Housing, construction; D_II

For technicians!

.

This chapter handles components of the housing and mechanical

construction of the scanner DESK_II (D_II).

Enhancements

Following improvements are done in Pannoramic DESK

scanners, delivered since summer 2016

These modifications do not result in another scanner type, but to bundle

all the modifications, the term DESK_II was created and is used internally.

Scanners, delivered since summer 2016 including all the following

improvements and modifications, appropriate replaced units, used in previous

versions are no longer delivered in new scanners.

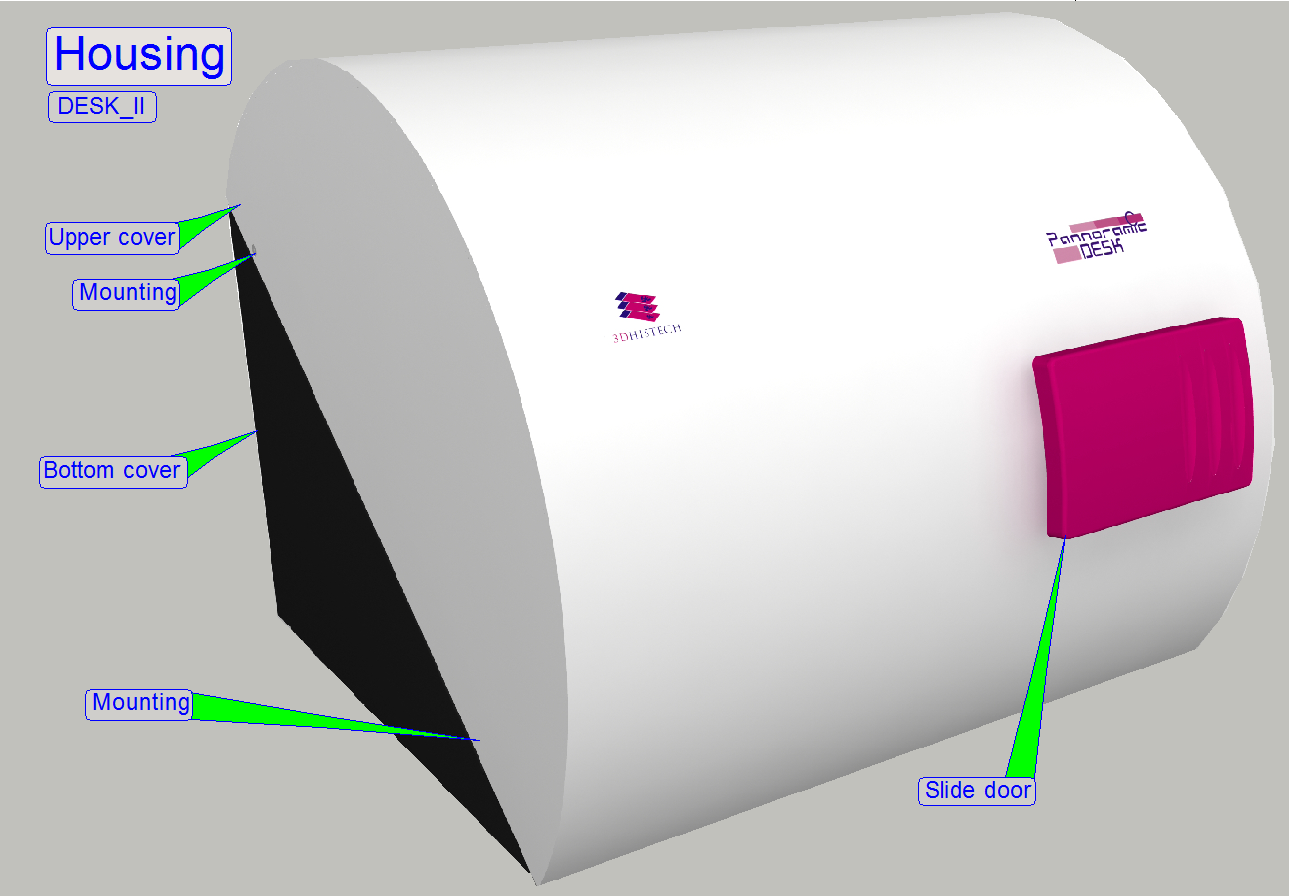

Housing

DESK_II's housing dimensions has changed, it is now nearly twice in

width

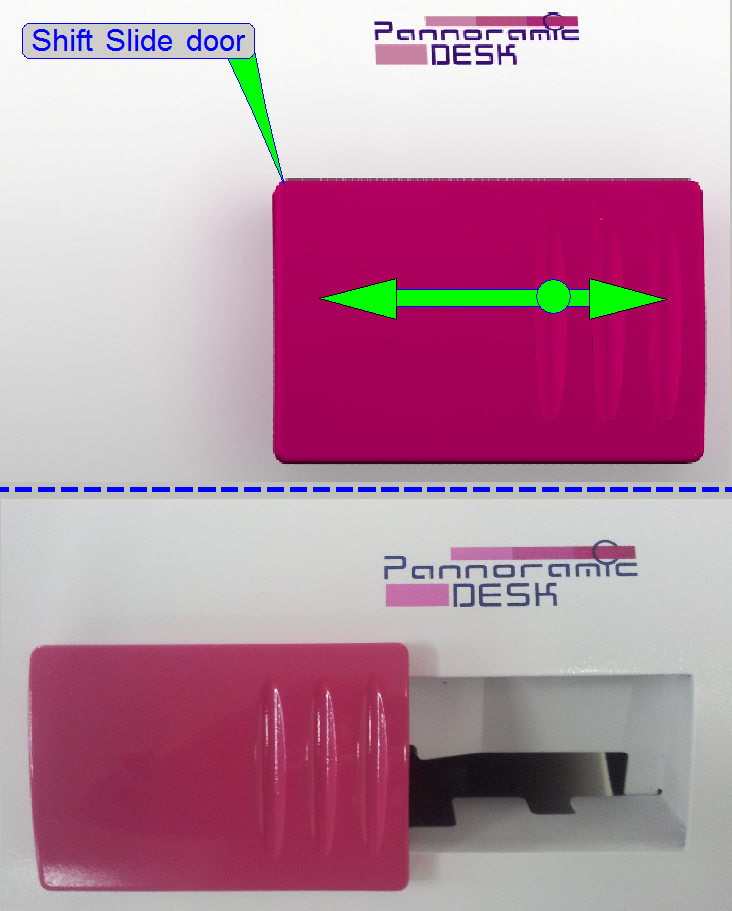

The slide door was modified, it is now enlarged to handle slides with

double width easily, the shift mechanics was modified.

The painting of the lower cover is black.

