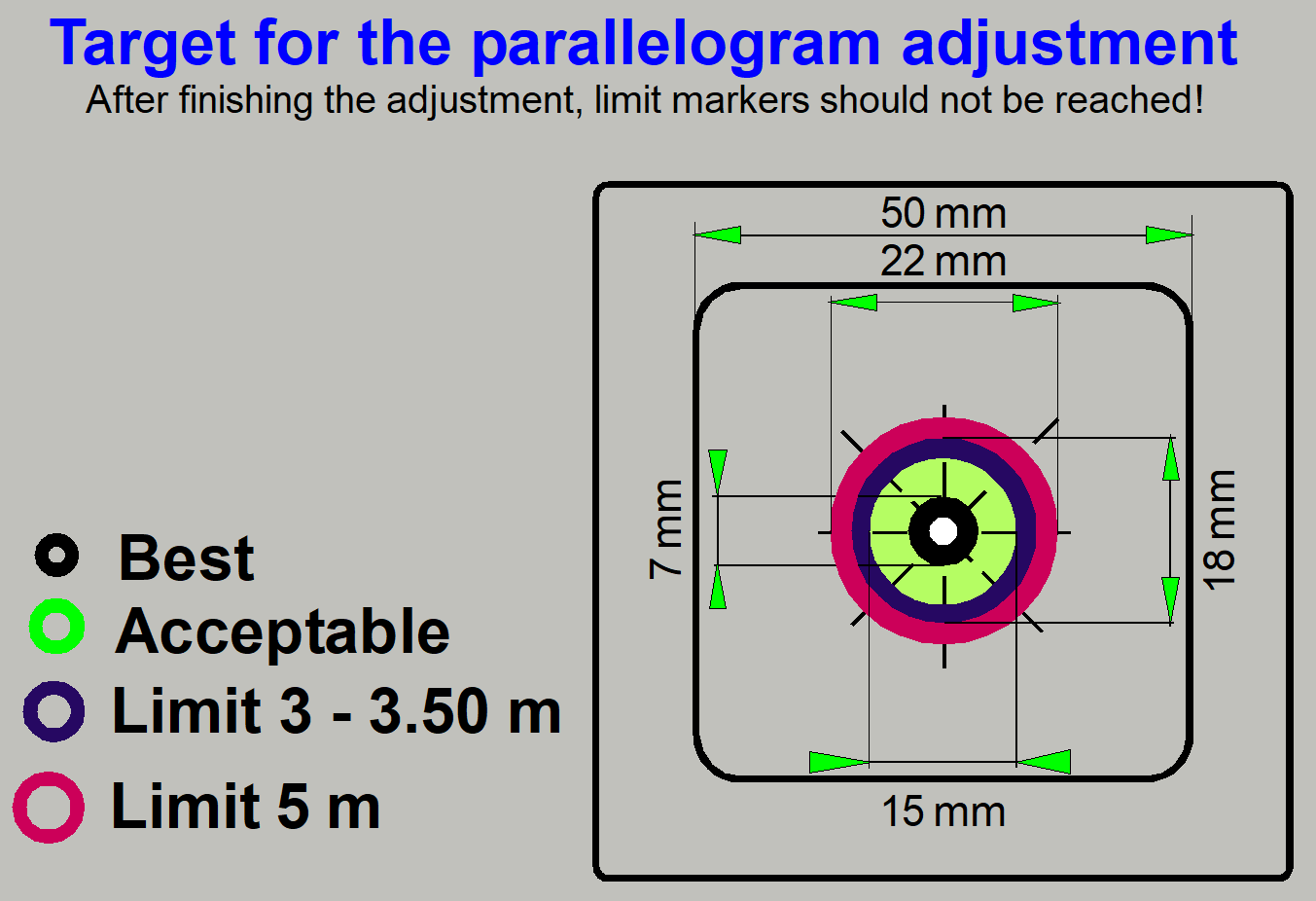

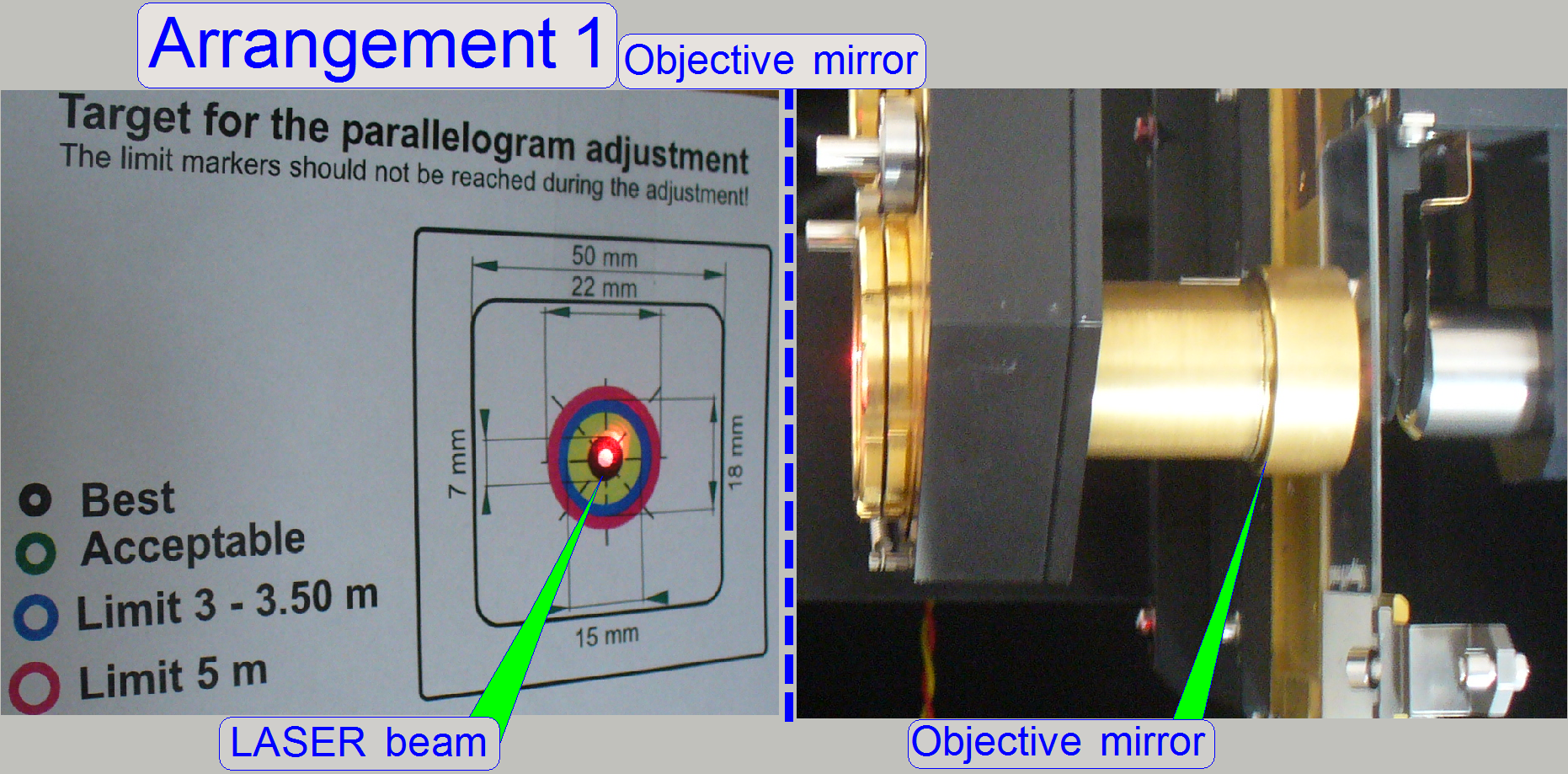

The target is placed in a nominal distance of about 3m

to 3.5m from the scanner onto the wall and is used as a screen.

The marker

areas on it are used to check the adjustment result.

The marker

areas on it are used to check the adjustment result.

The momentarily adjustment is qualified nearly in the

center of the scan area and in the focus positions:

-300 steps +500

steps and +1300 steps

If the travel of the LASER beam does not go out of the

green area during the focus movements (if the distance is in the range between

3m - 3.5m), you have shot the bull’s eye.

If the distance is shorter than 3meters (e.g. only

2.5m) the allowed movements should be closer to the black circle in the center;

the acceptable (green) area has to be defined smaller.

For best adjustment results a distance of at least 3m

is recommended; further details will be discussed later.

·

You may also create and print your own

target by the help of any image editor that is

able to draw circles or print the example target.

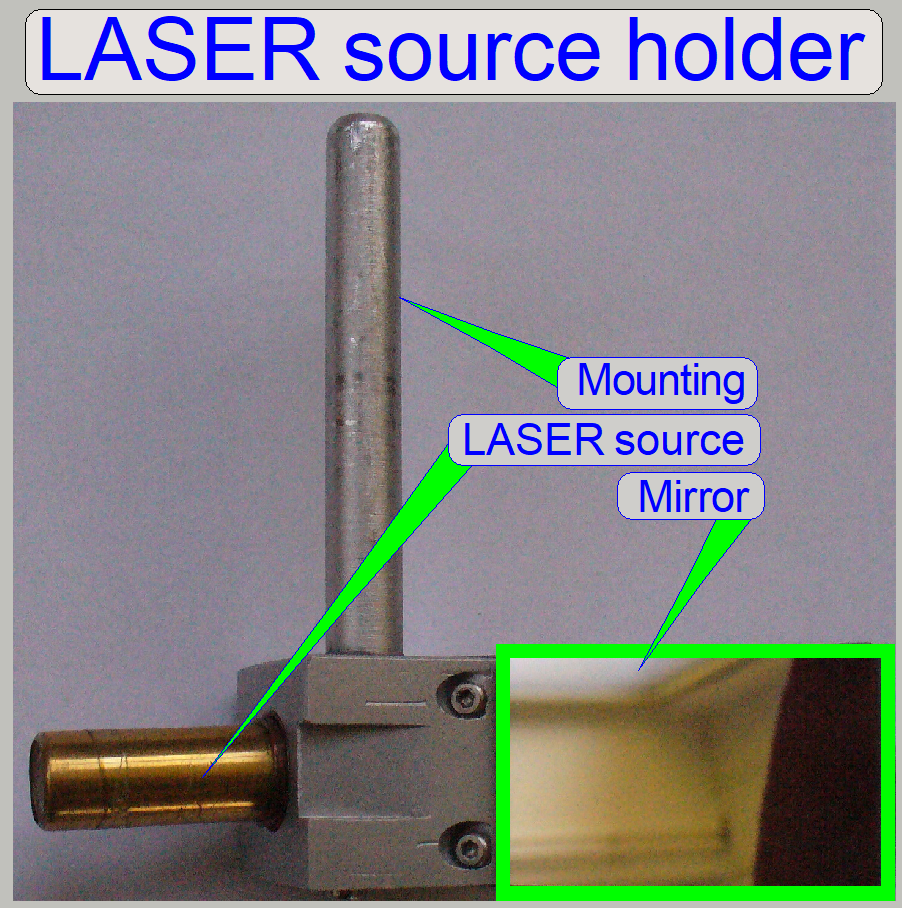

LASER

source holder with beam mirror

As light source of the LASER beam a LASER pointer or

any other kind of LASER source can be used; the mechanical construction may be

important for the mounting possibilities.

Precautions

Never look directly into

the LASER beam of the LASER source! The emitted LASER beam has only a power of about

0.01watts but this is enough to damage the retina of the eye!

The mirror is

mounted at an angle of 45º onto the LASER source holder and may be used to

reflect the beam sideways, onto the wall.

The LASER source holder can be mounted so, that the

beam passes the opposite side (or any side) of the LASER source mounting where

no mirror is mounted.

Into the “objective position

·

If the objective position is already

adjusted please do not loosen the objective nut (or the objective counter nut)

during removing the objective; otherwise the adjusted objective position will

be lost!

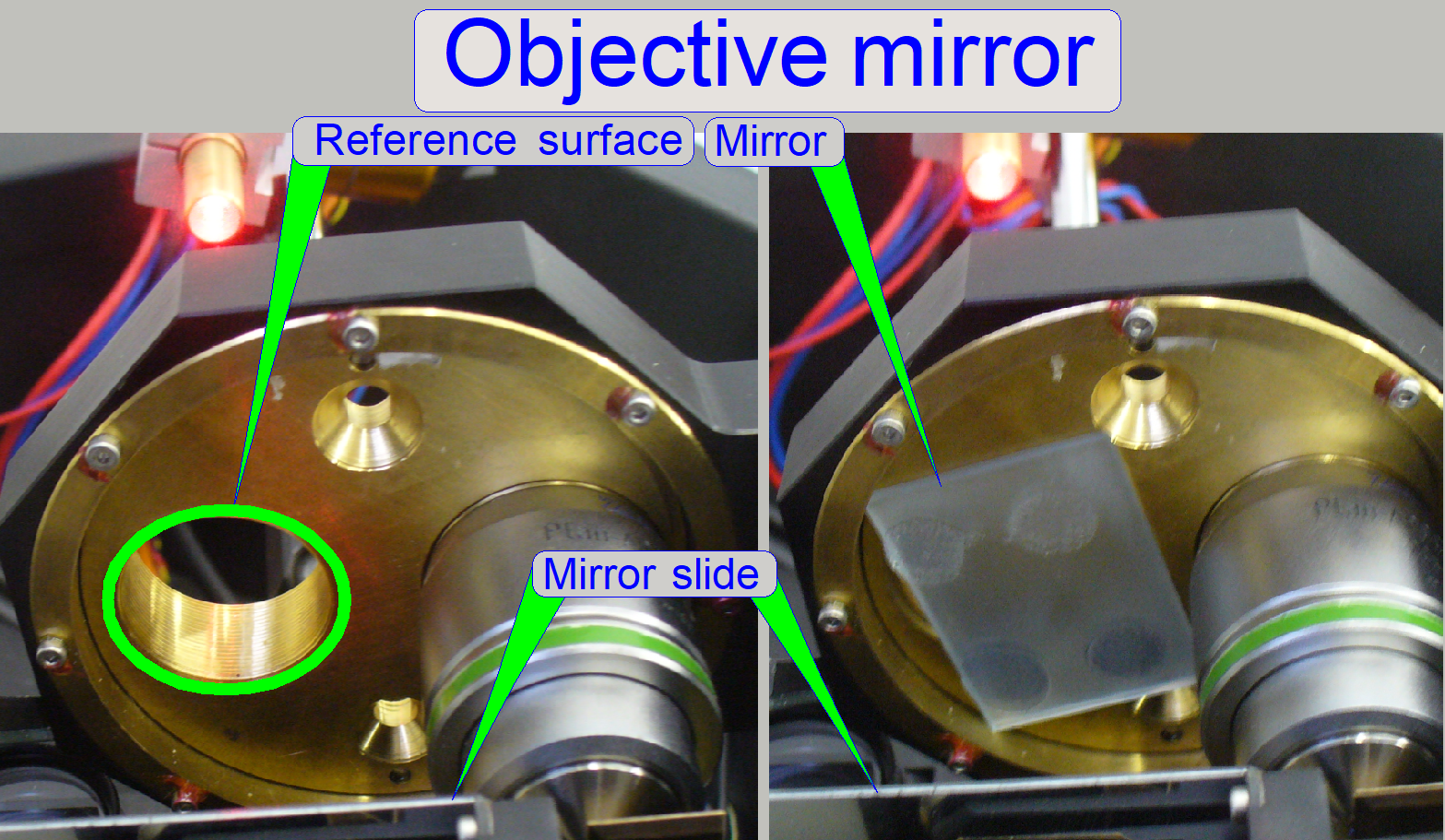

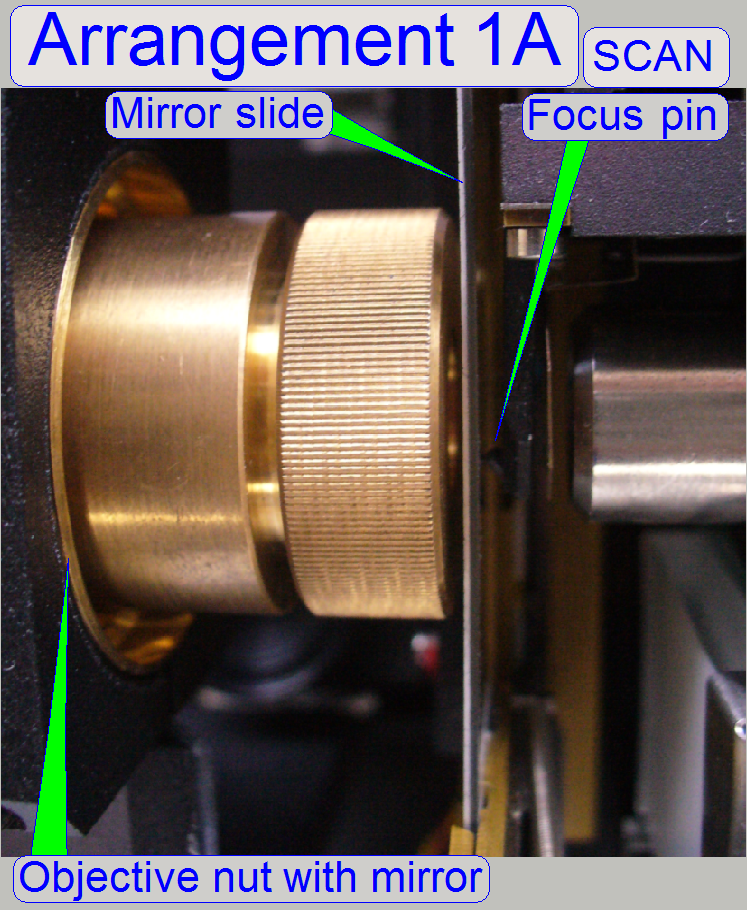

This mirror defines the plane of the objective pupil;

