USB and DC control;

D_II

For technicians and partly for sales managers!

The following description handles the electronics and electrical

components and cabling, used in the Pannoramic scanner DESK_II.

Contents

Important remark

·

After maintenance or

services and performed tests of the scanner are 100% finished, protective

ground connections and other safety regulations related to hazardous voltages,

accessible conductive parts and dangerous to life parts have to be checked

(again).

·

For safety regulations regarding

human health and scanner functionality please refer to: Precautions

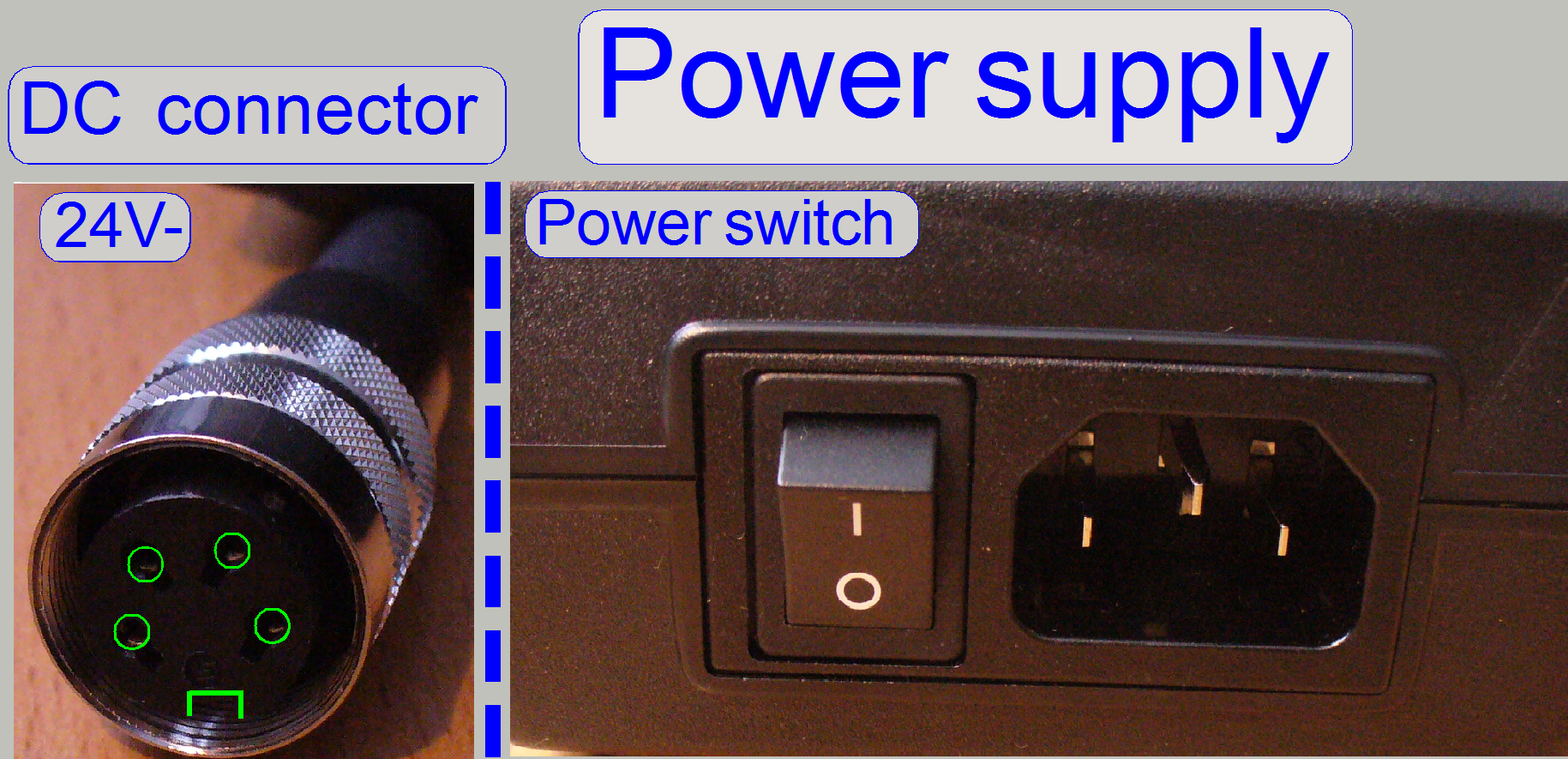

The connected power supply

MPU 100-108 with an input

voltage range of 100V~ to 240V~ AC and an output voltage of 24V- DC

supplies the motors and other internal units with power. Inside the

USB-controller, the DC-controller as well as in the stepper motor electronics a

local power supply is located and these create further, required voltages.

·

The power switch can also be used to switch off the

entire scanner if mechanical jamming or any other emergency situation occurs!

Important

230V~

or 100V~

The alteration of the mains power input in the range from 100V~ to 240V~

is reduced to the use of the appropriate mains power cable!

If the mains power is changed from 230V~ to 100V~ or vice versa, no

alterations are required inside the scanner; the change of the mains power is

fully handled by the input voltage range of the power supply.

