Slide Scanner Service

For technicians!

The service program

(SlideScannerService.exe; SSS) is an essential tool to setup, install and test

the scanners P250, Pannoramic SCAN,

The description of the tools

and options is based on the software version 1.17 and 1.18.

· Differences

according to the actual scanner and special dialogues are explained separately.

Contents

Contents

Section [Microscope] of MicroscopeConfiguration.ini

· Execute the

brightfield preview calibration

· Execute the

darkfield preview calibration (P250, PCON)

· Move the units of

the scanner on a low level

· Test and check

values of connected units

· Define and check hardware

limits

· Move the units in

a defined number of cycles or endless

· Clear the EEPROM

The following

list contains the path and locations of probably required files in different

operating systems and development stages of the scan program.

In software versions with the operating

system Windows® 7 x 64bit (since 2011):

MicroscopeConfiguration.ini and MicroscopeSettings.ini

· C:\ProgramData\3DHISTECH\SlideScanner\

Service program and scan program

· C:\Program

Files\3DHISTECH\SlideScanner\SlideScannerService.exe

· C:\Program

Files\3DHISTECH\SlideScanner\SlideScanner.exe

License file for the service program

· C:\Program Files\3DHISTECH\SlideScanner\MService.lic

In software versions with the operating

system Windows® XP x 32bit (2009 and later):

MicroscopeConfiguration.ini and MicroscopeSettings.ini

· C:\DocumentsAndSettings\AllUsers\ApplicationData\3DHISTECH\SlideScanner\

Service program and scan program

· C:\Program

Files\3DHISTECH\SlideScanner\SlideScannerService.exe

· C:\Program

Files\3DHISTECH\SlideScanner\SlideScanner.exe

License file for the service program

· C:\Program Files\3DHISTECH\SlideScanner\MService.lic

In early software versions with the operating

system Windows® XP x 32bit (2009 and

before):

tdhmic_Config.ini and

tdhmic_Settings.ini

· C:\Program Files\MIRAXSCAN\

Service program and scan program

· C:\Program Files\MIRAXSCAN\MService.exe

· C:\Program Files\MIRAXSCAN\MScan.exe

License file for the service program

· C:\Program Files\MIRAXSCAN\MService.lic

Setup

“SlideScannerService.exe”

The service program will be

installed automatically during the installation of the scan program

“SlideScanner.exe”; see also: “Setup the scan

program”.

Attention: Do not mix the versions of SlideScanner.exe and the

version of SlideScannerService.exe! Always use these programs with the same

version number; otherwise the program SlideScannerService.exe could produce

unwanted results and SlideScanner.exe does not work correctly or even freeze!

Attention: Do not mix the versions of SlideScanner.exe and the

version of SlideScannerService.exe! Always use these programs with the same

version number; otherwise the program SlideScannerService.exe could produce

unwanted results and SlideScanner.exe does not work correctly or even freeze!

· This is important for the options

“Brightfield preview calibration” and “Darkfield preview calibration” because these

options using *.dll-files of the SlideScanner software. The options “Clear

EEPROM” and “LowLevelService” working independent of the program

SlideScanner.exe; therefore, if these options are used only, the version number

is less important.

Requirements and start

the service program

·  Valid license file: “MService.lic”

in the folder: C:\Program Files\3DHISTECH\SlideScanner\

Valid license file: “MService.lic”

in the folder: C:\Program Files\3DHISTECH\SlideScanner\

· Before starting the software “SlideScannerService”, the USB driver has

to be installed!

· Start the program “SlideScannerService.exe” by clicking the icon

“SlideScannerService.exe” or from its folder.

For the actual path

(folder) of the service program please refer to “Paths and locations”

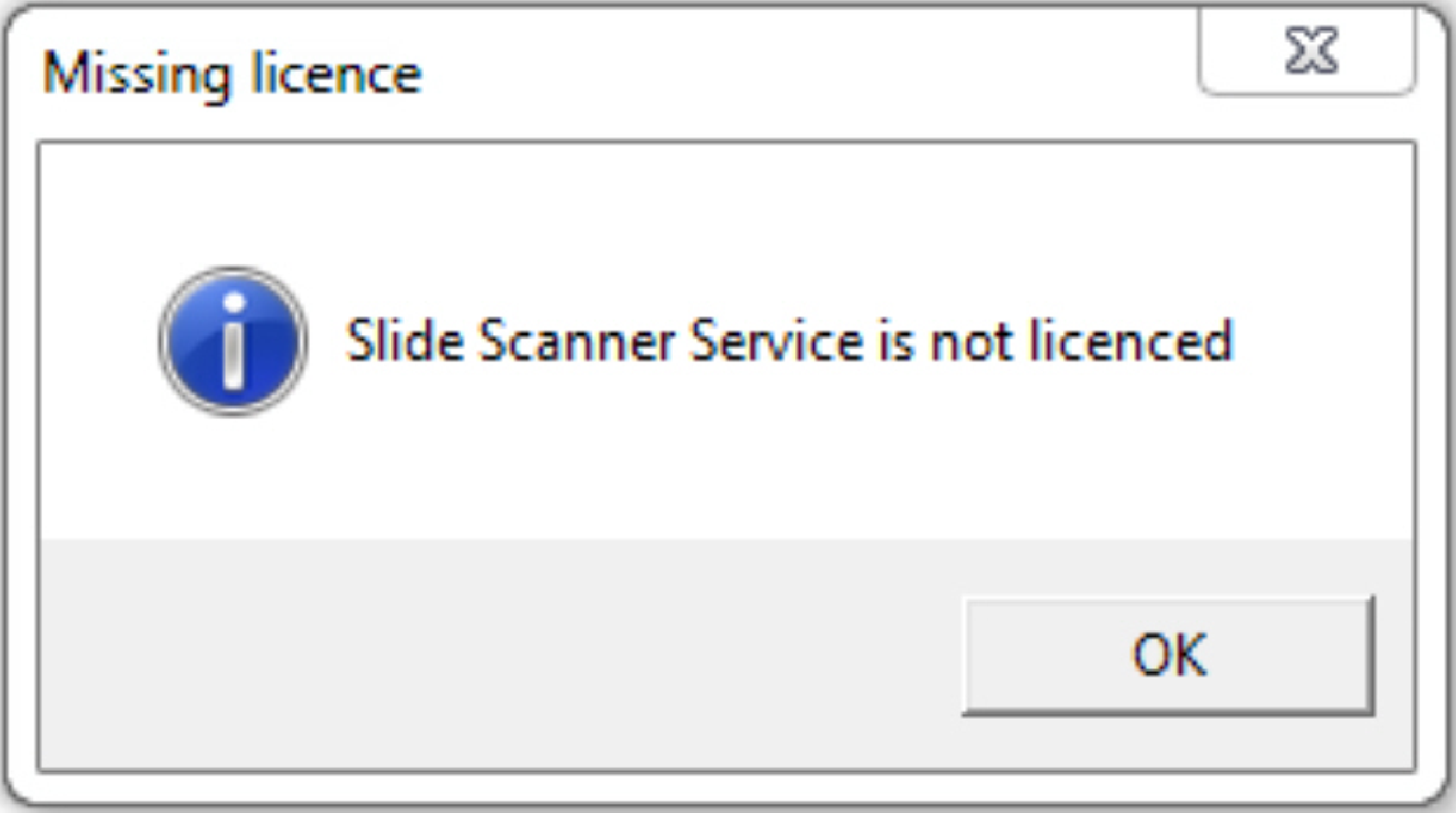

If the license file is not recognized or invalid, a

message “Missing license” is displayed.

If the license file is not recognized or invalid, a

message “Missing license” is displayed.

· Please check the presence of the license file; see “Paths and locations”

· Please check the validity of the license file

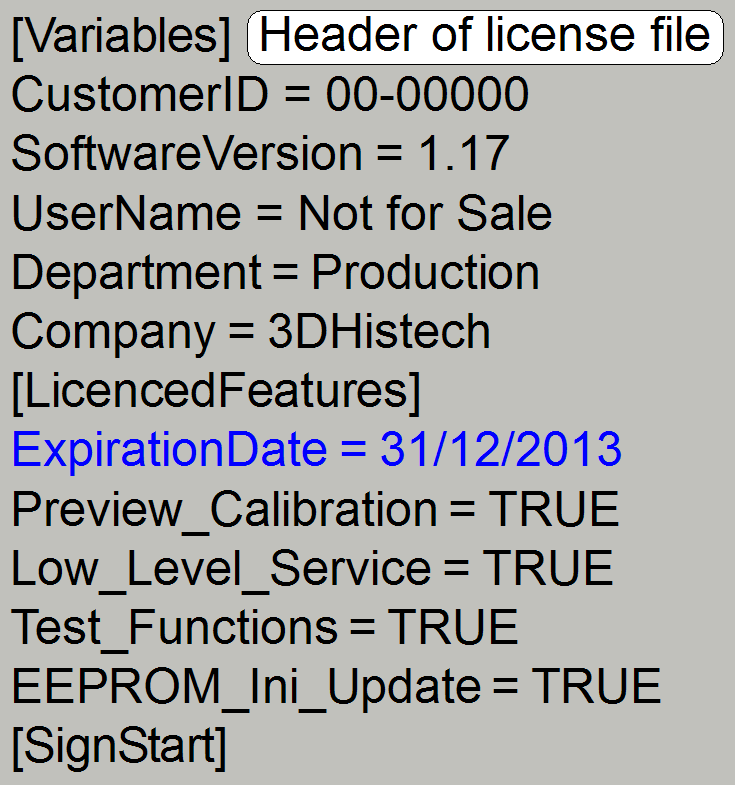

Check the validity of the license file

Open the license file

MService.lic with any text editor (e.g. Notepad or WordPad) and check:

· the expiration

date and

· licensed options

To avoid confusion, the

scanner type is recognized automatically by the service program (and the scan

program of course) during start up; only the tools, needed for the appropriate,

connected scanner can be reached; see also the parameter ”MicroscopeType” in the section [Microscope] of the file “MicroscopeConfiguration.ini”.

The found parameter value in

the found “MicroscopeConfiguration.ini” decides the available options.

The microscope type is

checked during the start of the service program and is true for all options of

the selector menu; especially important in the “Low Level Service” part.

The

microscope type can be:

MicroscopeType=

3DMic4 MIRAX SCAN microscopes before

the year 2006; equipped with the preview camera “Logitech QC

4000 pro”.

3DMic5 MIRAX DESK and Pannoramic DESK

3DMic6 MIRAX SCAN, the magazine has 50 slide

positions and is equipped with the preview camera “DFK 21F04”

3DMic7 MIRAX MIDI and Pannoramic

3DMic8 SCAN 150 (MIRAX SCAN upgraded to magazines with

25 slide positions) and Pannoramic SCAN

3DMic9 Pannoramic 250 (P250)

3DMIC10 MIDI_II; Pannoramic MIDI modular; (with

objective changer); see also: “Focus

unit OC”

3DMIC11 SCAN_II; Pannoramic SCAN modular; (with

objective changer); see also: “Focus

unit OC”

3DMIC12 DESK_II

This part of the service

program is an interactive tool and calculates the physical position (distance)

of the preview camera in relation to the scan (main) camera.

This part of the service

program is an interactive tool and calculates the physical position (distance)

of the preview camera in relation to the scan (main) camera.

More, detailed information can be found in the chapter

S_M_D: “Preview S_M_D”

and “Steps of

preview calibration”

P250: “P250_preview” and “Brightfield preview calibration procedure”

This part of the program

allows the handling of the components in a very high degree of freedom; see later in this description.

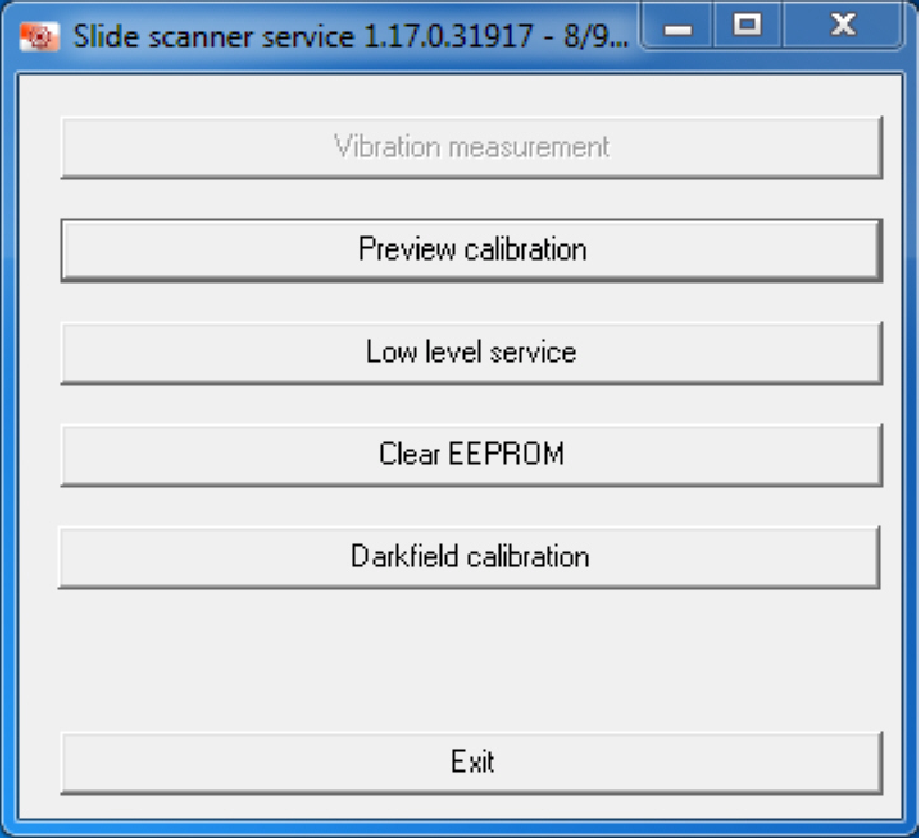

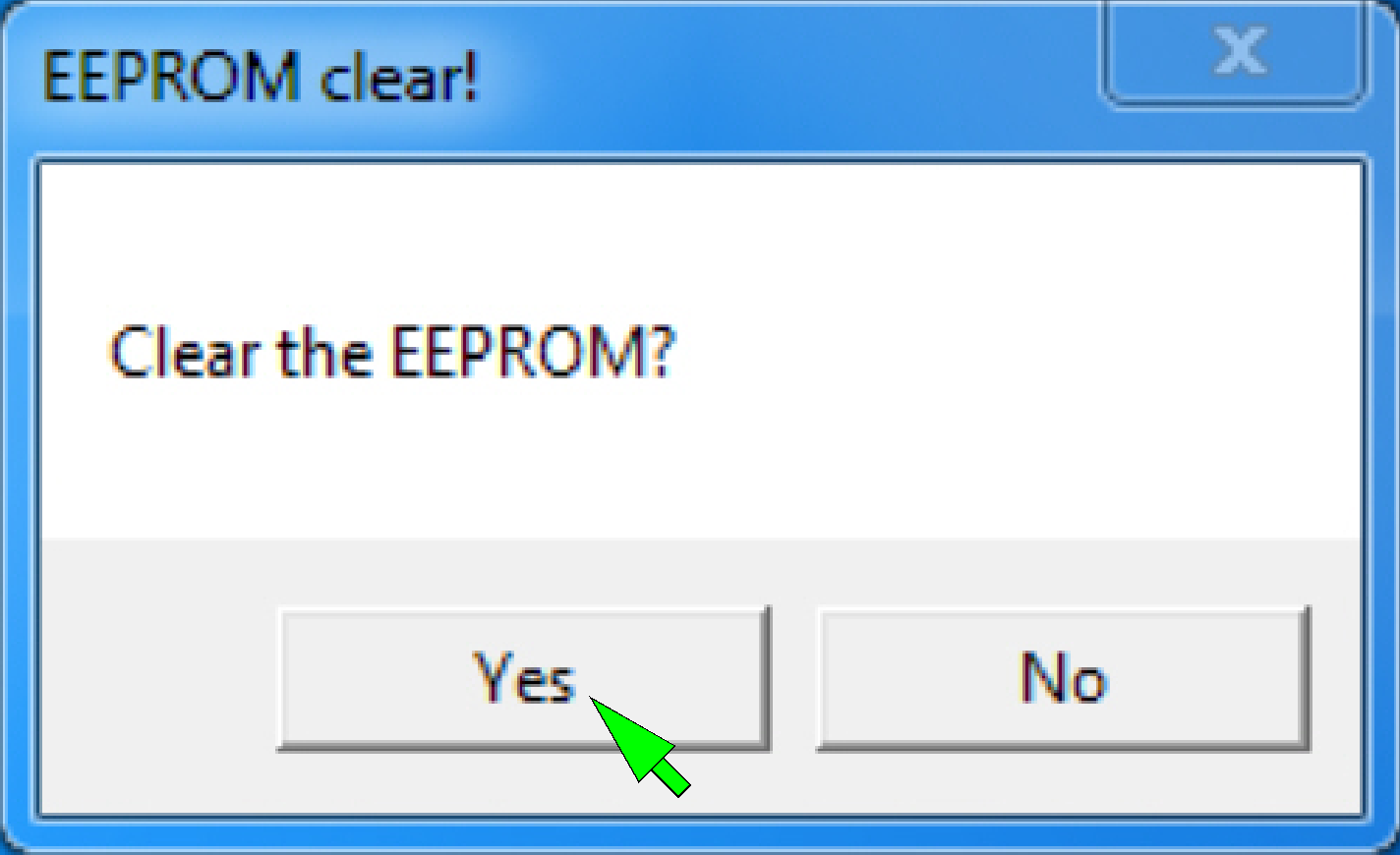

This option clears the EEPROM

content.

The EEPROM stores the scanner specific parameters and these are

collected in the files “MicroscopeConfiguration.ini” and “MicroscopeSettings.ini”

as well. To ensure an always proper function of the scanner, the content of the

EEPROM should be updated after adjustments are done or units are exchanged and

parameter values are modified.

·

To update the content, the EEPROM must be cleared

first; see also: “Clear the EEPROM”.

Darkfield calibration

This option uses a software

algorithm to calibrate the darkfield preview.

Please refer to the chapters

“Darkfield

preview”, “Darkfield

preview calibration” and “Calibrate

the darkfield preview”

This is leaving the service program.

Answer the question with

“Yes”.

·  If the scan

software “SlideScanner.exe” is started and the EEPROM is empty, the content of

the appropriate *.ini files is written automatically from the actual folder of

the HDD into the EEPROM, during the startup procedure of the program

“SlideScanner.exe”.

If the scan

software “SlideScanner.exe” is started and the EEPROM is empty, the content of

the appropriate *.ini files is written automatically from the actual folder of

the HDD into the EEPROM, during the startup procedure of the program

“SlideScanner.exe”.

· The

path of the *.ini-files, used to update the EEPROM in the version with the

operating system Windows® 7 is:

C:\ProgramData\3DHISTECH\SlideScanner\MicroscopeConfiguration.ini

and MicroscopeSettings.ini

· In the

version with the operating system Windows® xP is:

C:\ Documents and Settings\All

Users\ApplicationData\3DHISTECH\SlideScanner\MicroscopeConfiguration.ini and

MicroscopeSettings.ini

1.

Start the program “SlideScannerService.exe”, option

“Clear EEPROM”.

2.

Answer the dialogue with “Yes”; then the EEPROM is

cleared.

3.

Leave the selector dialog with “Exit”

4.

Start the program SlideScanner.exe; the *.ini-files

will be saved automatically from the appropriate HDD folder into the EEPROM

during startup the program, if the EEPROM is empty.