the mirror is mounted perpendicular to the optical axis and is used to arrange

the entire configuration for the real adjustment.

After the configuration is arranged, this mirror is

not needed for the real adjustment.

See also “Arrangement 1” and

“Arrangement 2”.

Remark

· Because

the plane of the objective pupil has to be checked more times during the

adjustment, we recommend to remove both objectives (the 20x and the 40x

objective or the dummy objective also).

·

By rotating the objective disc manually

into the objective position 1 or 2 respectively, you can easily and quickly

“switch” between the “Arrangement 1” and the “Arrangement 2”.

Another solution

A simple mirror may also be used to define the

objective plane, instead of the objective mirror; see also “Arrangement

Dismount the objective by unscrewing only the

objective from the objective nut; do not modify the adjusted objective position

(the wrenches should not be used).

- The reference surface of the objective nut should be smooth;

stickers / labels should not disturb the smoothness of the reference

surface.

- Put the mirror onto the reference surface of the objective nut as

shown and find a well reachable place on the wall for the screen; use the

laser beam.

- Stick the screen onto the wall with the laser beam in the center of

the marker.

- Then remove the mirror.

Important

The actual reference surface position should be

checked more times during the adjustment process.

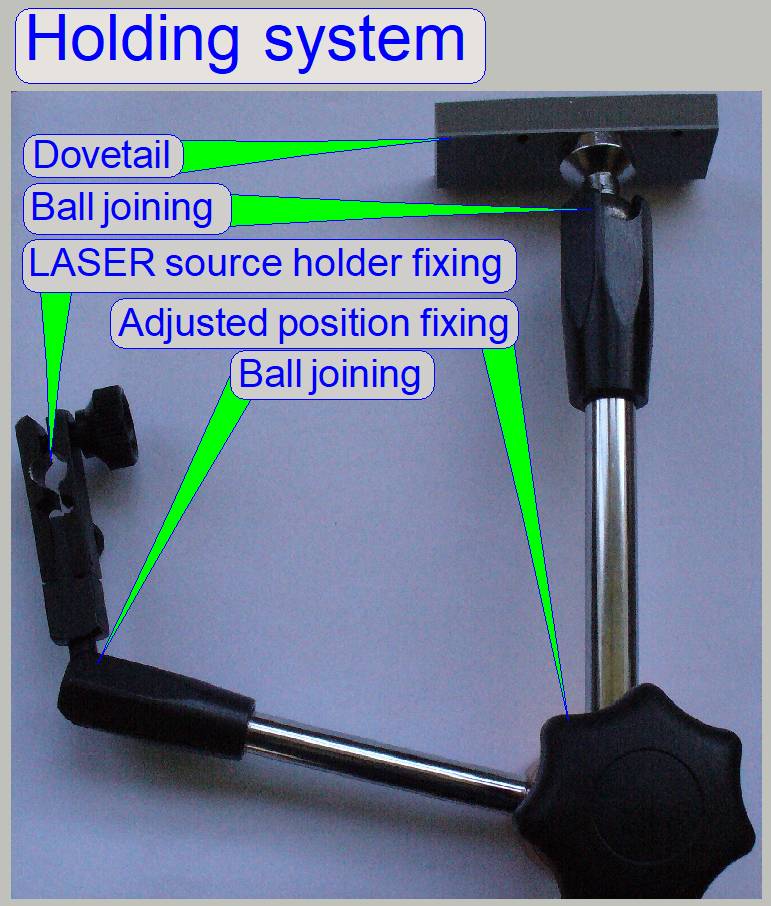

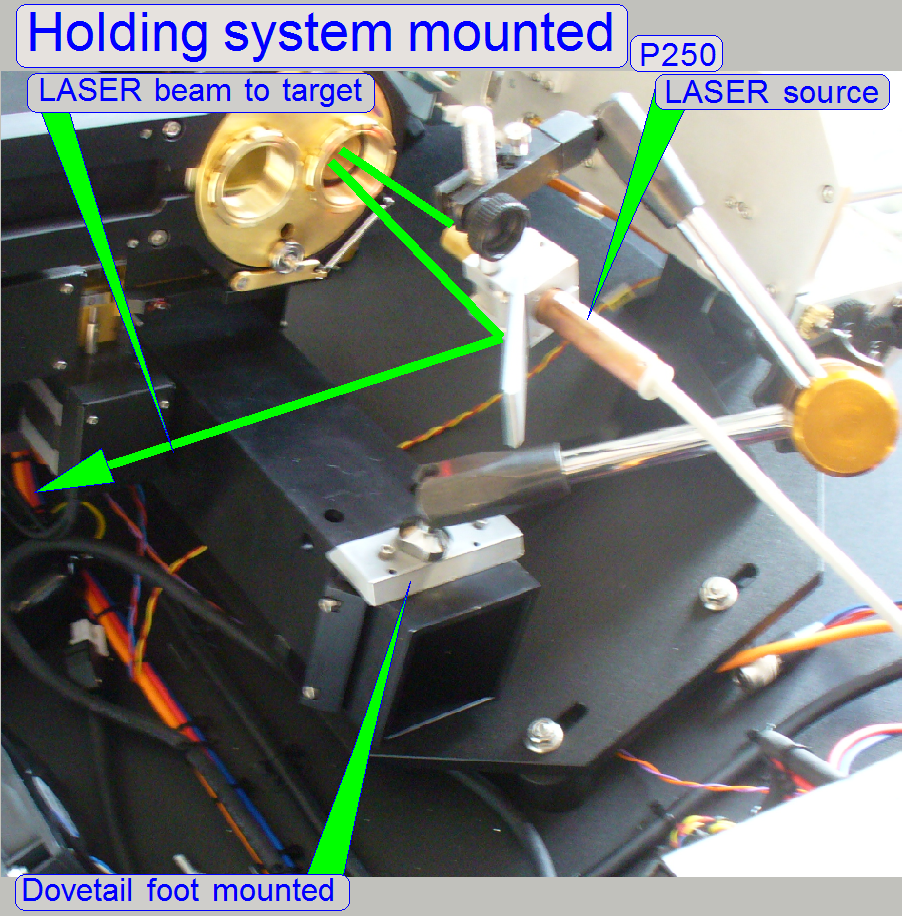

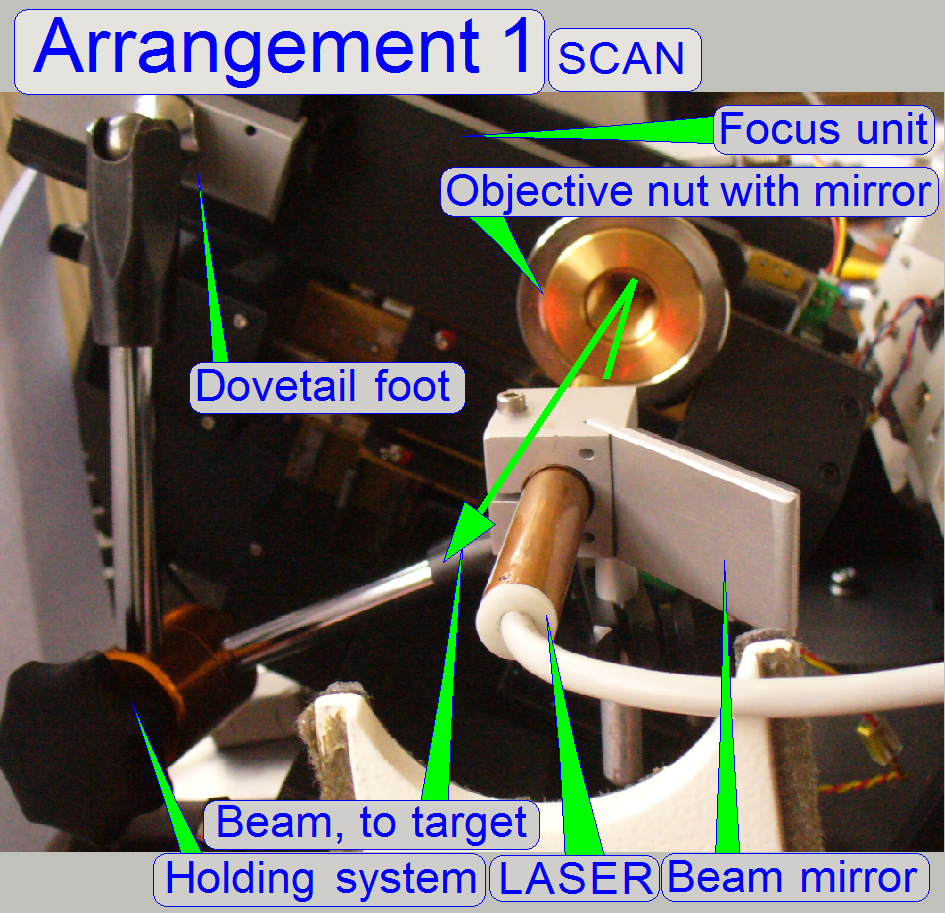

To mount the LASER source in the correct position over

the focus unit, this holding system is used; the dovetail foot is mounted onto

the truss, onto the position of the turret unit fixing clamp. Onto the other

end of the holding system the LASER source holder fixing with mirror is

mounted.

·

You can also use any holding system that

allows the position adjustment of the LASER source holder with mirror in the

X-, Y- and Z-direction of the room co-ordinates.

![]() Holding systems from NOGA “http://www.noga.com/”

Holding systems from NOGA “http://www.noga.com/”