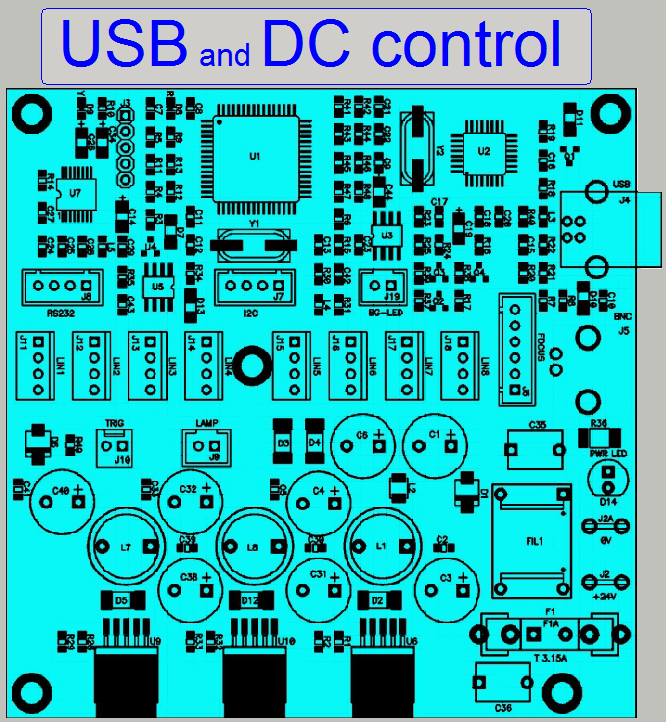

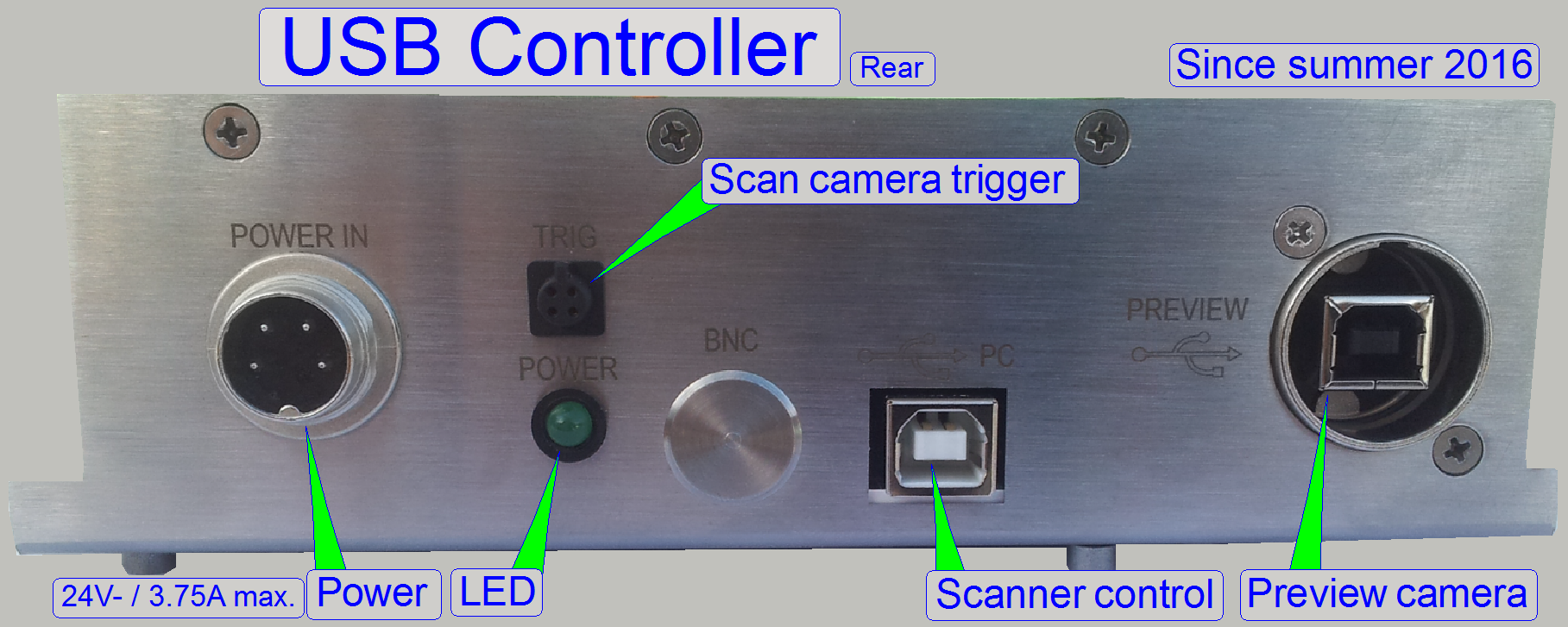

USB Controller

Modifications since summer 20116

Modifications since summer 20116

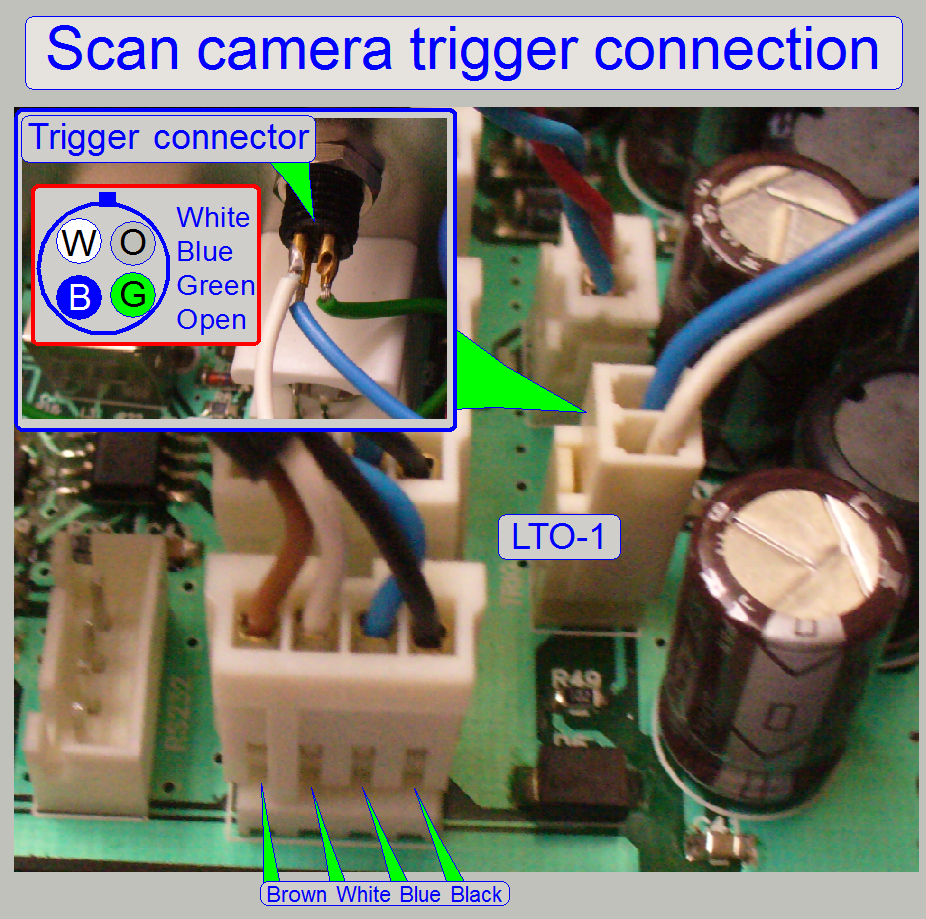

The BNC connector is left out and the trigger cable connector works for the

scan camera, especially for the

“Grasshopper3”.

The connector for the preview camera is always a USB 2.0 B-Type

Receptacle.

|

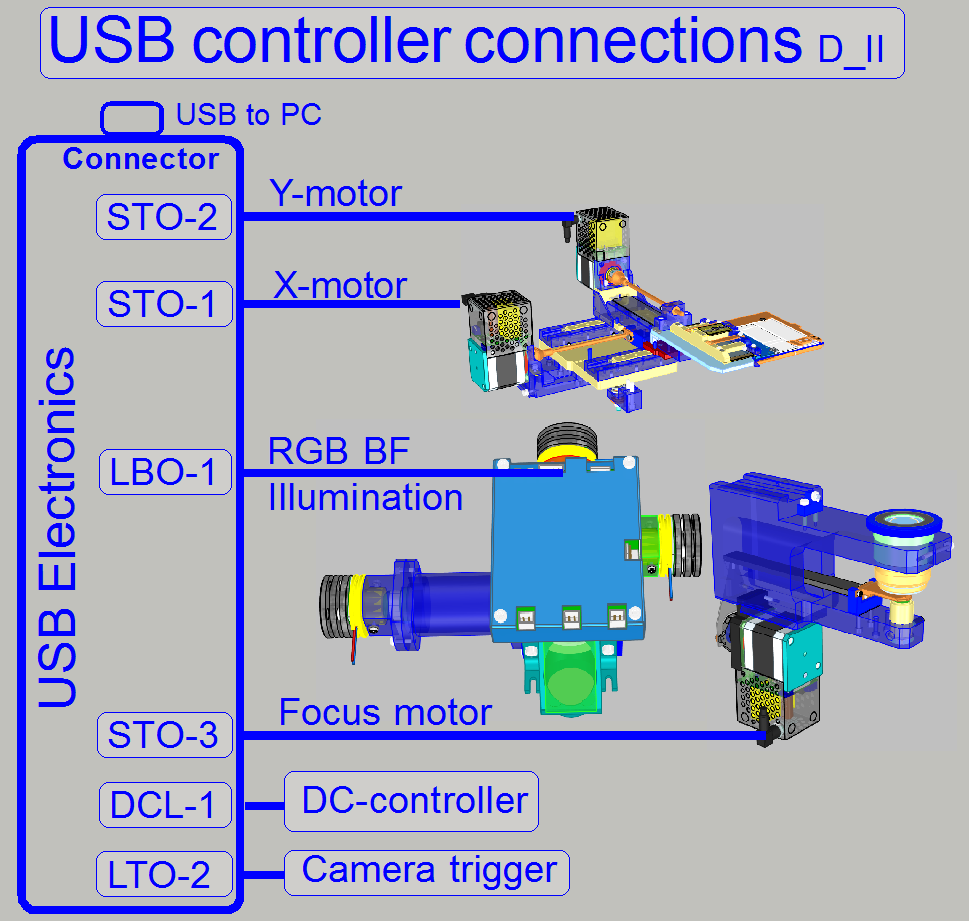

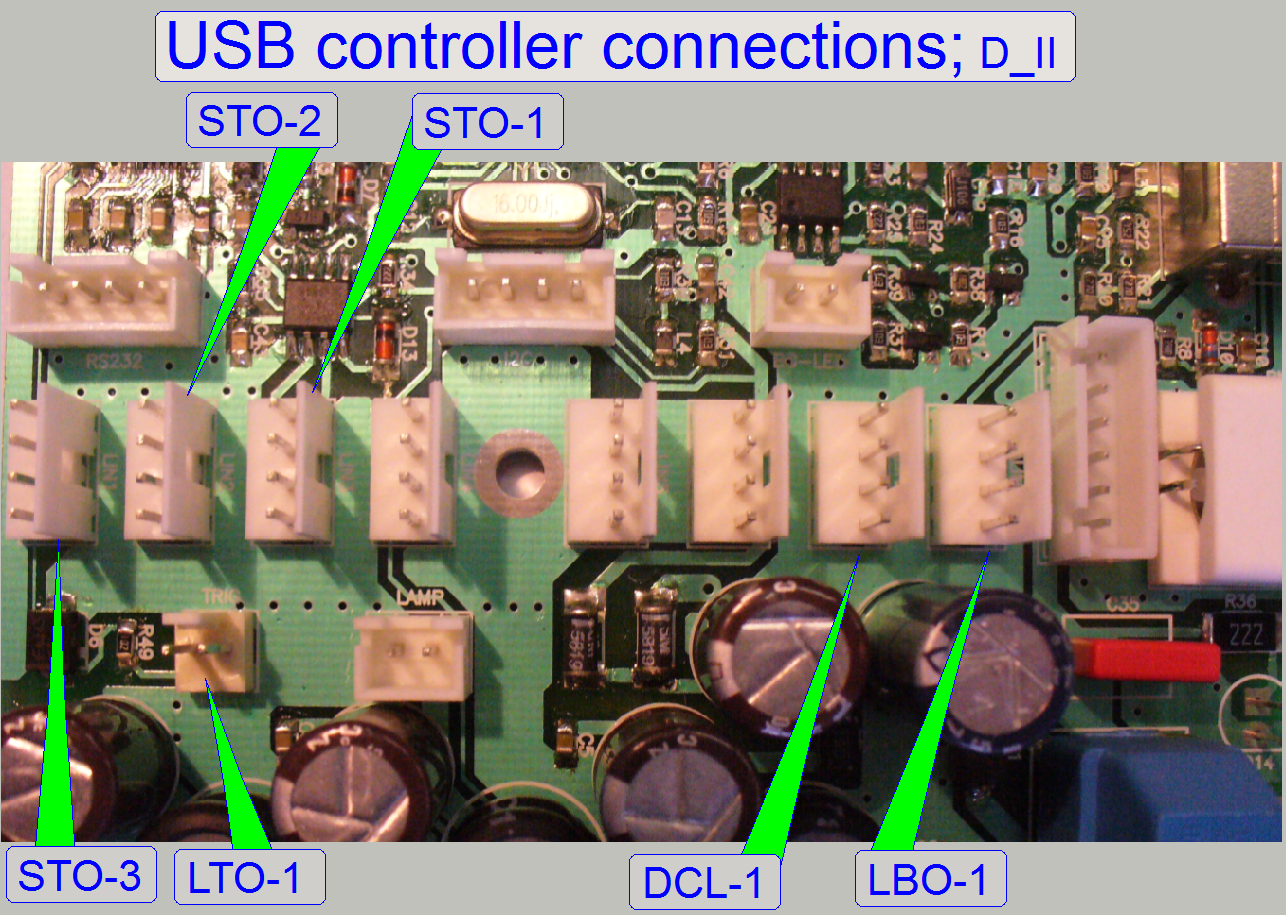

USB controller labels;