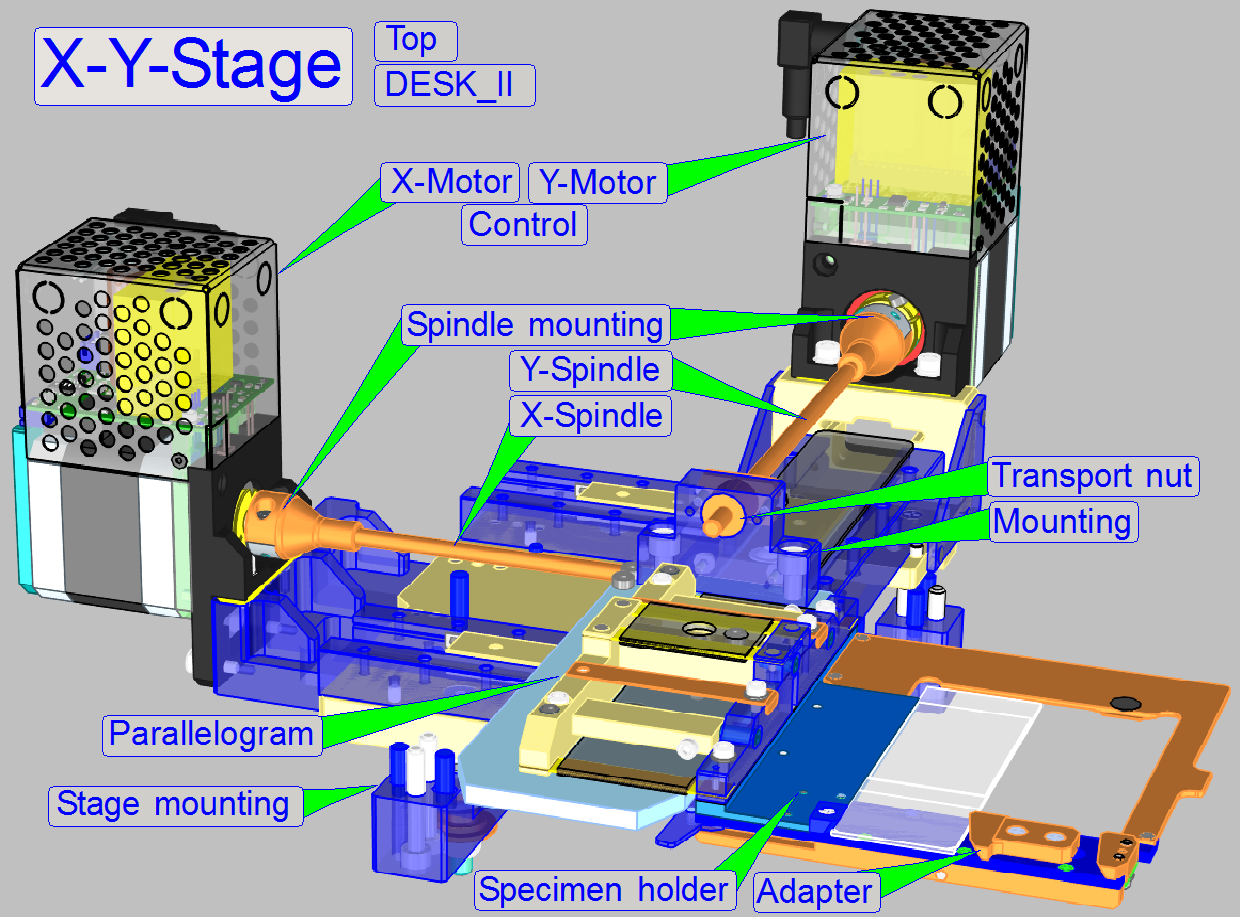

X-Y-Stage

Mounting

- Mounting of

the X-Y-stage unit to the scanner plate was modified, so vibration,

resonance and noise is reduced.

- The scanner plate

has a rectangular cut out for placing the X-Y stage unit's base plate into

it.

- The unit's

base plate is mounted to the bottom of the scanner plate with three

L-shaped holding elements and springs.

X-Y-Drive

- Using of

5-Phase stepper motors improves smoothness of the rotor’s movement to

reduce vibration and resonance.

- Newly

designed spindle mounting allowing simplified, easily adjustments and

exchange.

- Using an

integrated, slippage-free transport module (includes transport nut and

counter nut) simplifies adjustments.

- X-direction

prolonged to reach the double width of the slide.

X-Y-Rails

- Using of

improved X-rails and the modified distance

between the X-rails increases stability in X-direction.

- X-direction

prolonged to reach the double width of the slide.

- Newly

designed Y-rail solution increases stability in Y-direction.

Specimen holder

- Modifications

of the specimen holder allowing the movement of slides with a thickness of

1.2mm in the DESK_II.

- The DESK_II

can also hold slides of single width (25mm) by using a simple adapter or

double width (50mm); hereby the adapter is removed manually.

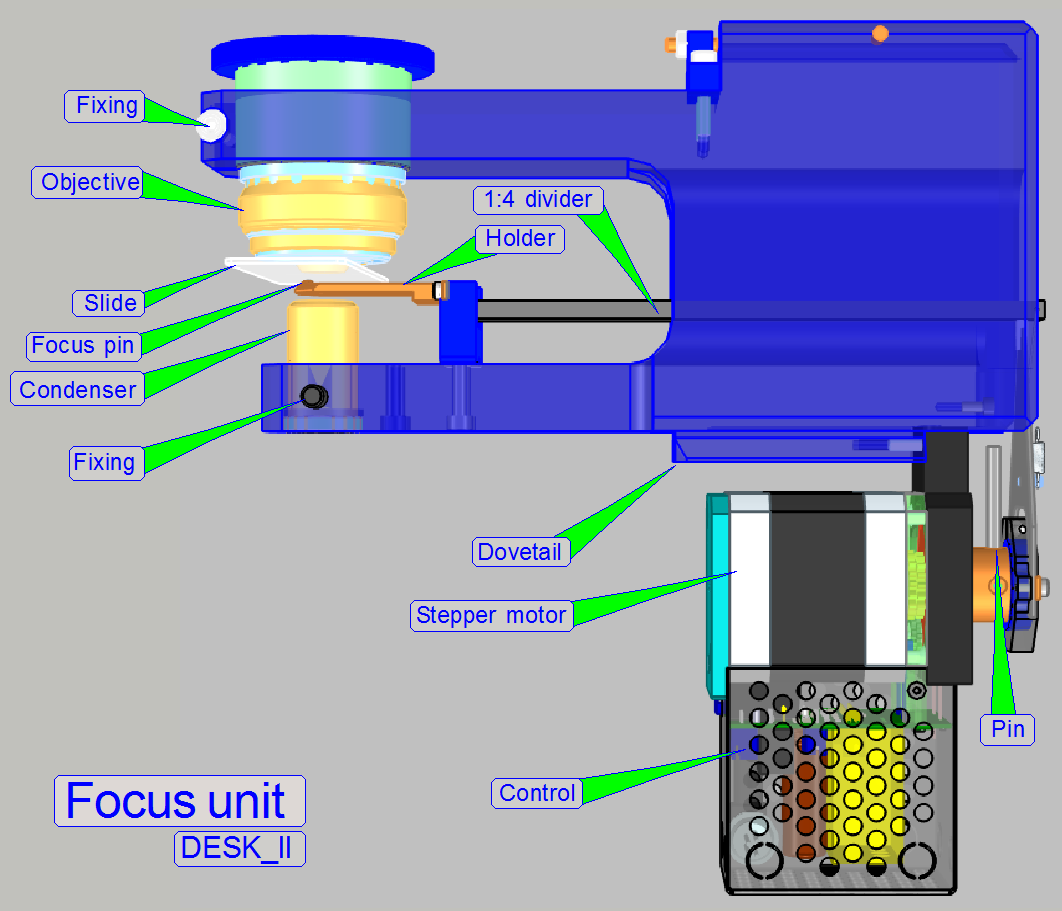

Focus unit

Shutter mechanics removed

Shutter mechanics removed

Because the scanner unit of the DESK is never able to scan slides in FL

scan mode, the mechanical shutter is also not required.

The ex-center of the focus unit may now rotate unlimited.

In DESK, the shutter unit was implemented for the Hardware limits and to

keep compatibility with SCAN and

Hardware limits not required

Because the shutter wire is removed, the rotation of the ex-center is no

longer limited. The ex-center may rotate unlimited.

Ex-center position visualization pin

In the position of the shutter arm of the ex-center, now only a

visualization pin is implemented to make the ex-center position adjustment

possible.

Stepper motor type exchanged

In the DESK, there was a 2-phase stepper motor with 200

full-steps/revolution used, so a resolution of the 3200micro-steps/revolution

is possible.

In the DESK_II a 5-phase stepper motor is implemented, this guarantees a

higher full-step resolution, and more

smooth movement of the rotor and so, vibration and noise are also reduced.

The revolution of the 5-phase motor's rotor after transforming is now

done in 6400µ-steps/revolution.

Increased slide thickness

The modified focusing solution allows now focusing of slides with a

thickness of 0.95mm to 1.20mm.

Modified focusing mechanics

To focusing slides with a thickness of 1.20mm, the movement range of the

focus pin had to be increased.

To reach this, the relation of the divider was modified to 1:4 and the

stepper motor's step angle was decreased.

The focus range is now 1600µ-steps, because the rotor's step size is now

reduced to the half, the rotor revolution is done in 6400µ-steps/ revolution.