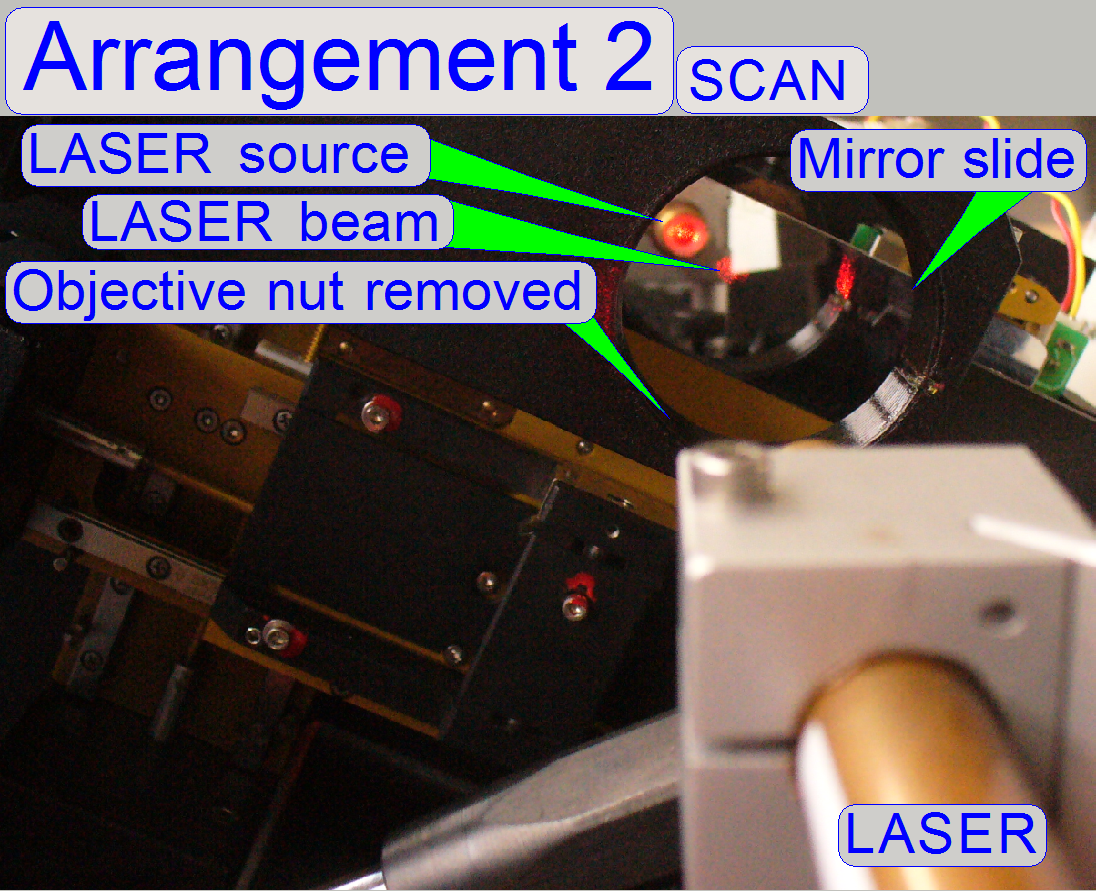

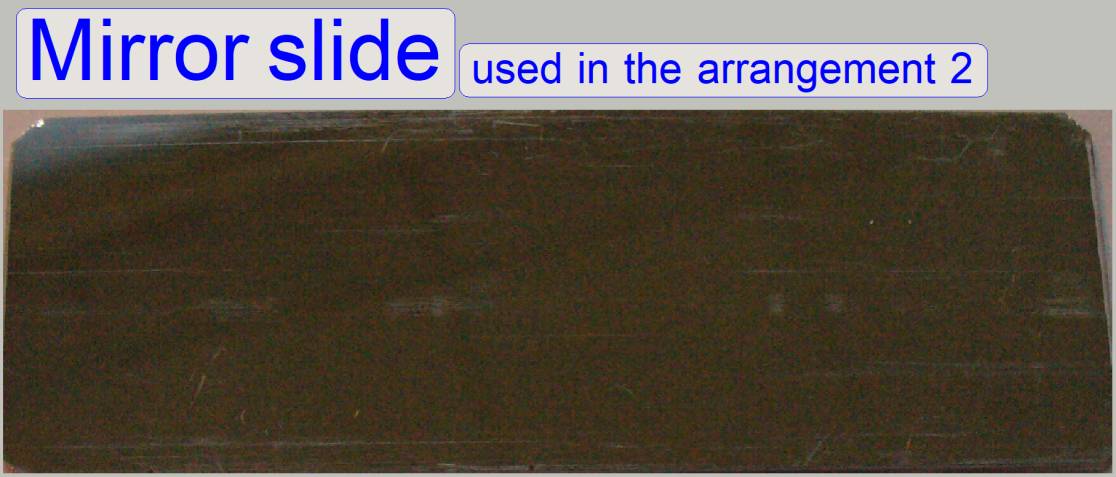

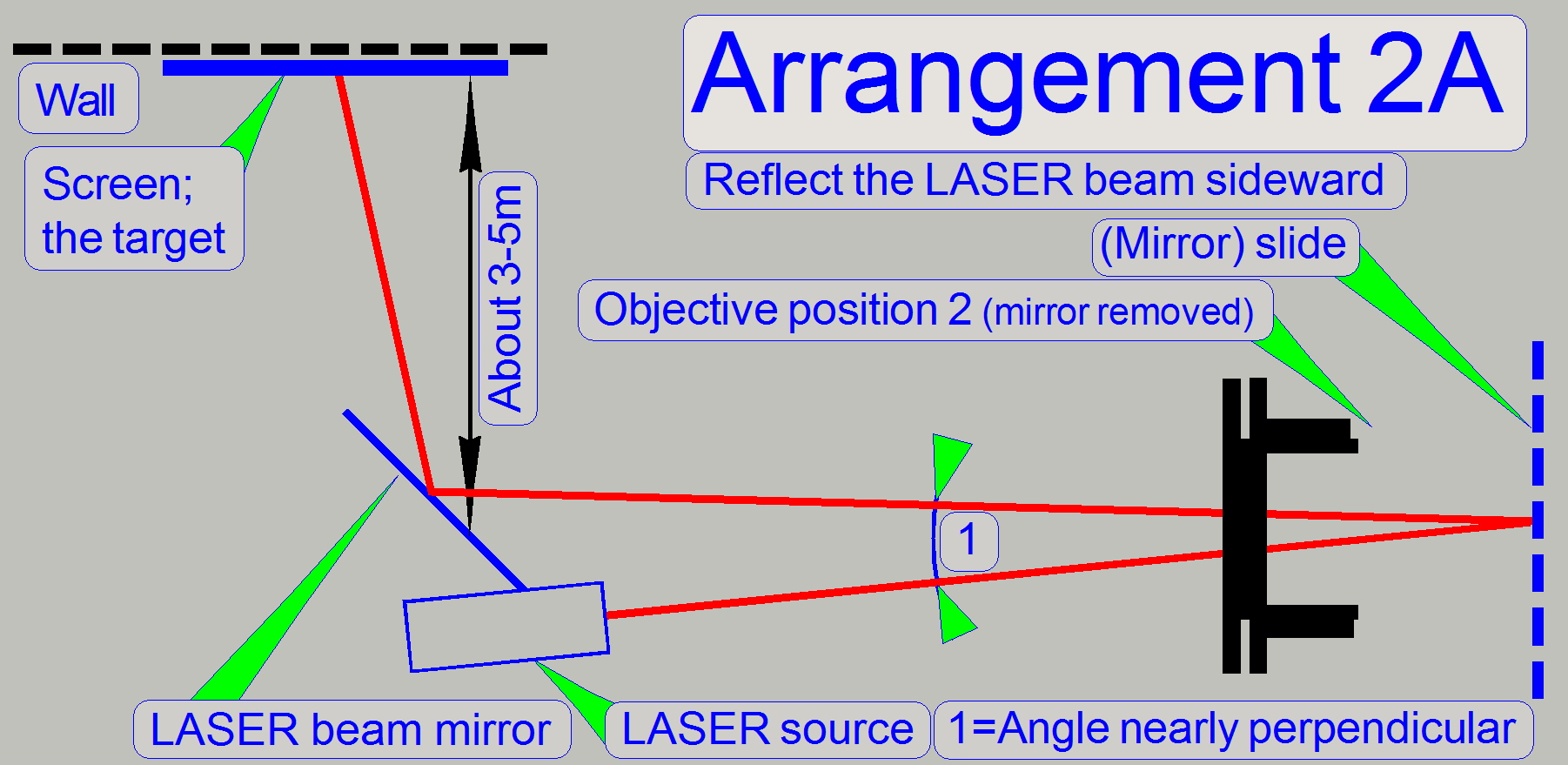

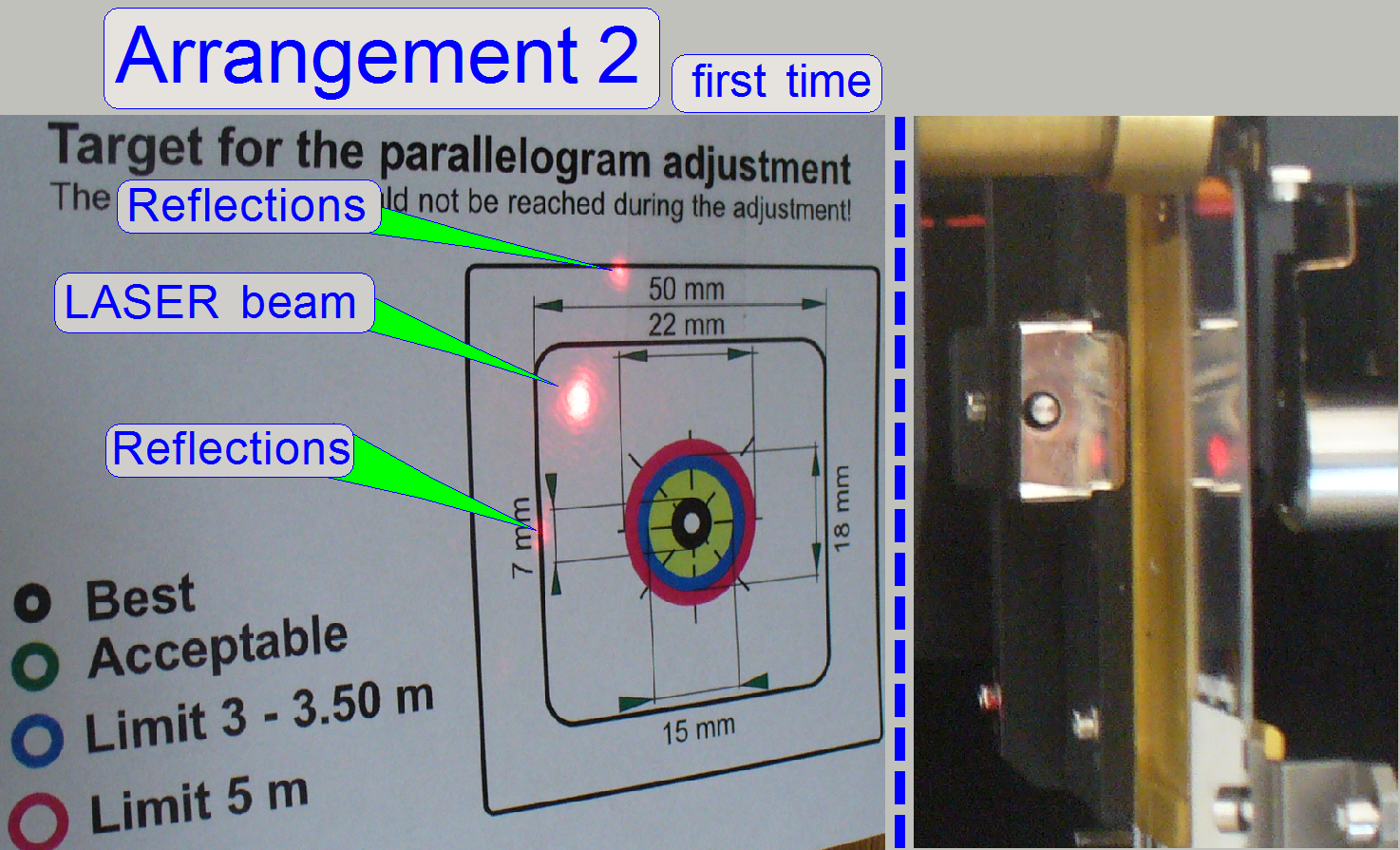

The

mirror slide is used in the “Arrangement 2”; it deflects the LASER

beam according to the inclination of the specimen holder; the angle of the

inclination is added to the angle of the LASER beam and so the LASER beam is

deflected more, less or equal in relation to the “Arrangement 1”.

The

mirror slide is used in the “Arrangement 2”; it deflects the LASER

beam according to the inclination of the specimen holder; the angle of the

inclination is added to the angle of the LASER beam and so the LASER beam is

deflected more, less or equal in relation to the “Arrangement 1”.

Remark

The LASER beam will be reflected on the surface of a

simple slide also; so it is not important to use a mirror slide in the

arrangement 2; but the description refers always to “the mirror slide”!

· Please

check the shape and the surface of the no-coated slide carefully before using

it during the adjustment!