See also: ”EEPROM”

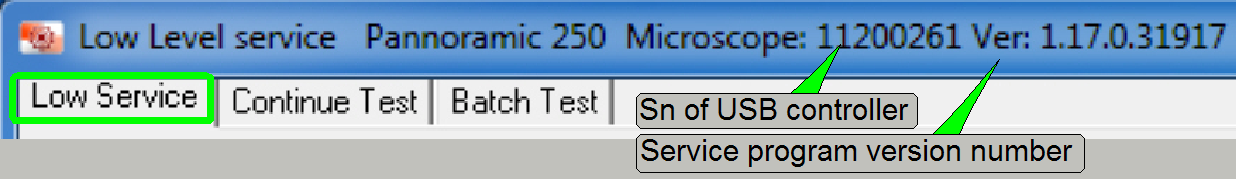

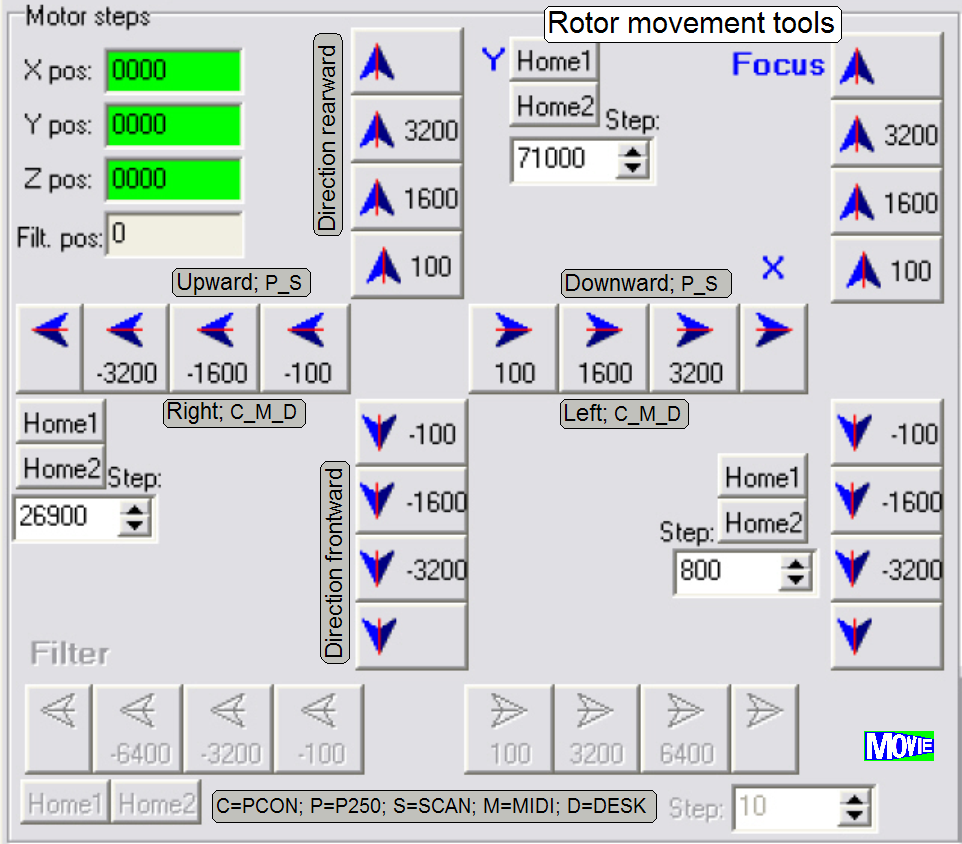

After selecting the

option “Low Level Service = LLS” the connected scanner type (Pannoramic 250),

the serial number of the connected USB controller (11200261) and the version

number of the service program (1.17.0.31917) is shown in the top line. The

scanner type is derived from the found “MicroscopeConfiguration.ini” file; see

also above “Scanner types”

After selecting the

option “Low Level Service = LLS” the connected scanner type (Pannoramic 250),

the serial number of the connected USB controller (11200261) and the version

number of the service program (1.17.0.31917) is shown in the top line. The

scanner type is derived from the found “MicroscopeConfiguration.ini” file; see

also above “Scanner types”

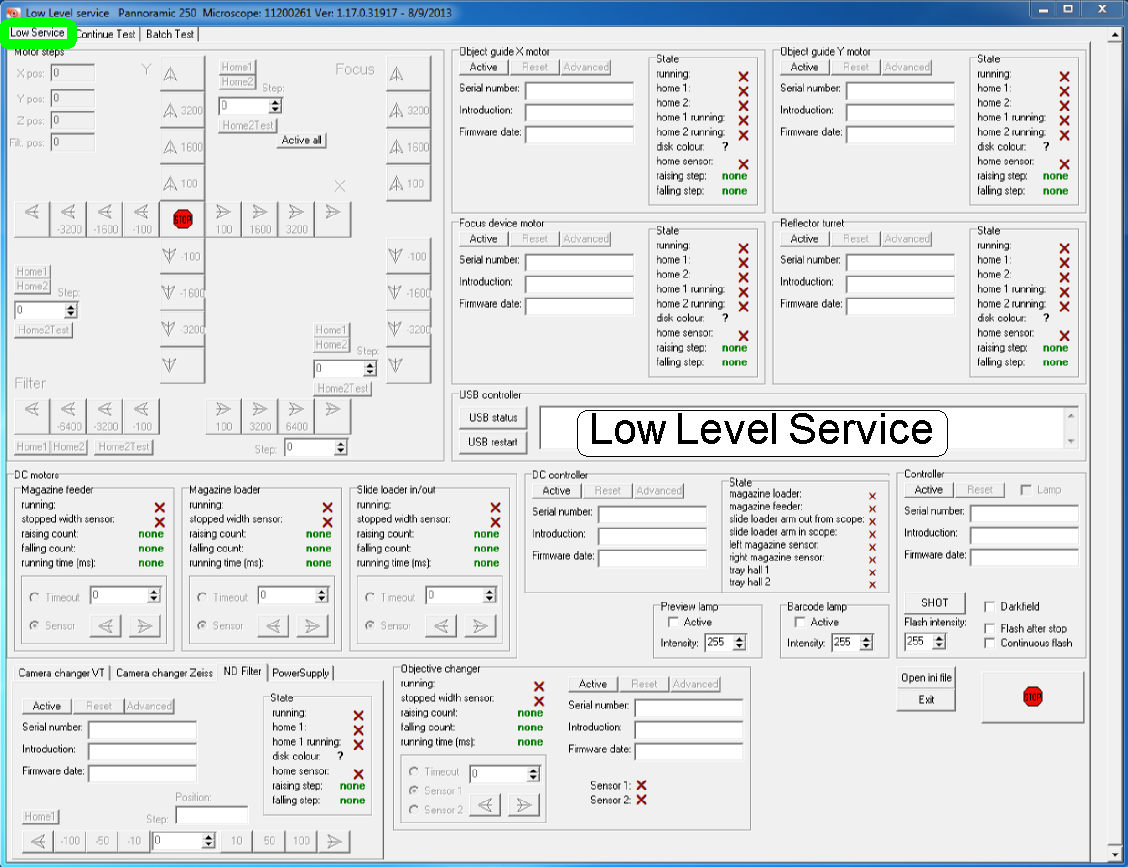

The upper half of the screen contains

the usual options like “X-Motor”, “Y-Motor”, “Focus-Motor” and “Turret-Motor”

tools, during the lower half of the screen contains scanner specific units like

DC controller, Objective changer and other special tools.

All the units of the scanner can be driven

independently from each other; the technician defines the action without limits

(the limits are given by the hardware limits of the construction).

All the units of the scanner can be driven

independently from each other; the technician defines the action without limits

(the limits are given by the hardware limits of the construction).

· Because the

sensors are handled in polling mode, the different units of the scanner may be

connected or disconnected (can be switched active or inactive (Reset))

separately to save execution and response time.

To

spend a very high degree of freedom for the Low Level Service part of the

program, only small software protections are implemented (and in addition,

these can be overridden)!

The

technician has to select carefully the action to be executed, otherwise units

might be damaged, bend or made unusable.

The Low Level Service

includes:

·

Set the stepper motors to Home1,2.

·

Check the functionality of the sensor Home2.

·

Move any stepper motor a predefined or user defined

number of steps; forward or backward respectively.

·

Showing always the actual motor position in steps,

proceeded from Home1,2.

·

Driving the DC-motors forward or backward as desired

for the action requested; the stop event may be:

- The sensor

action or

- The predefined runtime evaluated (named as

Timeout)

·

Showing always the actual state of the sensors.

·

Switching on or off illuminations

·

USB status monitoring

·

Checking and monitoring the status of the unit,

defined as “active”

·

Displays the serial number and the electronics version

number of the connected unit

·

Stop of all movements in emergency situations.

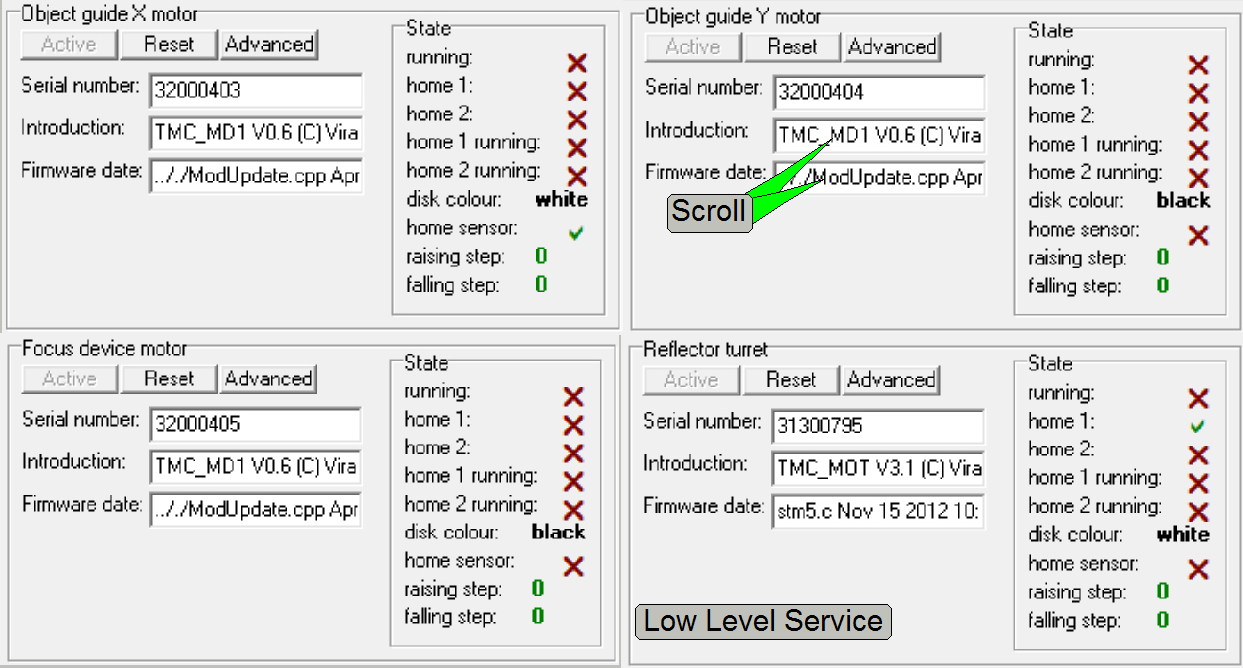

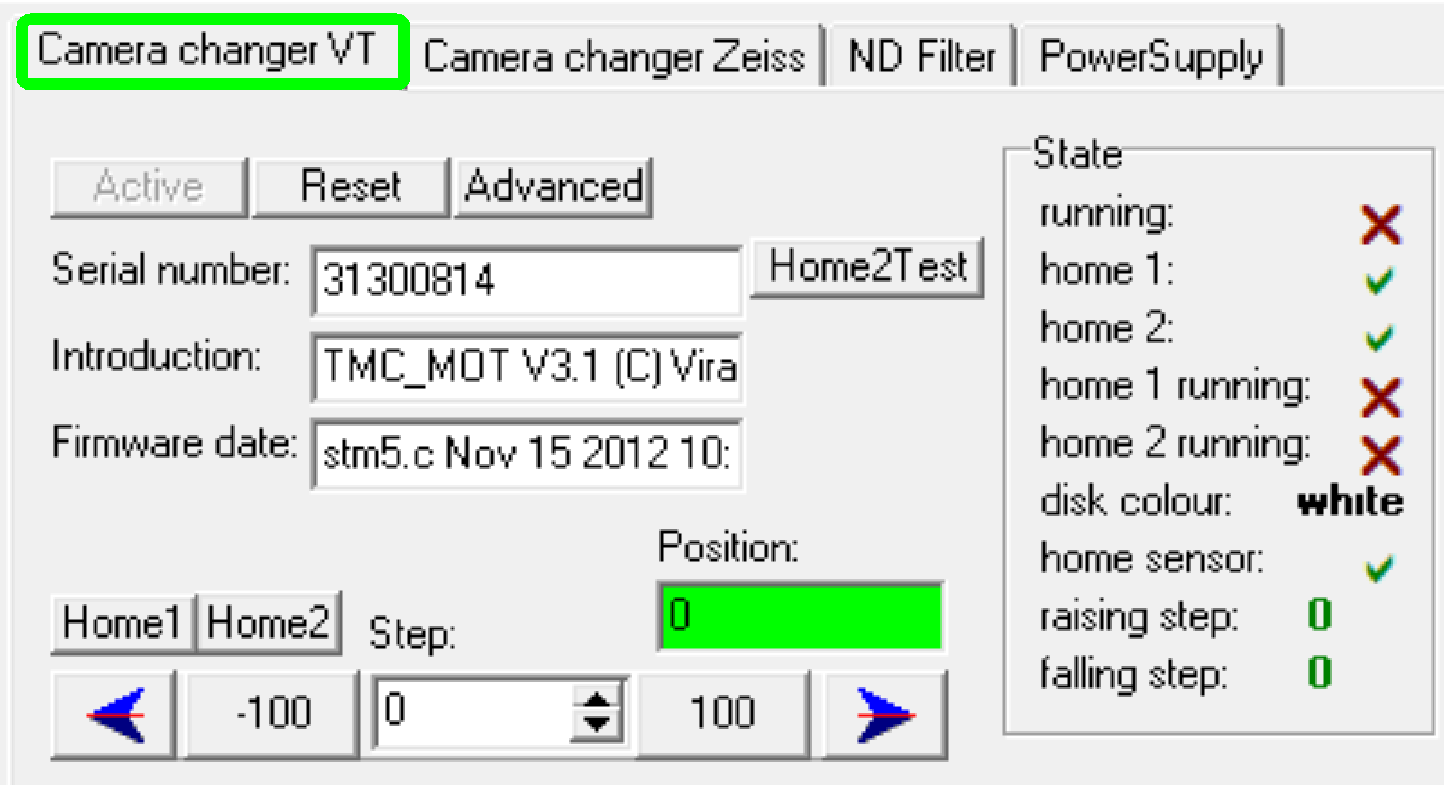

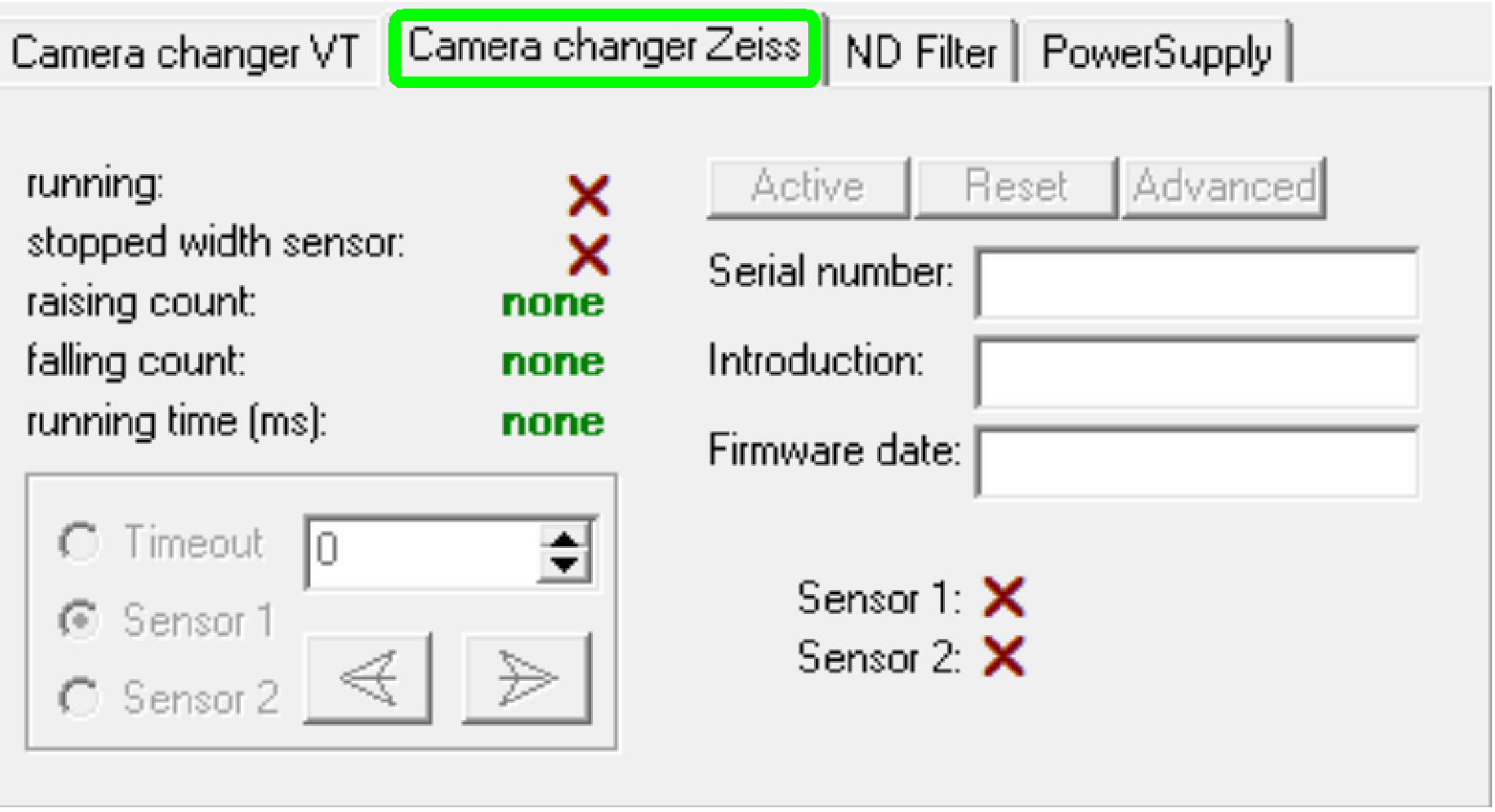

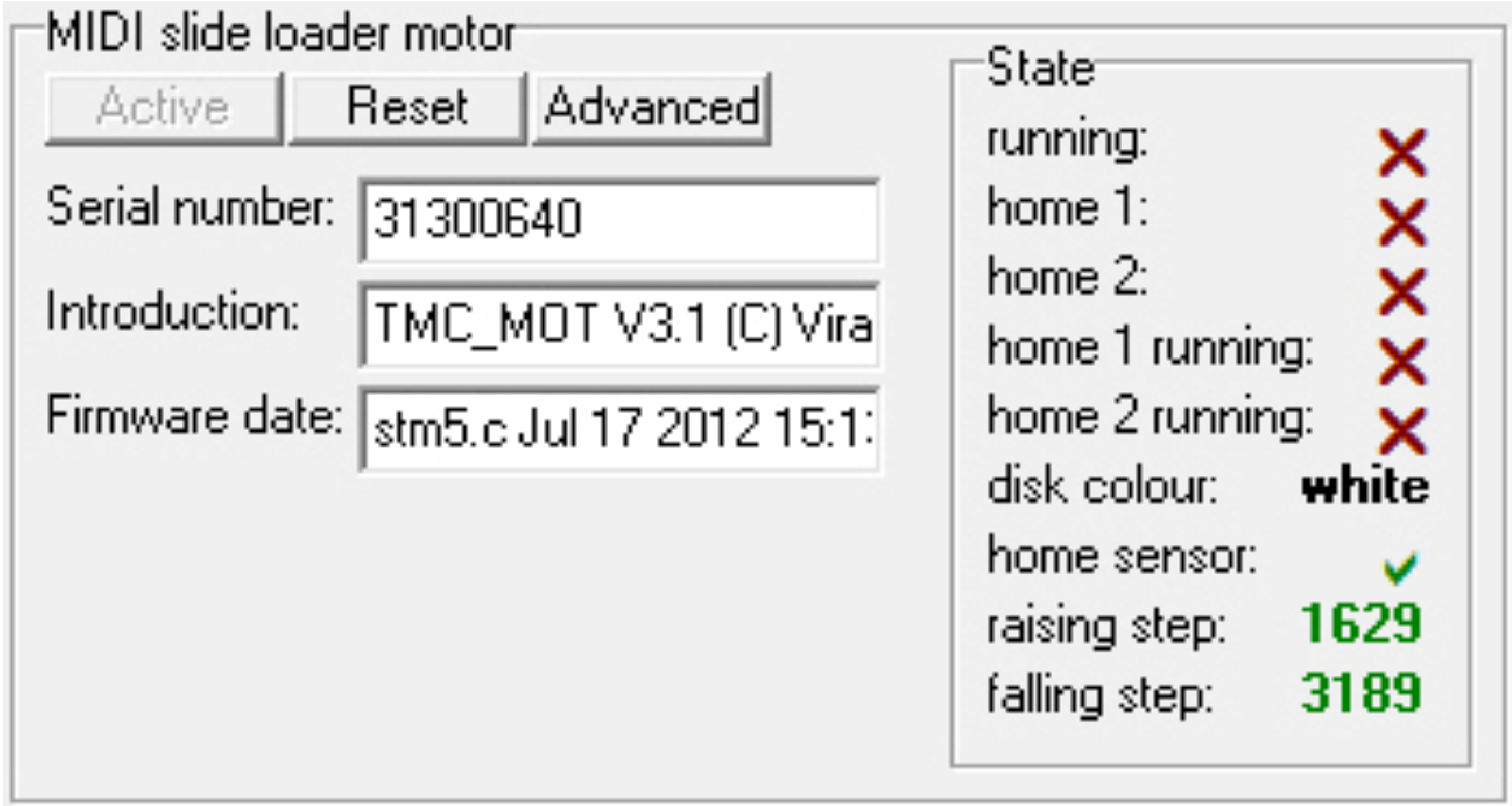

Active

Allows the use of

the appropriate unit and switches it into the active state. The service program

starts the communication with the motor or unit electronics. During this action

the serial number of the motor and the firmware version with date is read out

from the motor electronics.