Watch video: DESK II

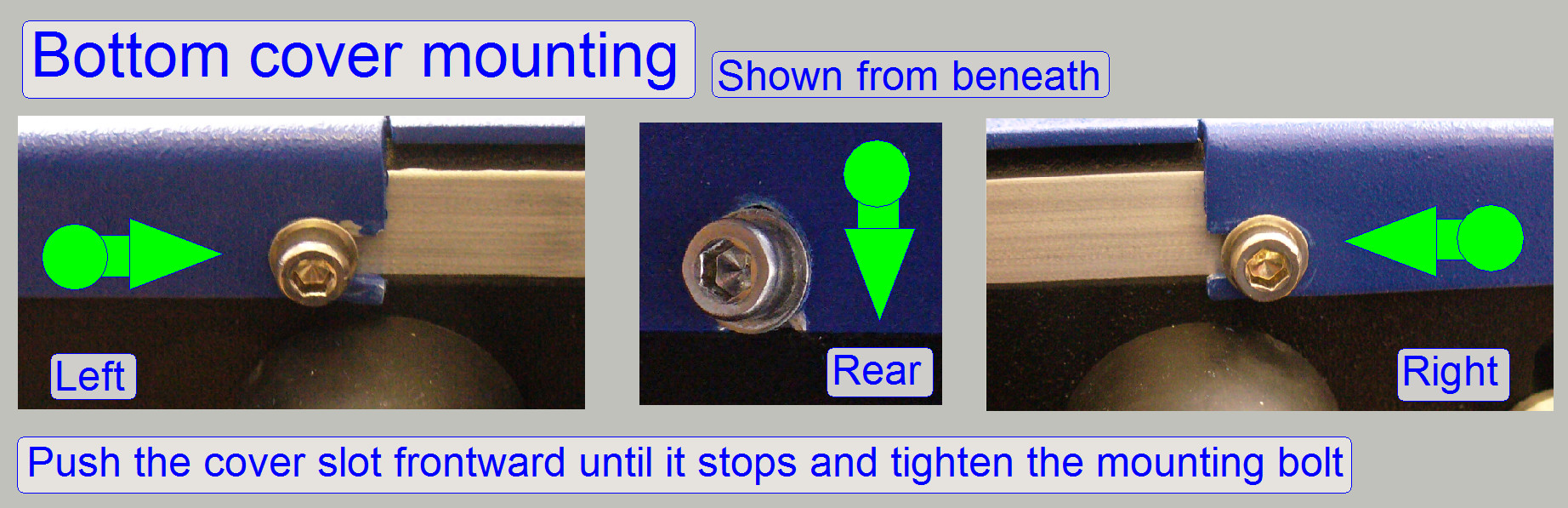

Remove the lower housing

Mount the lower housing

Mount the upper housing

Slide door

The DESK housing consists of an upper and a lower housing; the upper

housing is mounted to the lower housing by four bolts, two from the left side

and two from the right side. The lower part of the upper housing is held by

clamps; these acting independently if the upper housing is shifted frontward.

If the mounting bolts for the upper housing are removed on both sides,

the DESK can be opened.

Watch video: DESK II Cover

1.

Remove the upper cover mounting bolts on both sides

2.

Pull the rear part

of the upper housing upward of about 5mm and

3.

Shift the upper housing in direction to the front.

Shift the upper housing in direction to the front.

Watch video: Remove upper cover

4.

Remove the camera protector

as required.

5.

Rotate the DESK to the right and put it onto its right

side. Take care on the painting, do not scratch it!

6.

Loosen (or remove) the 3 mounting bolts of the lower

housing from the base plate.

7.

Rotate the DESK return onto the feet and shift the

entire lower housing backward.

Allowed slide dimensions

Single

width

Single

width

Length: 75.00 to

Width: 25.00 to

Thickness: 00.95 to

Double width

Length: 75.00 to

Width: 50.00 to

Thickness: 00.95 to

- If the first character of the serial number is an

“S” the tool is used to check the slide dimensions

of single width slides; thickness = 0.95 ... 1.05mm.

- If the first character of the serial number is a “P” the tool is used to check the

slide dimensions of single width slides; thickness = 0.95 ... 1.20mm.

- Please check the slide dimensions before

insertion of slides!

8.

Shift the lower housing from the rear to the front so,

that the mounting slots of the lower housing are shifted between the base plate

and the washers of the mounting bolts.

Shift the lower housing from the rear to the front so,

that the mounting slots of the lower housing are shifted between the base plate

and the washers of the mounting bolts.

9.

Rotate the DESK to the right and put it onto its right

side. Take care on the painting, do not scratch it!

10.

Press the rear part of the lower housing against the

base plate so, that there is only a very small or no gap and tighten the fixing

bolt on the front left side.

11.

Rotate the DESK

to the left and put it onto its left side. Take care on the painting, do not

scratch it!

12.

Now press the right part of the lower housing to the

front and tighten the appropriate mounting bolt in the front.

13.

Finally, tighten the mounting bolt on the rear.

14.

Put the DESK return onto the feet and mount the upper

housing.

15.

Insert the lower fixings into the appropriate slots of

the lower housing and push the upper housing in direction of the rear.

16.

Fit the rear part of the upper housing with the upper

part of the lower housing and drive in the mounting bolts from the left and right

side.

Watch video: Mount upper cover

The mechanical construction

of the slide door allows the shift of the door to the left or to the right

respectively. Please shift the door to the left to open the door and shift the

door to the right to close the door.

If the slide door is opened during the scan process is in progress, the

scan process will be stopped until the door is closed again; to avoid finger

squeezing.

Important

Please do not pull the door

to open the door!

Watch video: “Open and close the slide door”

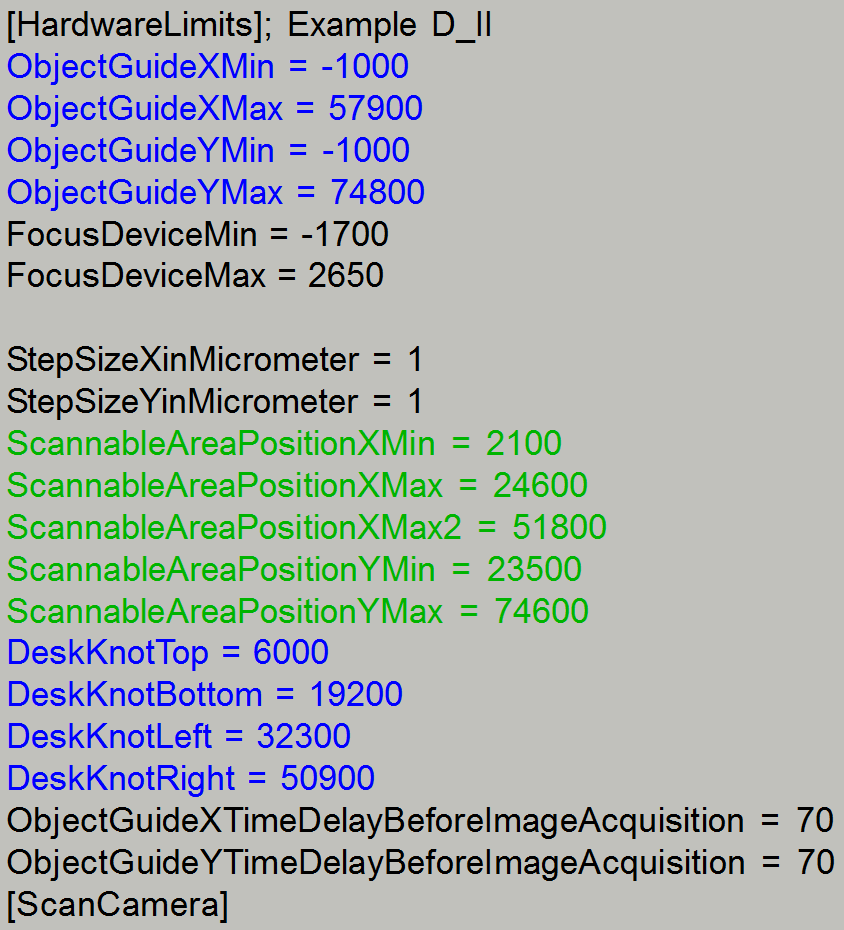

Since the software version 1.15, the scanner units are

configured in the “MicroscopeConfiguration.ini” file, in the section

[Microscope].

Since the software version 1.15, the scanner units are

configured in the “MicroscopeConfiguration.ini” file, in the section

[Microscope].

[Microscope]

SerialNumber = PDESK-02xxxxxx

MicroscopeType

= 3DMic12

ScanCameraType = ;value is

unimportant

PreviewCameraType

= CVrmc_m8_pPro_Double

BarcodeReaderType = PreviewCamera

LoaderType

= SL_1Slide_DoubleWide

CameraChangerType = CC_None

ReflectorTurretType = RT_None

BrightfieldLightSourceType

= RGBLedLight

ObjectiveChangerType =

OC_None

ObjectGuideXYZType

= OGXYZ_TypeDouble

FlashUnitType = NoFlashUnit

NDFilterType = ND_None

PreviewLightType =

PreviewLightUnitType_Type3

PowerSwitchBoardType

= PowerSwitchBoard_None

PowerSwitchBoardType

= PowerSwitchBoard_None

[HardwareLimits]

For more information about the parameters, used since software version

1.15, see the chapter INI-Files and the section

[Microscope].