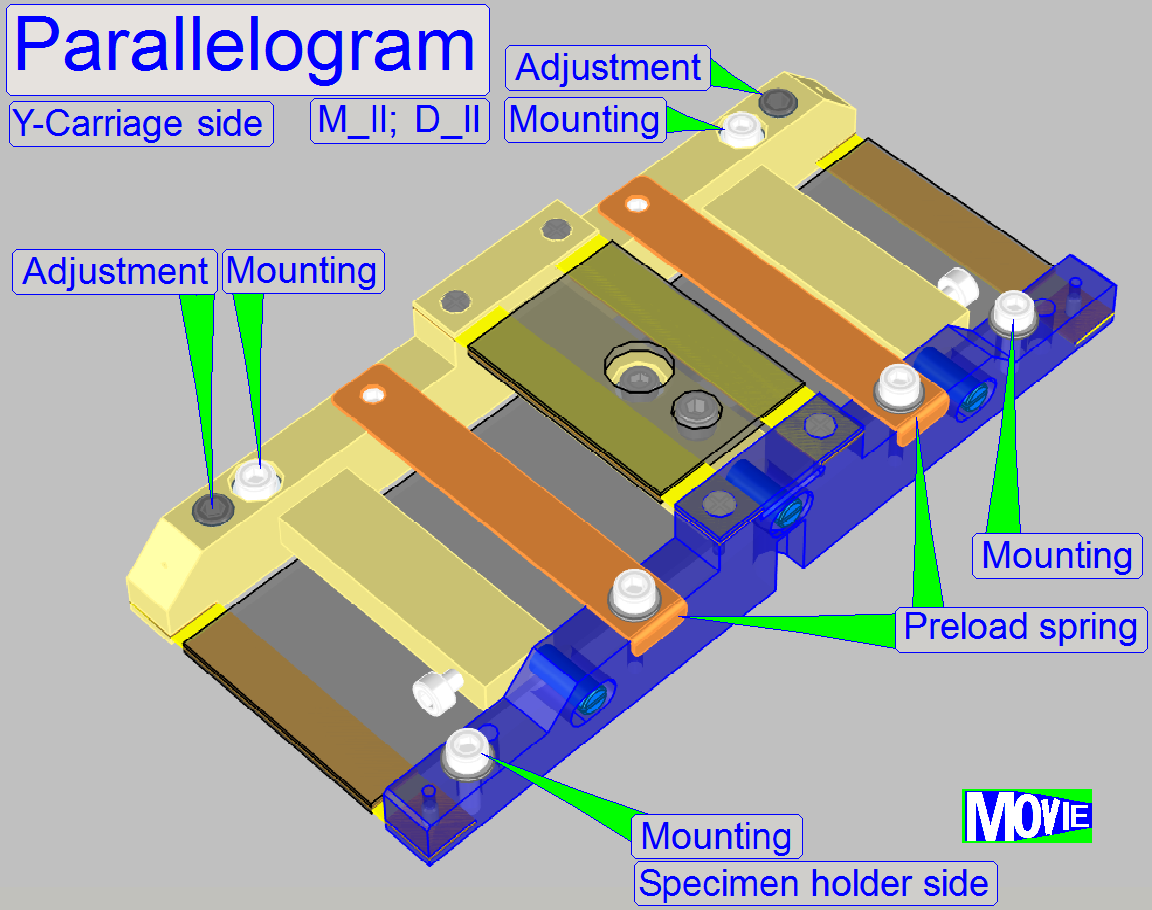

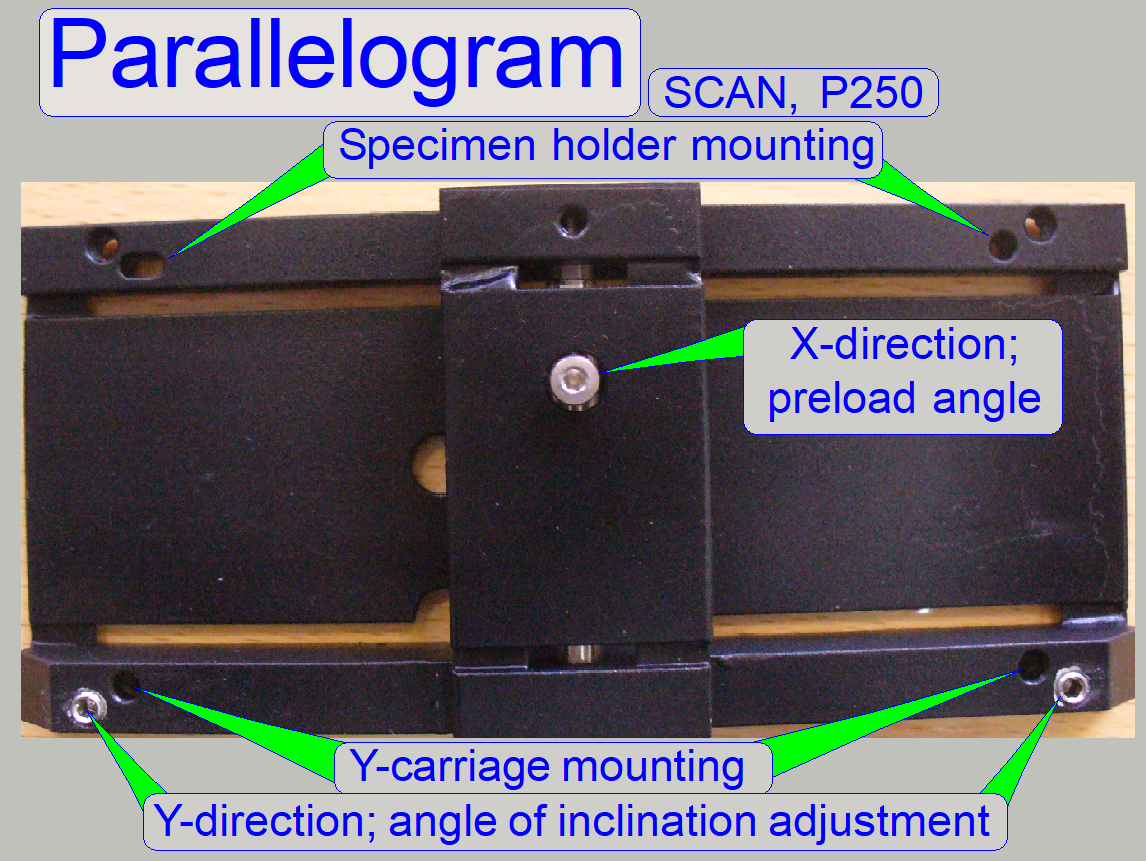

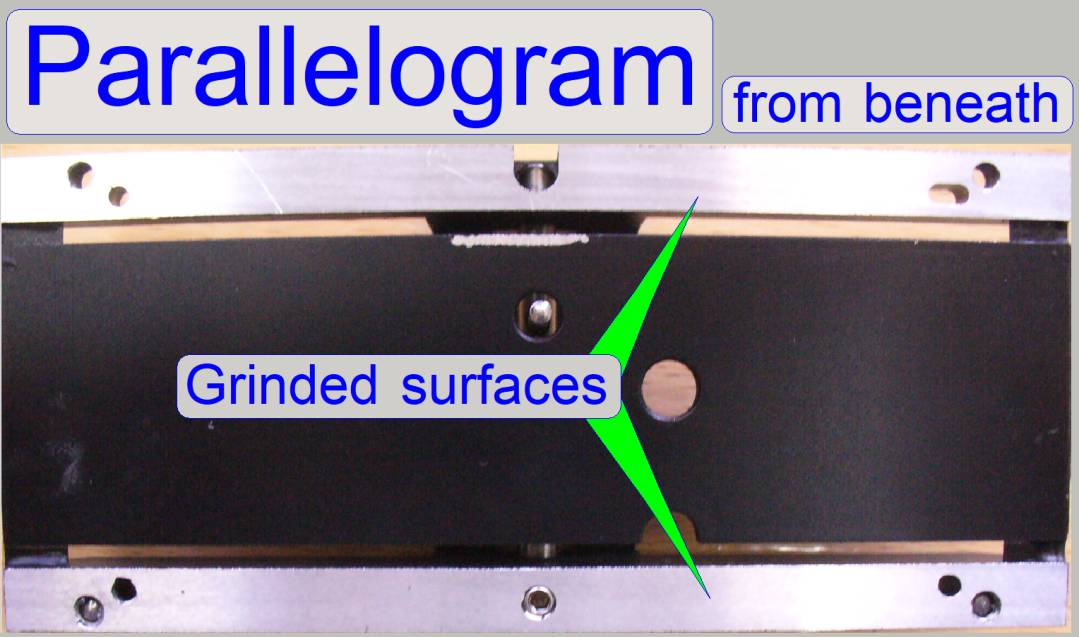

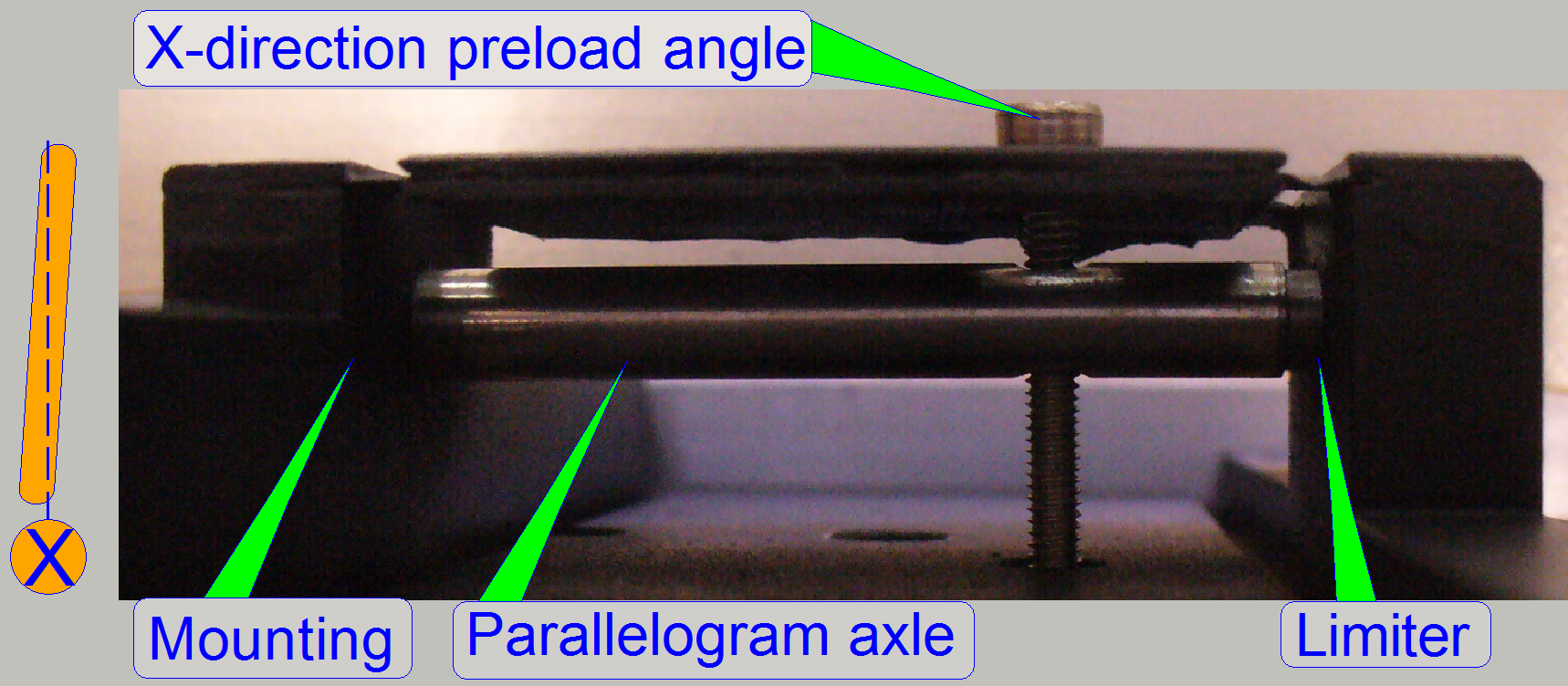

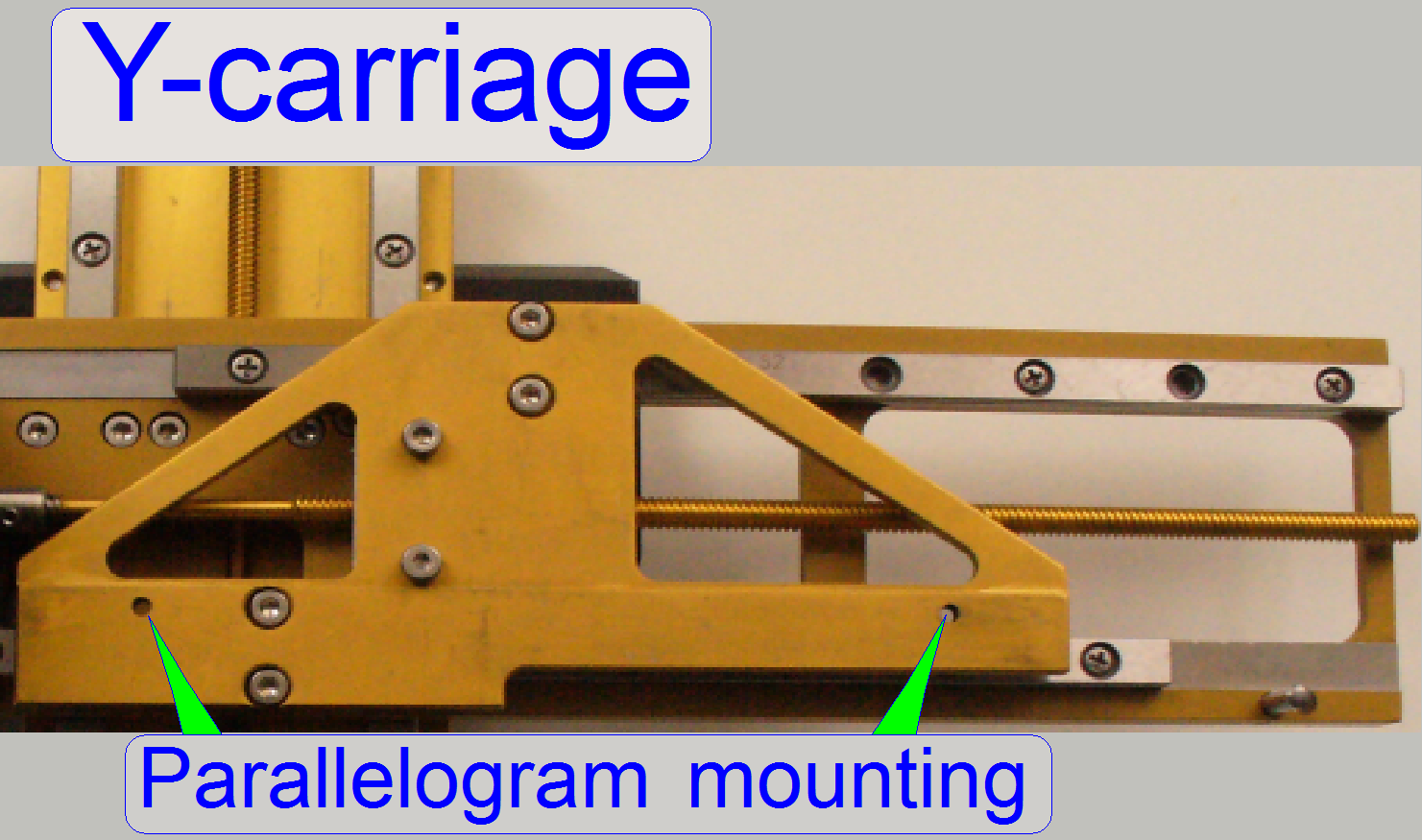

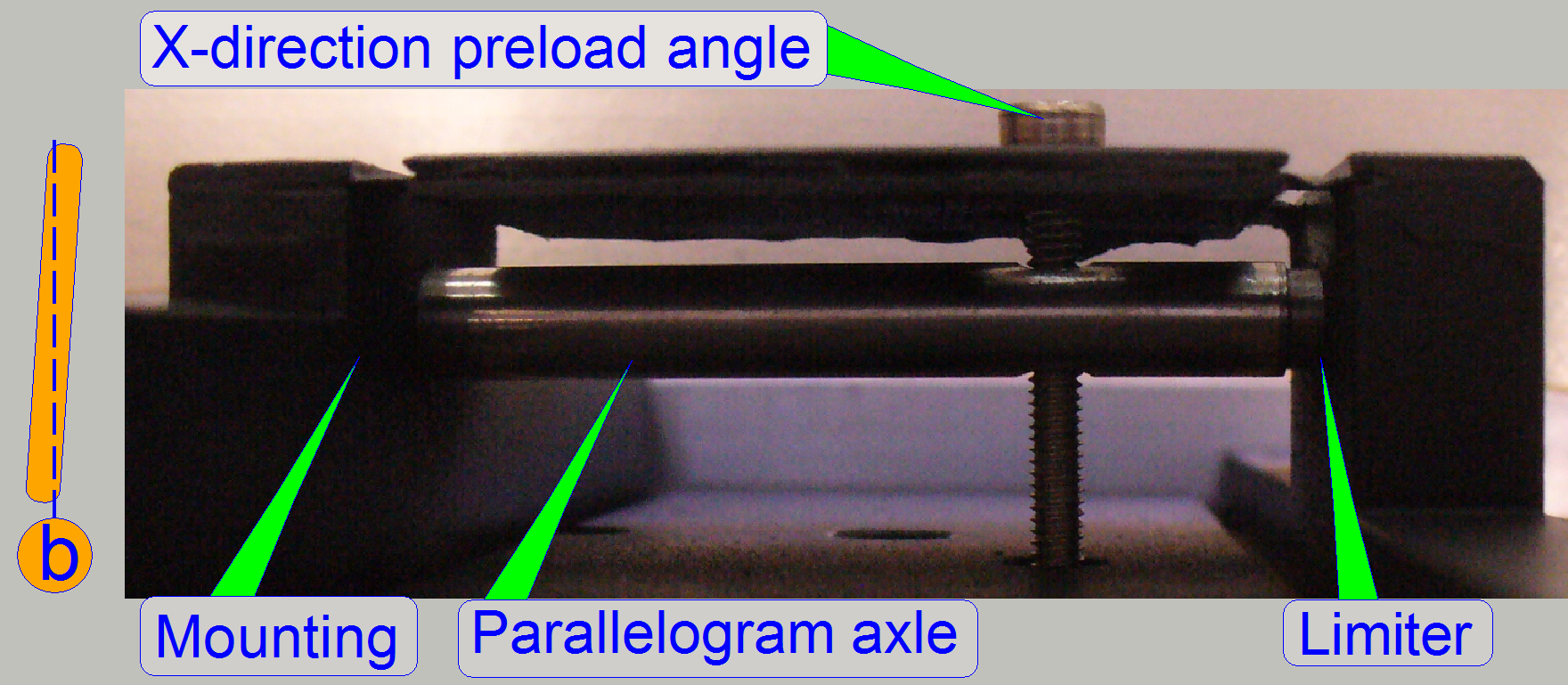

This component ensures the parallel shifting of the

X-Y plane if the focus pin moves the slide toward or away from the objective

(in Z-direction).

· The

position of the component in relation to the X-Y-plane of the slide defines the

perpendicularity of the optical axis in relation to the slide surface (tissue).

The connection surfaces to the Y-carriage and the

specimen holder are grinded to ensure the parallelism of both connected

components.

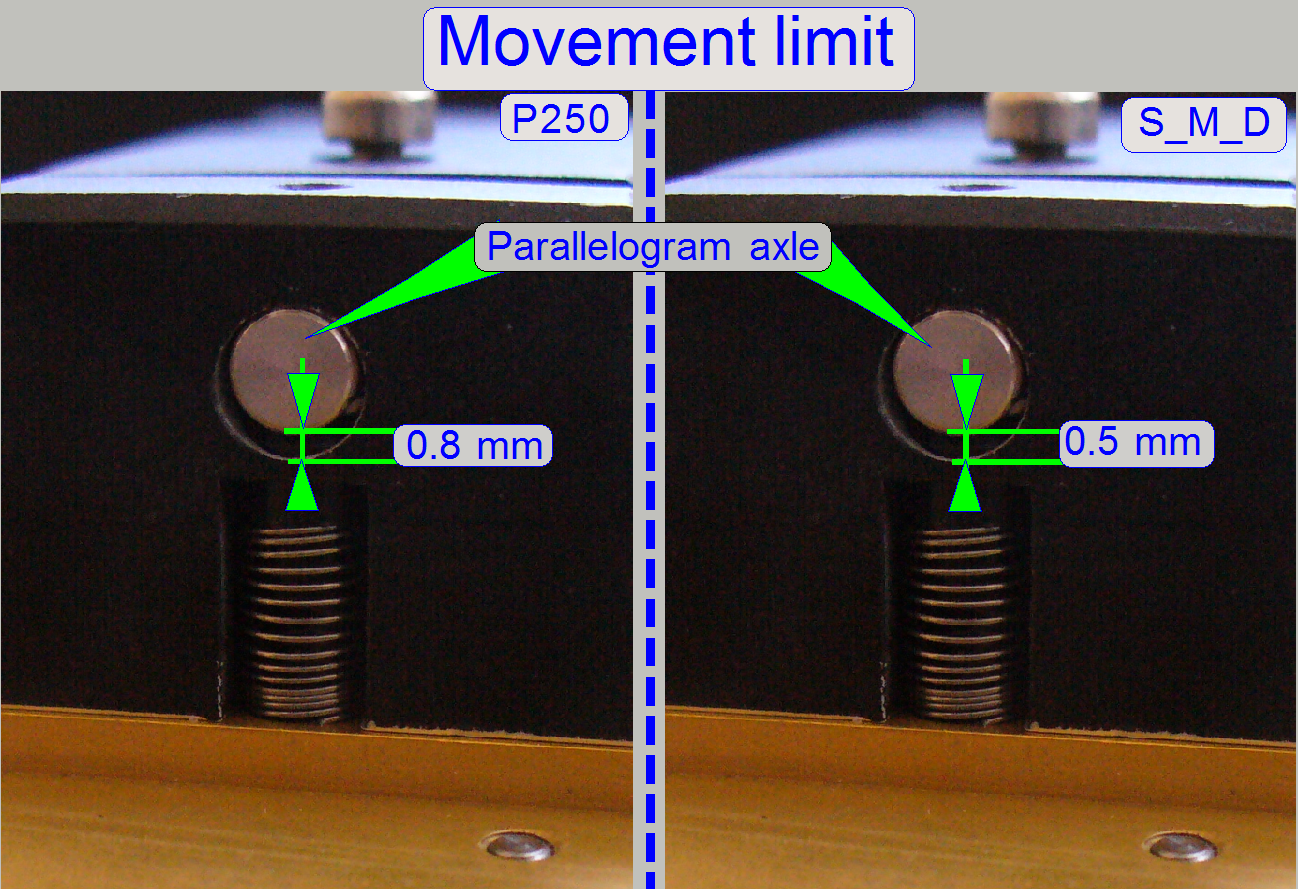

Parallelogram movement

limiter

The

allowed movement of the parallelogram is limited to be 0.8 mm over all in

P250 and S_M_D_II-type scanners (in opposite to S_M_D = 0.5mm). This limit is

constant and can not be adjusted separately. To adjust the correct limiter

position a fitting plate is used. The thickness of the used fitting plate

defines the correct position of the entire parallelogram and so the position of

the parallelogram axle in relation to the limiter also.