Allows the use of

the appropriate unit and switches it into the active state. The service program

starts the communication with the motor or unit electronics. During this action

the serial number of the motor and the firmware version with date is read out

from the motor electronics.

By dragging or scrolling in

the alphanumeric field the not shown part of the content can be displayed.

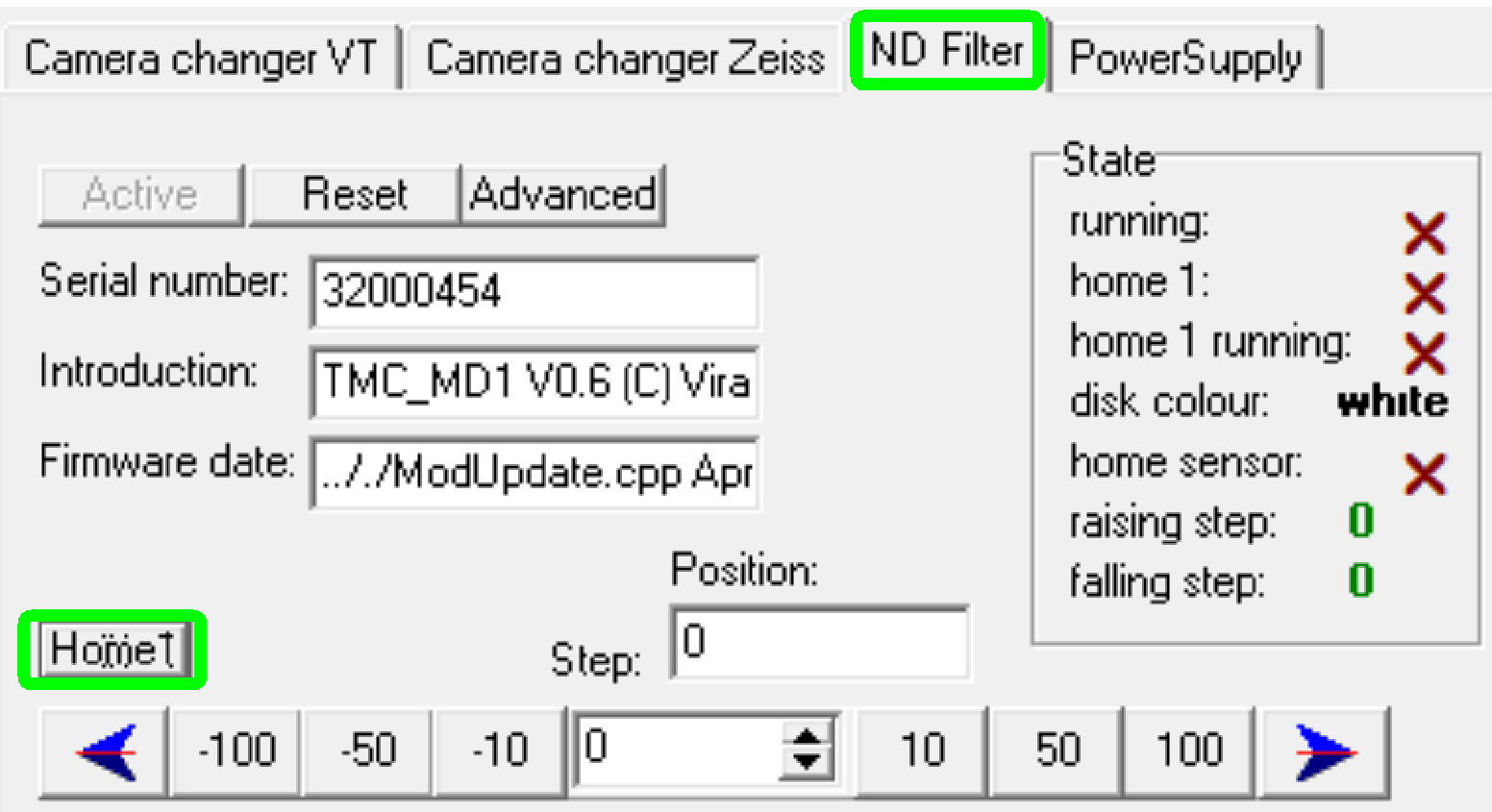

State

On the right hand side of the

appropriate unit, the current position of the sensors Home1 and Home2 are

shown; for information about the stepper motors and the sensors Home 1 and

Home2 please refer also to the chapter “Stepper motor

implementation” in the file “USB- and

DC-controlling” and “Sensor

Home1” and the hardware limits”.

Reset

Is used to switch inactive

the appropriate unit if it’s not in use; so the response time of the other,

active units is reduced.

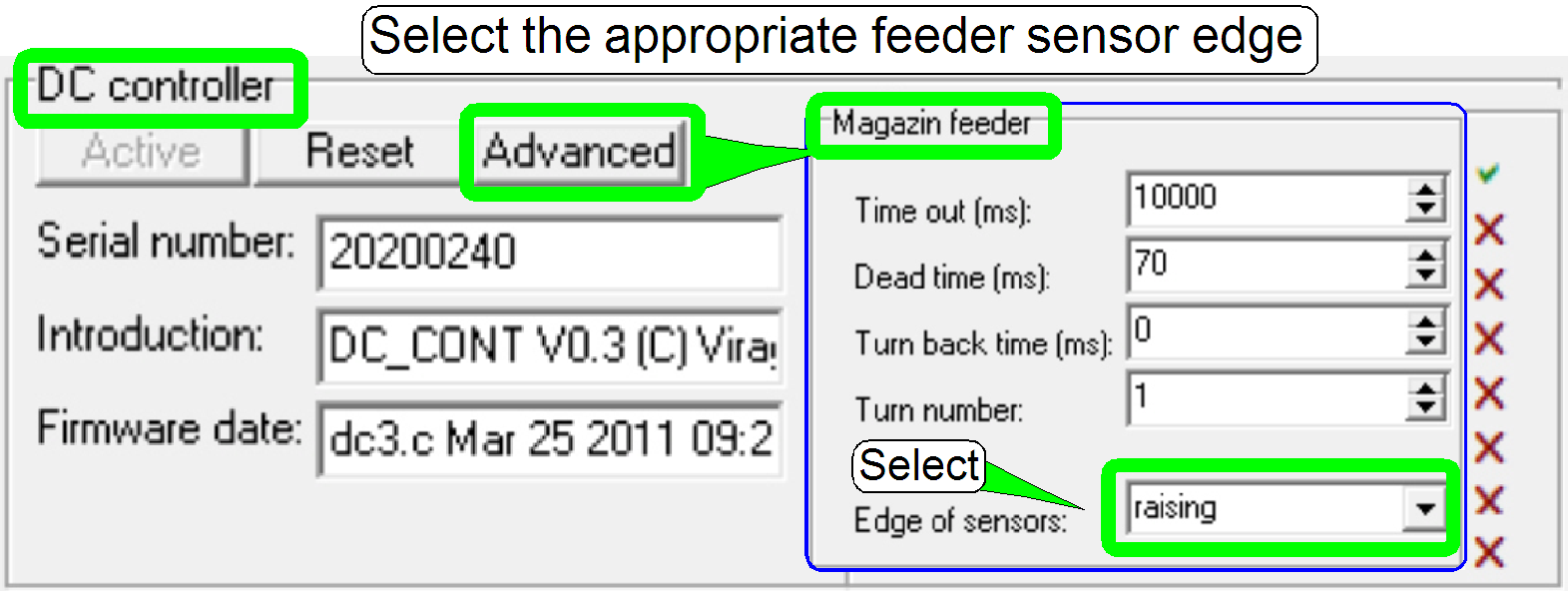

Advanced

A dialogue with special

parameters of the unit will be opened.

This option is used in

special conditions only; the default values are meeting almost always the setup

conditions. Exceptions will be discussed separately; in the part of the

appropriate unit.

In any cases, if

mechanical jamming occurs, all actions in progress are stopped.

In any cases, if

mechanical jamming occurs, all actions in progress are stopped.

·

Press this button if any action has to be stopped in

emergency situations.

·

The “Emergency power off” (P250) or the power switch

for the power supply (S_M_D) can also be used to abort any movements.

See also: “TaskManager”

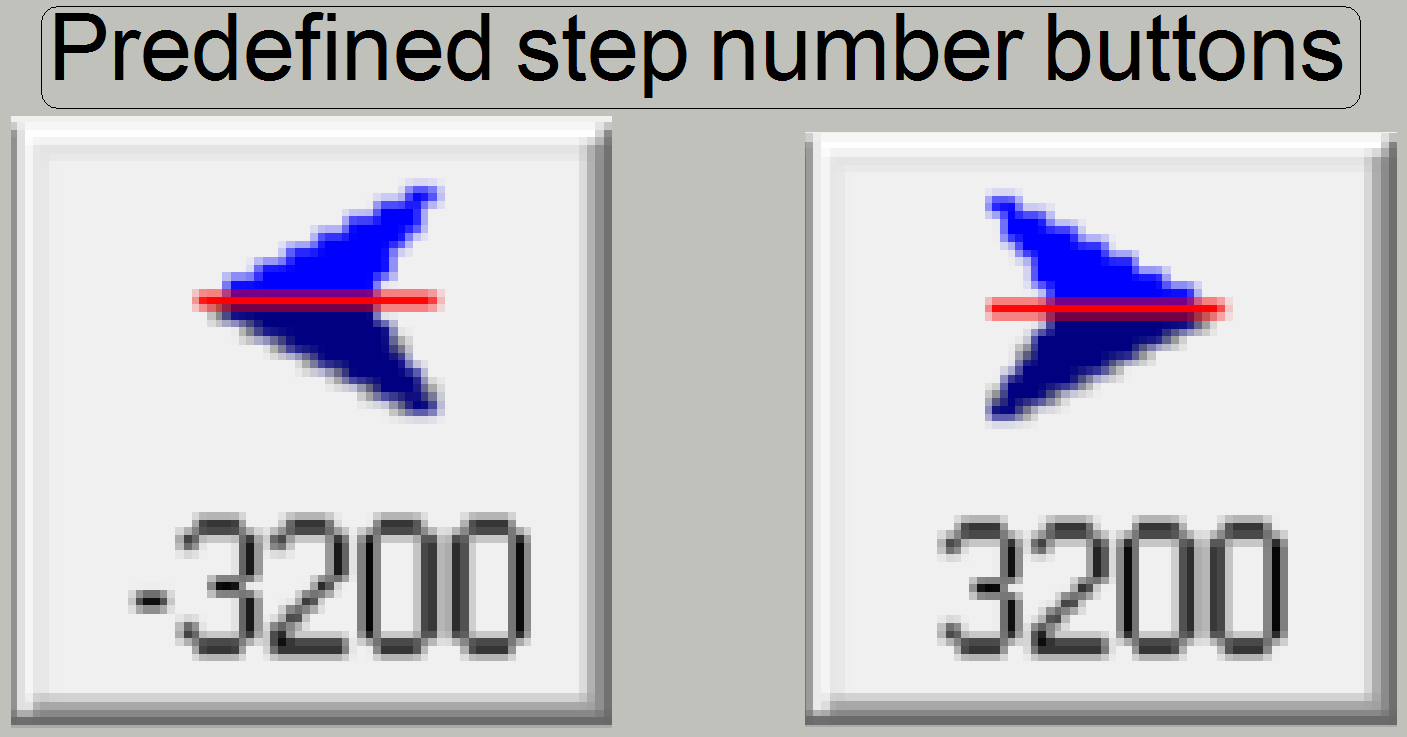

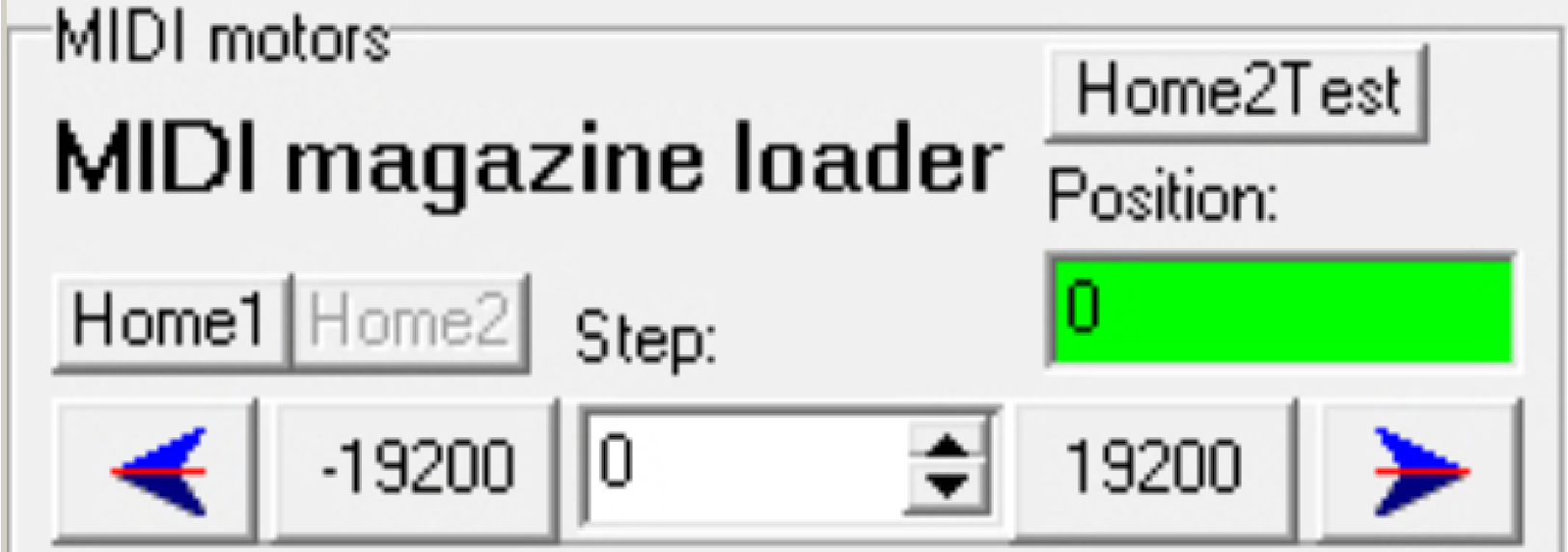

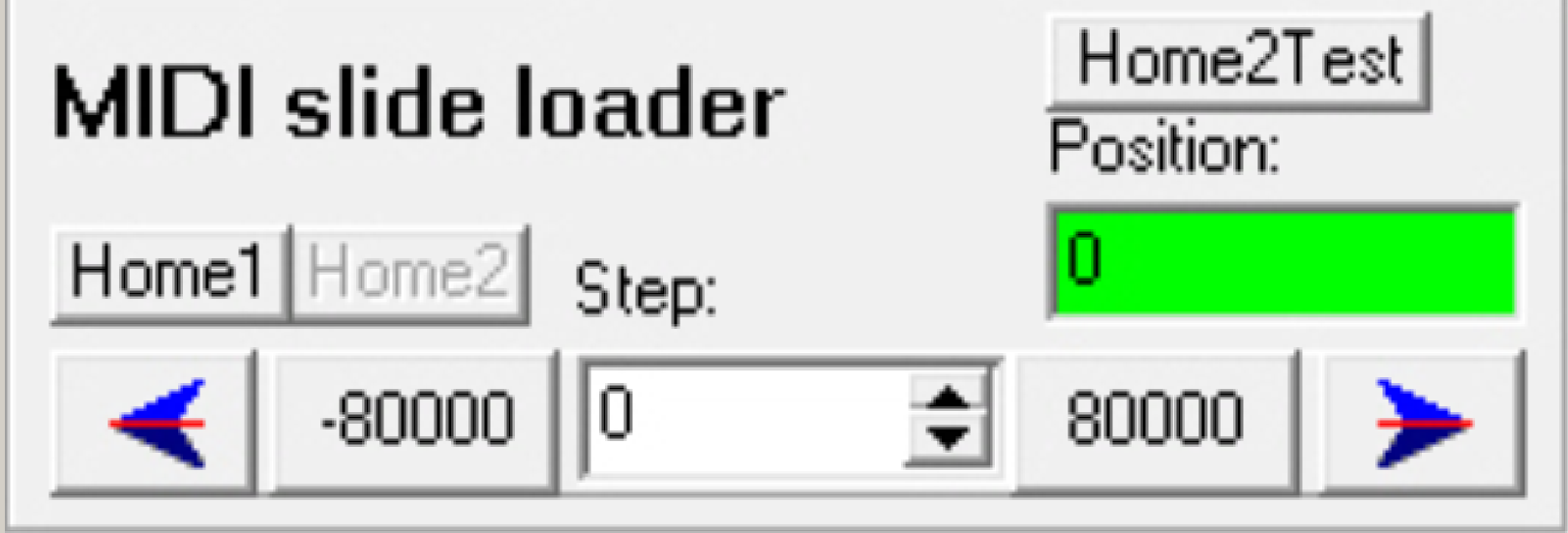

The movement of the stepper

motor’s rotor is realized with predefined step

number buttons.

The movement of the stepper

motor’s rotor is realized with predefined step

number buttons.

· In special

conditions, and to reach any required position, the user can also define a number of

steps to go, any time.