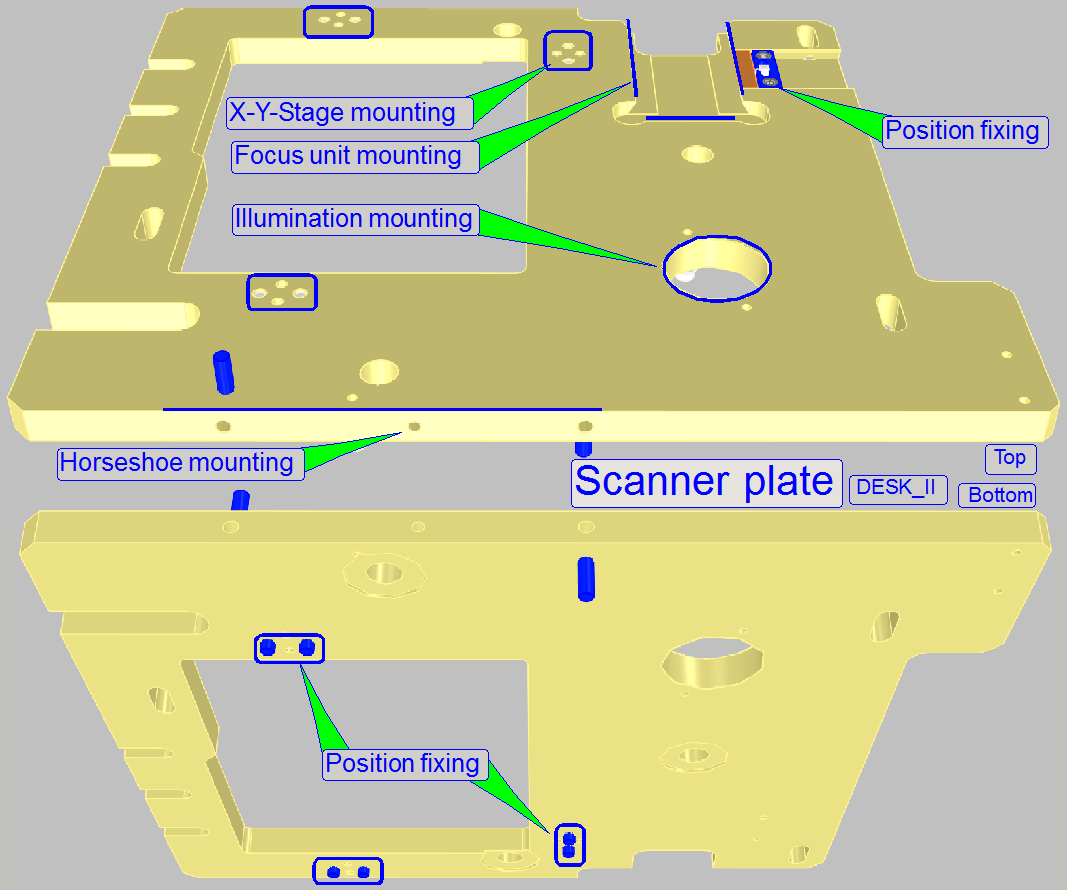

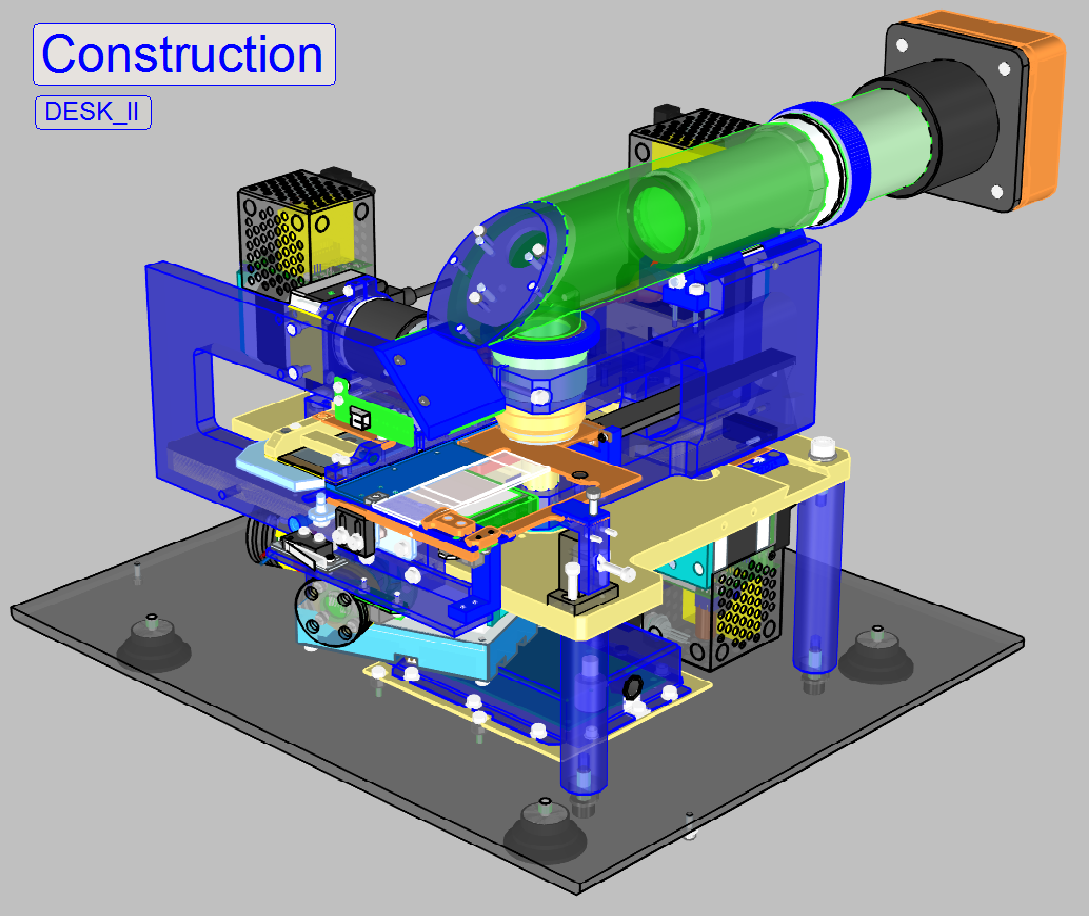

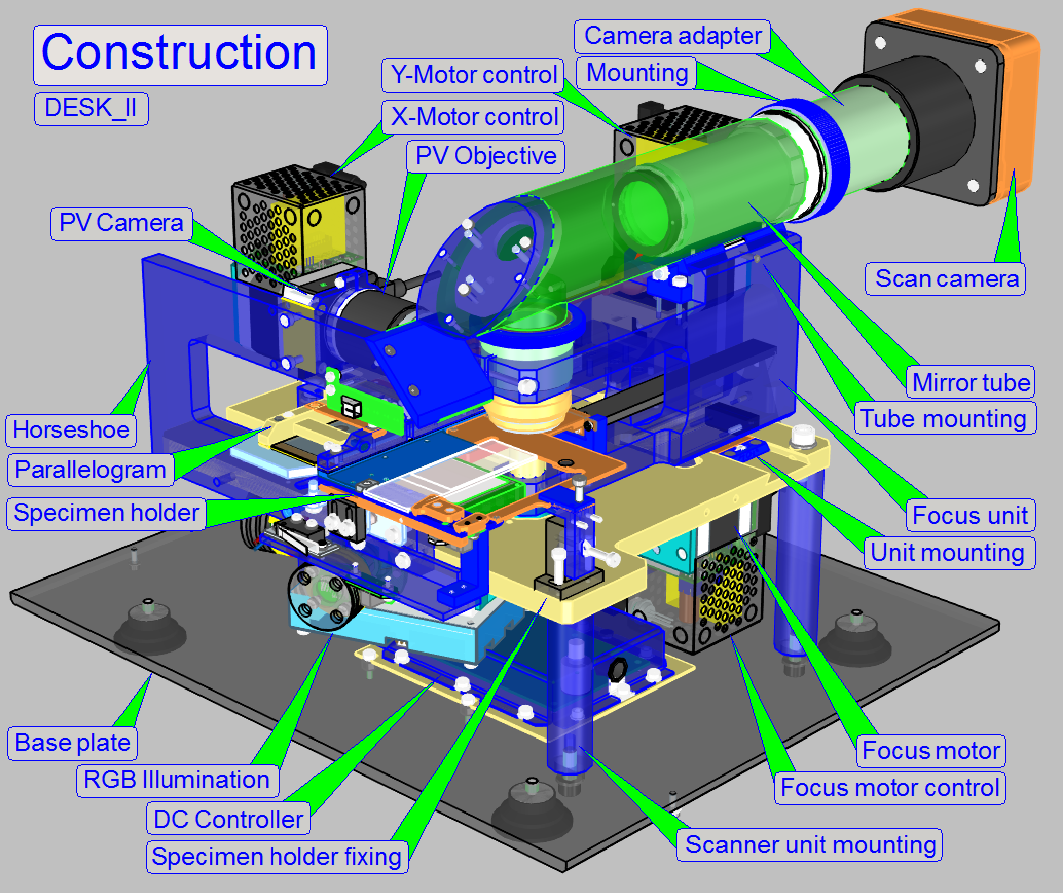

The mechanical construction of the DESK includes a

base plate and the scanner plate only. In this chapter components are shown and

adjustments are described.