summer 2016 |

|||

|

Unit |

SCAN |

|

DESK |

|

RGB BF

illumination |

LBF-1 |

LBG-1 |

LBO-1 |

|

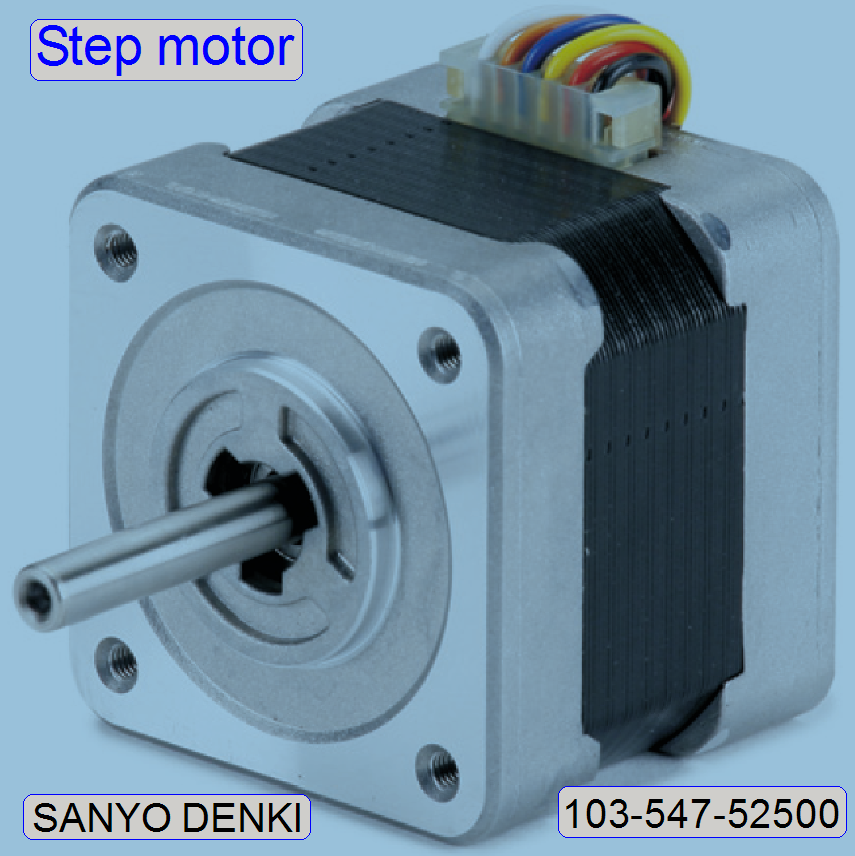

X-Motor |

STF-1 |

STG-1 |

STO-1 |

|

Y-Motor |

STF-2 |

STG-2 |

STO-2 |

|

Z-Motor |

STF-3 |

STG-3 |

STO-3 |

|

DC control |

DCF-1 |

DCG-1 |

DCL-1 |

|

Objective

changer |

DOF-1 |

DOG-1 |

---- |

|

Preview

illumination |

BGF-1 |

BGG-1 |

BGO-1 |

|

Barcode

illumination |

|

|

BGL-O |

|

RGB BF trigger |

LTF-1 |

LTG-1 |

LTO-1 |

|

Tray Loader

motor |

---- |

STG-5 |

---- |

|

Slide loader

motor |

---- |

STG-6 |

---- |

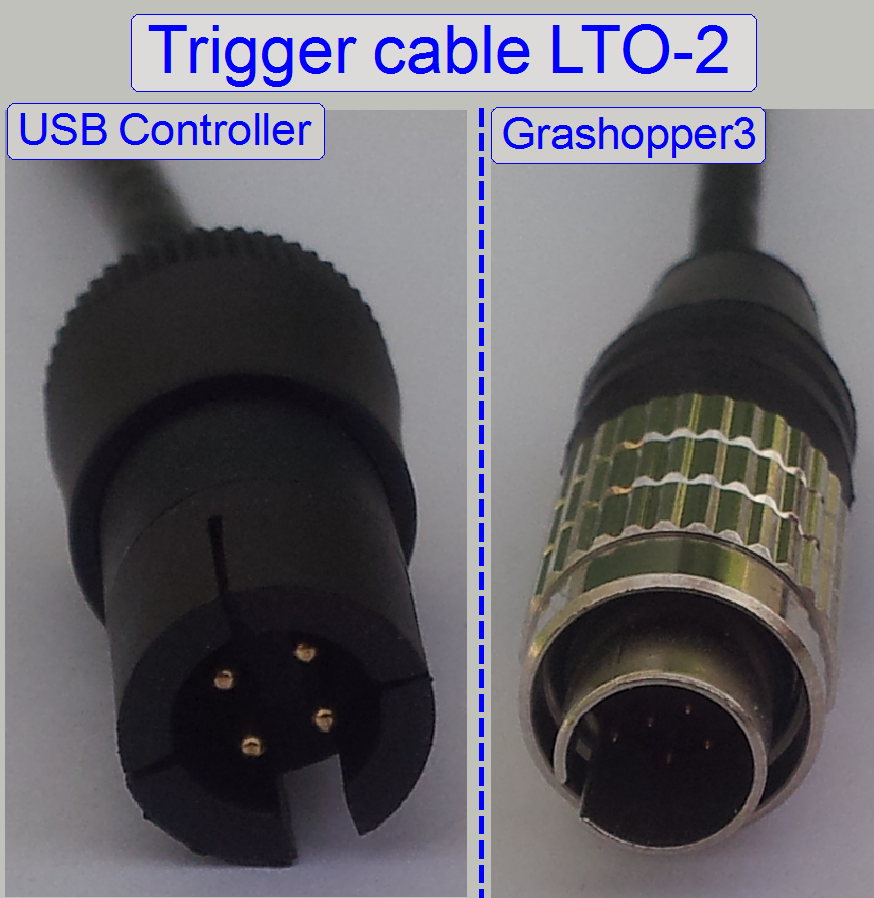

The trigger cable LTO-2 is used during only BF scan procedures (DESK; MIDI_BF,

SCAN_BF) with the camera “Grasshopper3”.

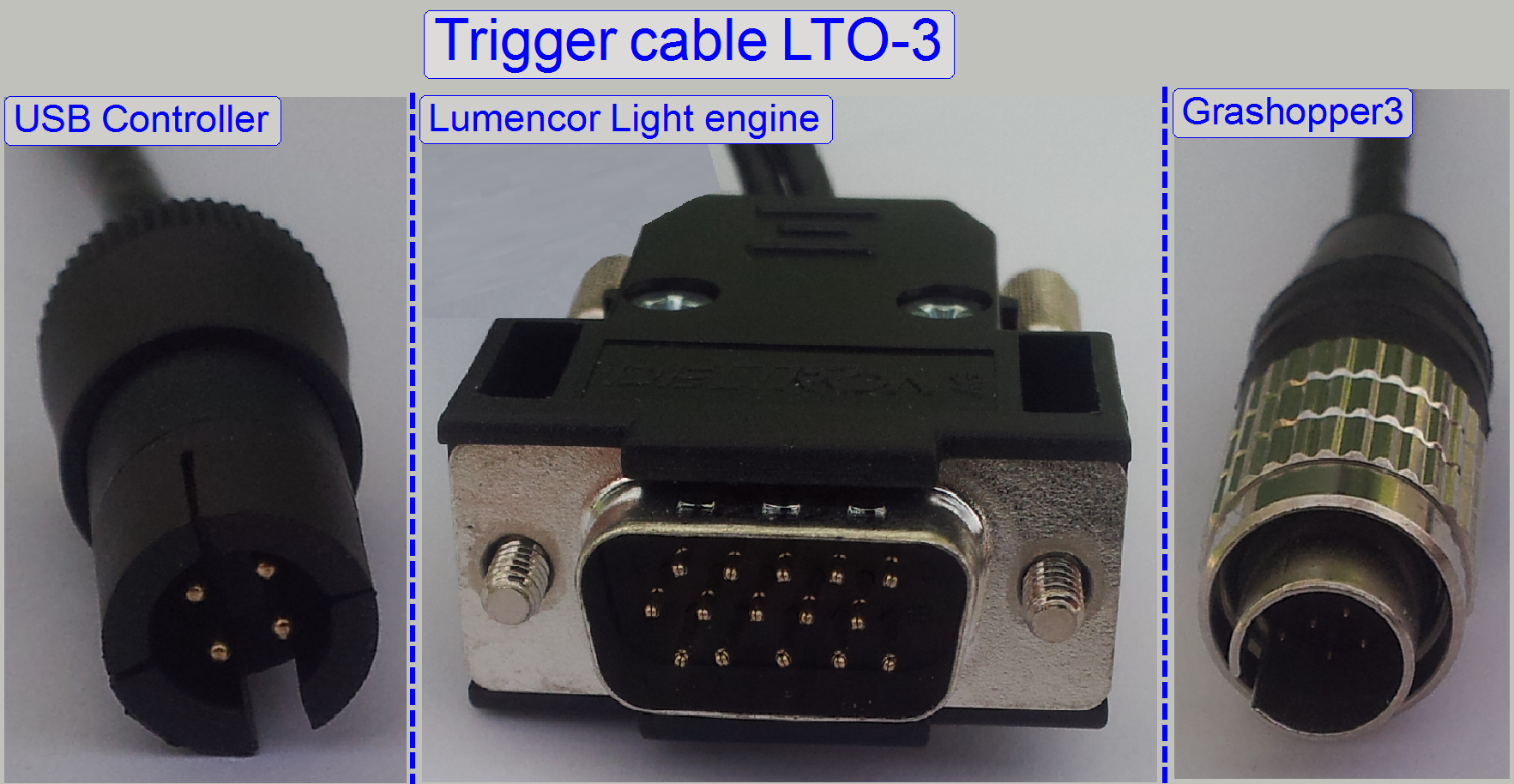

The trigger cable LTO-3 is used during BF and FL scan procedures with

the camera “Grasshopper3” (SCAN,

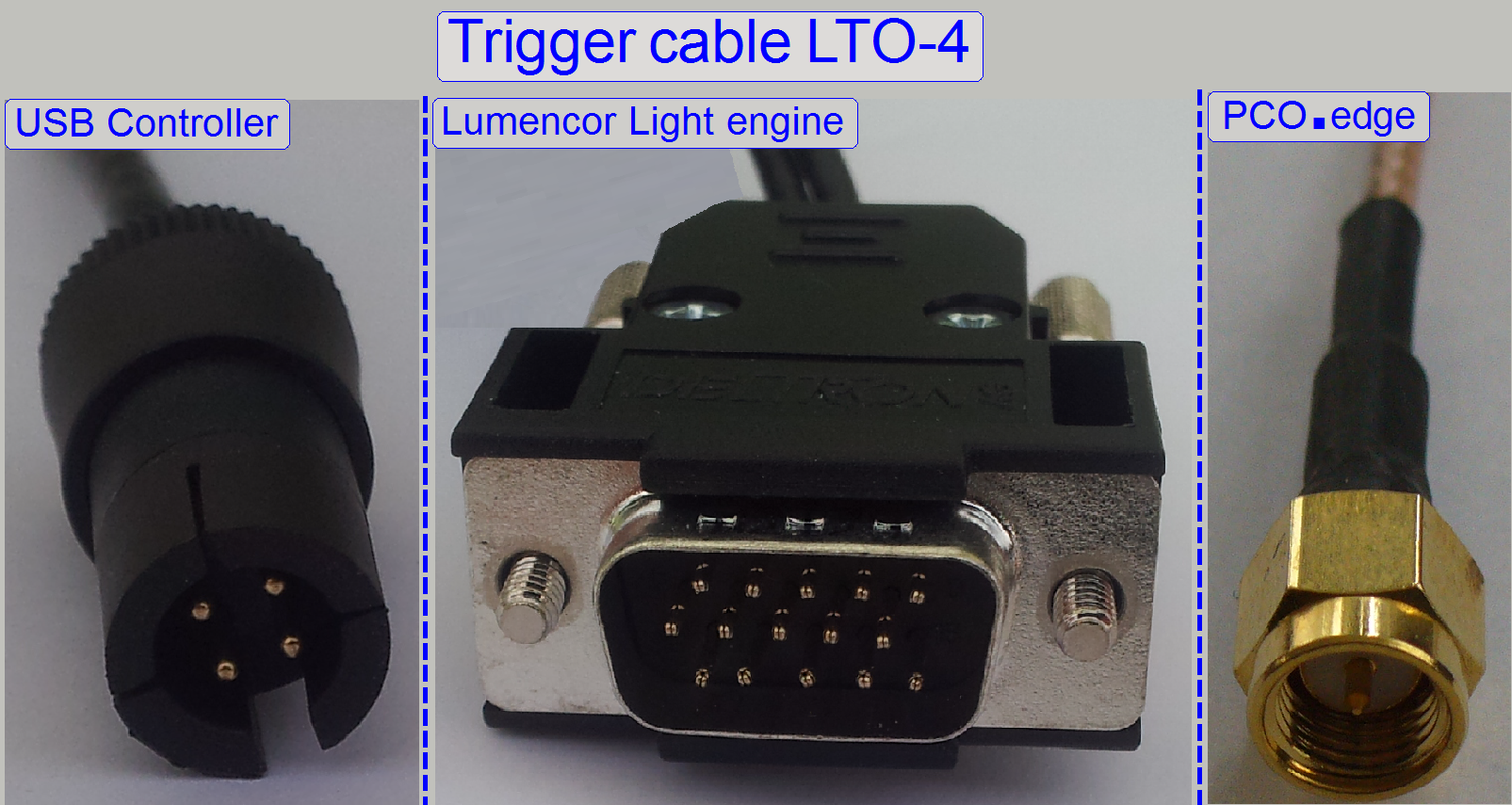

The trigger cable LTO-4 is used during BF and FL scan procedures with the

camera “PCO.edge” (SCAN,

The USB controller receives the command for the units from the program

SlideScanner.exe (the scan program) or the SlideScannerService.exe (the service program) via the Scanner

control port of the PC and the USB cable.