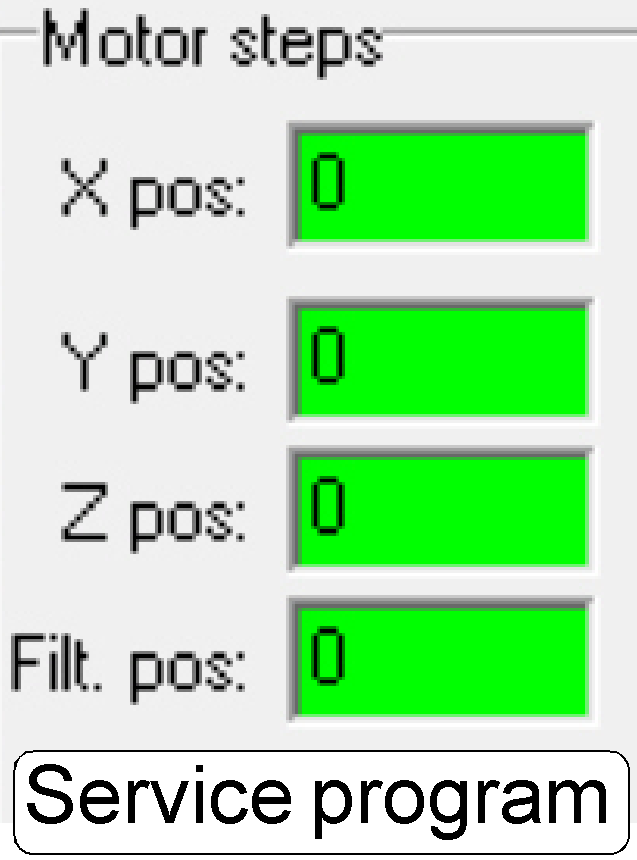

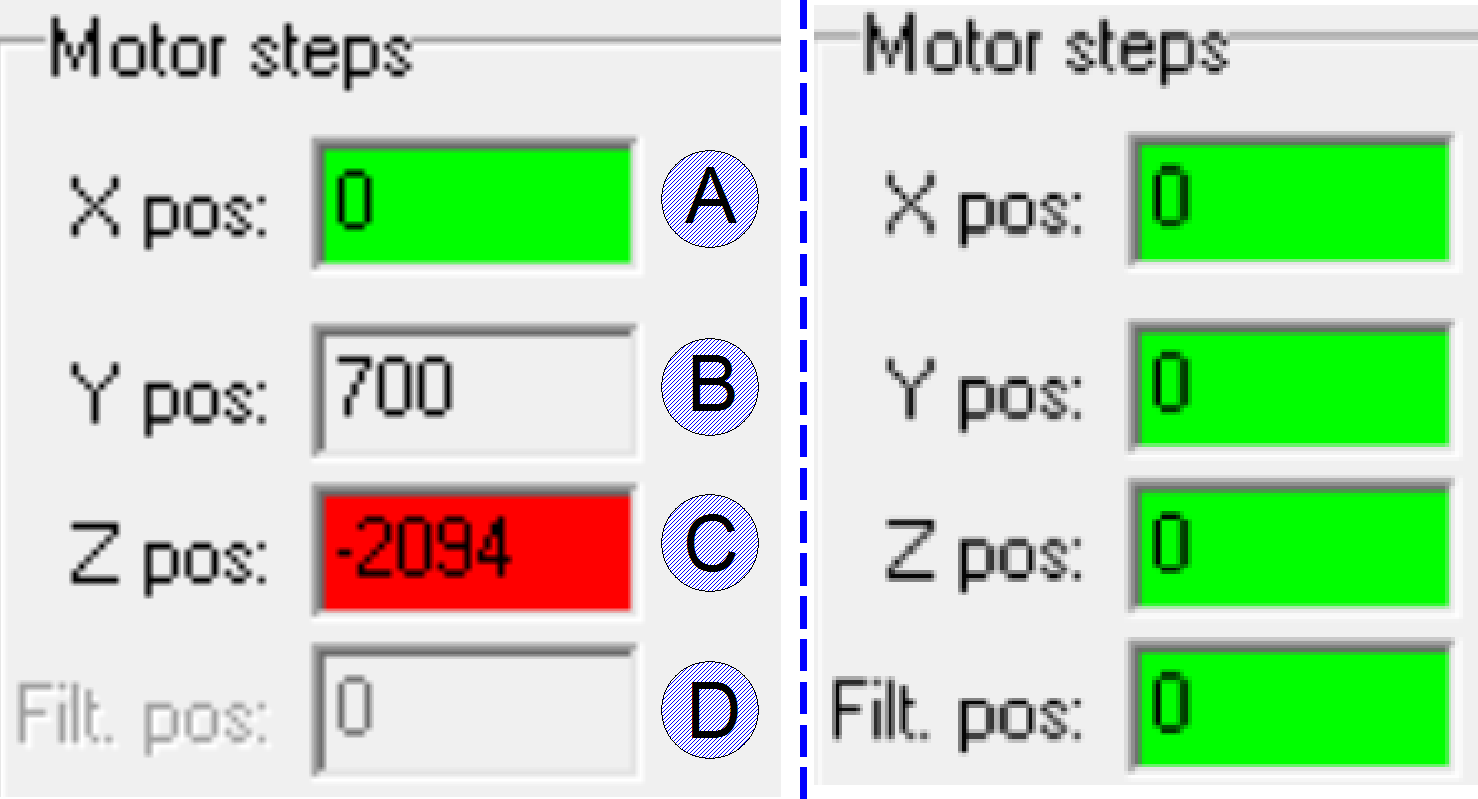

Motor steps

The actual position of the

rotor is shown in a number of steps in distance to the position Home1,2.

If the appropriate unit is

active, the content of the step counter is shown; see also “Motor steps”.

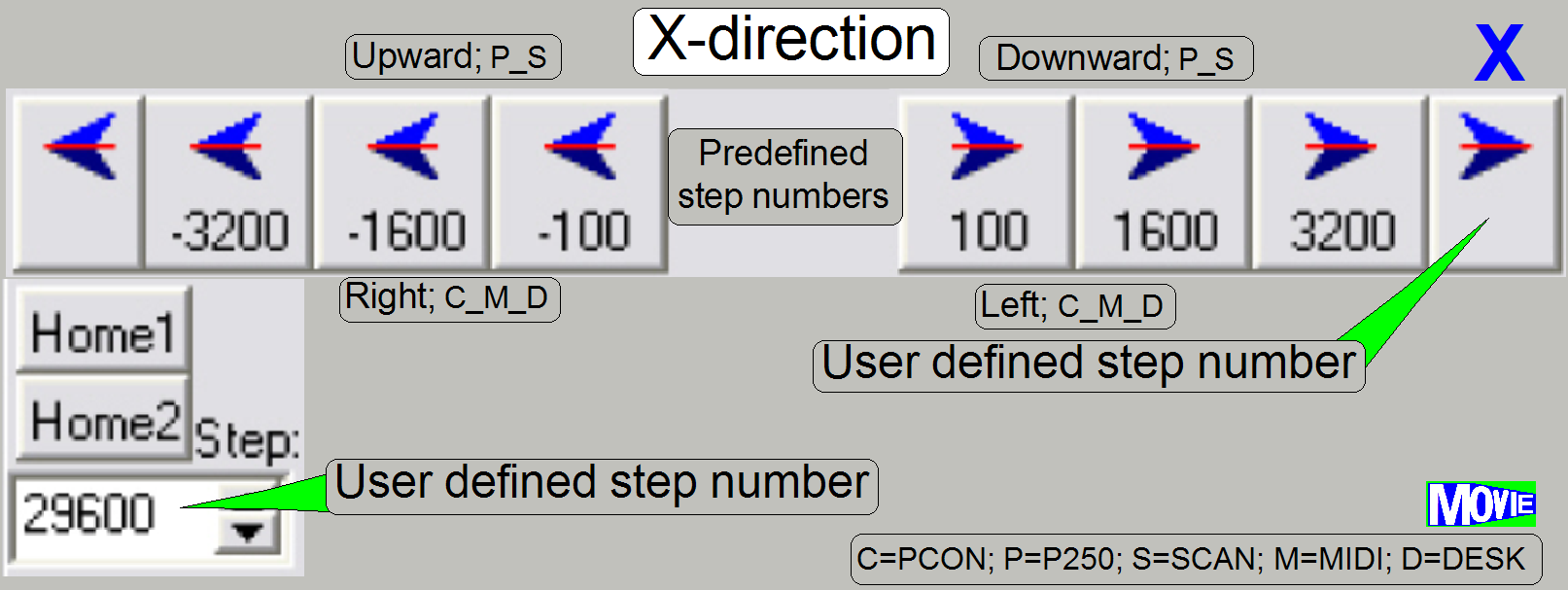

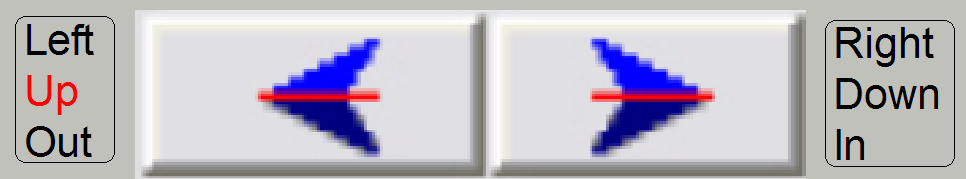

X-direction

The buttons are arranged

horizontally like the mathematical X-axis; ; see also “X-direction tools”.

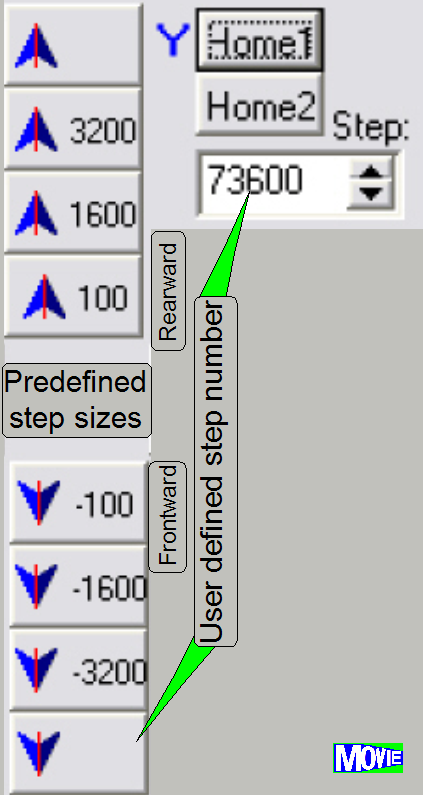

Y-direction

The buttons are arranged

vertically like the mathematical Y-axis; see also “Y-direction tools”.

Activate all

All the motors and controllers

are switched to the active state. This action is identical with the procedure

to press the button “Active” for each unit separately.

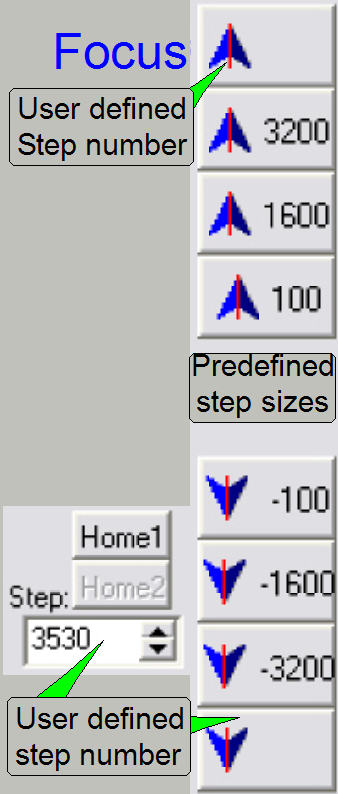

Focus

The nominal center of the

focus range is exactly 1600steps (in S_M_D) ; see also “Focus motor tools”.

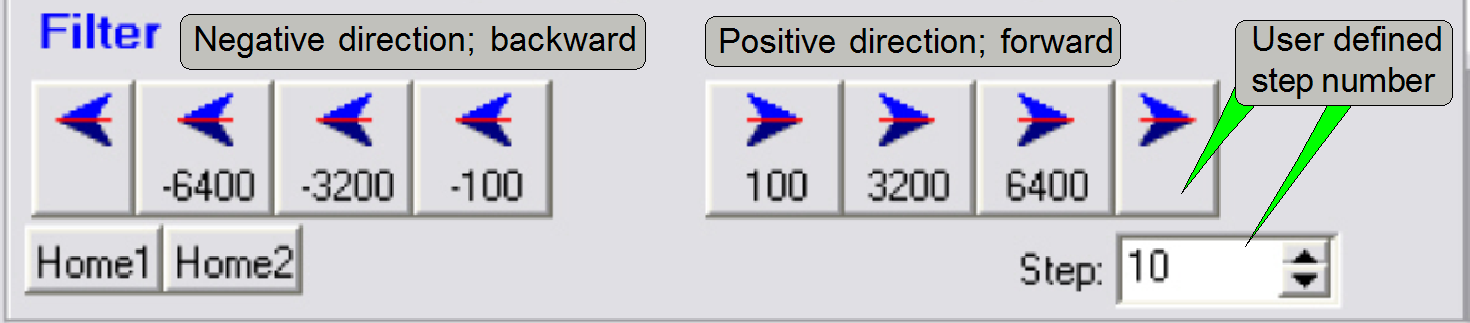

Filter

The filter wheel of the

reflector turret unit is driven by the use of these buttons.

The distance of two filter

positions is exactly 6400steps in the gear driven RTU; see also “FL reflector turret tools”.

Home1, Home2

By pressing the button Home1,

the rotor finds the start position inside of 1 revolution.

By pressing the button Home2,

the entire mechanical drive is moved to its home position and by pressing the

button Home2 second time, the step counter will be cleared.

See also “Home1,2”.

This part shows the step counter content of

the appropriate motor.

·

In this part the

actual position of the rotor is shown for the stepper motors.

In this part the

actual position of the rotor is shown for the stepper motors.

·

If positive numbers are shown, the position of the

rotor is identical with the step counter content.

·

Negative numbers showing always the step counter

content as a deviation in steps from the Home1,2 state in negative direction.

·

If the appropriate motor is switched active and the

Home1,2 position was found, the background is shown in green and the content is

“

·

If the unit is in active state but the commands

Home1,2 was not executed yet, the background is shown in white with “

·

If the unit not reached the position home1,2 after

issuing the command Home1,2, the background is shown in red; press the button Home2

again to reach the Home1,2 state; see (C) (focus motor with

6400steps/revolution). Press the button Home2 again, until the background is

shown in green!

·

If the unit is in the reset state, a single, grey “

·

The Z-position shows the actual number of steps of the

focus unit motor.

See also: “How to define

hardware limits” “Sensor “Home1” and hardware limits” and “Stepper motors”

The control of the stepper motor

is done with the following tools; these existing for each stepper motor

separately.

After switching active the

appropriate motor, the home position of the motor (and the entire mechanical

construction) have to be found by pressing the buttons Home1 and then press the

button Home2. Use this sequence also, if the home position of the entire

mechanical construction should be found any time.

If the mechanical drive

should be checked for lost steps, press Home1 only. If there are no steps lost

(+2 or -2 steps tolerance are maximal allowed); the number of actual steps

should be “

See also: “Sensors”, “Stepper motor

implementation” and “How to

define hardware limits”

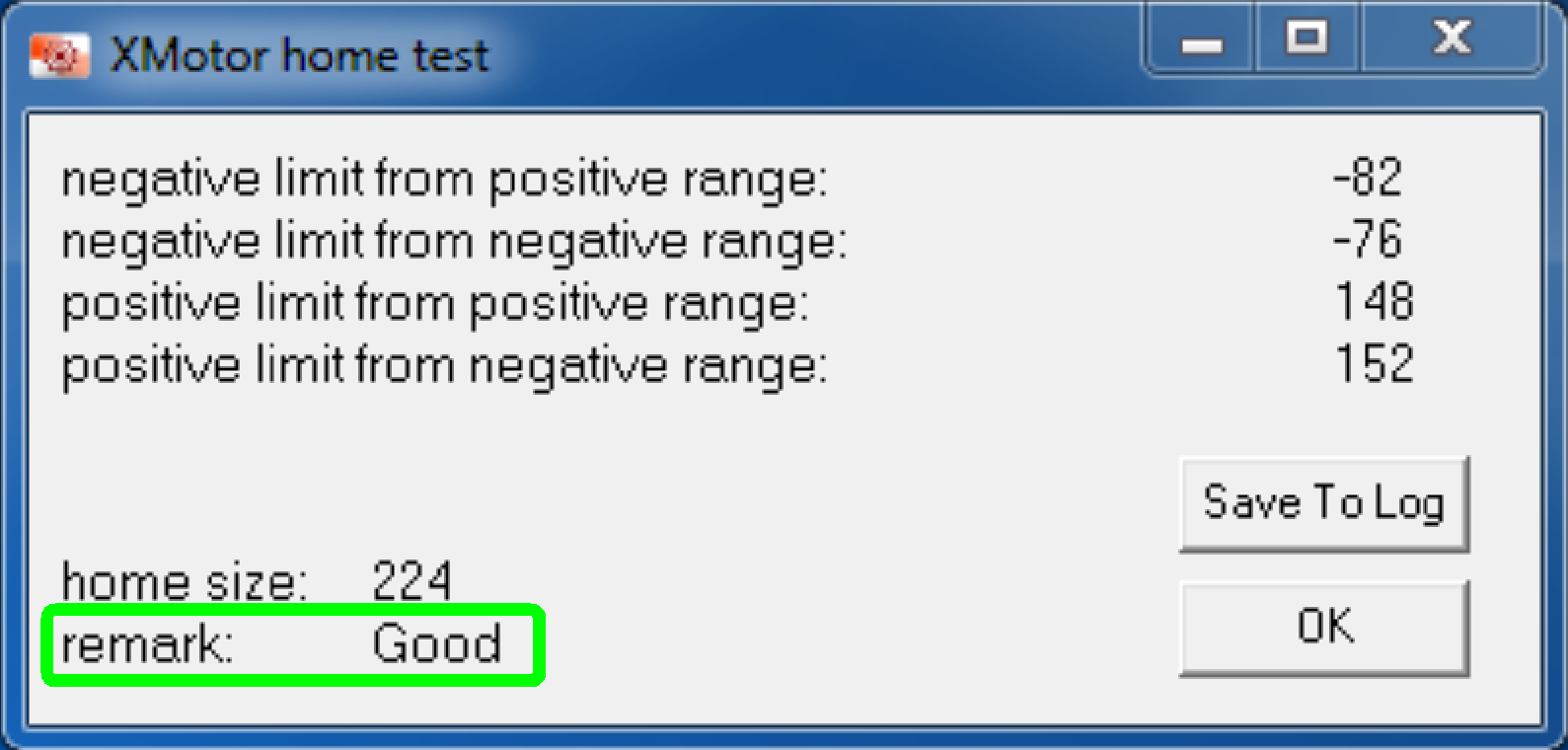

This button is

used to check the correct acting range of the sensor Home2.

This button is

used to check the correct acting range of the sensor Home2.

· If the remark

shows “bad”, the unit may work correctly, but the acting range of the sensor

“Home2” is outside the nominal limits.

See also: “Principle of sensor Home2”

These buttons are used to move

the rotor by 1 revolution, a half revolution and by 100 steps forward or

backward respectively. If the button of the predefined number of steps is

pressed, the number of steps is done from the actual rotor position in positive

or negative direction.

See also: “Motor steps”

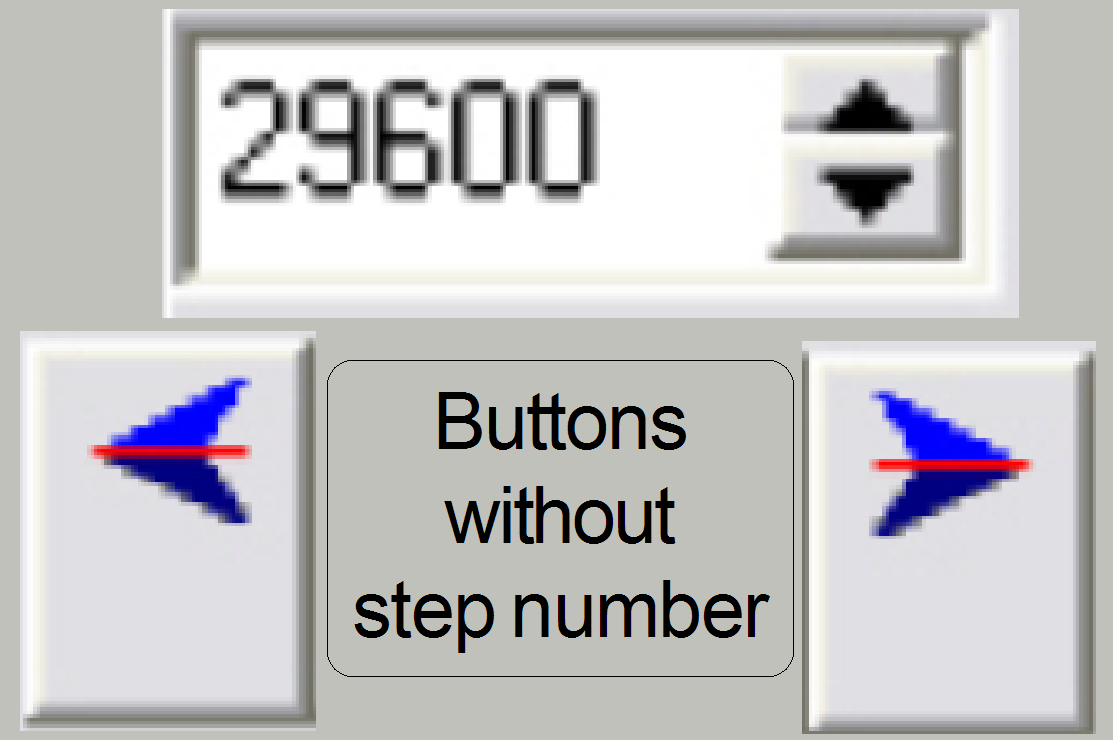

If the desired

number of steps can not be reached with the predefined step number buttons (or

the buttons should be pressed very often to reach the desired position) the

user can define in the numeric field a number of steps to go.