The mechanical construction of the DESK includes a

base plate and the scanner plate only. In this chapter components are shown and

adjustments are described.

Adjust

the scanner plate position

Adjust the

door switch position

Adjust the

specimen holder fixing

Watch video: D_II_Construction

· For

safety regulations regarding human health and scanner functionality please

refer to: Precautions

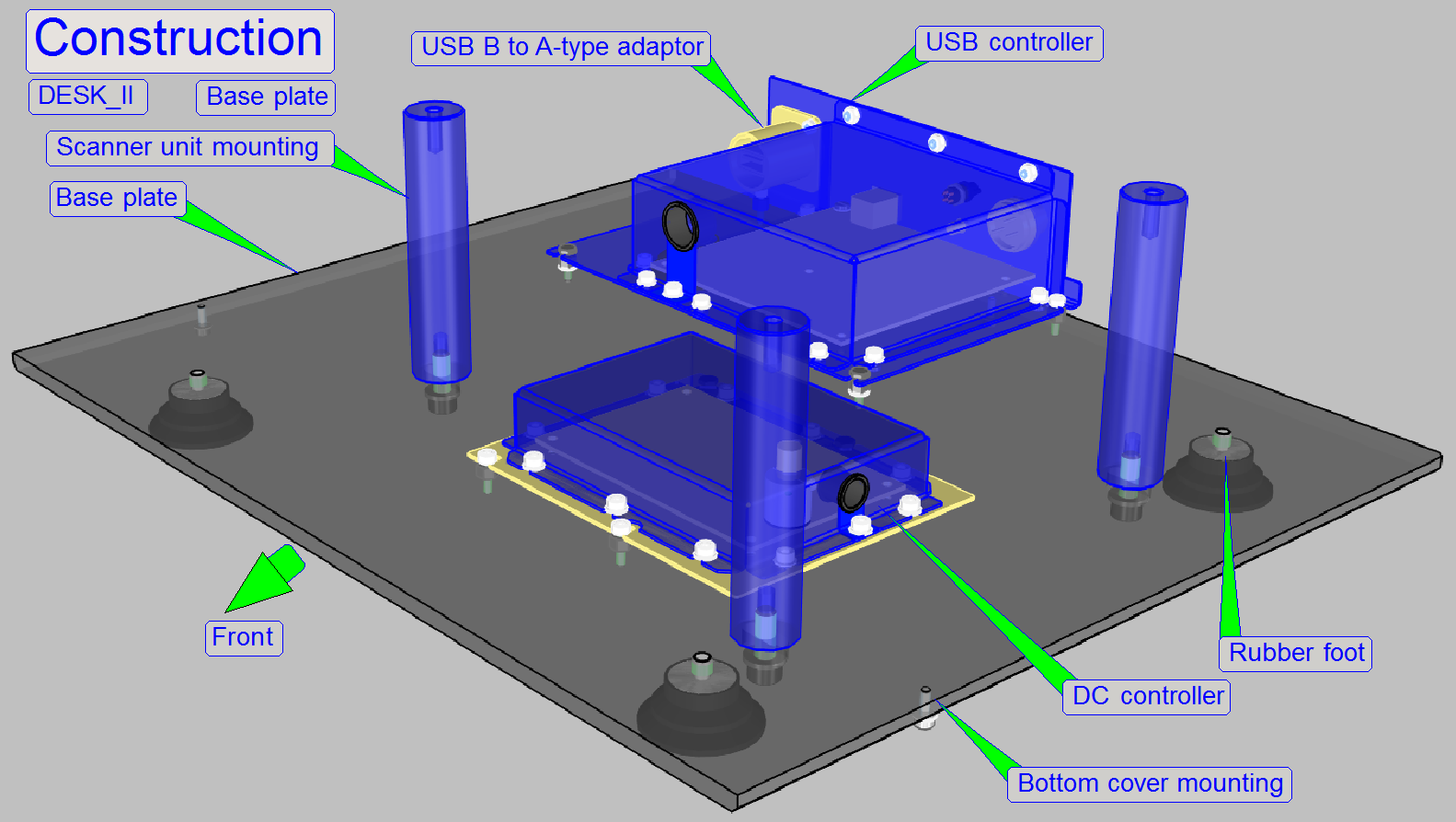

The base plate contains the USB- and

the DC-electronics box.

The scanner unit mounting is realized with three distance peaces.

·

The scanner plate is mounted to the distance peaces

with 5mm hexagon key bolts from the top.

·

Position of the scanner plate is adjustable.

In the DESK, like in the

The mounted main units of the scanner plate are:

- Focus unit

- X-Y-stage unit

- Preview and barcode

unit (the horseshoe)

- Brightfield RGB

illumination

- Image

path of the DESK is mounted onto the focus unit by using a mirror tube;

this is mounted by using a dovetail foot.

Watch video: Dismount

units

Mount

units

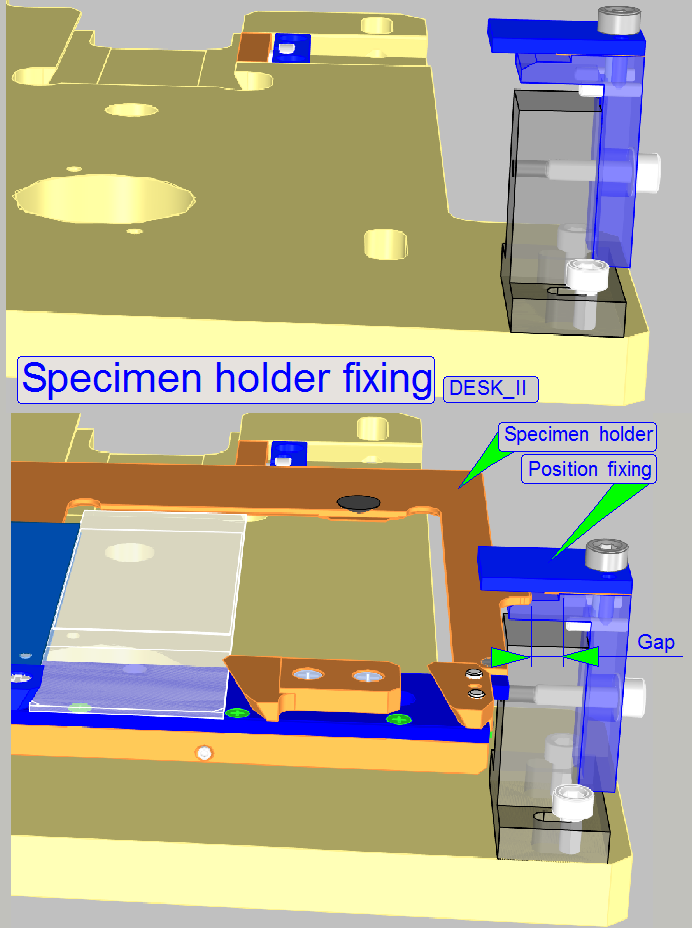

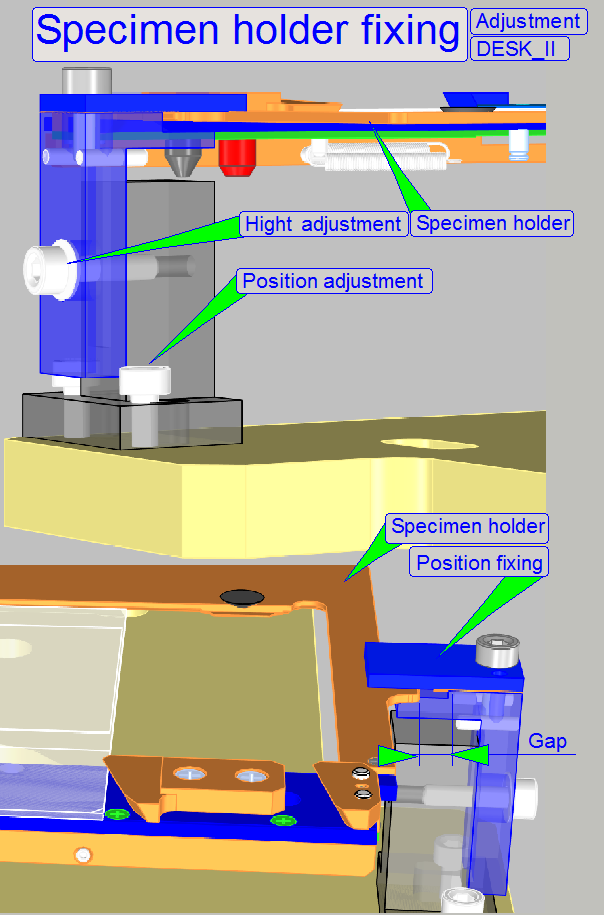

Specimen holder fixing

Because the slide

is inserted or removed manually into the DESK, the specimen holder must

be fixed during these actions.