All units that contain separate

electronics (stepper motors and DC-controller) are connected via a bus system.

To differentiate the units, connected to the USB controller, each stepper motor

electronics and the DC-controller as well has an address. Each data transfer

starts with the specified address for the unit and is listen by all units at

the same time, but only this unit receives the message, which internal address

and  the message address is identical. The stepper

electronics can receive commands (number of steps to go and direction) and can

send status information (desired position reached and the status of the sensors

Home1 and Home2). The status information

will be send via the USB cable to the software, hereby the address of the unit

is used also.

the message address is identical. The stepper

electronics can receive commands (number of steps to go and direction) and can

send status information (desired position reached and the status of the sensors

Home1 and Home2). The status information

will be send via the USB cable to the software, hereby the address of the unit

is used also.

With this solution it is possible

to change the stepper motor cable with another stepper motor cable (e.g. for

fault detection) without any risk or functional restrictions. The label of the

cable for digital electronics has no reason in functionality; it differentiates

the cables from each other instead, because some cables are shorter than

others.

Important

The

construction of the controller powering on the board and the power supply does

allow the drive of maximal 2 stepper motors at the same time!

· Please

take this into account, if you are working with the service program and the

batch test program module!

![]() Scanner

cabling and power supply

Scanner

cabling and power supply

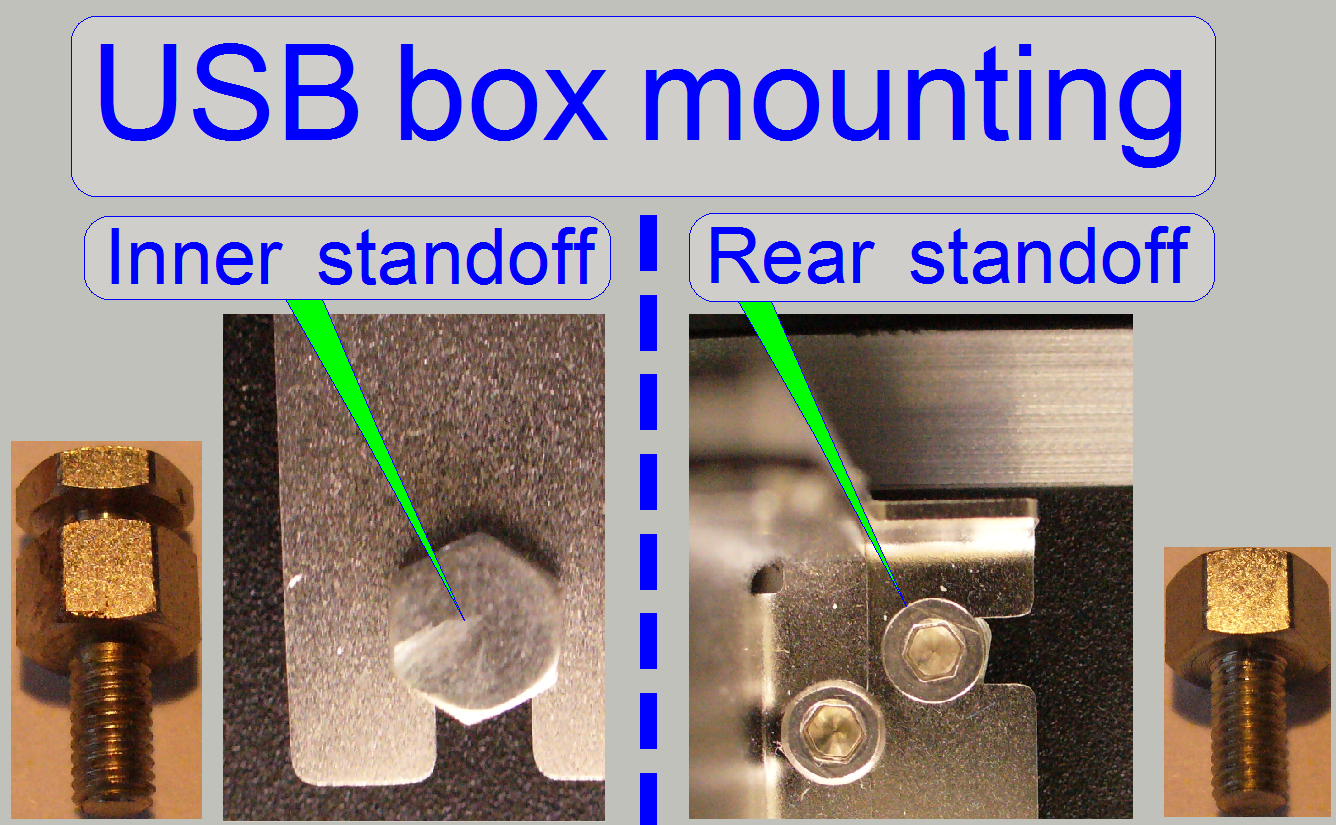

USB- and

DC-electronics box mounting

USB- and

DC-electronics box mounting

To allow an easy exchange of the USB controller box, the inner (not

reachable) standoffs have a slot, in which the unit is shifted in; during the

rear (reachable with the

screw driver) standoffs are fixing the USB- or DC-controller box by using a

bolt.

The trigger connector is used to allow hardware triggering of the scan

camera and the FL illumination unit. Momentarily the camera Grasshopper 3 and

the Lumencor SPECTRA light engine is controlled via this output.

- If the camera

is not recognized after changing the USB controller unit, please check the

correct cabling and the connections as shown on the right.

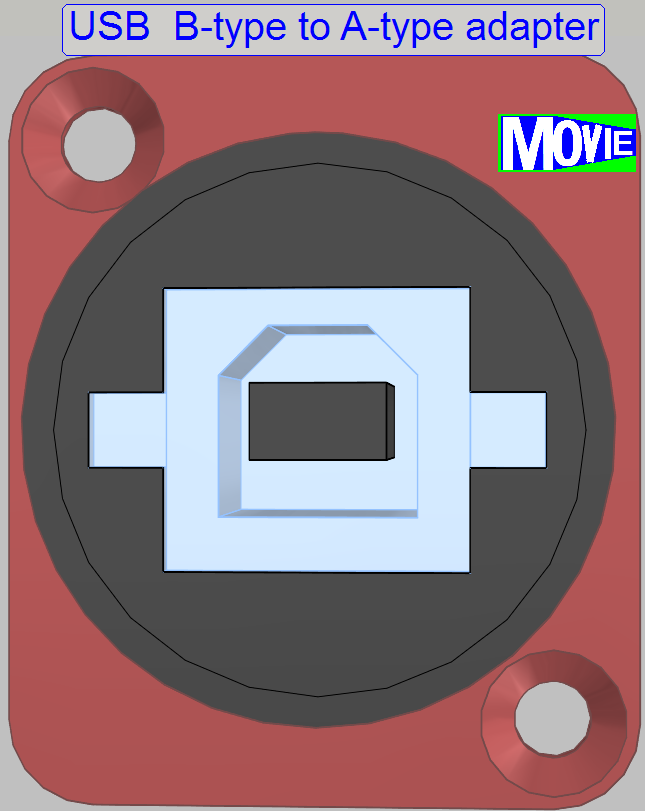

USB B-type to A-type receptacle

The adapter realizes the connection of the

internal A-type plug of the preview camera cable to the USB B-type plug of the

USB cable to the computer.

The adapter realizes the connection of the

internal A-type plug of the preview camera cable to the USB B-type plug of the

USB cable to the computer.

· ![]() “How

to check the preview camera”

“How

to check the preview camera”

|

Address of scanner

unit |

||

|

Unit |

Address |

Type |

|

X-Y-Z

control |

00 |

C_P |

|

USB-controller |

01 |

All |

|

DC-controller |

02 |

P_S_M_D |

|

X-motor |

03 |

S_M_D |

|

Y-motor |

04 |

S_M_D |

|

Z-motor |

05 |

S_M_D |

|

Turret

unit |

06 |

S_M_P |

|

Tray

loader motor |

07 |

M_C |

|

Slide

loader motor |

08 |

M_C |

|

Objective

changer |

09 |

C_P_S_M |

|

Camera

changer |

10 |

P |

|

RGB

BF illumination |

11 |

C_S_M_D_II |

|

Reserve |

12 |

--- |

|

Immersion

liquid unit |

13 |

C |

|

Mechanical

shutter |

14 |

C |

|

Switch

board |

15 |

C_P |

|

Legend:

C=Confocal; P=P250; S=SCAN; M= |

||

The addresses are used by the scan program and the service program to

select the unit; these addresses are programmed into the specified unit and can

be changed via special software only. It is important, that none of these

addresses should exist twice inside of one Pannoramic scanner, otherwise

command or status mismatch occurs.

If data transfer is in progress, all addressable units listen to the

address of the data stream; if the address of the unit is identical with the

address of the data stream, the addressed unit is found and this receives the

information.