If the desired

number of steps can not be reached with the predefined step number buttons (or

the buttons should be pressed very often to reach the desired position) the

user can define in the numeric field a number of steps to go.

· Easily type in the

desired number of steps to go into the appropriate numerical field

· Press the

corresponding buttons without step number in positive or negative direction,

the number of steps is executed from the

actual rotor position

This possibility is often

used if the hardware limits have to be defined or checked.

Important

· This options

can easily create mechanical jamming or lost steps (as any other step number

button also) if the number of steps to go is not calculated correctly.

· The

directions forward and backward are defined in relation to the movement of the

mechanical drive; the home position is always near to the negative limit

· Creating

lost steps can be used to find the correct hardware limits!

See also: “Motor steps” and “How to define hardware limits”

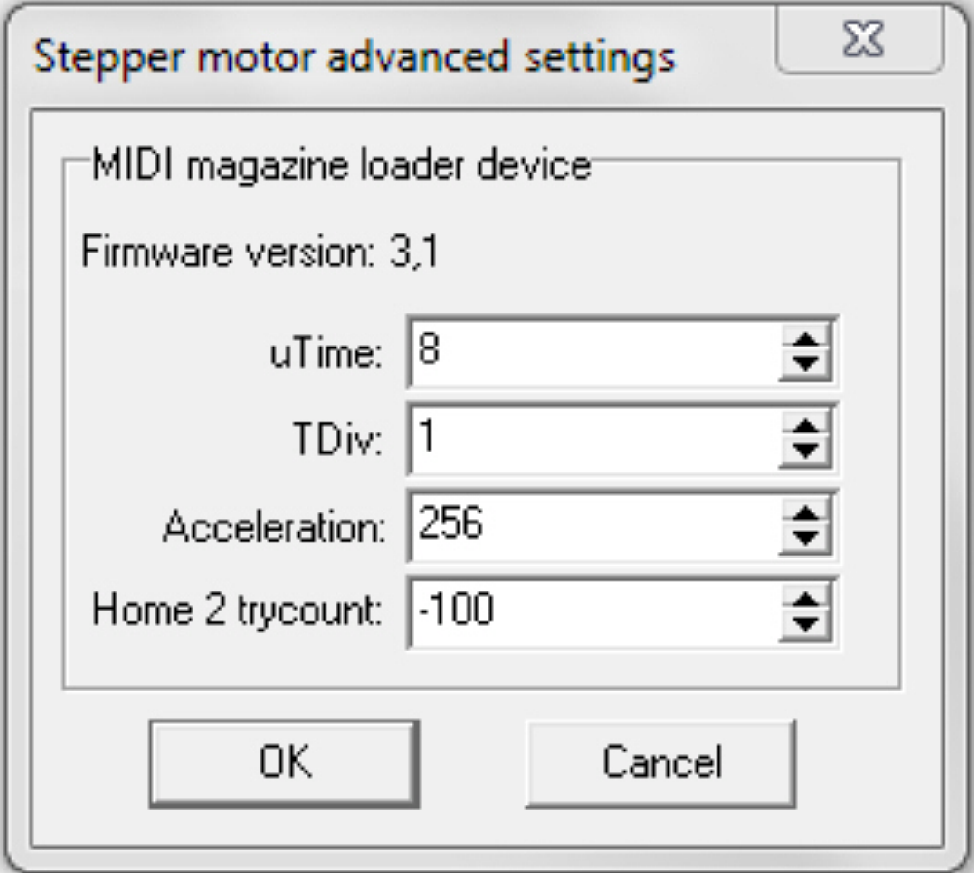

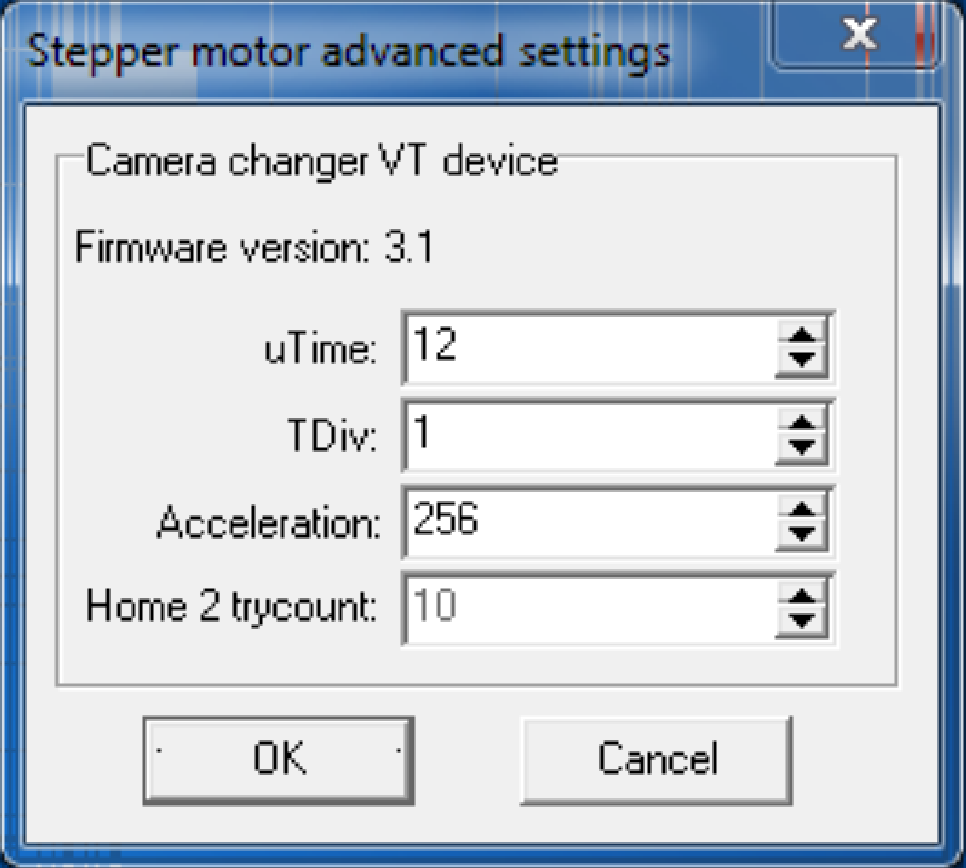

Stepper motor advanced

settings

The advanced

settings for the stepper motors are very similar to each other. For useable

values of the appropriate stepper motor driven unit please refer to:

The advanced

settings for the stepper motors are very similar to each other. For useable

values of the appropriate stepper motor driven unit please refer to:

SMD: “USB and DC-controlling”, “Stepper motor”, “Step control of

stepper motors”, “Calculate the u-time”

P250: “Power and control” , “Stepper motor”, “Step control of stepper motors”, “Calculate

the u-time”

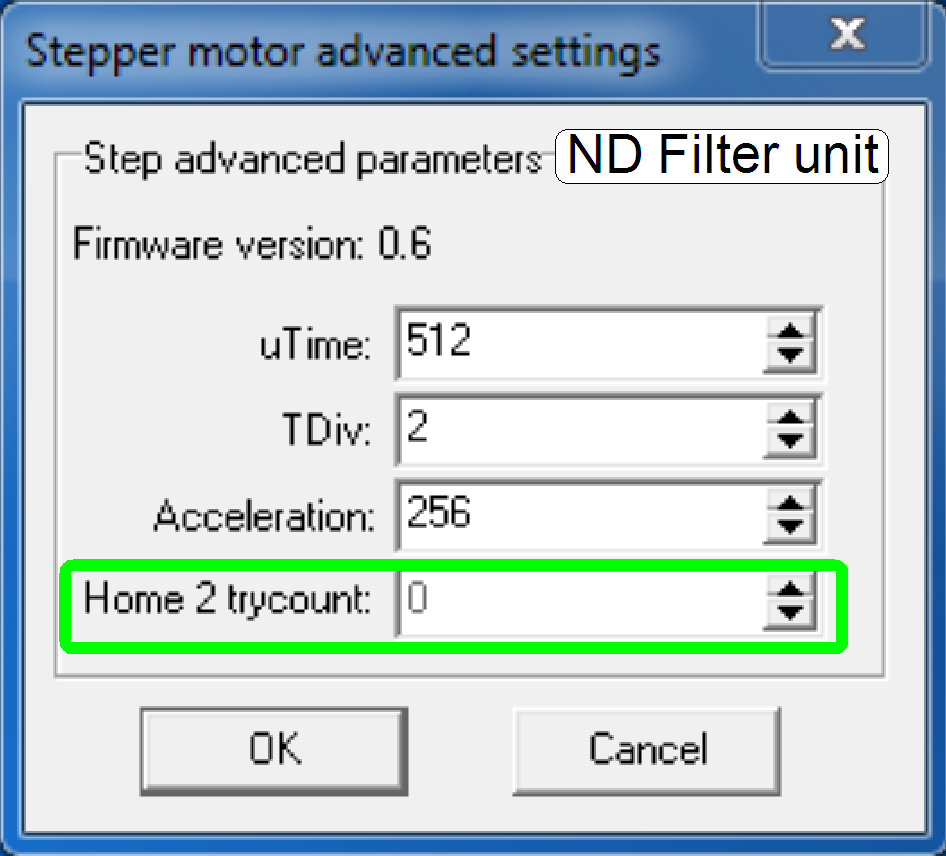

Home2 try count:

This number specifies the

maximal number of revolutions of the rotor axle to be done to reach Home2; see

also the hardware limits of the appropriate unit.

·

To activate the selected values close the dialog with

OK, press reset of the appropriate unit and then switch it active again.

Movement range: –hardware limit < Home1,2 <

+hardware limit

See also: “X-Y-stage unit S_M_D” and “How to define hardware limits”

P250

Movement range: –hardware limit < Home1,2 <

+hardware limit

See also: “P250_X-Y-stage unit” and “How to define hardware limits”,

Movement range: –hardware limit < Home1,2 <

+hardware limit

See also: “X-Y-stage unit S_M_D” and “How to define hardware limits”

P250

Movement range: –hardware limit < Home1,2 <

+hardware limit

See also: “P250_X-Y-stage unit” and “How to define hardware limits”,

SCAN,

Movement range: –hardware limit < Home1,2 <

+hardware limit

See also: “Focus uni S_M_D” and “How to define hardware limits”

P250

Movement range: –hardware limit < Home1,2 <

+hardware limit

See also: “P250_Focus unit with objective changer”

and “How to define hardware limits”,

The number of steps

between two filter positions is exact 6400steps (2 revolutions of the rotor);

in the gear driven RTU; in the belt driven RTU, the number of steps between two

filter positions is exact 3200steps.

The number of steps

between two filter positions is exact 6400steps (2 revolutions of the rotor);

in the gear driven RTU; in the belt driven RTU, the number of steps between two

filter positions is exact 3200steps.

SCAN and

Movement

range: –hardware limit < Home1,2

< +hardware limit

See also: “How to define hardware limits”, “Reflector

turret unit; MIDI, SCAN”

P250

Movement

limit: endless

See also: “How to define hardware limits”,

and “Belt driven RTU”

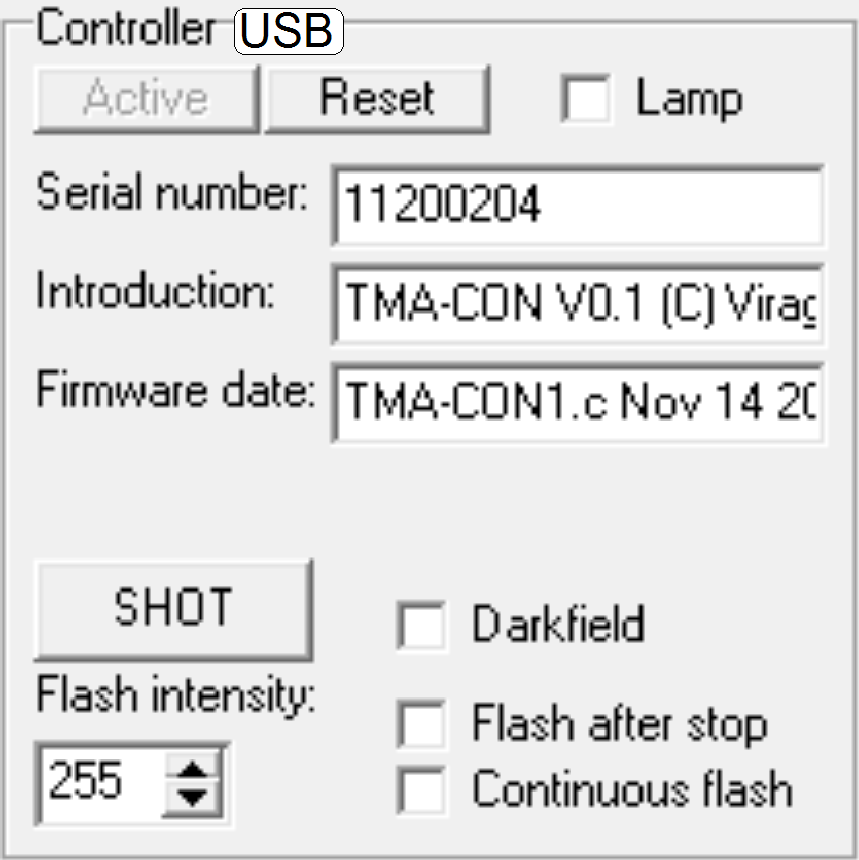

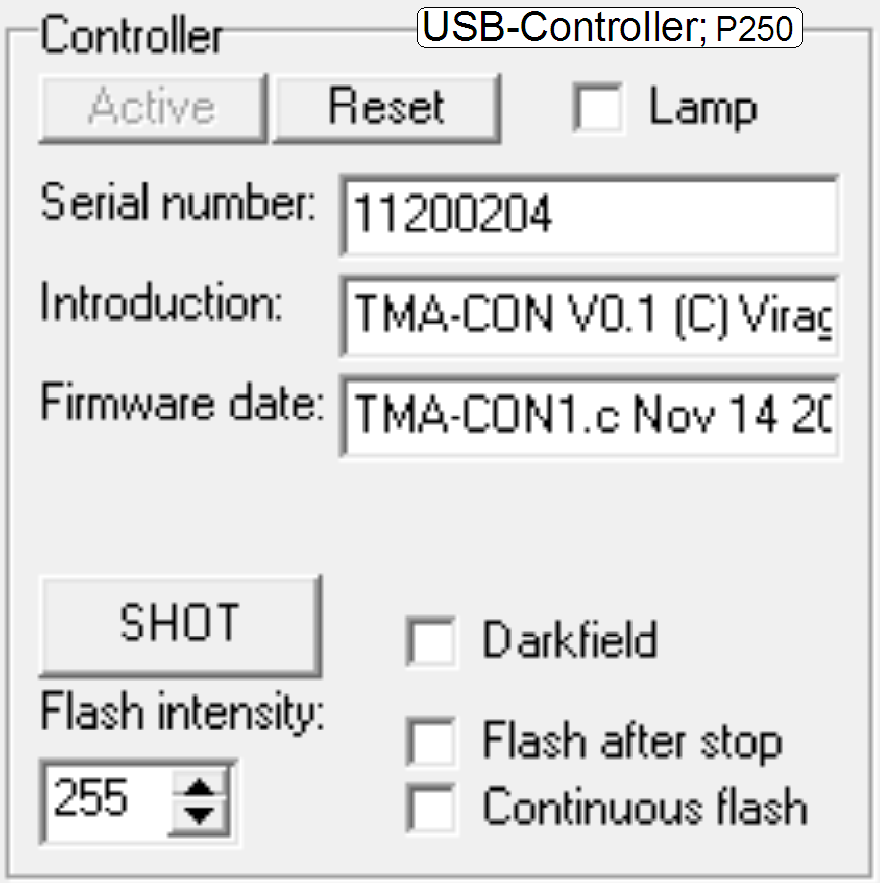

·  The USB controller

must be switched active only, if one of the following options should be used.

The USB controller

must be switched active only, if one of the following options should be used.

Darkfield

· Check the darkfield

illumination; switch it on or off

Continuous flash

· Generates flash

pulses.

· Check the

brightfield flash illumination for the main camera; switch it on or off

Shoot

· Generates a single

brightfield scan illumination flash pulse

Flash after stop

Flash intensity

· Defines the flash

intensity; not used

Important

Please switch all options

inactive, before SlideScanner.exe should be started.

For not shown options, please

refer to “Global unit

control” and “Tools of

DESK”

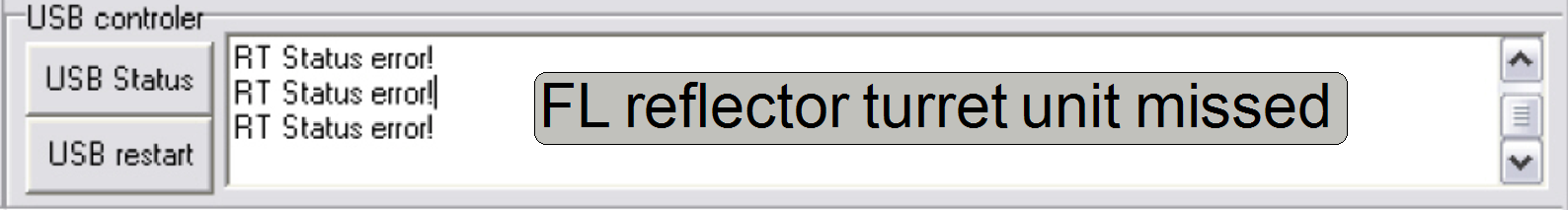

USB controller status

The USB controller

status field reports any error with an addressed unit.

The USB controller

status field reports any error with an addressed unit.

· If the unit is active

and will not respond to the USB controller, status errors are reported.

· In the example,

the turret motor cable is not connected.

Status error reports occur, if:

·

The power supply of the scanner is switched off or not

supplied to the scanner (more units are reported).

·

The cable to the unit is not connected and the service

program starts a communication with the unit (1 unit is reported).

·

The USB controller USB cable is not connected to the

PC or the USB cable is faulty (more units are reported).

·

The USB driver of the scanner is not (or wrong)

installed (more units are reported); see also “Install the USB driver”.

·

The addressed unit has no address or the same address as

another unit (1 or two units are reported).

·

The cable to the addressed unit is faulty (1 unit is

reported).

·

The addressed unit is faulty (1 or more units are

reported).

·

The USB controller is faulty (1 or more units are

reported).

· By double click in

the status report field the status messages are cleared and actualized (if

any).

Please detect the reason for

the status error more precise; see also

S_M_D P250

·

“USB- and DC-controlling”,

“Power and control”, “X-Y-Z-ND control”

·

“USB

controller”, “DC controller” “USB_controller”, “DC controller”

·

“Addresses”

and “Addresses” and

·

“Setup the USB driver”. “Setup the USB driver”.

PCON

·

“Power and

control”, “X-Y-Z-motor

control”

·

“USB_controller”,

·

“Addresses”

and

·

“Setup the USB driver”.