The

allowed movement of the parallelogram is limited to be 0.8 mm over all in

P250 and S_M_D_II-type scanners (in opposite to S_M_D = 0.5mm). This limit is

constant and can not be adjusted separately. To adjust the correct limiter

position a fitting plate is used. The thickness of the used fitting plate

defines the correct position of the entire parallelogram and so the position of

the parallelogram axle in relation to the limiter also.

How to check the acting range of the parallelogram and the

movement limiter?

1)

Move the stage with the service program

nearly into the middle of the scan area.

2)

Set the focus motor to Home 1,2

3)

Set the focus motor to the position -300

steps.

4)

Check the position of the parallelogram

axle in relation to the limiter; in this position a small gap should exist and

the focus pin should be in connection to the slide.

5)

Set the focus motor to the position +1300

steps.

6)

Check the position of the parallelogram

axle in relation to the limiter; in this position a small gap should also

exist.

· If a

small gap on both limit positions can be found, the focus pin is always in

connection with the slide and the inclination angle adjustment of the slide is

finished (the adjustment of the parallelogram position), the movement limit of

the parallelogram is well defined.

· During

the adjustment procedure of the parallelogram position please check this

behavior more times; even if the inclination angle of the slide in X-direction

was modified!

· If

there is no gap in the appropriate limit position or the slide is not in

connection with the slide over the entire focus range, the inclination of the

slide in X-direction may be wrong or the thickness of the fitting plate may be

selected incorrectly.

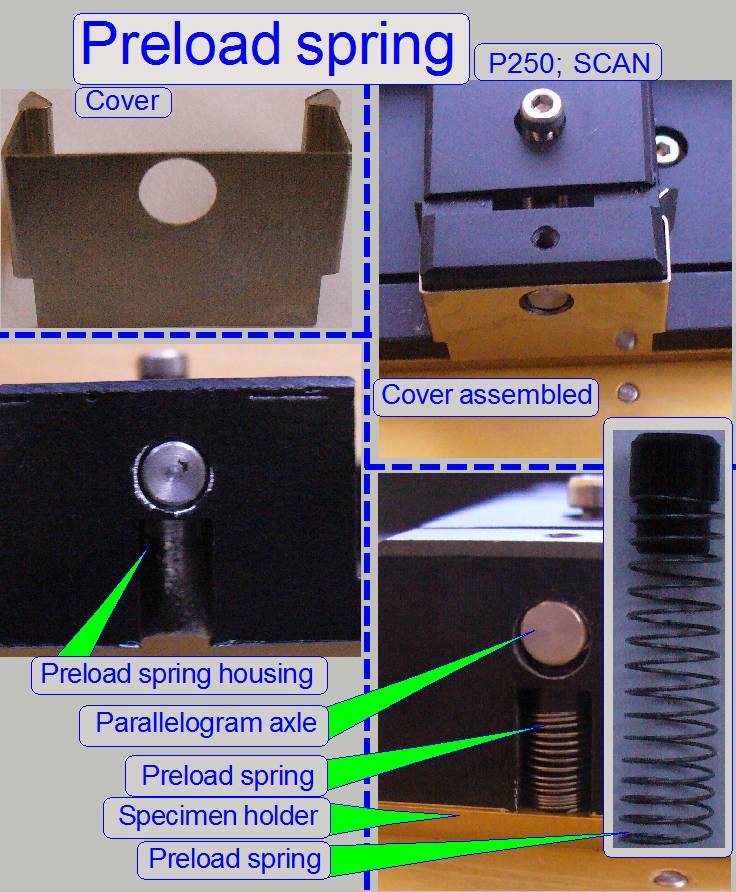

The

preload spring is used to create a force of the specimen holder against the focus pin, so a mechanical preload is created. With

this solution the slide is always in connection with the focus pin during

focusing or specimen holder movements in the scan process.

The

preload spring is used to create a force of the specimen holder against the focus pin, so a mechanical preload is created. With

this solution the slide is always in connection with the focus pin during

focusing or specimen holder movements in the scan process.

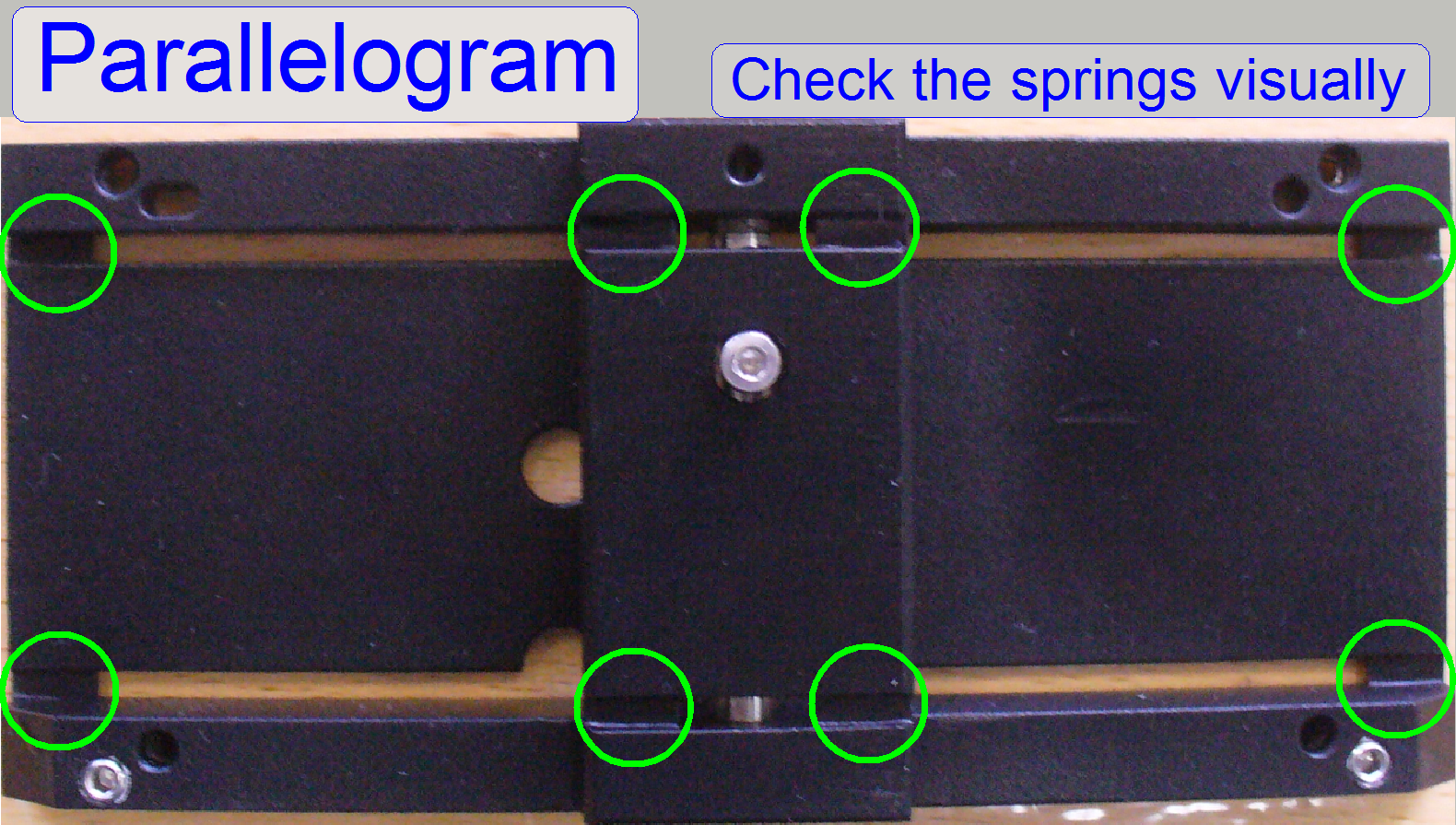

Before

you mount the parallelogram (even if a used one should be mounted) you have to

check it of functionality, visually. The parallelogram is correct if all 8

mounting spring leafs are not bent or broken. The flat springs are the most

sensitive parts of the parallelogram.

Before

you mount the parallelogram (even if a used one should be mounted) you have to

check it of functionality, visually. The parallelogram is correct if all 8

mounting spring leafs are not bent or broken. The flat springs are the most

sensitive parts of the parallelogram.

·

Compare the look of the springs to each

other!

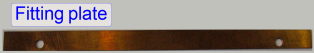

The fitting plate is used to define the parallelogram limiter

so, that the limiter does not limit the parallelogram movement in the range

between -300 and +1300 focus steps; the thickness of the selected fitting plate

is correct if there a small gap on the limiter exists if the focus position of

-300 steps is reached and even so, there have also to be a small gap if the

focus position of +1300 steps is reached.

· The fitting plate is mounted between the

Y-carriage and the parallelogram.

· The drillings and edges have to be burred;

the surface should be smooth.

· The nominal thickness of the fitting plate

can be 0.1 mm, 0.2 mm, 0.3 mm, 0.4 mm, 0.5 mm or

any combination of two fitting plates.

· The thickness of the fitting plate is

often found between 0 (no fitting plate used) and 0.5 mm.

· The fitting plate has to cover the entire

mounting surface of the parallelogram; see also below “Mount the parallelogram”.

· In exceptions, the fitting plate might be

mounted between the specimen holder and the parallelogram (if a negative value

for the fitting plate thickness have to be reached); in this cases, there have

not to be a fitting plate on the mounting surface between parallelogram and

Y-carriage; the adjustment bolt(s) are always used on the side, where the

fitting plate is placed.

Inclination angle adjustment in X-direction

This

adjustment bolt is used to define the angle of the parallelogram and so the

angle of the specimen holder (slide). By screwing the X-direction preload angle

bolt, the inclination angle of the parallelogram can be adjusted to zero (the angle of inclination

between X-min and X-max of the scan area).

This

adjustment bolt is used to define the angle of the parallelogram and so the

angle of the specimen holder (slide). By screwing the X-direction preload angle

bolt, the inclination angle of the parallelogram can be adjusted to zero (the angle of inclination

between X-min and X-max of the scan area).

IMPORTANT: The limit of the parallelogram movement limiter is

affected also and has to be checked always after driving the bolt.

![]() “How to check the acting range of the parallelogram”

“How to check the acting range of the parallelogram”