Because the slide

is inserted or removed manually into the DESK, the specimen holder must

be fixed during these actions.

If the specimen holder is in the Home1,2 position or anywhere in

direction to the negative limits, the slide action can be done. In this

position, the specimen holder is fixed on the right side and supported by the

specimen holder supporter on the left side. With this solution, the slide

insert or remove action can be done safely, without bending the specimen holder

or the parallelogram.

The right hand supporter of the specimen holder fixing contains

chamfered edges in –X- and –Y-direction, so the specimen holder fixing guide

will not jam if the specimen holder is moved in negative direction.

Drive

The X-Y-Stage unit is used to move the slide into the appropriate

positions during slide insertion and remove, during the preview creation

process and barcode capturing to the positions of the preview camera's field of

view and during the specimen scan process, the slide is moved continuously to

capture the Field Of Views for the scan camera.

To reach the required movements, a spindle driven mechanics is used in

both directions, so a resolution of 1µm/rotor step is realized.

The spindles are driven by a 5-phase stepper motor with a transformed

resolution of 3200µ steps/revolution, so a distance of 3.2mm movement is done

after 1 revolution of the rotor.

Parallelogram

The parallelogram allows shifting of the slide (and so the specimen) in

Z-direction during focusing, the movement is possible over the entire focus

range (and a bit more). By using a parallelogram, an inclination of the

specimen during focusing is avoided.

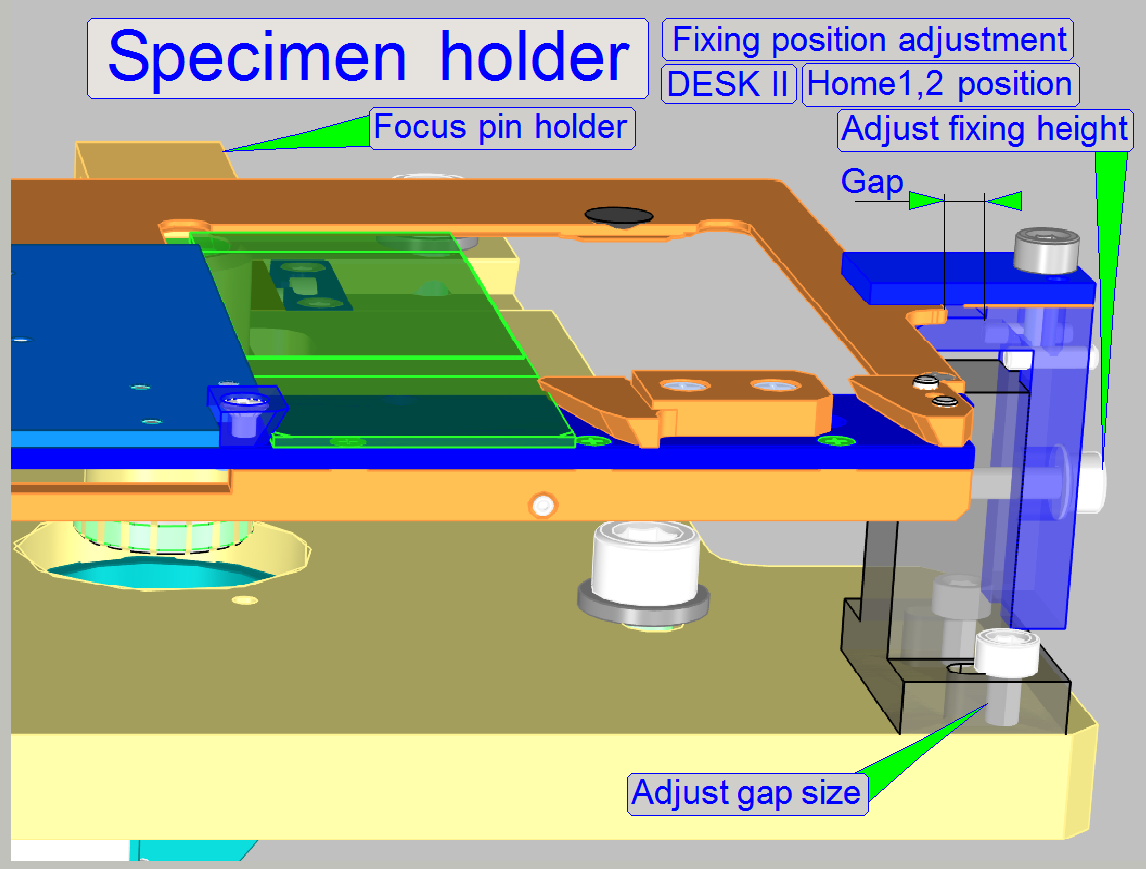

Specimen holder

Newly designed specimen holder mechanics allows the insertion and

scanning of single width and double width slides with a thickness of up to

1.20mm.

By using a removable single width adapter, the software knows whether a

single width slide (adapter present) or a double width slide (adapter removed)

should be scanned.

The adapter is inserted or removed manually by the user.

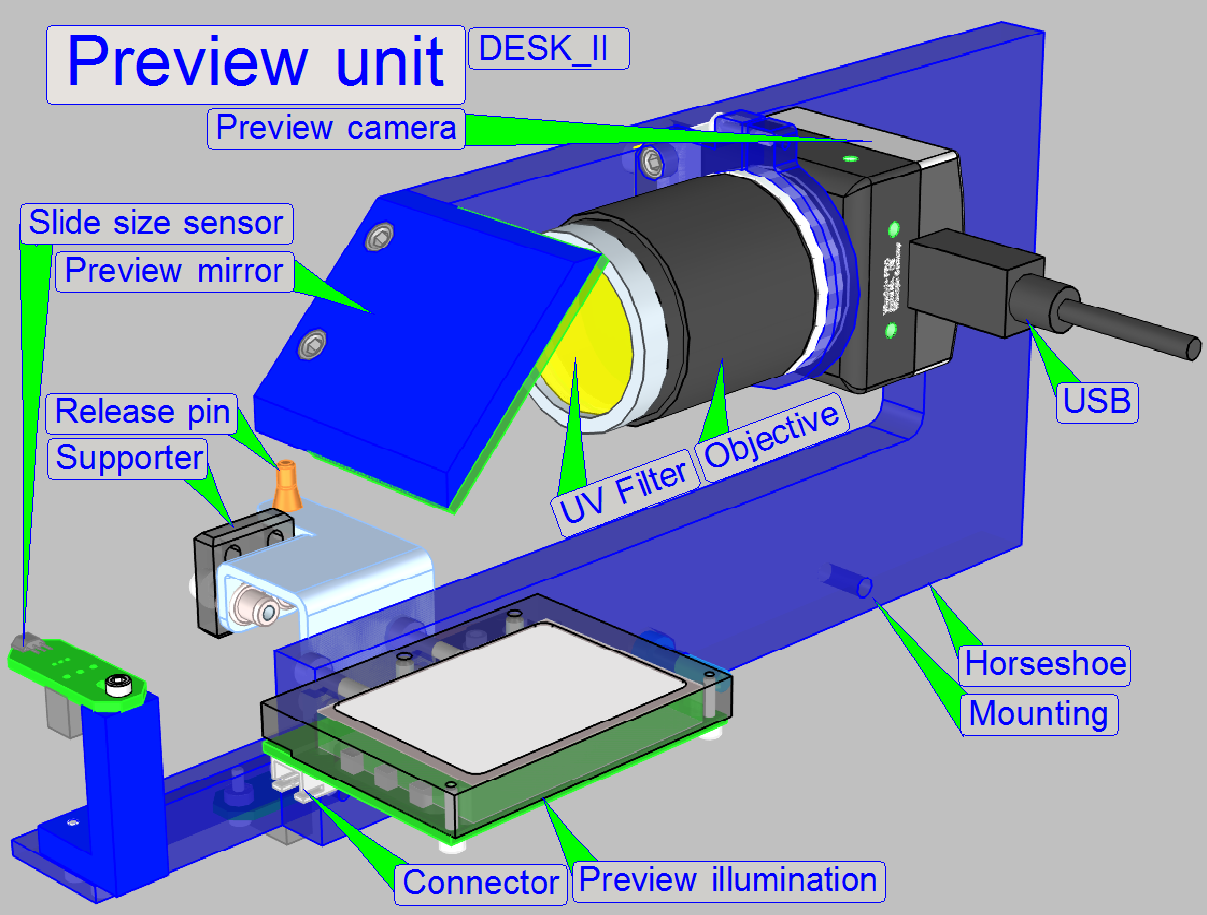

The preview unit creates the preview of the slide, so the user knows the

position of the sample on the slide and may select the tissue for scanning or

only parts of interest.