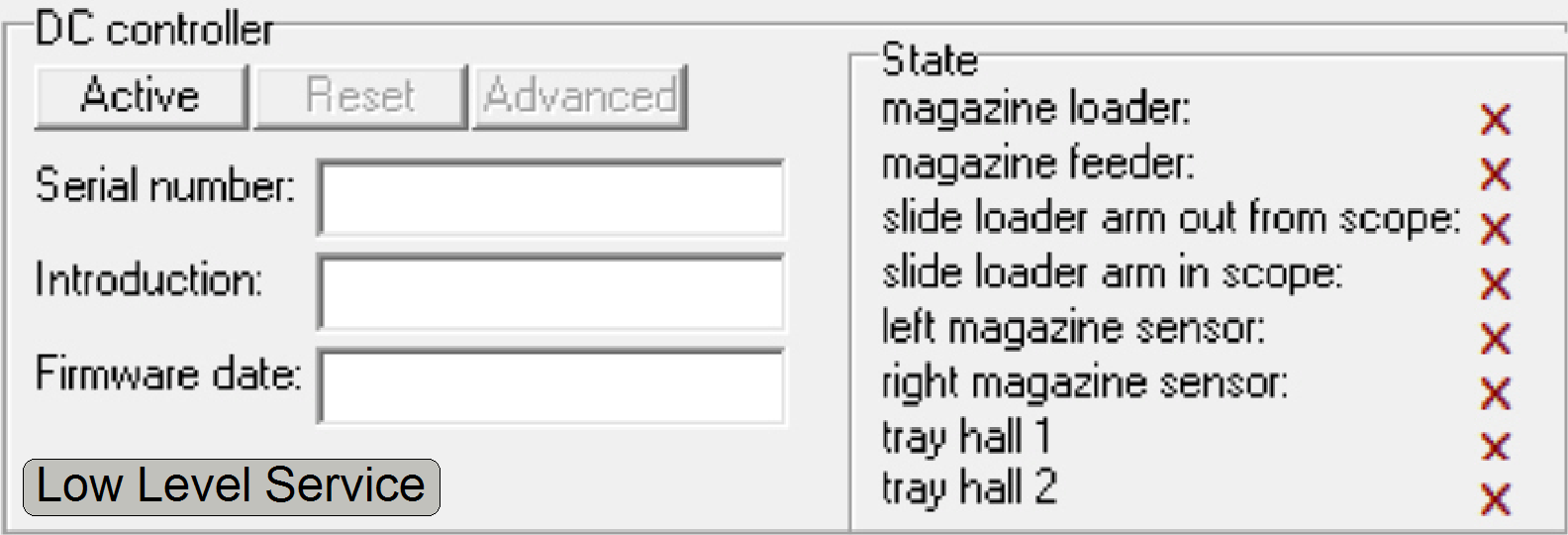

Please refer to “Global unit control”

Please refer to “Global unit control”

See also:

S_M_D: “USB

and DC controlling”; “DC

controllers”; “Hall_sensors”

P250: “Power and control”; “DC controller” and “Hall_sensors”

· To use any

component, connected to the DC-controller please switch it first into the

active state!

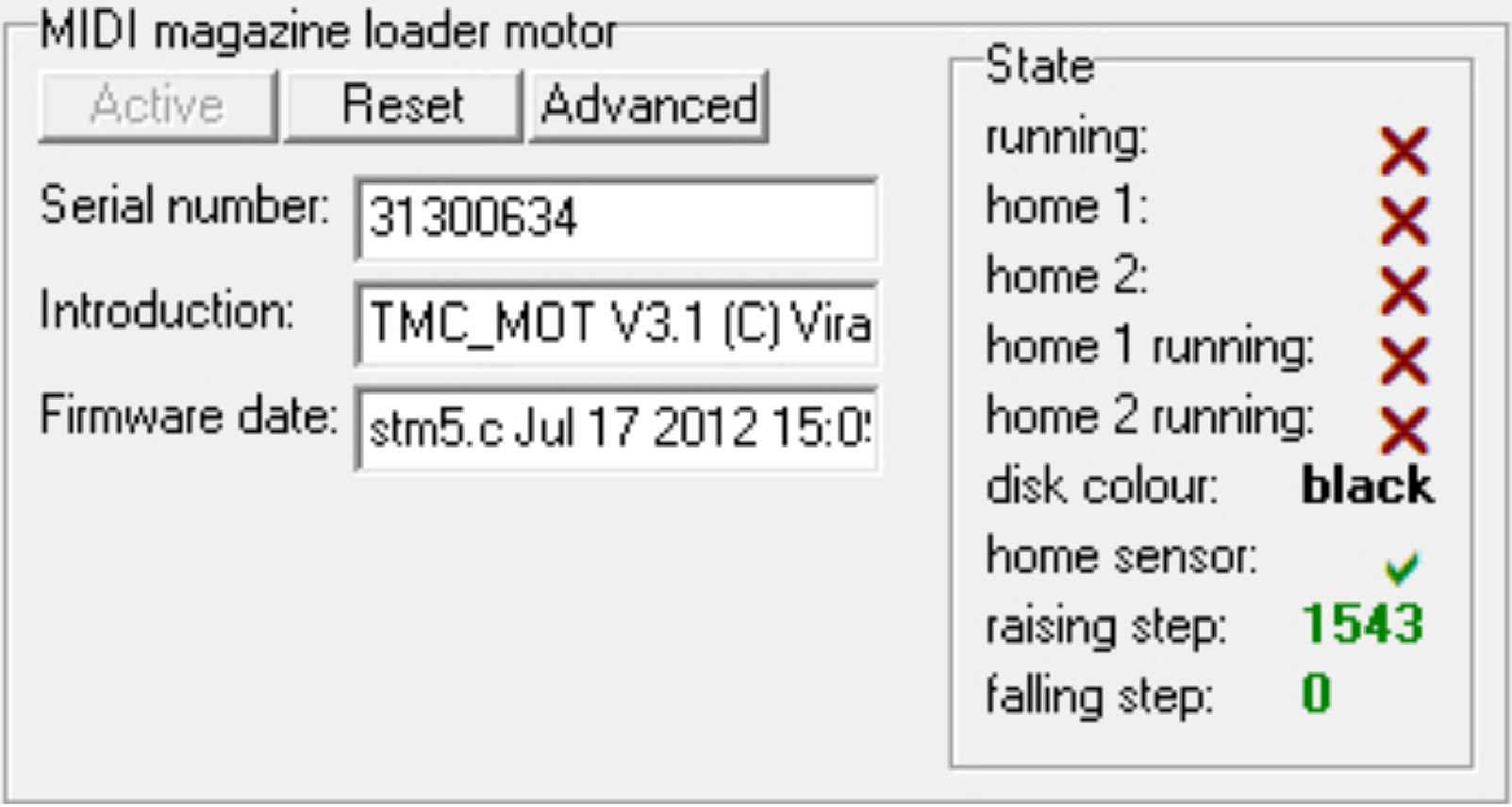

Following sections are

supported only in the P250 and the SCAN.

·  Detailed

information about the behavior of the units and their sensors can be found in

the chapters:

Detailed

information about the behavior of the units and their sensors can be found in

the chapters:

SCAN: “Magazine unit and slide handling”; “Magazine feeder unit”; “Magazine load unit” and “Slide loader”

P250: “Magazine unit and slide

handling”; “Magazine

feeder unit”; “Magazine

load unit” and “Slide

loader”

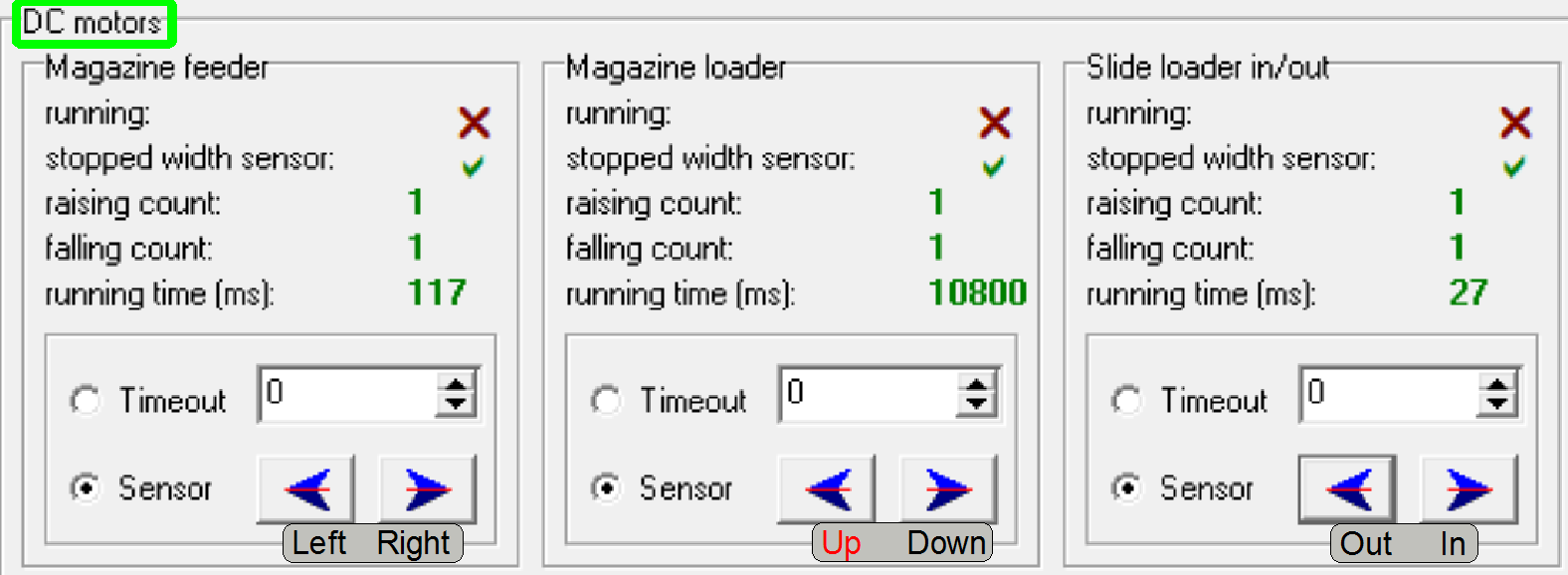

By using the

timeout option of the appropriate unit, the motor is switched on for the time

[ms], specified in the numerical field.

By using the

timeout option of the appropriate unit, the motor is switched on for the time

[ms], specified in the numerical field.

The maximal reachable time is

10 000ms = 10s.

·

Select the option “Timeout”,

·

Type into the numerical field a value in [ms] and

·

Press the appropriate button as required.

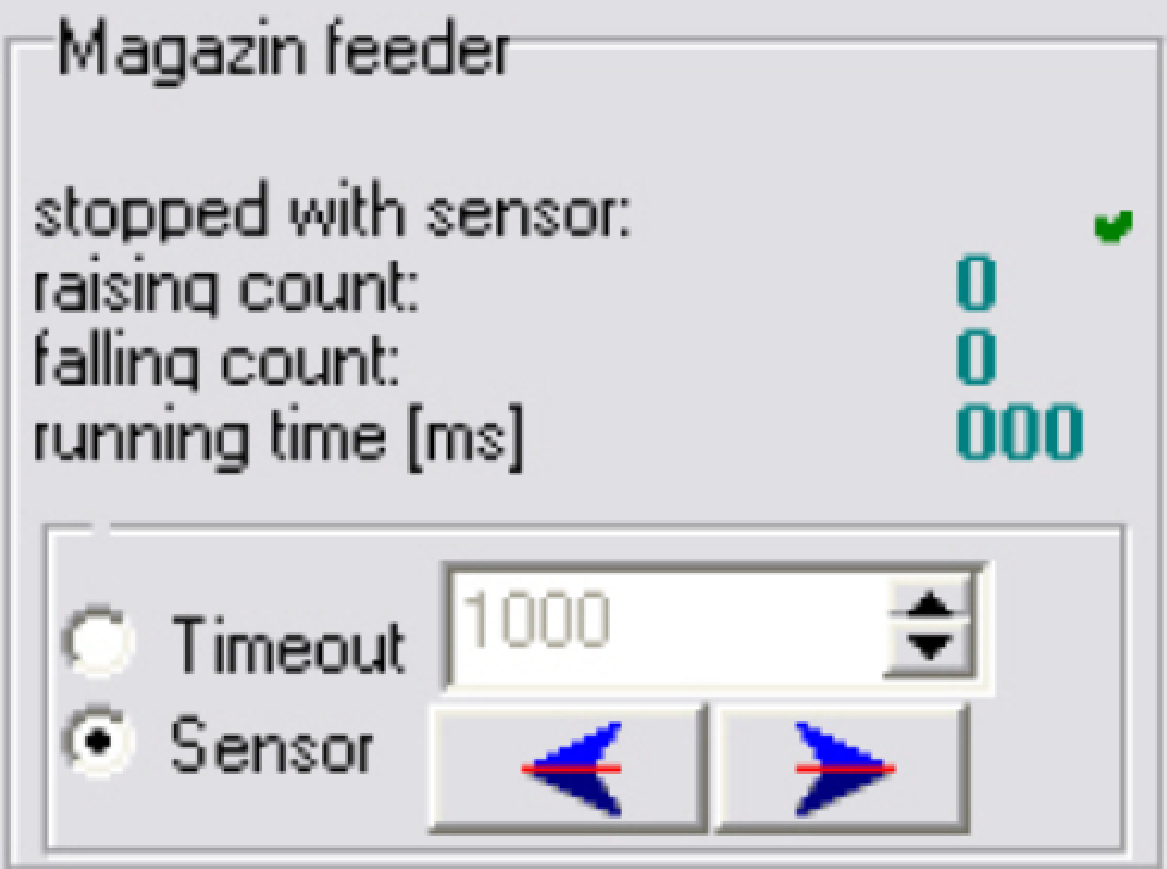

The Magazine

feeder unit moves the

magazine in the feeder channel by the help of the feeder DC-motor with drive.

The stop event may be:

The Magazine

feeder unit moves the

magazine in the feeder channel by the help of the feeder DC-motor with drive.

The stop event may be:

Sensor: The appropriate sensor will stop the

movement; please refer to:

SCAN: “Magazine feeder unit”; “Magazine feeder channel”

and “Magnet disc”.

P250: “Magazine

feeder unit”; “Magazine

feeder channel” and “Sensor disc”.

Time

out: The motor drive will be

stopped with a time out event.

·

In the numerical field, please type in a run time [ms]

between 1 … 10 000.

·

Start the drive by pressing the appropriate movement

button below.

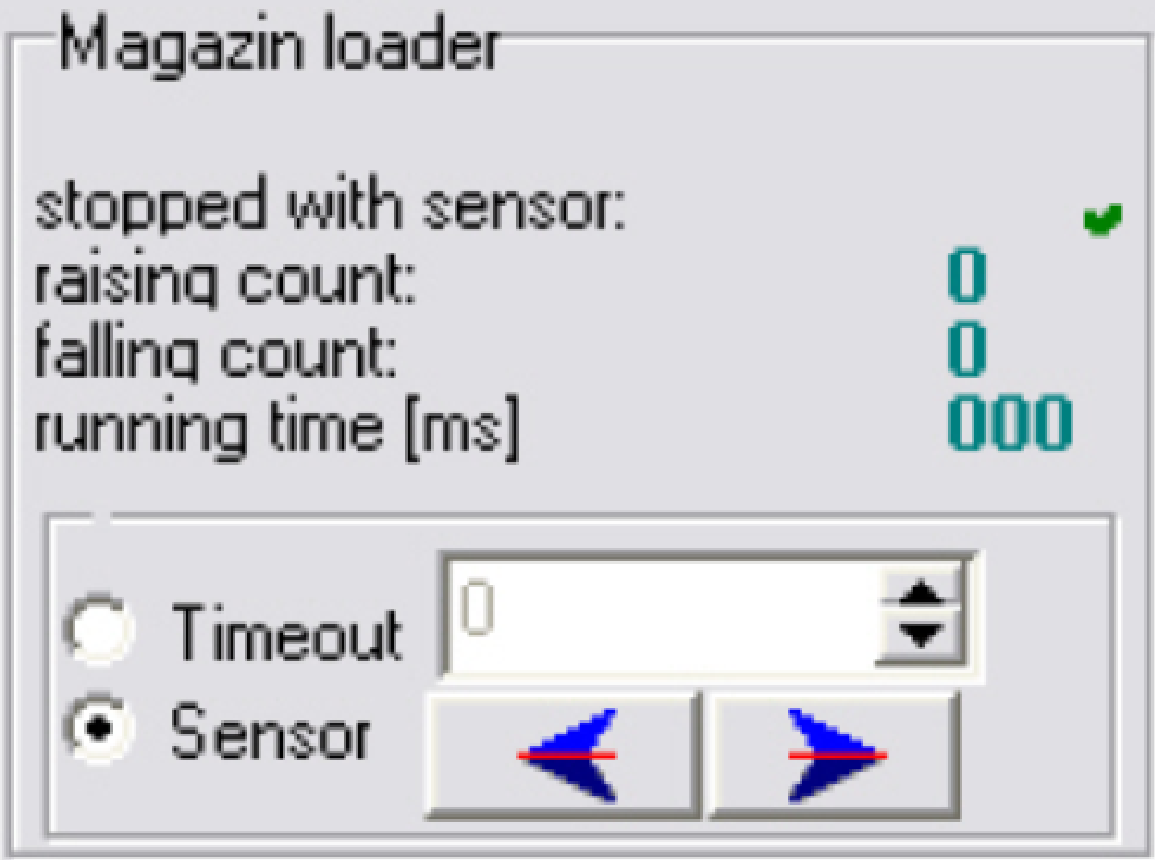

The Magazine

loader unit moves the

magazine from the input stack to the feeder channel and, in the same time, from

the feeder channel to the output stack by the help of the loader motor with

gear. The stop event may be:

The Magazine

loader unit moves the

magazine from the input stack to the feeder channel and, in the same time, from

the feeder channel to the output stack by the help of the loader motor with

gear. The stop event may be:

Sensor: The appropriate sensor will stop the

movement; please refer to:

SCAN: “Magazine load unit” and “Magazine load sensor”.

P250: “Magazine

load unit” and “Magazine

loader sensor”.

Time

out: The motor drive will be

stopped with a time out event.

·

In the numerical field, please type in a run time [ms]

between 1 … 10 000.

·

Start the drive by pressing the appropriate movement

button below.

Important

The backward direction may

create magazine stumble or magazine jamming; bee careful!