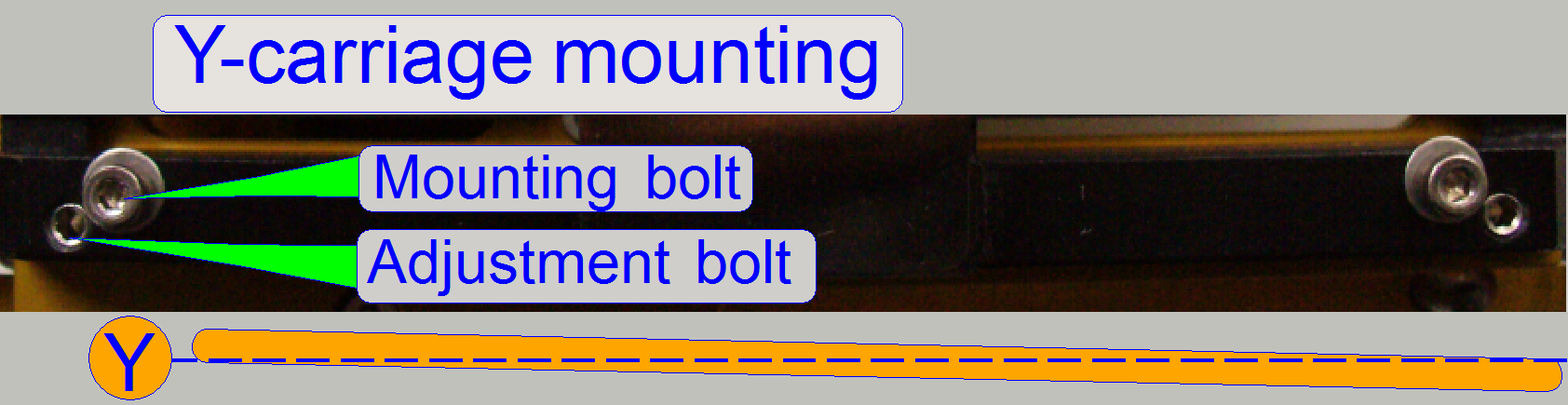

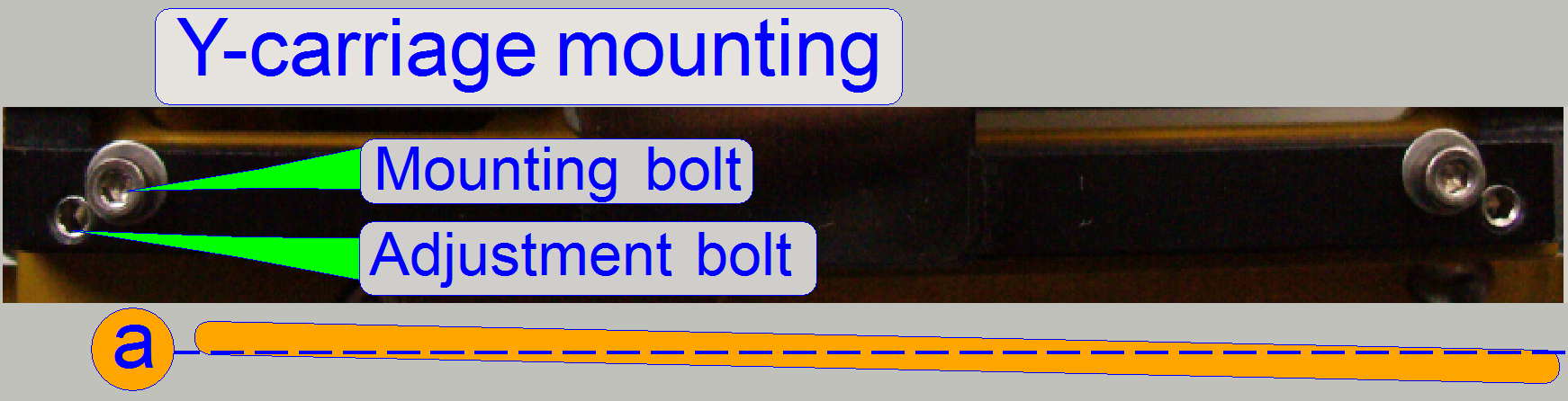

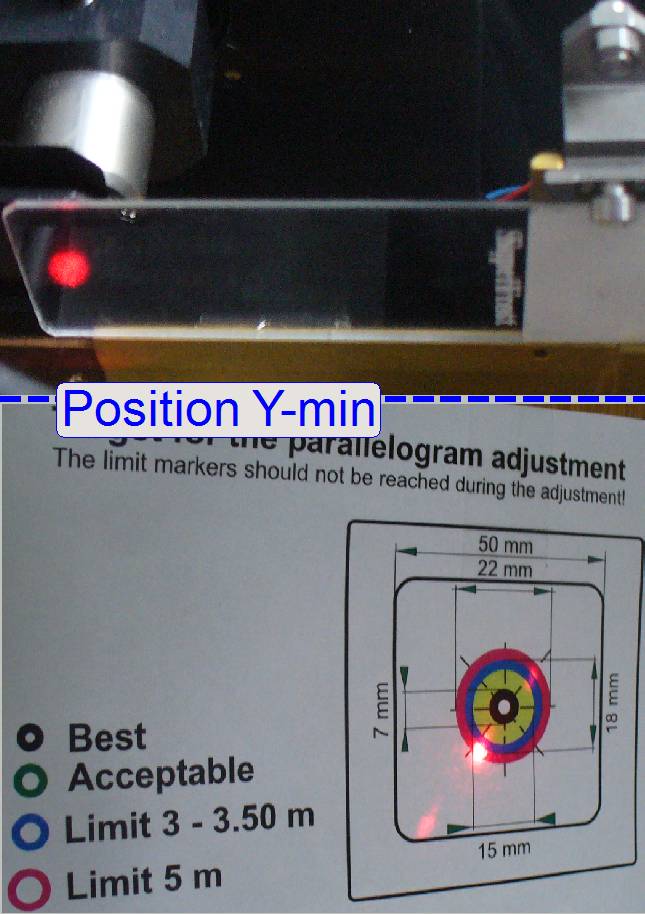

Inclination angle adjustment in

Y-direction

With

this adjustment the angle of inclination in Y-direction is reduced /

eliminated; it means the inclination angle

between Y-min and Y-max of the scan area.

With

this adjustment the angle of inclination in Y-direction is reduced /

eliminated; it means the inclination angle

between Y-min and Y-max of the scan area.

· By loosening the mounting bolt and

tightening the adjustment bolt or by loosening the adjustment bolt and

tightening the mounting bolt, the angle of the inclination in Y-direction is

modified.

· The adjustment is done only on one side;

the adjustment bolt of the opposite side should be fully loosened (or removed)!

· If the adjustment on the actual side does

not deliver the desired result, change the adjustment bolt to the opposite side

and execute the adjustment there.

On this

side the parallelogram is mounted together with the fitting plate (if needed).

On this

side the parallelogram is mounted together with the fitting plate (if needed).

· Place the fitting plate so, that the

entire (grinded) mounting surface of the parallelogram is covered by the

fitting plate.

· If the thickness of the fitting plate has

to be modified, dismount the entire parallelogram with specimen holder,

exchange the fitting plate and mount the parallelogram again (the two mounting

bolts).

On the opposite side of the parallelogram the specimen

holder is mounted, usually without fitting plate and without adjustment bolts.

In exceptions, the fitting plate is mounted between

the specimen holder and the parallelogram (if a negative value for the fitting

plate thickness have to be reached); in this cases, there have not to be a

fitting plate on the mounting surface between parallelogram and Y-carriage; the

adjustment bolt(s) are always used on the side, where the fitting plate is

placed.

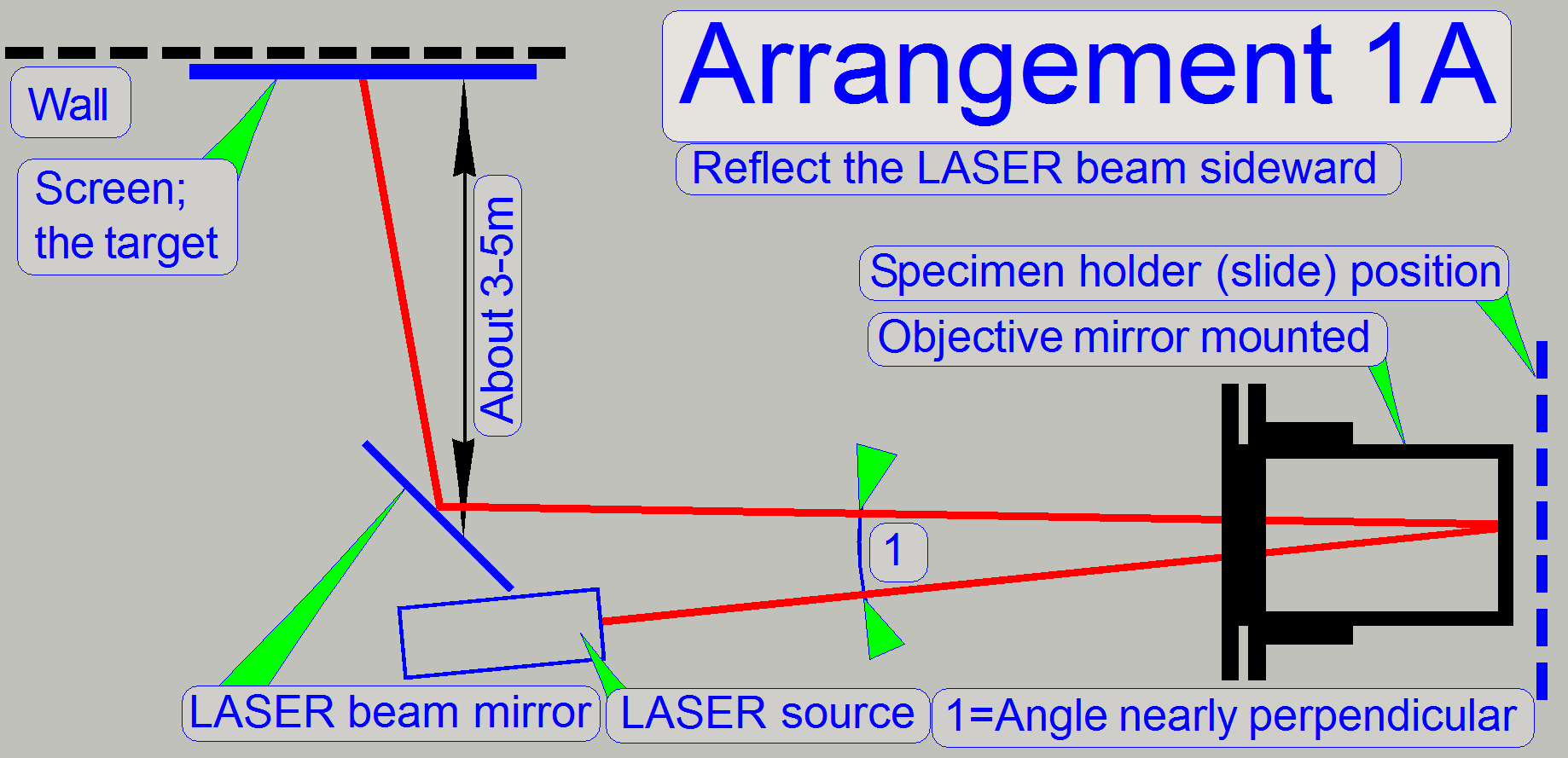

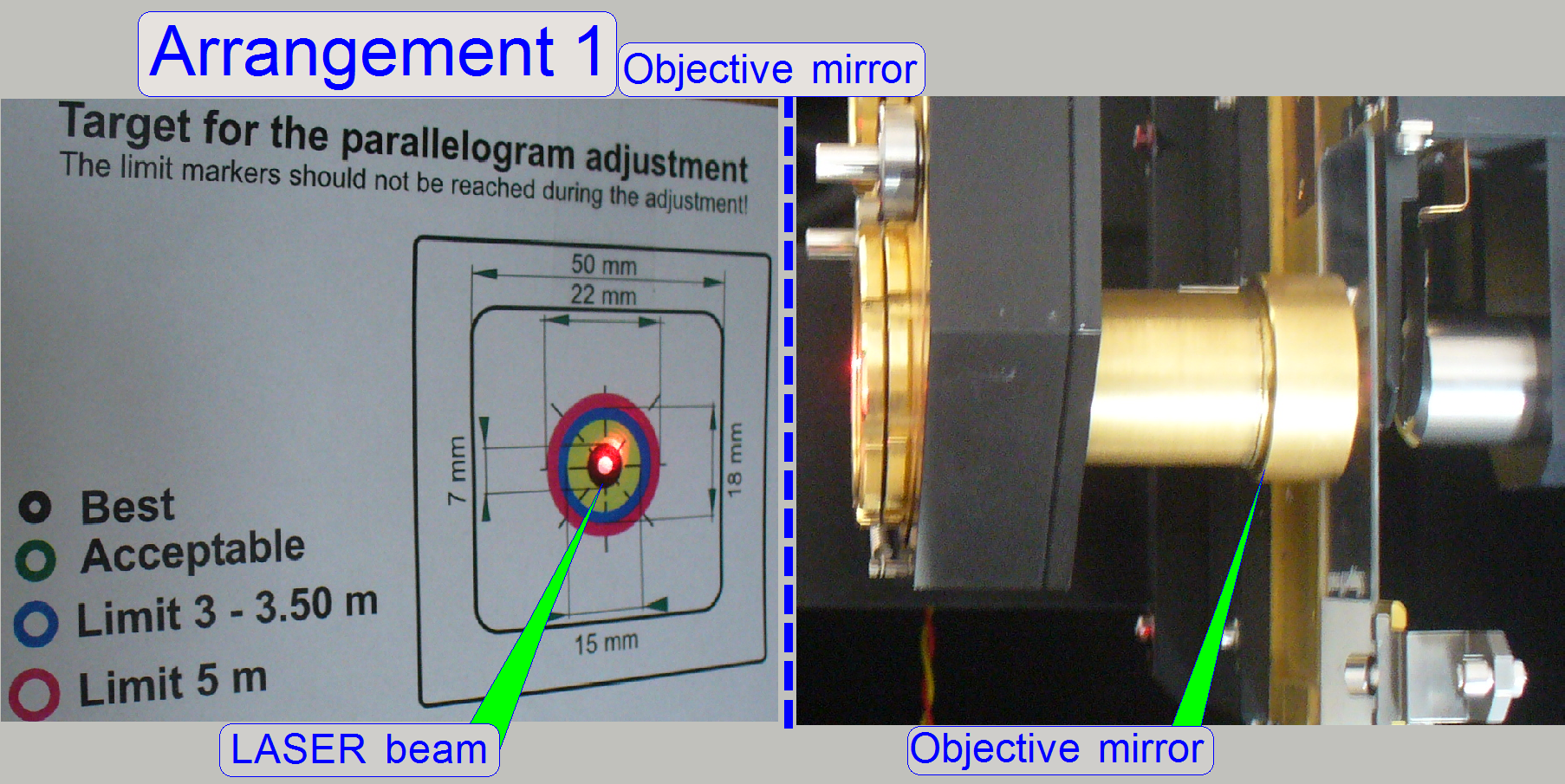

In

“Arrangement 1” the position of the entire scanner, more precise, the

position of the objective nut will be defined; in “Arrangement 2” the

position of the specimen holder in relation to the previous arrangement will be

defined. In other words, the plane defined by the objective mirror is used as

reference plane and the plane of the specimen holder with the mirror slide will

be adjusted to the reference plane. Therefore it is important, that the found

position of the reference plane during the “Arrangement

In

“Arrangement 1” the position of the entire scanner, more precise, the

position of the objective nut will be defined; in “Arrangement 2” the

position of the specimen holder in relation to the previous arrangement will be

defined. In other words, the plane defined by the objective mirror is used as

reference plane and the plane of the specimen holder with the mirror slide will

be adjusted to the reference plane. Therefore it is important, that the found

position of the reference plane during the “Arrangement

This means:

· The

position of the components must not be altered until proper alignment is

reached.

Please

do not move

· The

table

· The

entire scanner or the truss

· The

holding system (it may occur if the parallelogram bolts are driven)

·  The LASER source (it may occur if

the parallelogram bolts are driven) and

The LASER source (it may occur if

the parallelogram bolts are driven) and

· The

screen until the entire adjustment is not finished correctly.

If one

of the named components changed its position, please rotate or insert the

objective mirror into the optical axis again, remove the target and stick it

again onto the wall in the right beam position; or start with “Arrangement

If one

of the named components changed its position, please rotate or insert the

objective mirror into the optical axis again, remove the target and stick it

again onto the wall in the right beam position; or start with “Arrangement

Change

the objective to the objective mirror.

Change

the objective to the objective mirror.

Mount the LASER source holder with the holding system

over the objective nut.

Adjust the position of the laser source holder so,

that the LASER beam is reflected by the objective mirror to the LASER beam

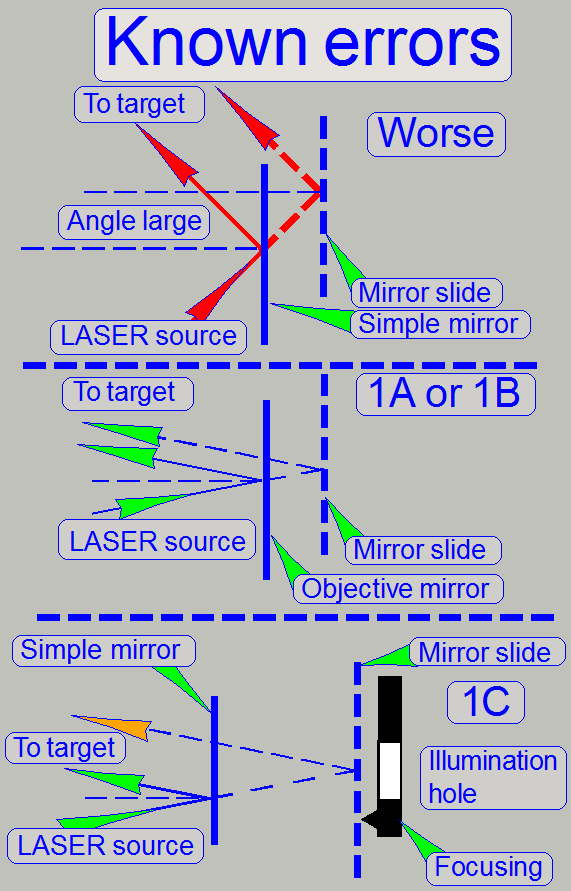

mirror in an angle that is nearly perpendicular.

The angle of the laser beam, reflected by the

objective mirror should be as small as possible; so the error of the adjustment

will be small also.

· To

reach this, the LASER beam source holder should be mounted at a large

distance from the objective nut.

By positioning the entire scanner and the holding

system find a well reachable and visible part on the wall (use the LASER beam)

and stick the screen onto the wall with the LASER beam in the center of the

marker position.