![]() “Cabling

of addressable units”

“Cabling

of addressable units”

Address assigning tool Serial.exe and start “Serial.exe”

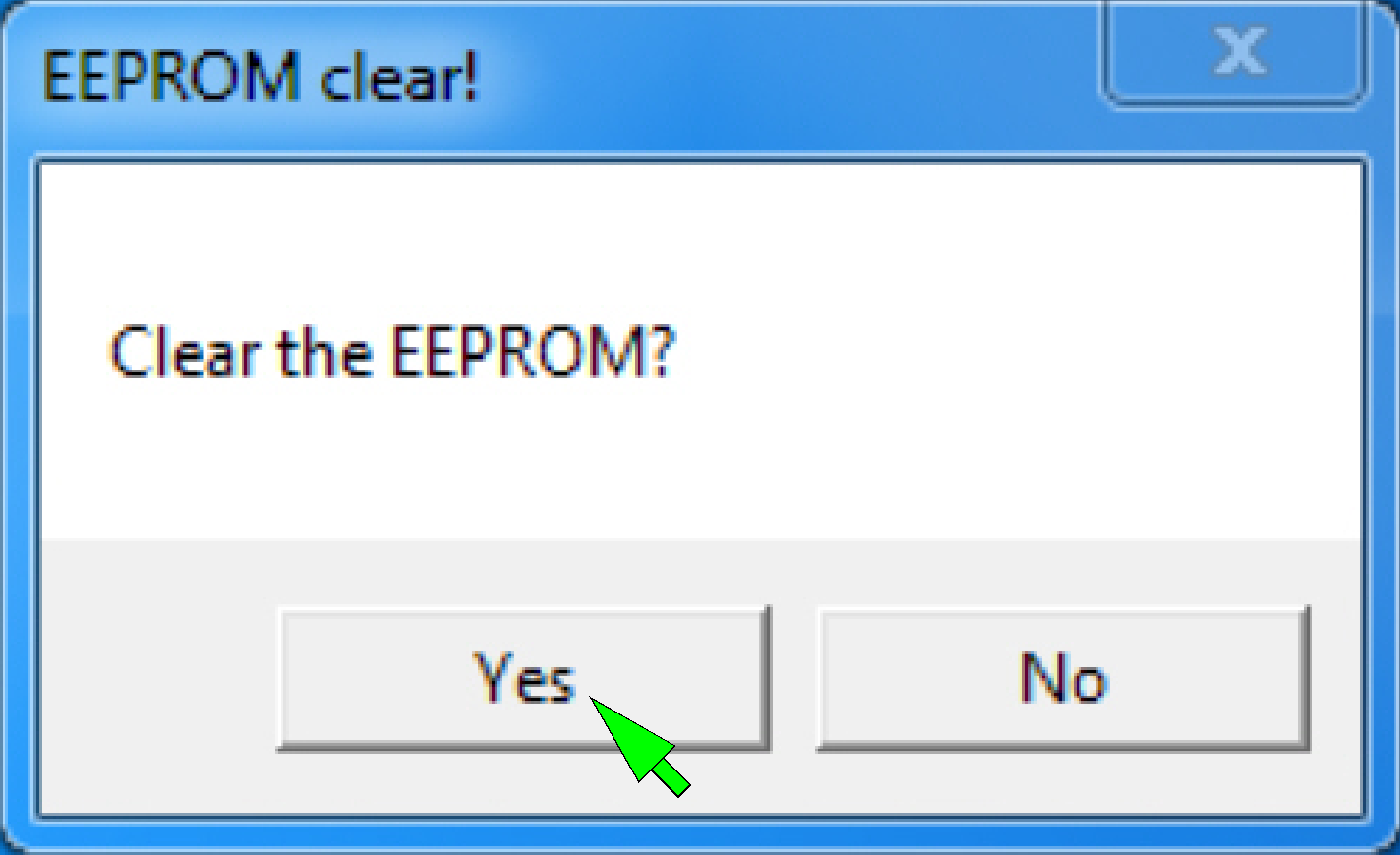

The EEPROM stores the

scanner specific parameters and these are collected in the files

MicroscopeConfiguration.ini and MicroscopeSettings.ini. To ensure an always

proper functioning of the scanner, the content of the EEPROM should be updated

after adjustments are done or units are exchanged and parameter values are

modified. The EEPROM is a part of the USB controllers PCB.

The EEPROM stores the

scanner specific parameters and these are collected in the files

MicroscopeConfiguration.ini and MicroscopeSettings.ini. To ensure an always

proper functioning of the scanner, the content of the EEPROM should be updated

after adjustments are done or units are exchanged and parameter values are

modified. The EEPROM is a part of the USB controllers PCB.

·

To update the content, the EEPROM should be cleared

with the service program.

·

If the scan software is started and the EEPROM is empty,

the content of the appropriate *.ini files will be written automatically from

the HDD into the EEPROM.

1. Start the program

“SlideScannerService.exe”, option “EEPROM clear”.

2. Answer the

dialogue with “Yes”; then the EEPROM is cleared.

3. Exit the service

program with “Exit”

4. Start the program

“SlideScanner.exe”; the *.ini-files will be automatically saved from the

appropriate HDD folder into the EEPROM during startup of the scan program, if

the EEPROM is empty.

![]() “Service program”; clear

EEPROM

“Service program”; clear

EEPROM

Compressed content of the EEPROM (P250, SCAN,

The compression of the EEPROM content is required since the software version

1.16, because there are newly implemented parameters and the capacity of the

EEPROM is limited to be 2kB.

· By compressing the

content, memory space is won.

In systems, delivered with the version 1.16 the modified handling of the

EEPROM content will not be noticed by the user; the files

“MicroscopeConfiguration.ini” and “MicroscopeSettings.ini” staying on the HDD

in uncompressed form.

· If the EEPROM

content is written, the files “MicroscopeConfiguration.ini” and

“MicroscopeSettings.ini” will be compressed before these are stored in the

EEPROM.

· If the EEPROM is

read, the content will be uncompressed before it is stored as file

“MicroscopeConfiguration.ini” and “MicroscopeSettings.ini” on the HDD.

If an upgrade is made (from the version 1.15 or lower to the version

1.16) the content in the EEPROM is uncompressed but the version 1.16 expects a

compressed content; therefore:

Before you are installing the software version 1.16

· Make sure; the

content of the files “MicroscopeConfiguration.ini” and “MicroscopeSettings.ini”

is the most recent content on the HDD.

· Save these files

to a save place

Install the software version 1.16

· Start the program

“SlideScanner.exe” first time.

· The compression of

the EEPROM content will be done automatically.

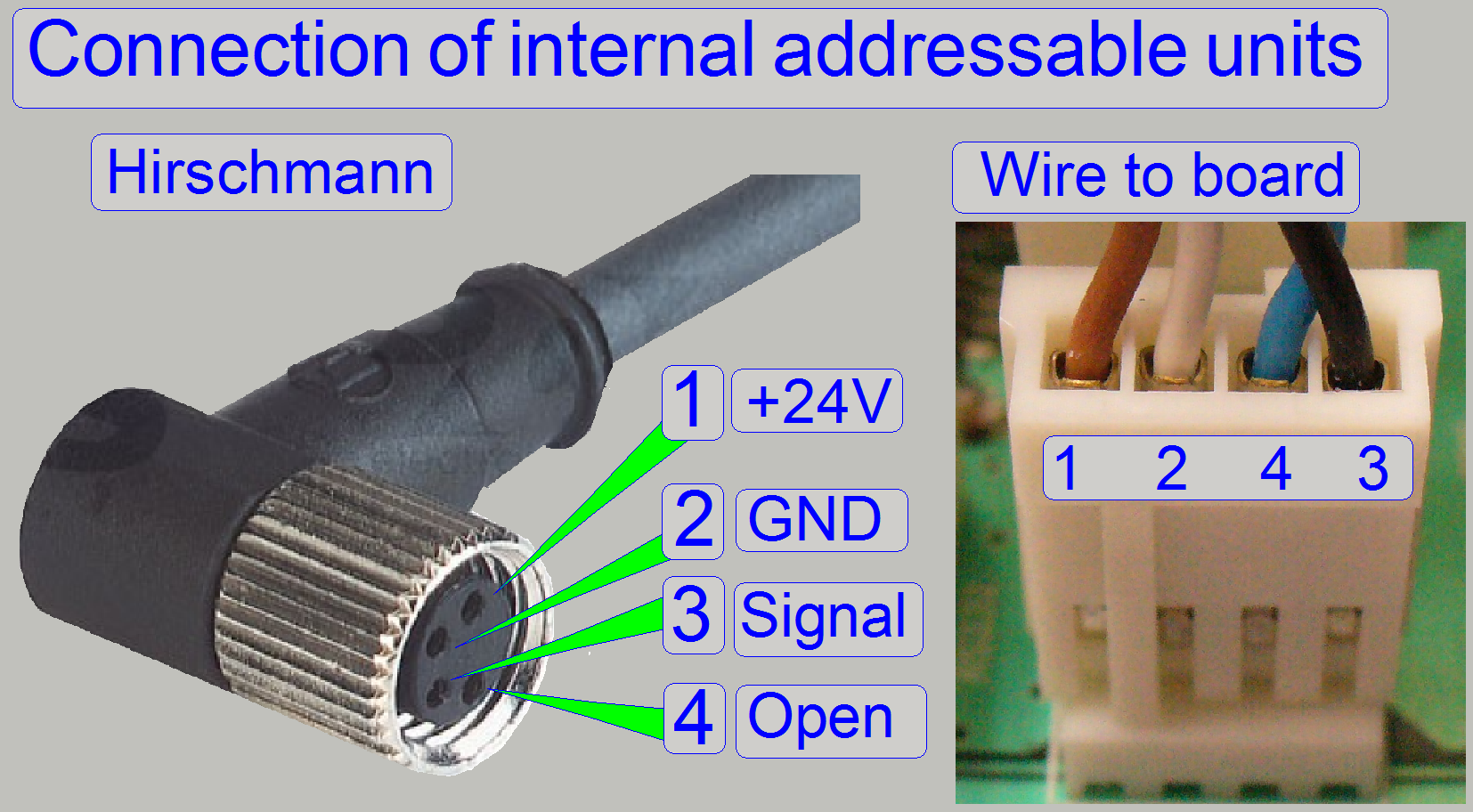

All the addressable units are connected with the “Hirschmann” connector;

the connection is secured with a knurled nut. On the other end of the cable a

“wire to board” connector is used.

Attention

Please switch off the power supply before cable connecting or

disconnecting.