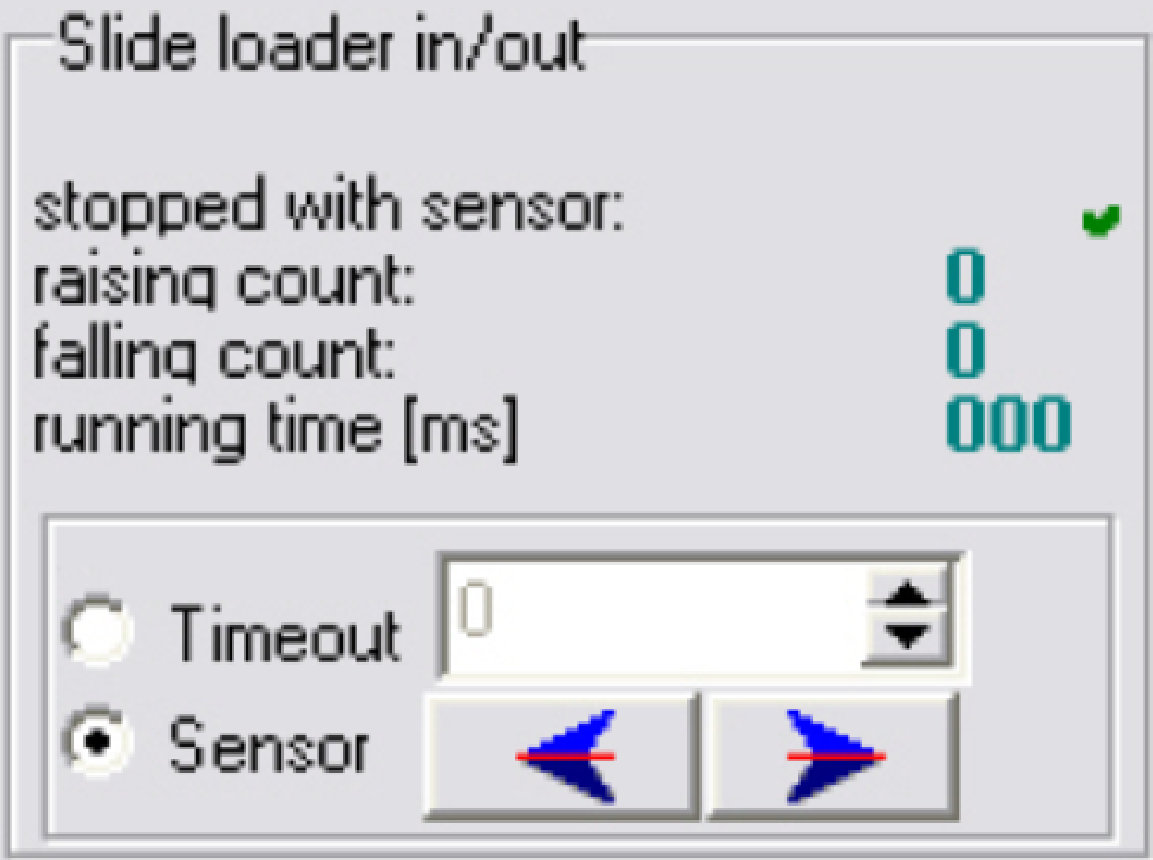

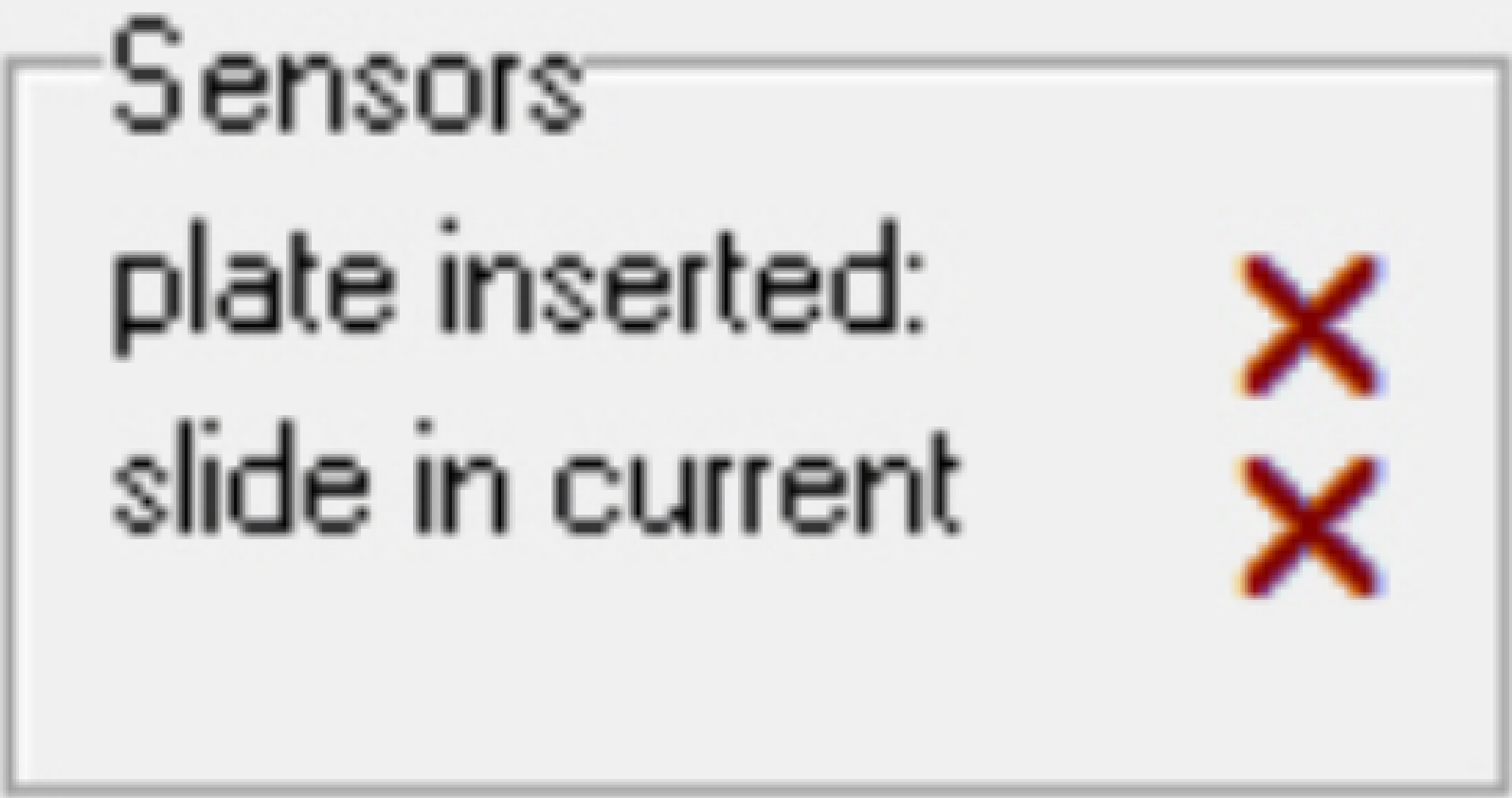

Slide loader

The slide loader unit moves the slide into the specimen

holder or return to the position over the magazine by the help of the slide

loader moveable part. The stop event may be:

The slide loader unit moves the slide into the specimen

holder or return to the position over the magazine by the help of the slide

loader moveable part. The stop event may be:

Sensor: The appropriate sensor will stop the

movement; please refer to:

SCAN: “Slide Loader”

and “Check

the function of the slide loader sensors”.

P250: “Slide

loader” and “Check

slide loader sensors”.

Time

out: The motor drive will be

stopped with a time out event.

·

In the numerical field, please type in a run time [ms]

between 1 … 1200.

·

Start the drive by pressing the appropriate movement

button below.

Important

The value for Timeout should

not exceed 1200ms! The possible value is limited to be 10 000ms by

SSS_software!

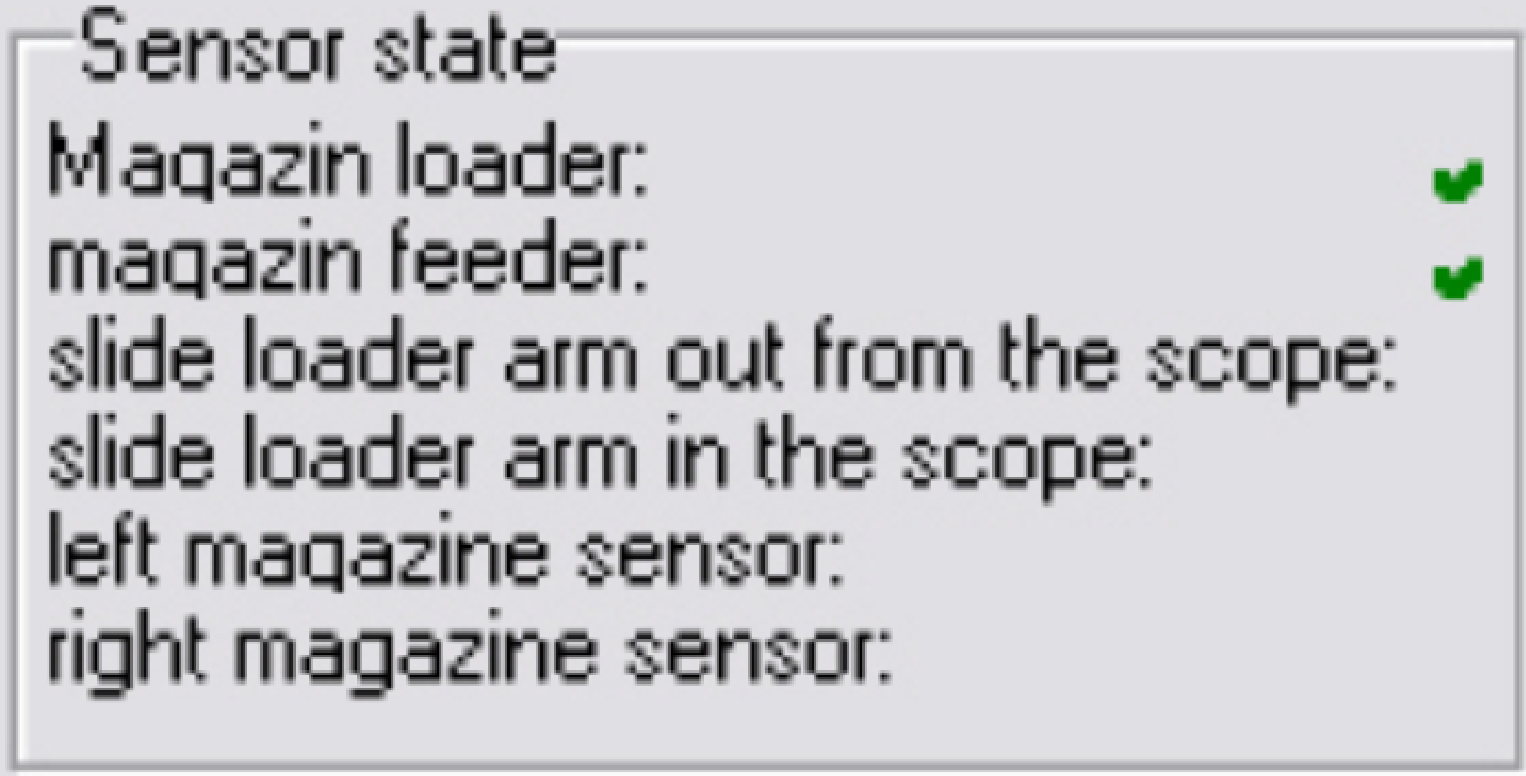

Always the actual

sensor state is shown, if the appropriate unit is in the active state.

Always the actual

sensor state is shown, if the appropriate unit is in the active state.

· The sensor state

of the “Magazine feeder” on the right is shown with the falling edge of the

sensor disc!

Please refer to the following

chapters:

SCAN: “Magazine loader

sensor”, “Magazine feeder

sensor”, “Inner and

outer slide loader sensor”, “Magazine input (left) sensor”

and “Magazine output

(right) sensor”.

P250: “Magazine

loader sensor”, “Magazine feeder

sensor”, “Inner

and outer slide loader sensor”, “Magazine

input (left) sensor” and “Magazine

output (right) sensor”.

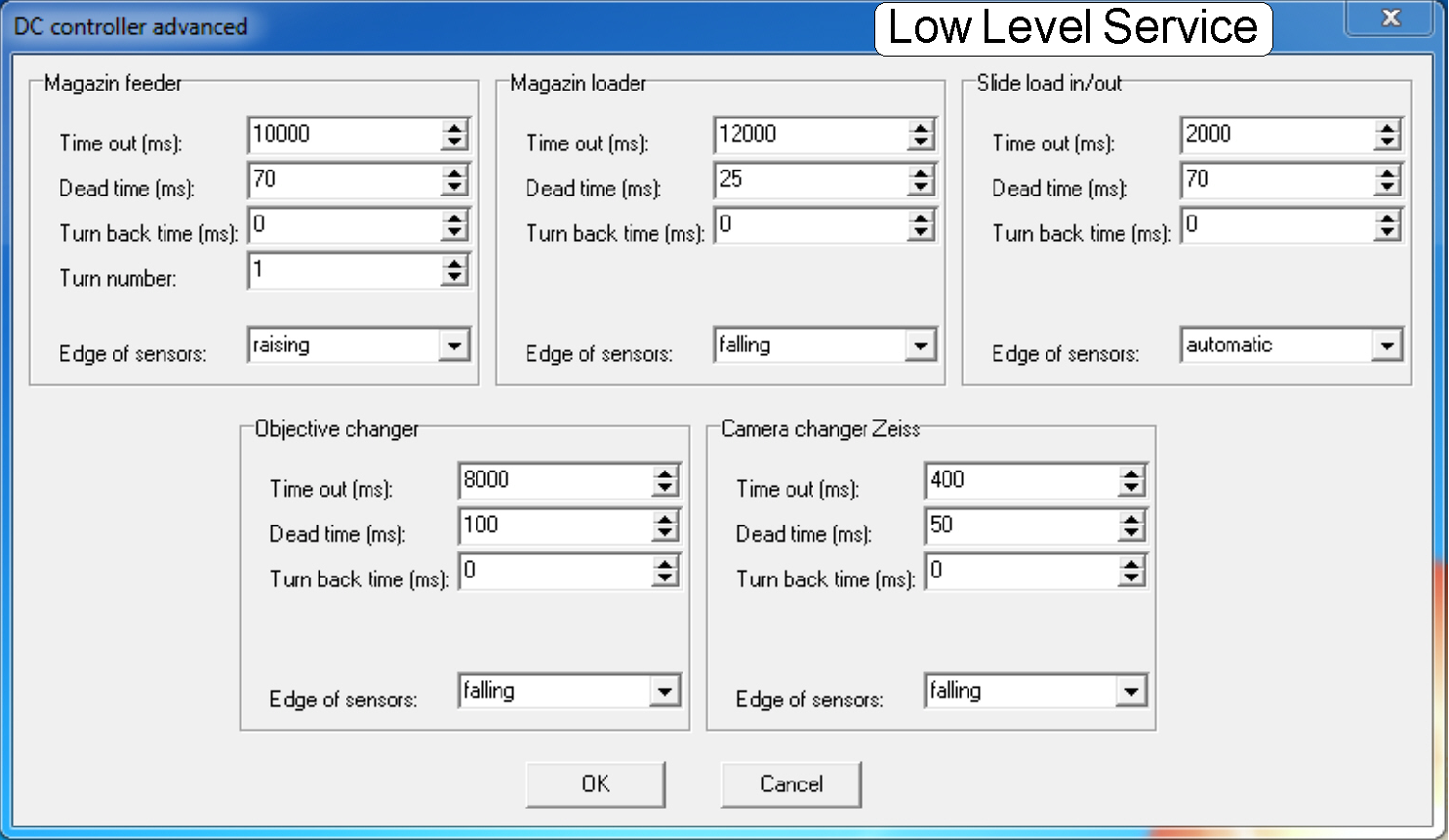

·  This section

defines special conditions, often time out values for DC-motor driven units and

the rising or falling edge of the appropriate sensor.

This section

defines special conditions, often time out values for DC-motor driven units and

the rising or falling edge of the appropriate sensor.

An often used

option is the parameter “Edge of the sensor” in the SCAN and the P250.

An often used

option is the parameter “Edge of the sensor” in the SCAN and the P250.

SCAN: Select

the edge of the feeder sensor as required for the appropriate scanner version,

please refer to: “Magnet disc” and “Define the feeder edge”

P250: In

the P250 always the rising edge of the feeder sensor is used, please refer to: “Set

the feeder rising edge”

Remark:

In the service program, the falling edge of the feeder is

selected by default, after start. Please check and set this option before any

magazine unit adjustments are done!

Please refer to “Global unit control”

See above “USB Controller”

· Please refer to “Flash light

source” and “Optics and

illumination”

· Please refer to “Camera changer unit”

Because the camera

changer mirror rotates exactly by 180º only, and a usual stepper motor

with control electronics is used, the Home2 try count is limited.

Because the camera

changer mirror rotates exactly by 180º only, and a usual stepper motor

with control electronics is used, the Home2 try count is limited.

Important

If the home2 can not be

reached if the Camera changer unit is assembled, please disassemble the motor

from the Camera changer housing, Set the motor to Home1,2 and reassemble the

motor to the housing again.

Procedure

to adjust the home position of the motor

1.

Disassemble

the motor from the housing

2.

Open the dialogue “Camera changer VT Advanced”

3.

Set the “Home2 try count” to 100 and close the

dialogue.

4.

Press the buttons Home1 and Home2

5.

If the rotor stops, press the buttons Home1 and Home2

again

6.

Repeat the previous 2 steps until no movement of the

rotor is expired; may be you have to press Home1,2 four times.

7.

If Home1 and Home2 are pressed and no rotation of the

rotor can be expired, the home position is found; see also the field “Position”

in the image above.

8.

Reassemble

the motor to the housing.

9.

Open the dialogue “Camera changer VT Advanced”

10. Set the “Home2 try

count” to 2 and close the dialogue.

11. Check the home

position again.

12. Mount the adjustment

tools and check

or define the

mirror rotation angle.

See also: “Adjust the Camera

changer unit” and “Adjustment

techniques”

Not used; the unit does not

exist!

· Please refer to “ND-Filter unit”

and “Optics and illumination”

Because the movement range of

the ND-filter disc is exact 1 revolution of the stepper motor, all required positions

can be reached inside of 1 revolution and therefore, a sensor Home2 is not

required.

· Home2 try count is

always inactive; not used.

P250: “Power and control” , “Stepper motor”, “Step control of

stepper motors”, “Calculate the u-time”

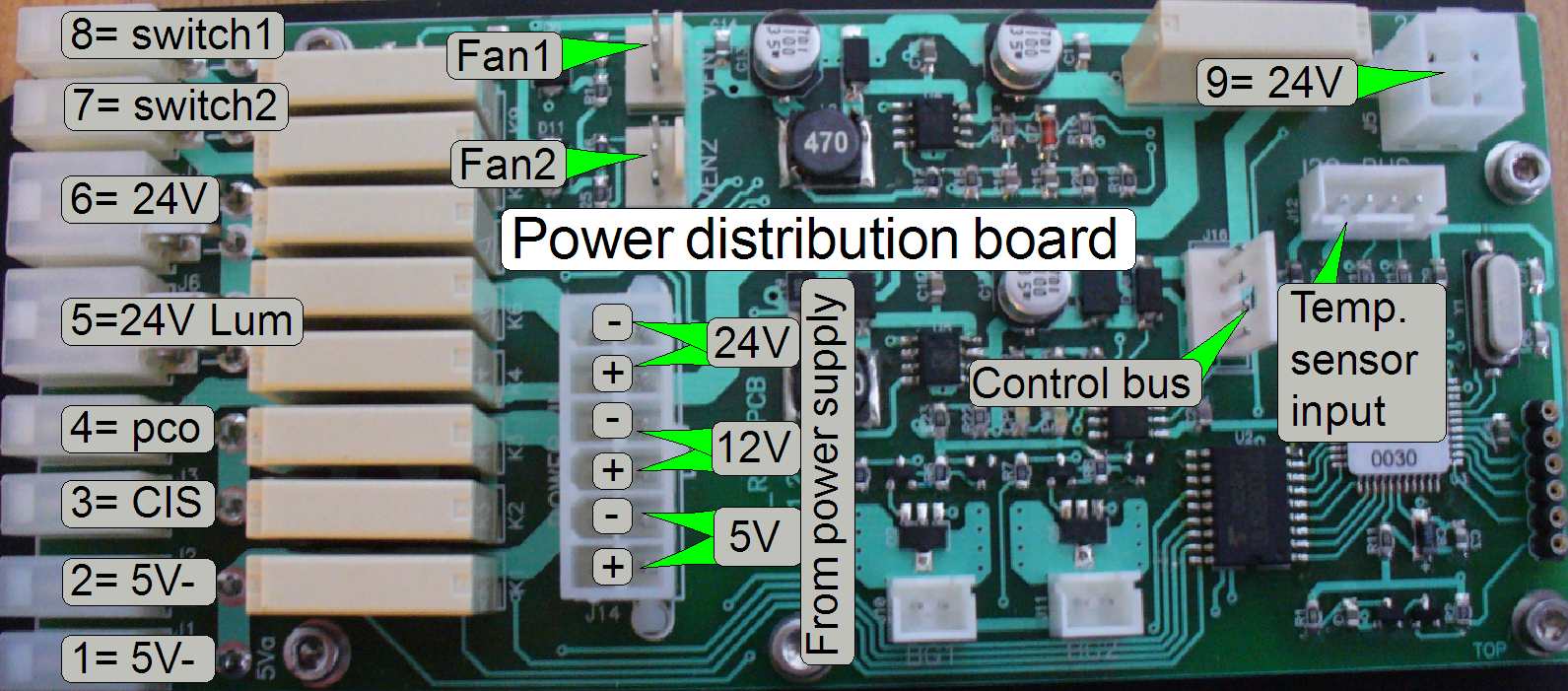

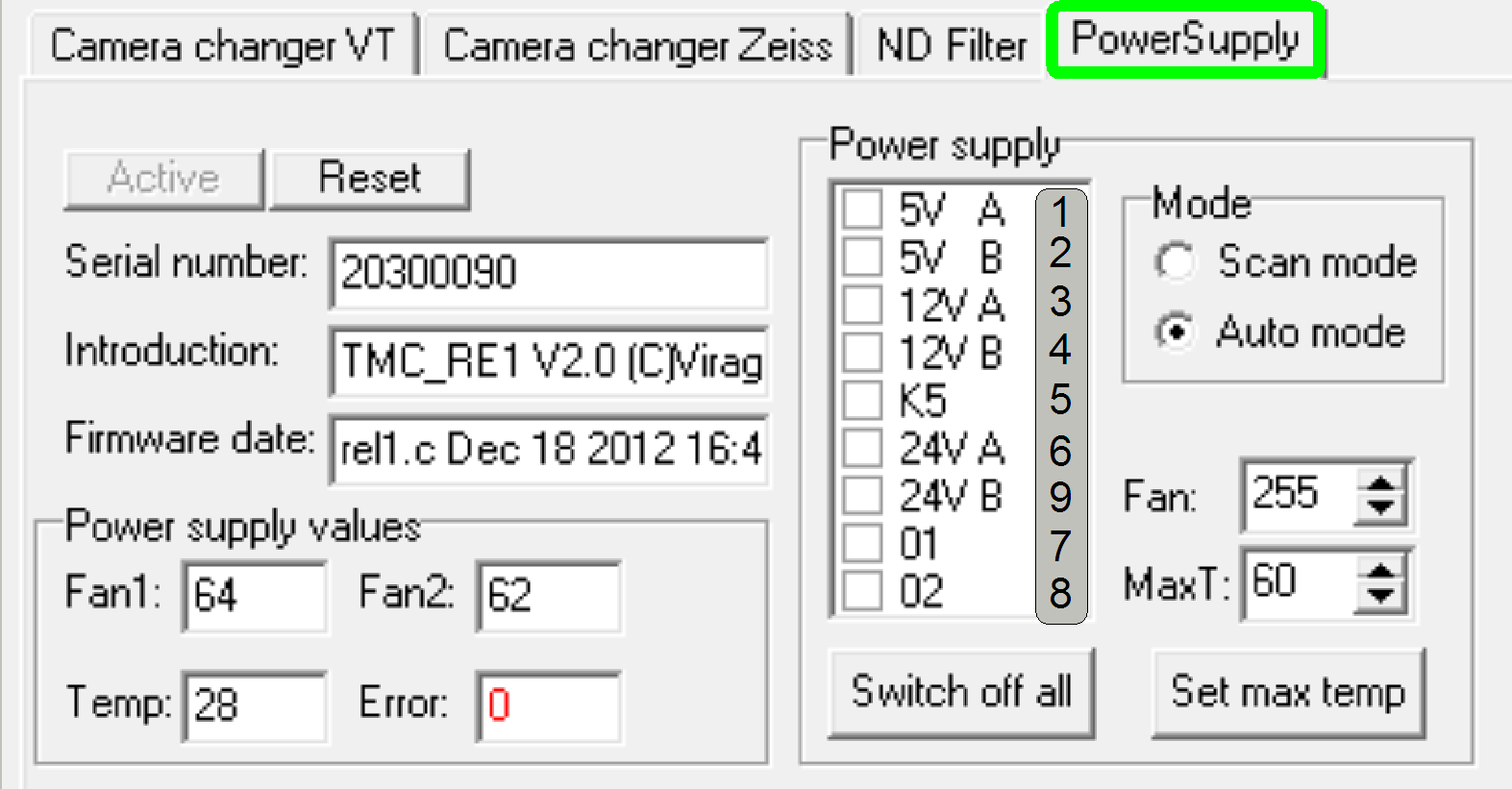

To allow the power to the

appropriate output, please check the relevant checkbox.