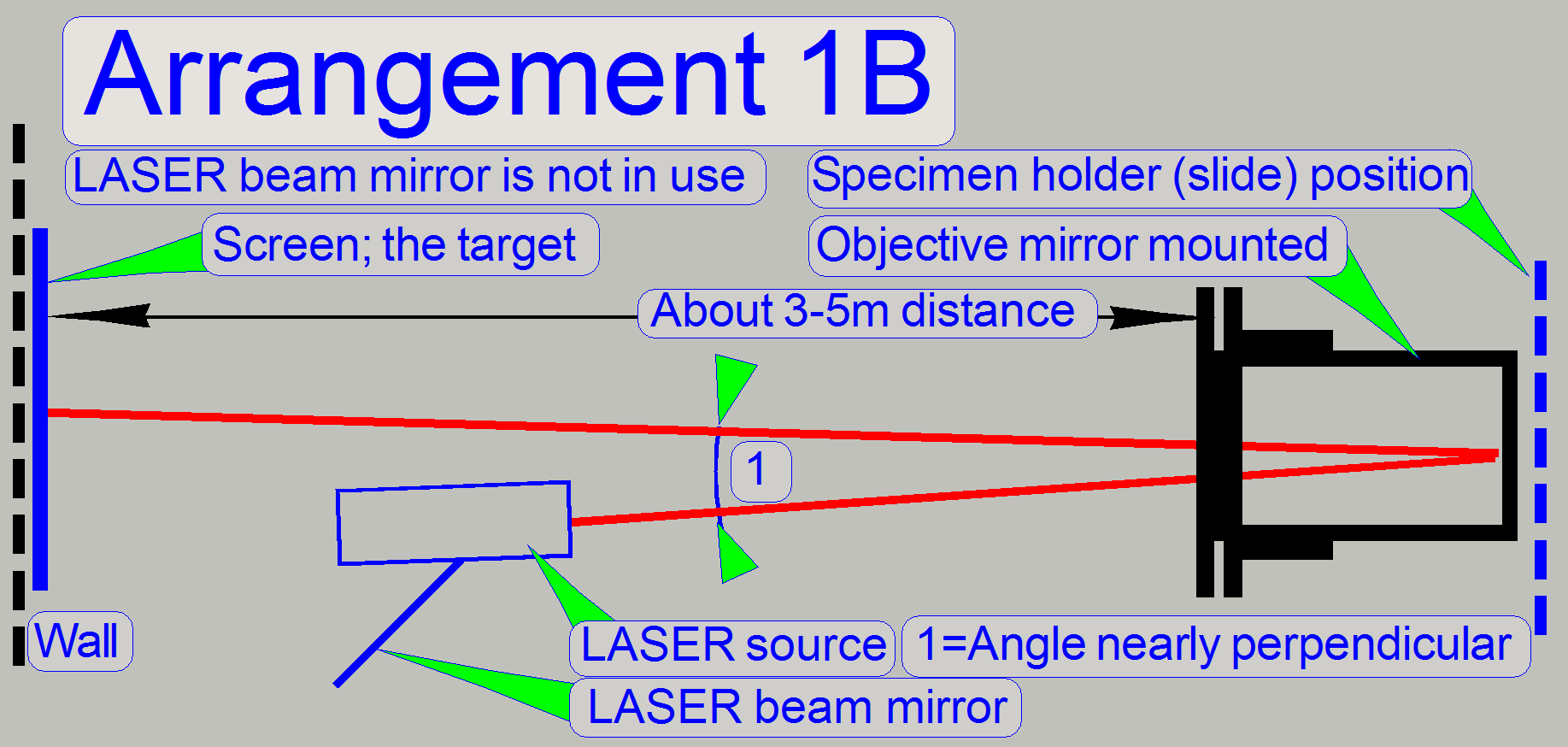

Arrangement 1B

The only difference to the arrangement 1A is the use

of the LASER beam mirror.

· In the

arrangement 1B the LASER beam mirror is not used.

· Important: The LASER beam source

holder should be mounted at a large distance to the objective nut.

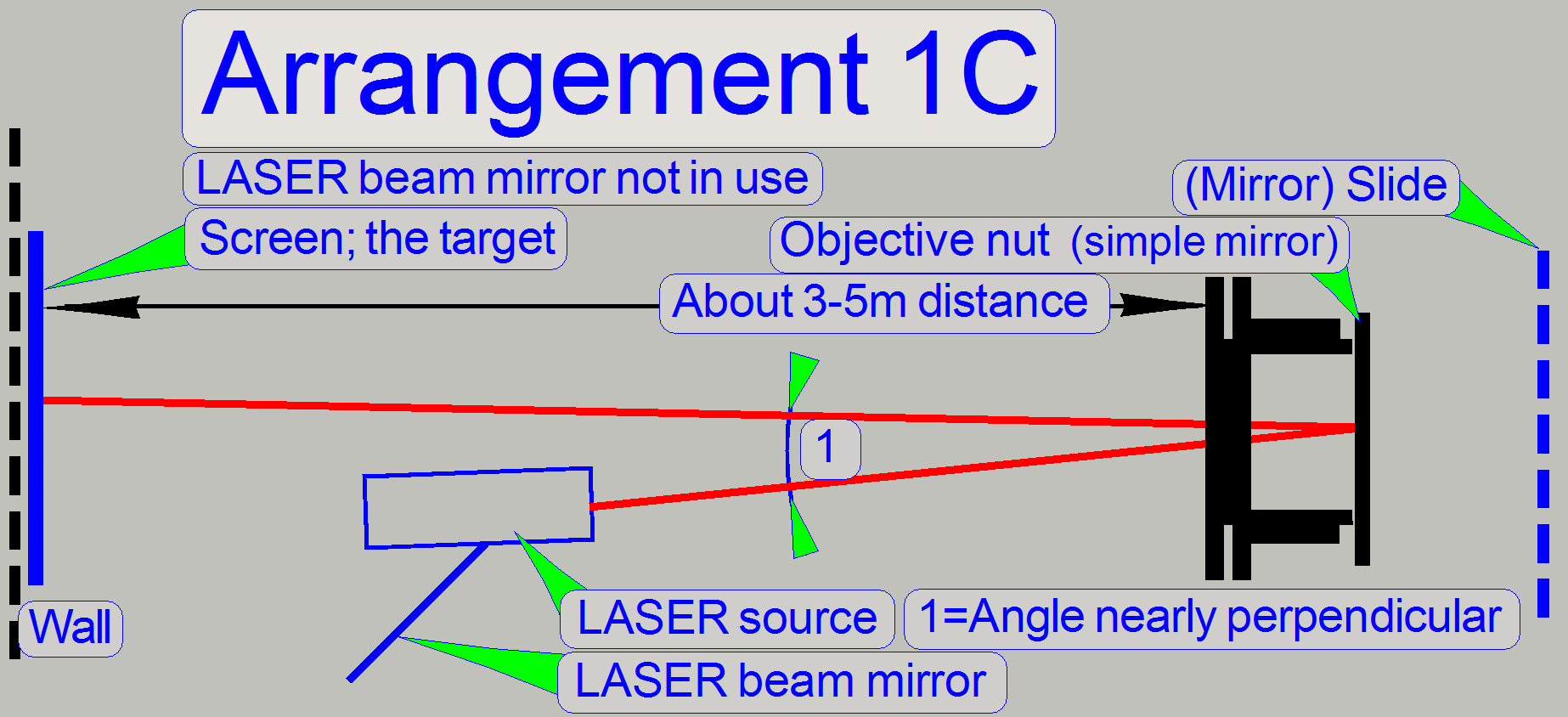

Arrangement

·  The

LASER beam mirror may be used or not like shown in the arrangement 1A or 1B.

The

LASER beam mirror may be used or not like shown in the arrangement 1A or 1B.

· The main

difference to the arrangement 1A or 1B is the use of a “simple mirror” on the

objective nut instead of the objective mirror.

This version needs more accuracy during the

preparation of the adjustment

· Important: The LASER beam source

holder should be mounted at a large distance to the objective nut.

Arrangement

2A

Rotate

the objective disc into the objective position 2 (there is no objective

present).

Rotate

the objective disc into the objective position 2 (there is no objective

present).

If arrangement

See also: Known errors

Insert the mirror

slide (manually); the LASER beam should be visible on the

screen again.

With the X-Y-stage tools of the service program find a

position for the specimen holder nearly in the middle of the mirror slide’s

scan area.

Set the focus position with the service program to

-300 steps and +1300 steps and check the movement of the LASER beam on the

screen several times.

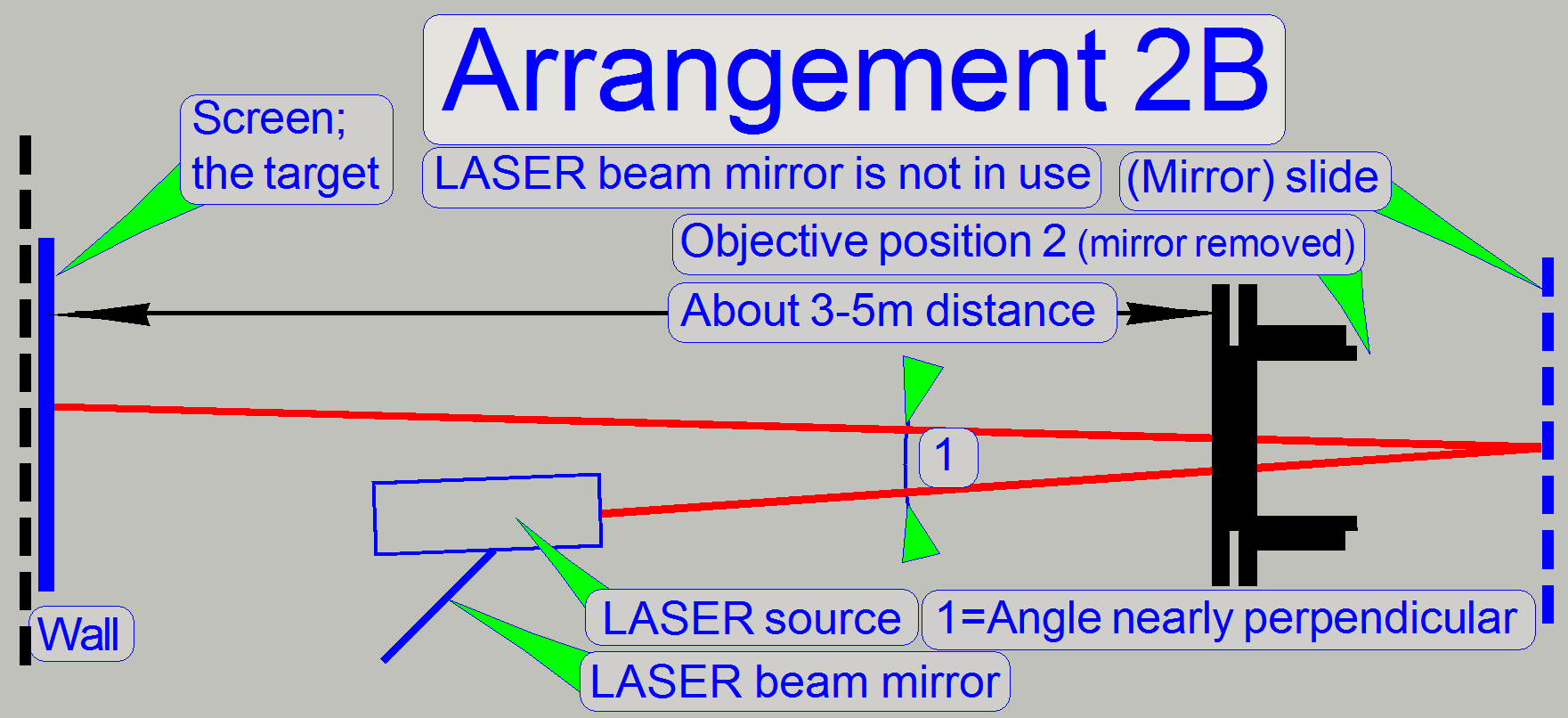

Arrangement

2B

The

only difference from arrangement 2A is the use of the LASER beam mirror;

depending on the used arrangement 1.

The

only difference from arrangement 2A is the use of the LASER beam mirror;

depending on the used arrangement 1.

· In the

arrangement 2B the LASER beam mirror is not used.

The mirror

position difference between the mirror slide and the objective mirror in the

arrangement 1 and 2 contains automatically a measurement error.

The mirror

position difference between the mirror slide and the objective mirror in the

arrangement 1 and 2 contains automatically a measurement error.

· To

reduce adjustment errors, the angle of the LASER beam should be as close to

perpendicular as possible!

· To

reach an angle of the LASER beam close to perpendicular, the LASER

source holder should be mounted far away from the objective nut as much as

possible and the reflected LASER beam should pass the LASER source as close as

possible.

Arrangement 1A or 1B

If the objective mirror is used, the angle is always

close to perpendicular (very small), because the mirror surface is small and

the LASER beam is routed in a tube.

Arrangement

To minimize the error of the adjustment, the angle of

the LASER beam should be close to perpendicular and should match the

illumination hole of the focusing part.

· Arrange

the position of the LASER source precise with a very small angle!

Because a simple mirror is used on the objective

mounting nut, the distance of the simple mirror to the mirror slide

is more than in the arrangement 1A or 1B; there is no tube

part used to route the LASER beam and the mirroring

surface of the simple mirror is large; the error of the

adjustment will also be more.

·

Please take all this into account if the tools will be arranged!

Prepare the scanner for

the adjustment

1)

Remove the upper housing

cover.

3)

Remove the entire

preview unit

4)

Set the working position of

the objective changer unit to the objective position 1.

5)

Remove the

objective changer drive unit.

6)

Dismount the 20x

objective.

7)

Mount the

objective mirror.

8)

Dismount the 40x

or the dummy objective.

9)

Mount the holding system onto

the truss, use the mounting bolts of the upper clamp and tighten the dovetail

foot.

10) Mount

the LASER source holder with LASER source as shown in the “Arrangement 1A or 1B”; see

also Known errors

11) By

positioning the entire scanner find a well reachable / visible part on the wall

(use the LASER beam) and stick the screen onto the wall with the LASER beam in

the center of the marker position.

12) If the

position is found as desired and the screen is stuck onto the wall the “Arrangement

1” is finished.

· If the

screen is stuck onto the wall the entire arrangement position must not be

altered until the entire adjustment is finished; see also The principle of the adjustment.

· If one

of the used components changed its position, please rotate / insert the

objective mirror again into the optical axis and check / adjust the “Arrangement 1”

again.

13) Rotate the objective disc into

the objective position 2 manually.

14) If the

arrangement

15) Insert

the mirror slide (manually); the LASER beam should be visible on the screen

again; see also: “Images of the

adjustment steps”.

16) With

the X-Y-stage tools of the service program find a position for the specimen

holder nearly in the middle of the mirror slide’s scan area.

17) Set

the focus position with the service program to -300 steps and +1300 steps more

times and check the movement of the laser beam on the screen.

18) Set

the focus position to -300 steps.

19) Adjust

the parallelogram limiter position by selecting the appropriate thickness of the fitting plate (if

required).

20) Check the behavior

of the parallelogram movement limiter.

21) Incline the mirror

slide in Y-direction so, that the LASER beam moves in direction

to the center of the target.

22) Check the

momentarily adjustment.

23) Set

the focus position to +500 steps.

24) Repeat

the previous 3 steps until the inclining of the mirror slide in Y-direction

will not improve the result.

25) Check

the “Arrangement 1”

26) Incline the mirror

slide in X-direction so, that the LASER beam moves in

direction to the center of the target.

27) Check the

momentarily adjustment.