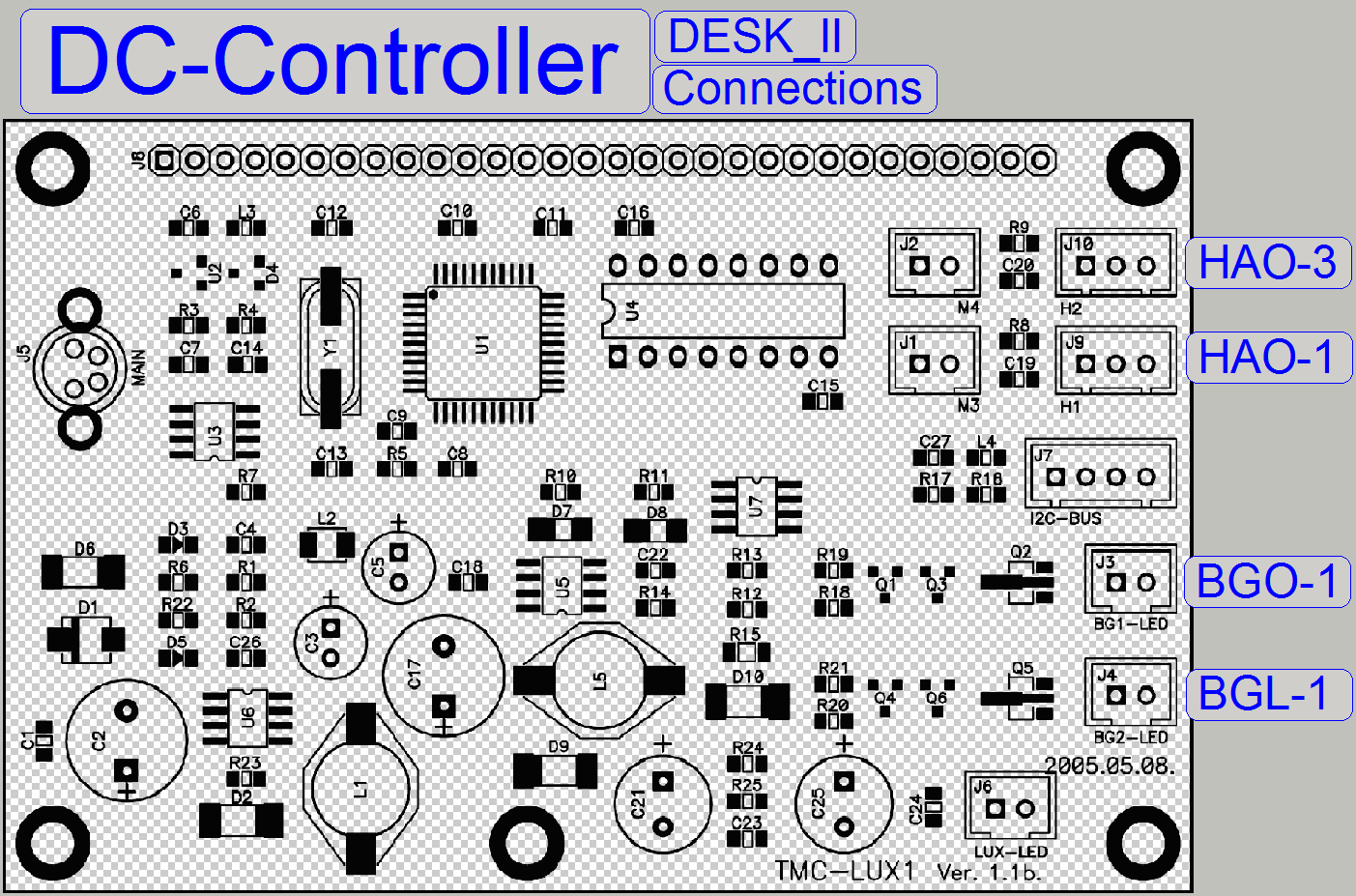

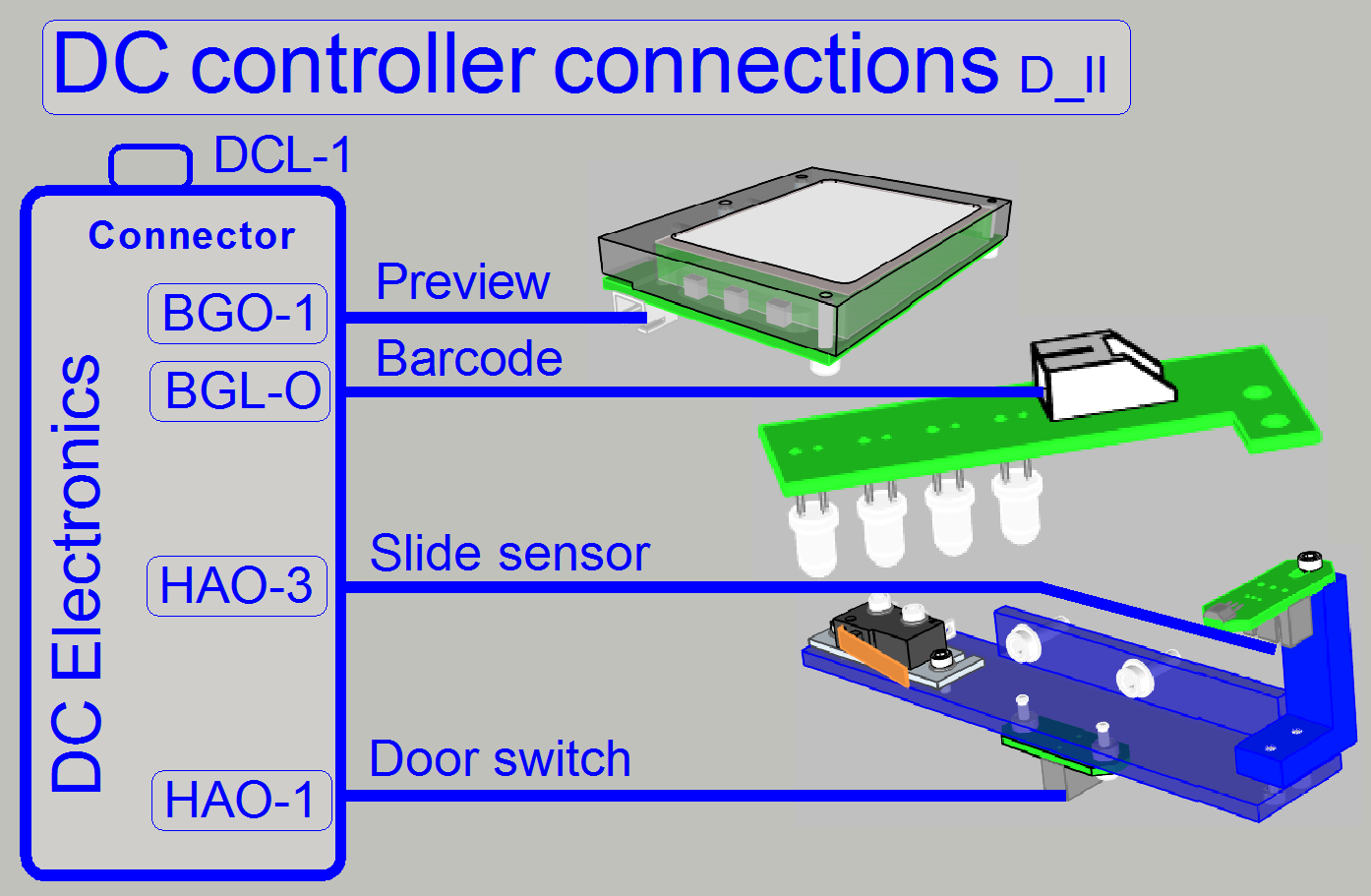

The internal construction of the DC-controllers is different to each

other; the number of the connected cables is limited or extended according to

the requirements.

The DC-controller switches the preview illumination on or off; collects

the status information of the connected sensors and transmits these to the

USB-controller.

About basics, theory and

principles please refer to:

About basics, theory and

principles please refer to:

http://www.solarbotics.net/library/pdflib/pdf/motorbas.pdf

Stepper

motor basics (stored)

Drive circuit basics (stored)

Stepper motor and driver (stored)

External

recirculation diodes (stored)

Stepper motor driving (stored)

Stepper motors 2011 (stored)

Electrical components

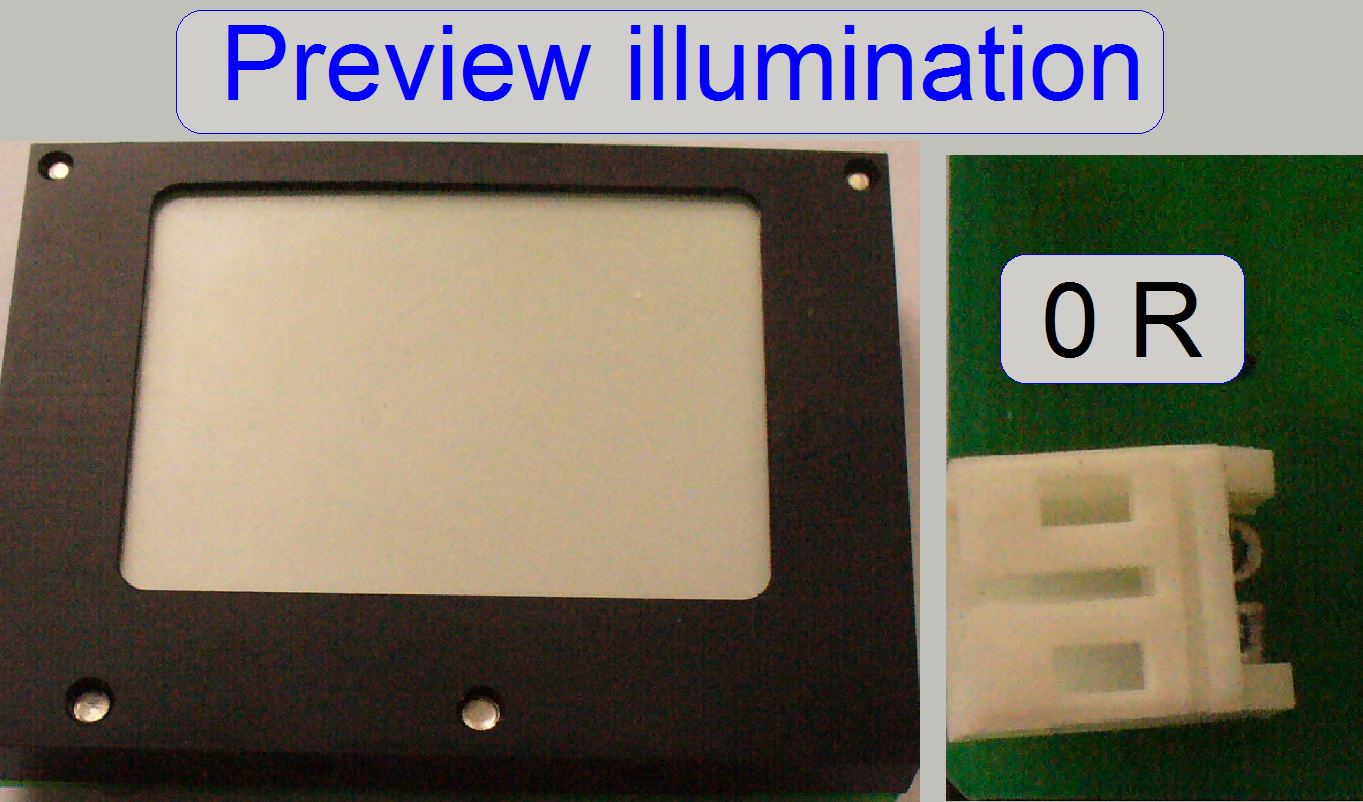

Background (preview) illumination

The preview illumination

consists of 6 LEDs and is used to illuminate the scan area part of the slide

and makes so the sample visible for the preview camera.