· Please refer to “Power and control”, “Power

distribution and switch board” and “Temperature

sensor, fan and fan control”

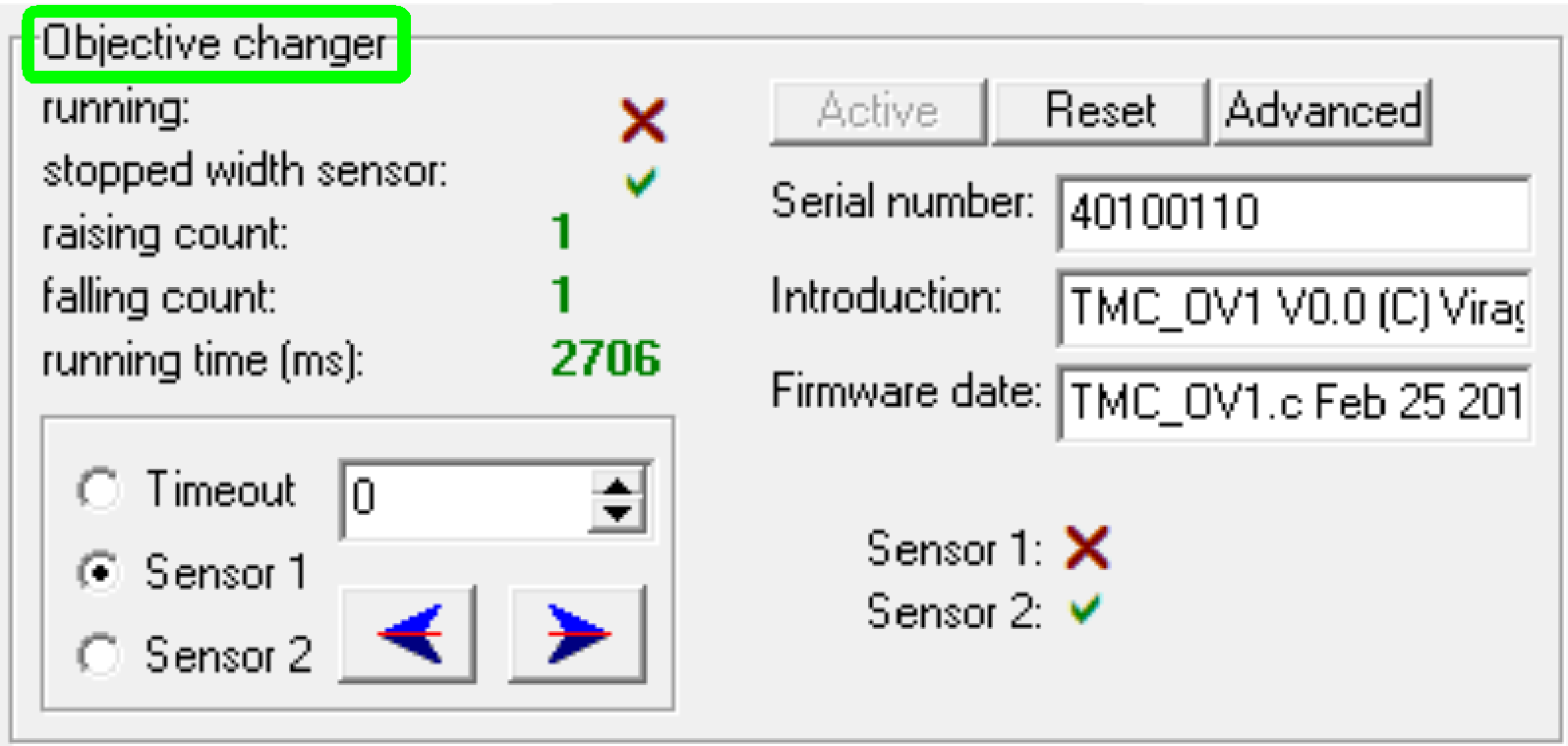

·  Please refer to “Objective changer”

Please refer to “Objective changer”

Tools of

Please refer to “Global unit control”

Move the tray of the

See also: “Precautions”,

“Tray and slide loading”, “Tray”, “Tray conveyor unit”,

“Setup and adjustment procedures”

Please refer to “Global unit control”

Please refer to “Global unit control”

Move the slide into

the specimen holder or return to the tray.

Move the slide into

the specimen holder or return to the tray.

See also: “Precautions”, “Tray and slide loading”, “Principle of support plate and slide loader spreading”, “Slide loader and

support plate mechanics”, “Setup

and adjustment procedures”

Tray not inserted,

therefore, a slide can also not be detected; correct statement

Tray not inserted,

therefore, a slide can also not be detected; correct statement

If a tray is inserted and a

slide is not present in the tray position1

· Sensor position is

adjusted wrong or the mounting bolt is not tightened

· DC-controller not

connected to the USB-controller; check the connection of the cable “DCX-

· Contact fault or

the cables are connected to the opposite (wrong) sensor; check the cables and

positions

· DC-controller

defective or wrong connection of the sensor cables inside the DC-controller.

· Permanent magnet

is missed in the tray.

See also: “Tray sensor”, “Slide sensor”, “DC-controller”

If a tray is inserted and a

slide is present in the tray position1

· Tray and slide

recognized; correct statement

If the tray is not inserted

· None of the

sensors connected

· Contact fault;

check the cables

· DC-controller

defective or no connection of the sensor cables inside the DC-controller.

See also: “Tray sensor”, “Slide sensor”, “DC-controller”

If the tray is inserted and

no slide in the tray position 1

· Incorrect sensor

connection; exchange the cable connection of the cables HAG-1 and HAG-2 on the

sensor side or in the DC-controller.

See also: “Tray sensor”, “Slide sensor”, “DC-controller”

The shown sensor

state is correct, if a tray is inserted and a slide is not present in the first

slide bay.

The shown sensor

state is correct, if a tray is inserted and a slide is not present in the first

slide bay.

If a slide is present in the

position 1, probably errors may be:

· The slide is too

short; check the functionality of the sensor.

· Slide sensor not

connected or contact faulty cable.

· Slide sensor is

connected to a wrong connector position inside the DC-controller

· Slide sensor not

adjusted well, even if the shortest allowed slide is inserted.

· DC-controller

defective.

· Permanent magnet

is missed in the slide sensor.

See also: “Tray

sensor”, “Slide

sensor”, “Adjust tray sensor position”, “Adjust slide sensor position”, “DC-controller”

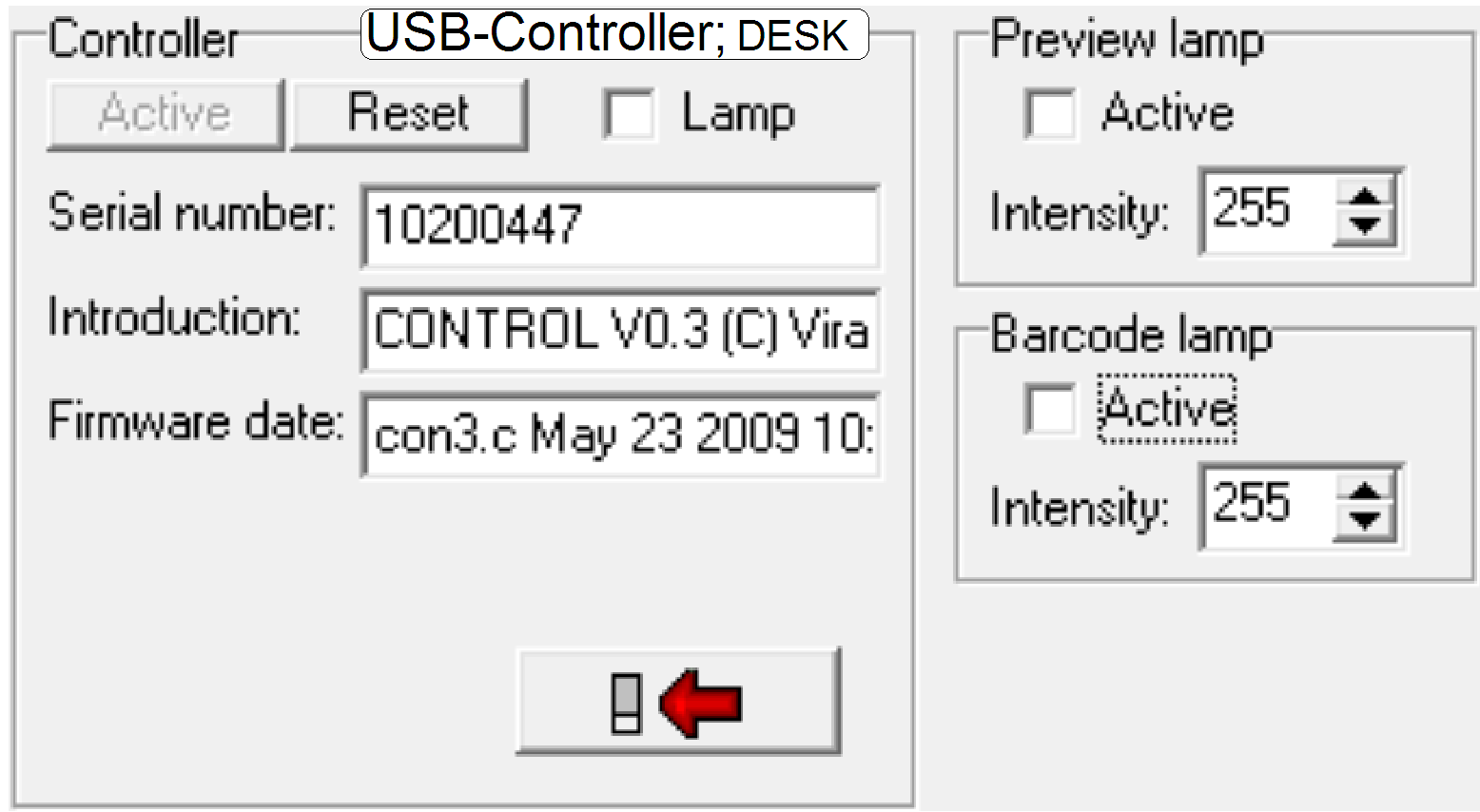

If the DESK is recognized all the units not

used in the DESK are disabled or not shown.

If the DESK is recognized all the units not

used in the DESK are disabled or not shown.

Please refer to “Global unit control”

Lamp:

Check the working of the main

camera’s brightfield illumination,

The

“Background Intensity” is used to test or check the Preview illumination.

·

Check the checkbox “Active” and

·

Type in a numerical value between 1 and

·

See also “USB- and

DC-controlling” and “Preview

illumination”.

The

“Barcode Lamp Intensity” is used to test or check the barcode illumination.

·

Check the checkbox “Active” and

·

Type in a numerical value between 1 and

·

See also “USB- and

DC-controlling” and “Barcode

illumination”.

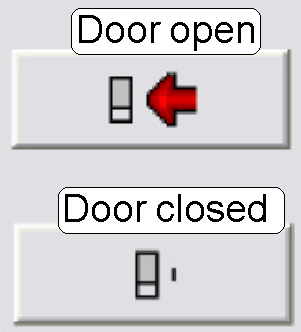

The

state of the door (sensor) is shown with these two symbols on the

right.

For more information see:

·

“USB- and DC-controlling”

and “Hall sensors”.

· “Housing and construction” and “Adjust the door sensor

position”

· Possible

only since the software version 1.18

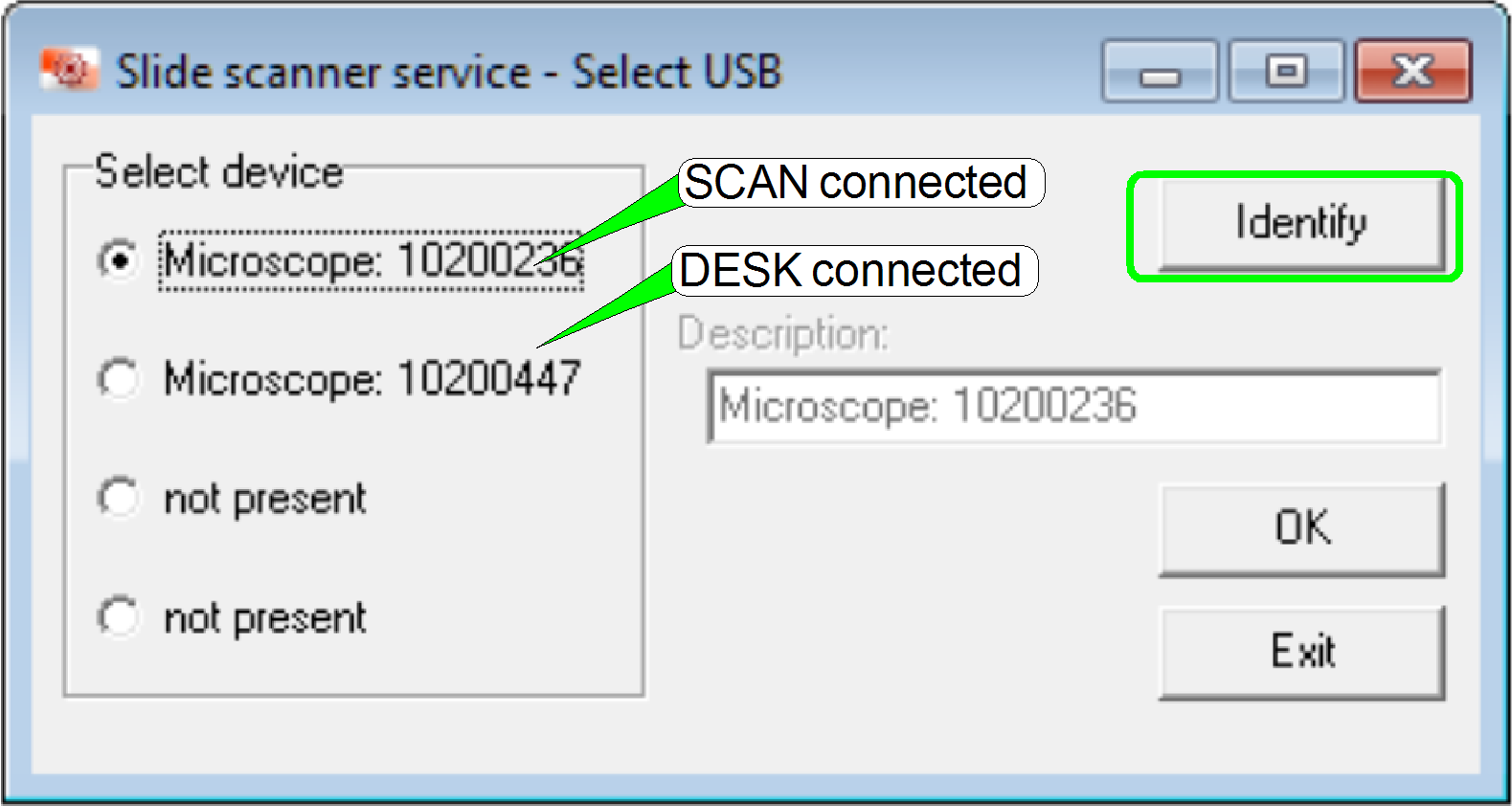

After the Low

Level Service part (LLS) is started and there are more USB controllers

connected, the dialogue “Select USB” is opened.

After the Low

Level Service part (LLS) is started and there are more USB controllers

connected, the dialogue “Select USB” is opened.

If an USB connection between

USB controller and the computer exists, the serial number of the found USB

controller is shown and used to identify the connected scanner or units.

By pressing “OK” the

activated LLS part will be opened for the selected controller.

If two USB controllers are

connected, the corresponding ini-file of the second unit should be located in a

different folder; e.g. “UnitTest”

Example:

· C:\ProgramData\3DHISTECH\SlideScanner\MicroscopeConfiguration.ini First unit or scanner

· C:\ProgramData\3DHISTECH\SlideScanner\UnitTest\MicroscopeConfiguration.ini Second unit

Software version 1.18; Pannoramic

SCAN with objective changer

Software version 1.18; Pannoramic

SCAN with objective changer

[Microscope]

MicroscopeType=3DMic11

LoaderType=SL_6Mag_25Slide_NoSensor_Vertical_2CameraChangerType=CC_None; VT_Type Camera changer not present; but a manual camera changer may existReflectorTurretType=RT_3DH_10Pos_Gears; Gear driven RTU presentBrightfieldLightSourceType=BLS_Halogen_5W; Brightfield illumination type; in opposite to the P250ObjectiveChangerType=OC_2Pos; Objective changer unit as used in the P250; focus unit is the same as described in the S_M_D focus unit. ObjectGuideXYZType=OGXYZ_1.0mm; the nominal slide thickness is 1.0mm; see also: SCAN; slide dimensionsFlashUnitType=NoFlashUnit; Flash light illumination not present; NDFilterType=ND_NonePreviewLightType=PreviewLightUnitType_Type3; Camera Vrmagic and tamron objective; see also: Preview_S_M_DPowerSwitchBoardType=PowerSwitchBoard_None

[Focus]NoFocusPinOnTheObjectHolderX=29600; X-stage position during objective change procedureNoFocusPinOnTheObjectHolderY=18000; Y-stage position during objective change procedure

[ObjectiveChanger]ObjectiveChangerTimeout=7000; Time out value during a half revolution of the objective disc movement

Software version 1.18; MicroscopeConfiguration.ini

(

[Microscope]

MicroscopeType=3DMic10; The

difference to the SCAN with objective changer

LoaderType=SL_1Mag_12Slide_Sensor_Horizontal

CameraChangerType=CC_None

ReflectorTurretType=RT_3DH_10Pos_Gears

BrightfieldLightSourceType=BLS_Halogen_5W

ObjectiveChangerType=OC_2Pos

ObjectGuideXYZType=OGXYZ_1.0mm

FlashUnitType=NoFlashUnit

NDFilterType=ND_None

PreviewLightType=PreviewLightUnitType_Type3

PowerSwitchBoardType=PowerSwitchBoard_None

[Focus]

NoFocusPinOnTheObjectHolderX=26000; X-stage position during objective change procedure

NoFocusPinOnTheObjectHolderY=18000; Y-stage position during objective change procedure

[ObjectiveChanger]

ObjectiveChangerTimeout=7000