Single width slides

If single width slides are inserted, the entire preview of the scan area

is made by 3 images of the camera, the fourth image is the barcode area.

The 3 images are assembled by software to the preview, shown in the

preview window of slidescanner.exe.

Double width slides

Because the slide width is doubled, the preview creation process is also

doubled.

The preview camera makes 6 images of the slide's scan area and assembles

these to the preview, shown in the preview window of SlideScanner.exe

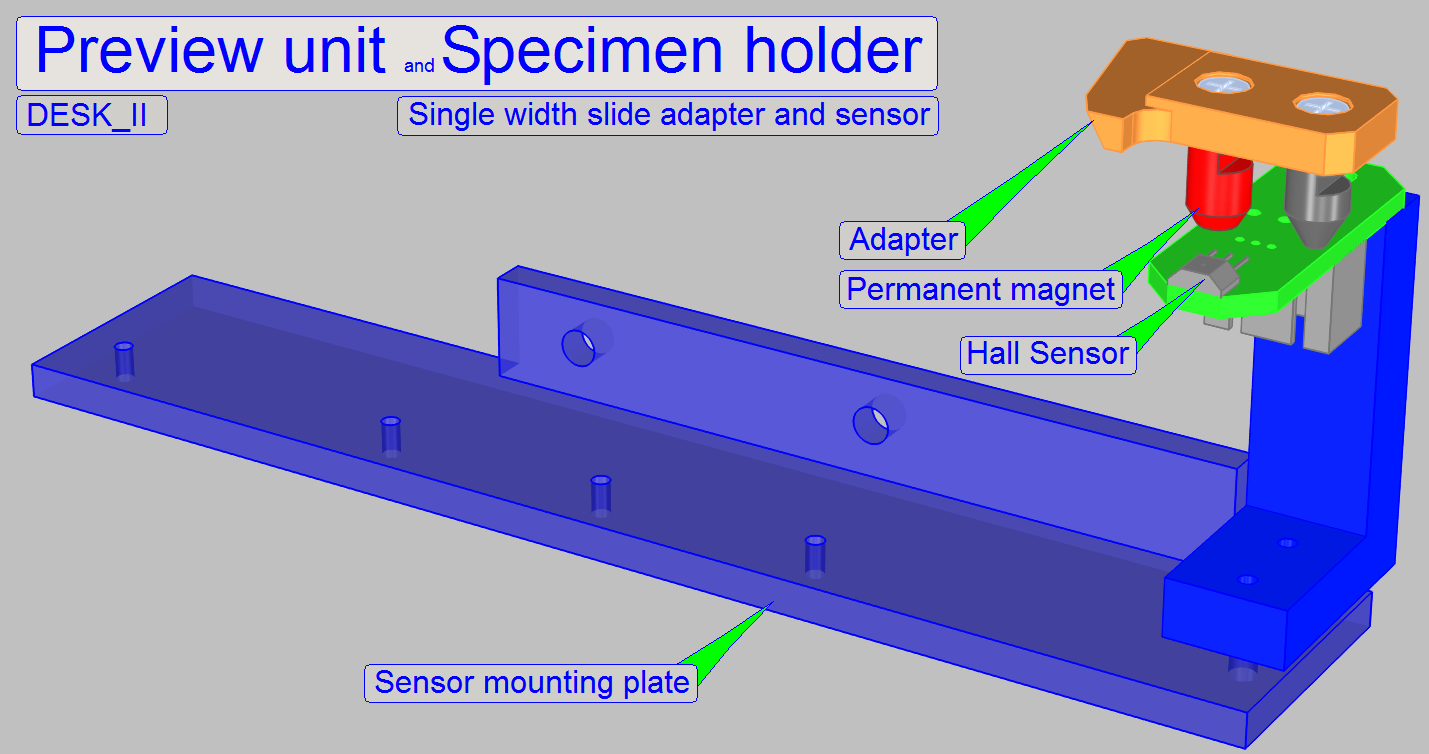

Single width slide adapter and sensor

Single width slide adapter and sensor

As mentioned above, the specimen holder may hold slides with single

width and double width.

If single width slides should be inserted into the specimen holder an

adapter is used.

To tell the software, that the adapter is present, a Hall sensor,

mounted on the preview unit's sensor mounting plate is used.

If the sensor shows the active state in the slide insert position, the

adapter is present, slides with single width will be inserted.

Adjustment

Move the X-Y-stage with the service program to the slide insert position

and insert and remove the adapter more times. During these actions, the

presence or absence of the adapter have to be surely and correctly.

- Check this

behavior more times.

If checks failed, adjust the sensor position more precise

Physically, the focus

position is defined by the distance of the objective to the tissue. If the

tissue is in the focus of the objective, a sharp image is seen by the camera.

Because the tissues are different from each other in thickness, and the

thickness can change inside the same tissue also, the focus position must be

checked and corrected always, during the scan procedure.

- In Pannoramic scanners, as well as in the

DESK_II, the real focus position is found by moving the slide toward or

away from the objective via the focus pin.

- The focus position is influenced by both,

the fixed (adjustable) objective position and the actual position of the

focus pin.

Furthermore, if the slide as

well as the objective will be changed, the specimen holder must be moved away

from the objective to avoid collision.

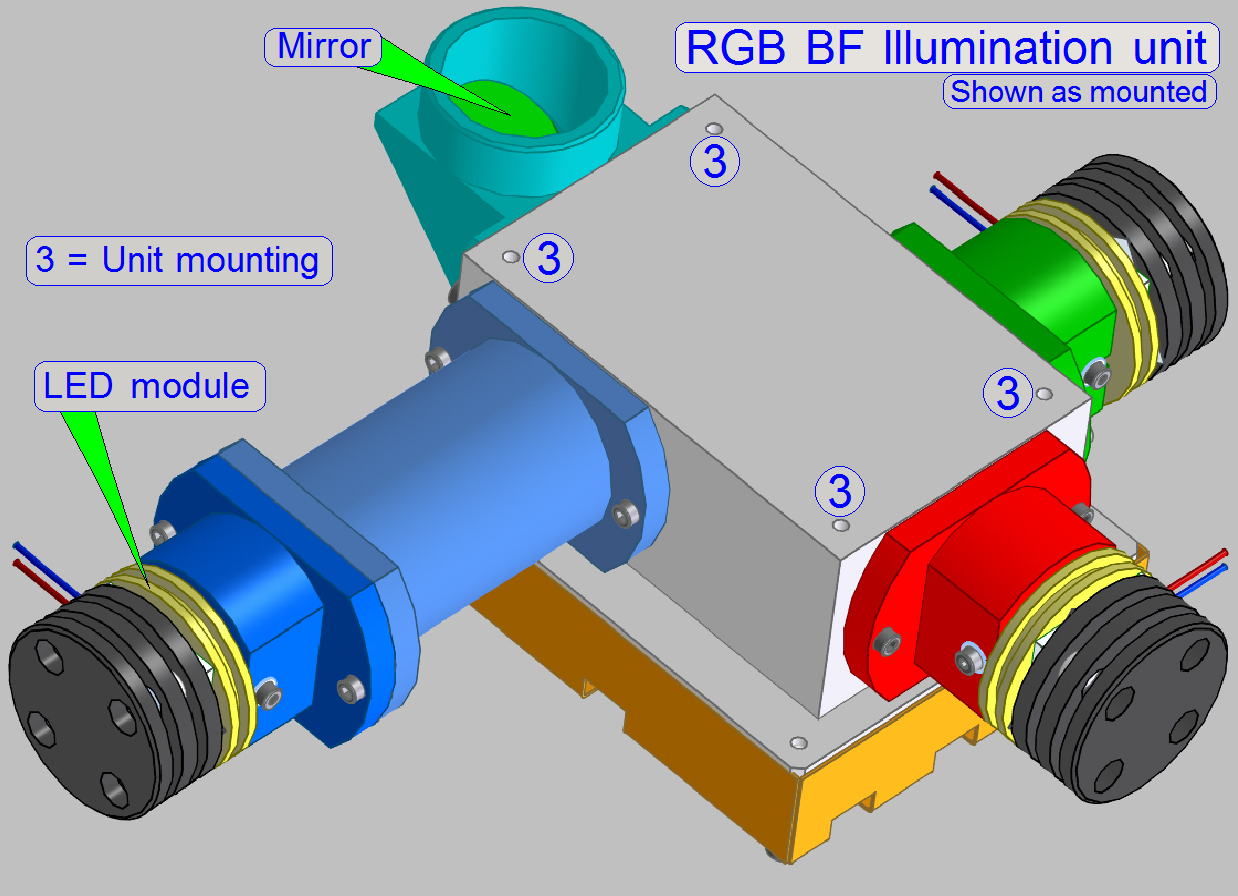

Watch video: RGB BF Illumination unit

Monochrome cameras requiring monochrome illumination.