The preview illumination

consists of 6 LEDs and is used to illuminate the scan area part of the slide

and makes so the sample visible for the preview camera.

.

![]() LED Wikipedia

LED Wikipedia

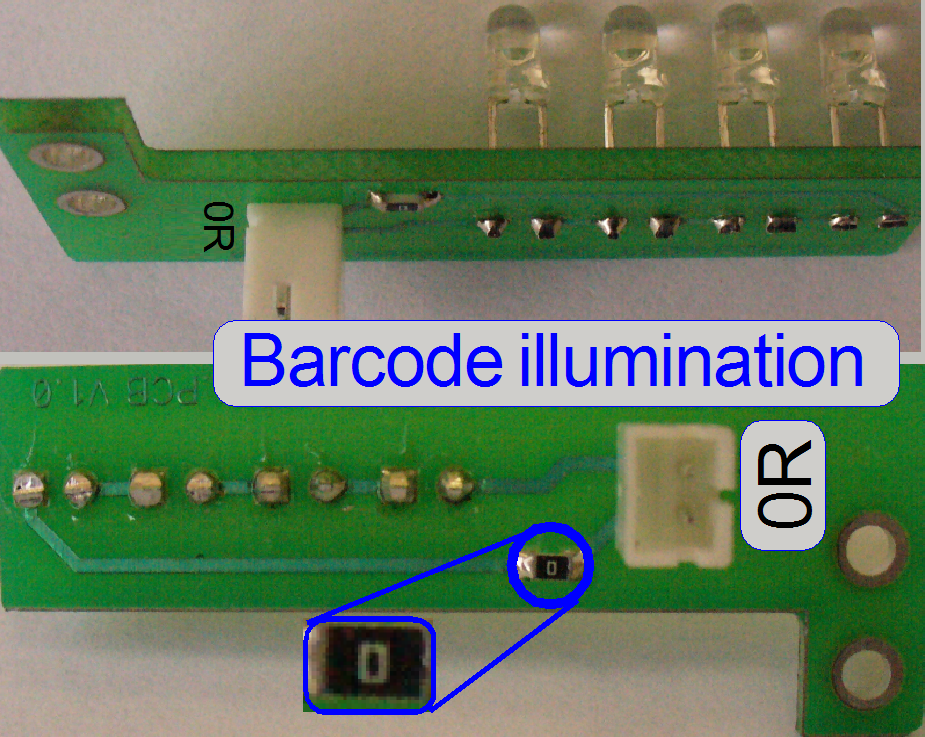

The barcode

illumination consists of four LEDs and is used to illuminate the barcode area

of the slide and makes so the barcode visible for the preview camera.

The barcode

illumination consists of four LEDs and is used to illuminate the barcode area

of the slide and makes so the barcode visible for the preview camera.

![]() LED Wikipedia

LED Wikipedia

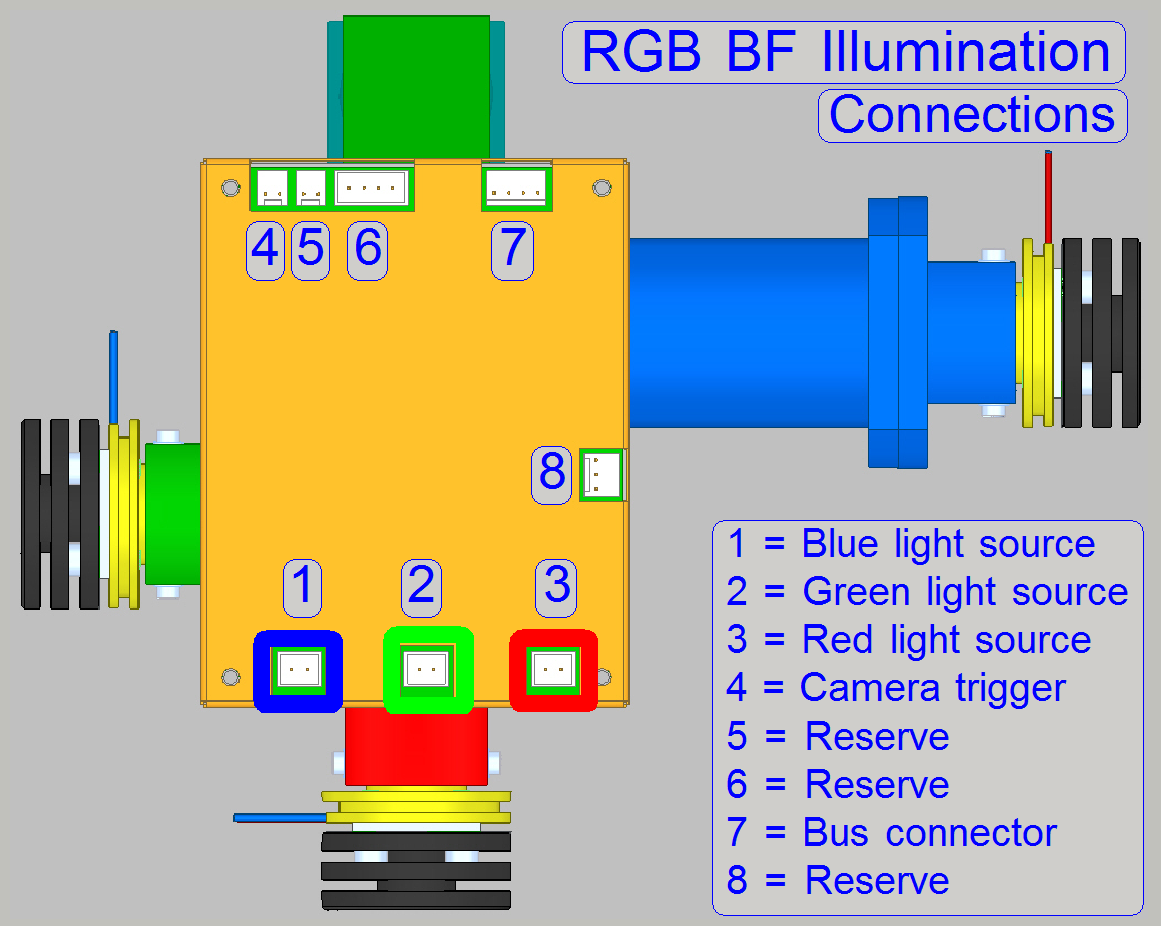

RGB

BF illumination unit

Modifications since summer 2016

By using a monochrome scan camera for brightfield scan sessions also,

the FL scan camera as well as the camera changer unit can be left out of the

equipment, because the same camera can be used for BF and FL scan sessions.

On the other side, to create color information for the BF scanned

tissue, the tissue needs to be captured 3 times; each image is illuminated with

another color.

To do this, an RGB illumination unit is required.

By triggering the illumination unit with the shutter of the camera, a

Red, a Green and a Blue illuminated image of the Field of View will be created.

Each image contains the grey scale of the used wavelength (range); so the

partial intensity of the appropriate color is known. By assembling the three images to a Field of

View and using the software coloring method (combining the intensity of gray

from each taken image for each pixel), the true color information of each pixel

is found.

By using cameras with a large image sensor, low shutter time and high

pixel resolution, the scan time of the tissue can be held in acceptable

boundaries and the result is an image with high resolution and high color

fidelity.

|

Connections

of RGB BF illumination |

||

|

Number |

Name |

Label |

|

1 |

LED for

Blue light |

|

|

2 |

LED for

Green light |

|

|

3 |

LED for

Red light |

|

|

4 |

Camera

trigger |

LTO-1 |

|

5 |

Reserve |

|

|

6 |

Reserve |

|

|

7 |

Bus

connector |

LBO-1 |

|

8 |

Reserve |

|

|

|

||

· Please

connect the appropriate cable to the corresponding connector!

5W

HI-POWER LED White Data Sheet

Power: 5W

Forward Voltage: 3.8V (4.3V max peak)

Current: 1400mA (1500mA max peak)

·

Driving LED without heat sinking device is forbidden.

· It is strongly recommended

that the temperature of lead be not higher than 55ºC.

![]() “Power LED module”

and “Brightfield

RGB illumination unit”

“Power LED module”

and “Brightfield

RGB illumination unit”