28) In the

focus positions -300 steps and +1300 steps check the gaps of

the movement limiter.

29) Set

the focus position to +500 steps.

30) Repeat

the steps from step 21 until only a movement inside the limits of the target

can be expired.

31) Check

the “Arrangement 1”

32) Check the

momentarily adjustment.

33) Check

the entire adjustment near to the limits of the scan area; see also: “Images of the

adjustment steps”

34) Check the behavior

of the parallelogram movement limiter.

35) Check

the “Arrangement 1”

36) Move

the stage to the center of the scan area and check the movement of the LASER

beam on the target in the focus positions -300 steps, +500 steps and +1300

steps.

37) Check the behavior

(acting range) of the parallelogram movement limiter.

38) Check

the entire adjustment near to the limits of the scan area; see

also: “Images of the

adjustment steps”

· If the

movement of the LASER beam on the target is inside the limits in the named

positions, the adjustment is finished and the scanner can be assembled.

39) Mount the

objectives.

40) Mount the

objective changer drive unit.

43) Check / adjust the

position of the magazine unit.

44) Check / adjust the

correct position of the specimen

holder fixing fork.

45) Check / adjust the

objective position

46) Check

/ define the scan area

47) If the

scan area was modified, please execute the preview

calibration also.

48) Check / adjust the

darkfield preview.

Check the momentarily

adjustment

Move the stage near to the center of the scan area and

check the beam behavior on the target in the focus positions

P250; SMD_II: -300

focus steps +500 focus

steps and +1300 focus steps.

S_M_D: 1200 focus steps 1600 focus steps and

2000 focus steps.

![]() Focus unit P250, S_II, M_II, D_II, SMD

Focus unit P250, S_II, M_II, D_II, SMD

The LASER beam should move only a little bit.

· Check the behavior

of the parallelogram movement limiter

Check the behavior of the

parallelogram movement limiter

· In the

positions -300 focus steps and +1300 steps please check the limit of the parallelogram

limiter; a small gap should exist.

· In the

position -300 focus steps please check the connection of the slide with the

focus pin; the focus pin should touch the slide.

If any requirement is not fulfilled, select the

correct thickness of the fitting plate.

Incline the slide in

X-direction

Move

the stage nearly into the center of the scan area.

Move

the stage nearly into the center of the scan area.

Set the focus motor to the position +500 steps.

Drive the X-direction preload angle bolt carefully in

the appropriate direction; the beam should move in direction to the center of

the marker circles.

Check the behavior

of the parallelogram movement limiter

Incline the slide in

Y-direction

Move

the stage nearly into the center of the scan area .

Move

the stage nearly into the center of the scan area .

Set the focus motor to the position +500 steps.

Modify the

position of the parallelogram in Y-direction; the beam should

move in direction to the center of the marker circles.

Dismount the objective and mount the objective mirror

1.

With the program SlideScannerService.exe set

the X-Y-stage to the positions Y-Home1,2 and X-Home1,2.

With the program SlideScannerService.exe set

the X-Y-stage to the positions Y-Home1,2 and X-Home1,2.

2.

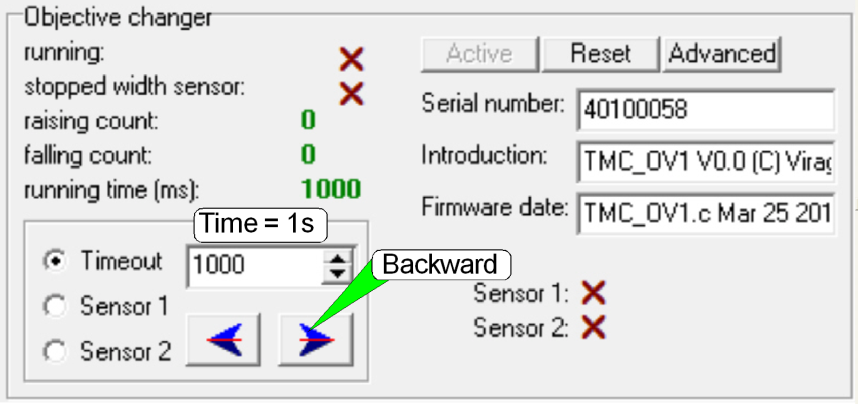

In the tab “Objective changer” move the objective (position),

to be dismounted or mounted into the working position.

3.

Select the option “Time out”, set a numerical value of

about 1000ms and press the button Backward.

4.

Dismount / mount the objective (mirror). Hold the

mounting nut with the delivered wrench and remove / mount the objective

(mirror) by hand.

·

Please do not modify the objective nut position;

otherwise, the adjusted focus position will be lost!

5.

Select the appropriate sensor and press the button forward;

the actual dismounted position or the mounted objective should move into the

working position.

6.

Repeat the steps 2 to 5 with the other objective

(position), if necessary.

7.

If the 40x objective was mounted, check / select the

thickness of the cover slip; see also “The 40x objective”.

Images of the adjustment

steps; P250

The

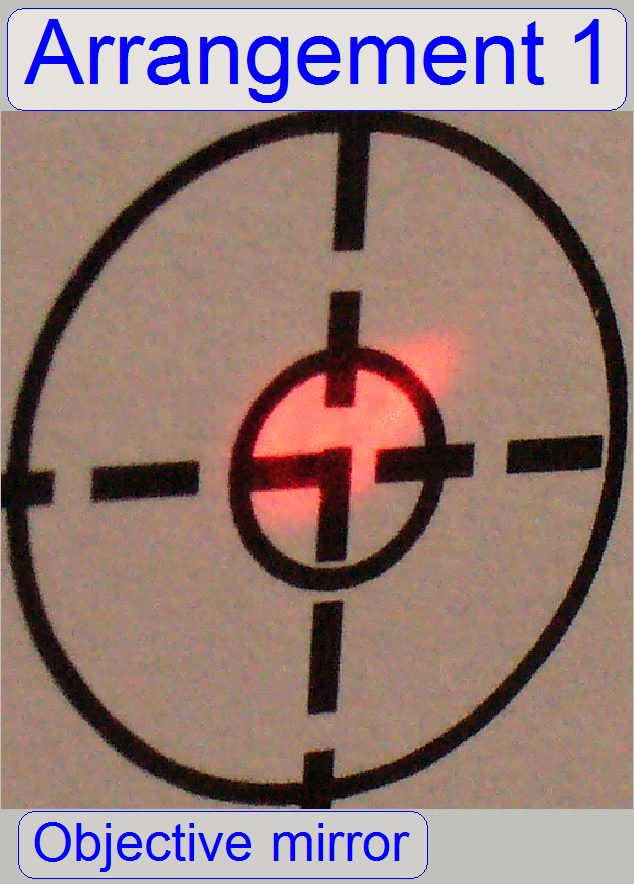

LASER beam is shown after sticking the screen onto the wall (after finishing the arrangement 1).

The

LASER beam is shown after sticking the screen onto the wall (after finishing the arrangement 1).

· The

distance of the screen to the scanner’s objective nut is ~4.8m.

The

mirror slide is inserted; the LASER beam is shown first time with the mirror

slide; nearly in the center of the scan area.

The

mirror slide is inserted; the LASER beam is shown first time with the mirror

slide; nearly in the center of the scan area.

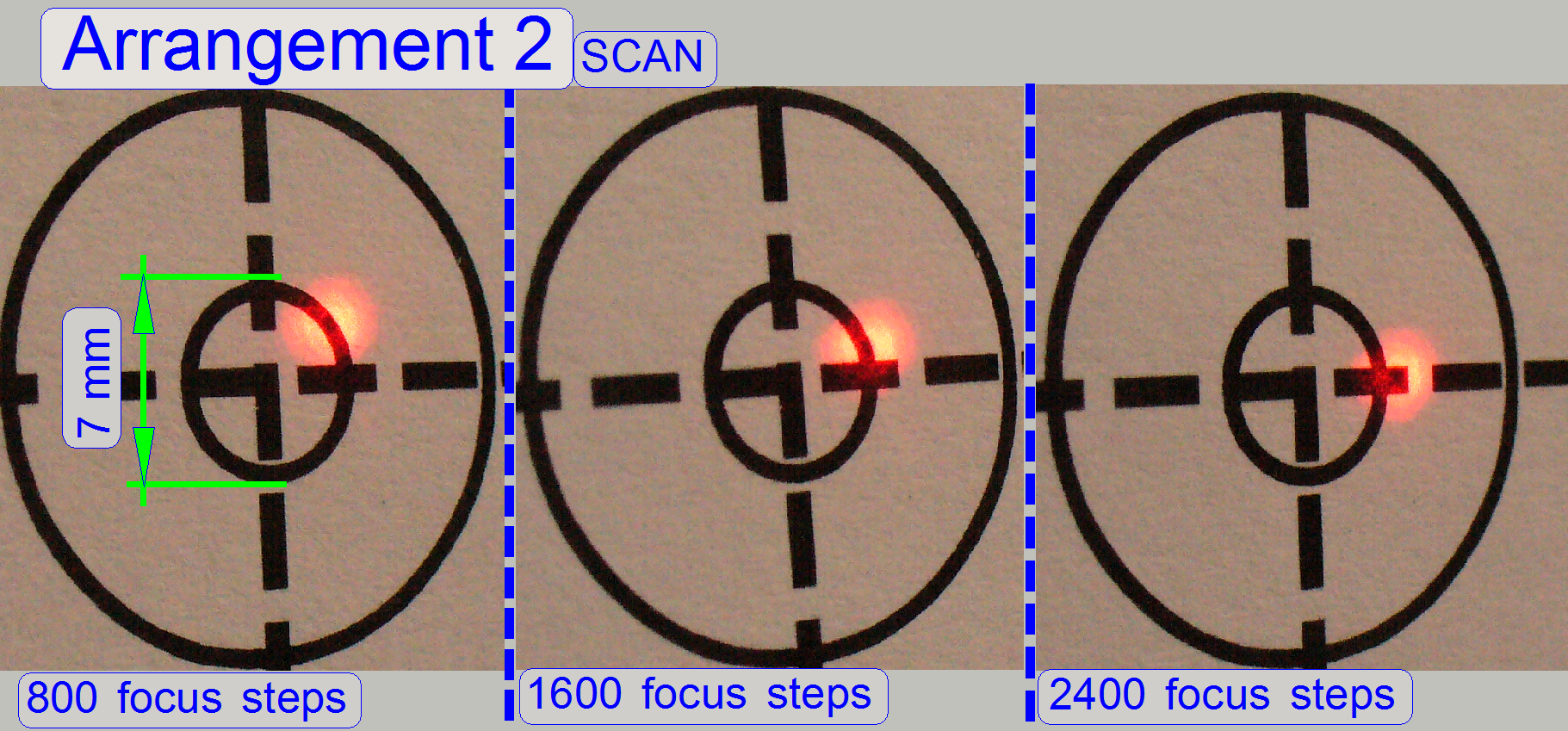

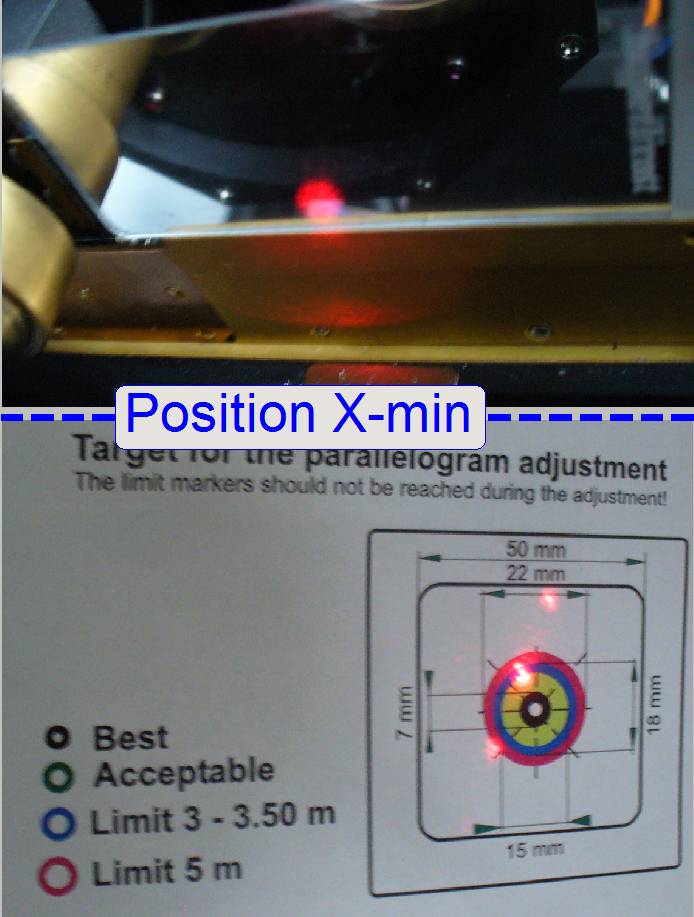

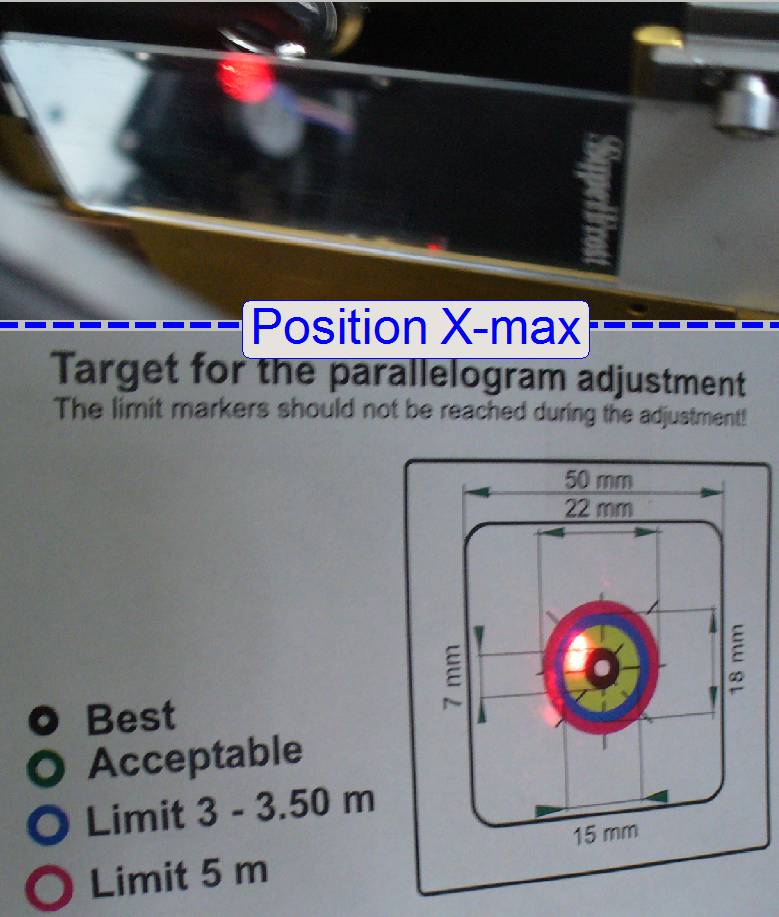

Images

of the adjustment steps; SCAN

Objective

mirror and arrangement 1

Arrangement

2; objective nut with mirror removed

Adjustment

results; SCAN

The distance between scanner and

wall is 3.10m; the pictures are taken nearly in the middle of the scan area.

·

Check the

adjustment with the stage skew check; see “Stage skew check”

Check the

adjustment with the stage skew check; see “Stage skew check”

·

Check the scan area; see “Scan area”, and check the preview in SlideScanner.exe or execute the preview calibration respectively, if

required!