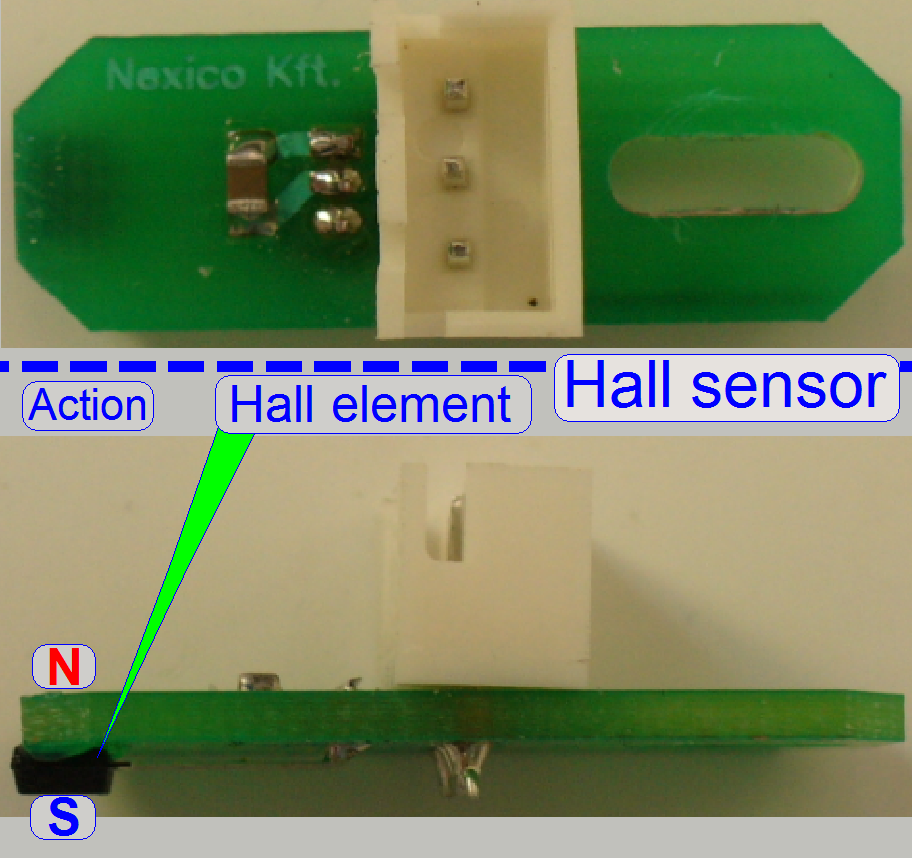

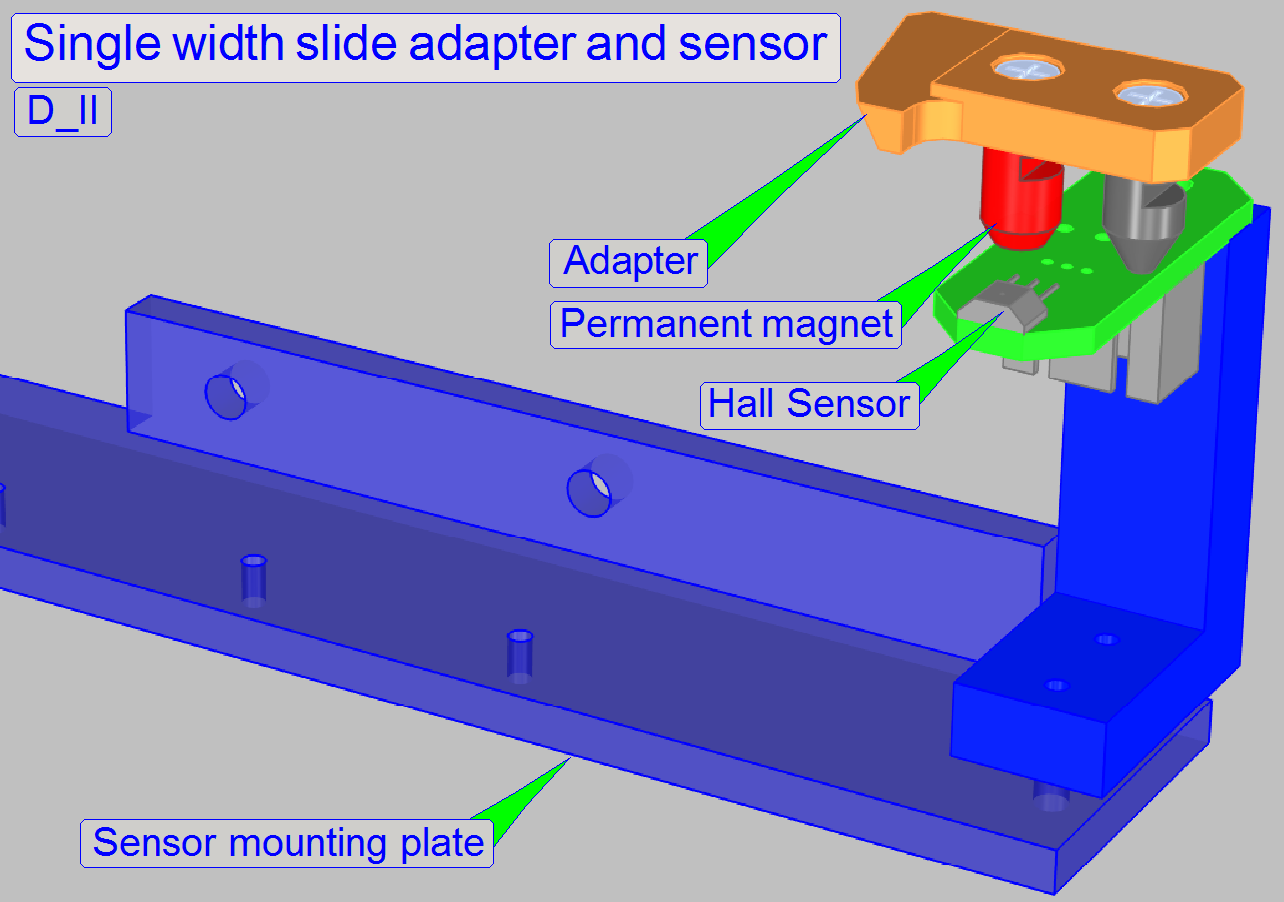

The “Slide sensor” is

realized with Hall element.

- If the south pole of a magnet is over the Hall element or the north

pole on the opposite side, the switch is closed and this state is recognized

by the software.

- If the polarity of the permanent magnet is inverted or a magnetic

field is not present, no action occurs.

- The sensors are so implemented, that the south pole of the permanent

magnet stays over the sensor surface if the action position is reached.

· The sensor

position is adjustable.

· For adjustment procedures see

the appropriate chapters.

· The sensor does

not need maintenance.

![]() “Hall effect” Wikipedia

“Hall effect” Wikipedia

TLE4905L Data sheet; stored

USB-

and DC-controller cabling; summary

Cable labels

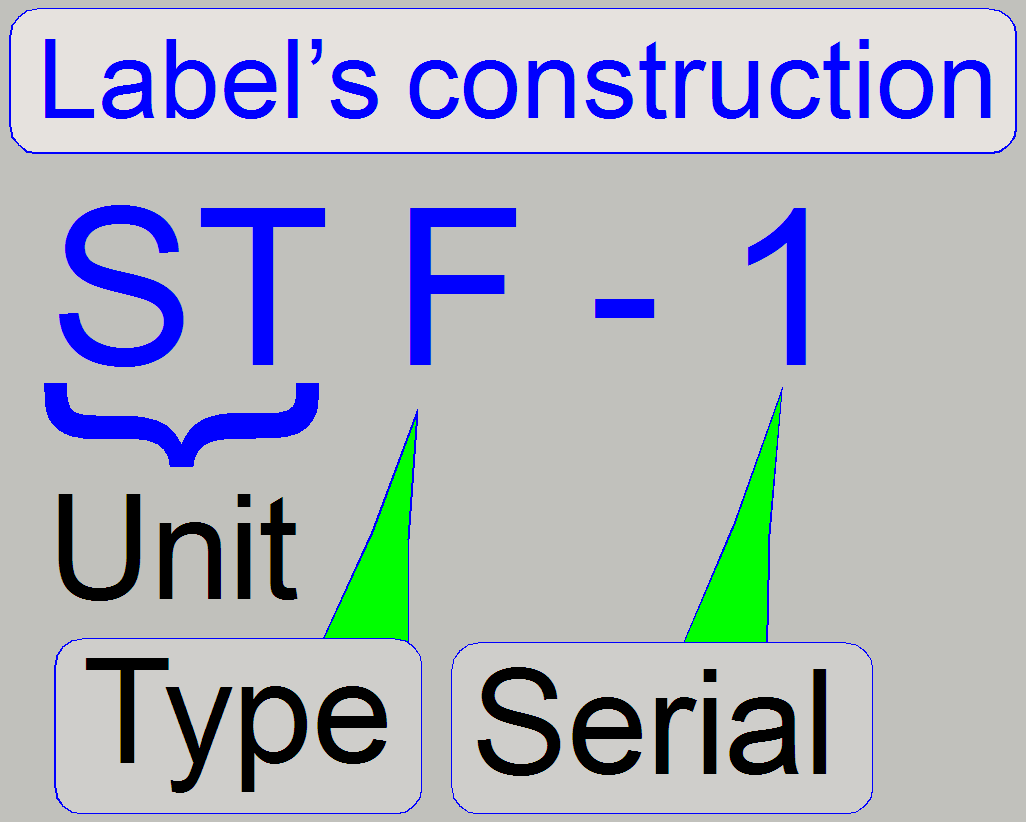

The first 2 letters of the cable label shows the dedicated unit, the 3rd

character defines the electronics version and the scanner type.

Unit

The first 2 letters are defining the unit to be connected.

Type

The type defines mainly the scanner and the electronics version while

delivering the scanner (since 2010). Previously delivered scanners (S_M_D) had

always the letter “C”

Serial

The number “Serial” defines the dedicated unit of the scanner. Often the

unit exists more times (like stepper motors) so the units from the same type

are distinguished. The serial number of stepper motor labels defines mainly

different cable lengths instead of different signals!

Example

The label “STF-

See also: “Cabling of addressable

units” and “Addresses”

|

USB-controller

cabling; summary |

Cable

label |

|||

|

Unit |

Address |

DESK_II |

MIDI_II |

SCAN_II |

|

Reserve |

00 |

|

|

|

|

USB-controller |

01 |

USB

control cable from PC |

||

|

DC-controller |

02 |

DCL-1 |

DCG-1 |

DCF-1 |

|

X-motor |

03 |

STO-1 |

STG-1 |

STF-1 |

|

Y-motor |

04 |

STO-2 |

STG-2 |

STF-2 |

|

Z-motor;

focus |

05 |

STO-3 |

STG-3 |

STF-3 |

|

Turret

unit |

06 |

- |

STG-4 |

STF-4 |

|

Tray

loader motor |

07 |

- |

STG-5 |

- |

|

Slide

loader motor |

08 |

- |

STG-6 |

- |

|

Objective

changer |

09 |

- |

DOG-1 |

DOF-1 |

|

RGB BF

illumination |

11 |

LBO-1 |

LBG-1 |

LBF-1 |

|

Trigger

cable |

--- |

LTO-1 |

LTG-1 |

LTF-1 |

|

USB

connector; external |

- |

Preview

camera cable to PC |

||

|

USB

connector; internal |

- |

FWI-1 |

FWG-1 |

FWF-1 |

|

DC-controller

cabling; summary |

Cable

label |

||

|

DESK_II |

MIDI_II |

SCAN_II |

|

|

USB-controller |

DCL-1 |

DCG-1 |

DCF-1 |

|

Door

switch |

HAO-1 |

- |

- |

|

Preview (background)

illumination |

BGO-1 |

BGG-2 |

BGF-2 |

|

Barcode

illumination |

BGL-O |

BGG-1 |

- |

|

Slide

sensor |

- |

HAG-2 |

- |

|

Tray

sensor |

- |

HAG-1 |

- |

|

Left (input)

magazine sensor |

- |

- |

OPF-1 |

|

Right (output)

magazine sensor |

- |

- |

OPF-2 |

|

Magazine

loader sensor |

- |

- |

HAF-1 |

|

Magazine

feeder sensor |

- |

- |

HAF-2 |

|

Slide

loader cable |

- |

- |

HMF-1 |

|

Magazine

loader motor |

- |

- |

DMF-1 |

|

Magazine

feeder motor |

- |

- |

DMF-2 |

|

Slide loader

DC motor |

- |

- |

DMF-3 |