The construction of the BF optical path uses only a monochrome camera,

so only monochrome images can be produced.

To create color information of the tissue with a monochrome camera, we

illuminate the tissue with monochrome light.

If the tissue is illuminated by blue light, and we are making an image

of the Field of view, the gray scaled camera image contains the intensity of the

blue parts in the tissue.

Because the pixel resolution of the camera is very high and the

resolution of the image's gray scale is 10bit per pixel (or higher), very

detailed information of the blue part in the FOV related to the appropriate

pixel can be reached.

If we repeating the procedure with the colors Green and Red, 3 images of

the same FOV are produced and so, the software knows detailed color information

about each pixel of the Field Of View.

By using the software coloring method the true color information of each

pixel is found.

By using cameras with a large image sensor low shutter time and high

pixel resolution (small pixel size), the scan time of the tissue can be held in

acceptable boundaries and the result is an image with high resolution and high

color fidelity.

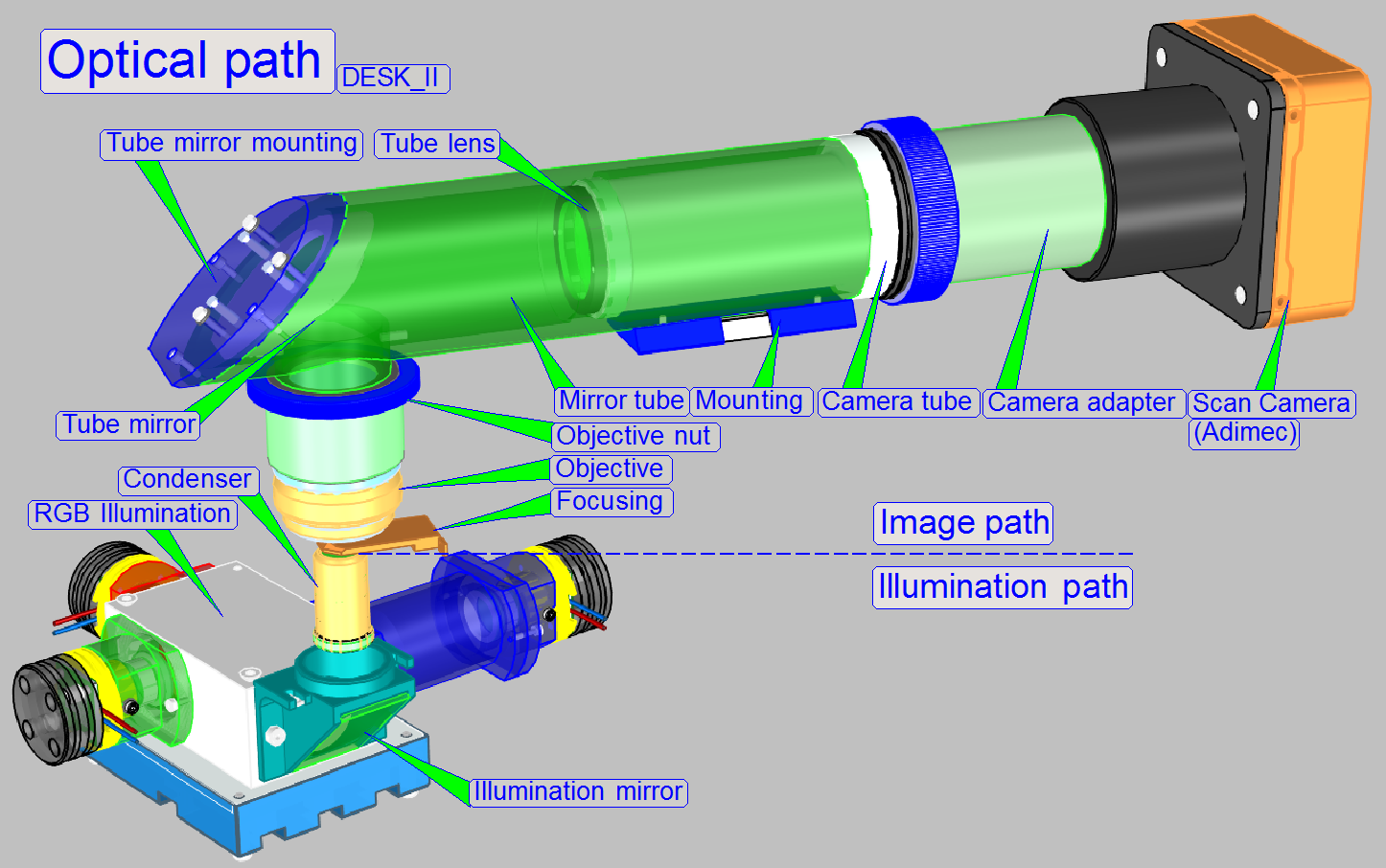

The optical path can be devided principially into an

illumination part and an image part.

The border between both is the specimen.

The bottom of the specimen is illuminated, while the

top of the specimen emits the image.

Illumination

In the DESK_II the specimen's illumination is done by

an RGB illumination unit, an illumination mirror and the condenser.

The RGB illumination unit creates monochrome light in

the wavelength of Red, Green and Blue, sequentially, so, the specimen's Field

of View is three times illuminated.

The control of the illumination is mainly done by the

shutter time of the camera (triggering), the timing may be done hardware or

software controlled.

The created monochrome, parallel wavelengths are reflected by the illumination

mirror in an angle of 90° to the condenser and this focuses the lightrays to

the field of view, observed by the Objective.

Image

The Quality of the image is mainly influenced by its size, resolution,

brightness and contrast.

Size and resolution is influenced by the camera adapter and the sensor

parameters of the scan camera, while other image parameters are mainly

influenced by the construction of the image path, the image illumination and

image magnification.

The objective gathers the light rays, passed through the image and

arranges these, together with the tube lens to an image.

The size and resolution of the image may be varied in limits by the

magnification of the camera adapter.

If the limit in –X-direction is reached, a small gap of

about 0.1mm should exist, so jam may not occur in –X-direction.

If the limit in –X-direction is reached, a small gap of

about 0.1mm should exist, so jam may not occur in –X-direction.

Adjust the scanner

plate position

To ensure, that the scanner plate and any internal part

do not touch the housing, its position can be adjusted.

To ensure, that the scanner plate and any internal part

do not touch the housing, its position can be adjusted.

The mounting of the scanner plate consists of 3pillars, mounted to the

base plate from beneath, the scanner plate is mounted with the bolts 1,2 and 3

to the pillars.

The long holes in the base plate allow a positioning of the scanner

plate in the mathematical X-direction and the long holes in the scanner plate

allow the positioning in Y-direction.

·

Mount the lower housing (see above “To mount the

lower housing”).

·

Adjust the position of the scanner plate so; that no

internal part touches parts of the correctly mounted lower housing.

·

Especially, check the distance of the focus plate and 4:1

divider of the focus unit in relation to

the rear part of the lower housing, no part of the focus unit should touch the

back wall; a gap of about 0.5 ...1 mm is required (adjust the

Y-position)!

·

Fit the upper housing, open the slide door and check

the gap between specimen holder and right side of the housing, if the specimen

holder is in the negative limits; there should be a gap of about

·

Furthermore, check the position of the mirror tube; it

should be nearly in the middle of the housing opening.

·

If the scanner plate position was modified or adjusted

the following adjustments have to be done or checked:

o

The door sensor acting position (see “The door closed

position” and “To adjust the

door sensor position”

o

The specimen holder fixing position (see “Adjust the specimen

holder fixing”)

o

Adjust the supporter position (see “Adjust the supporter

position on the left side of the specimen holder”)

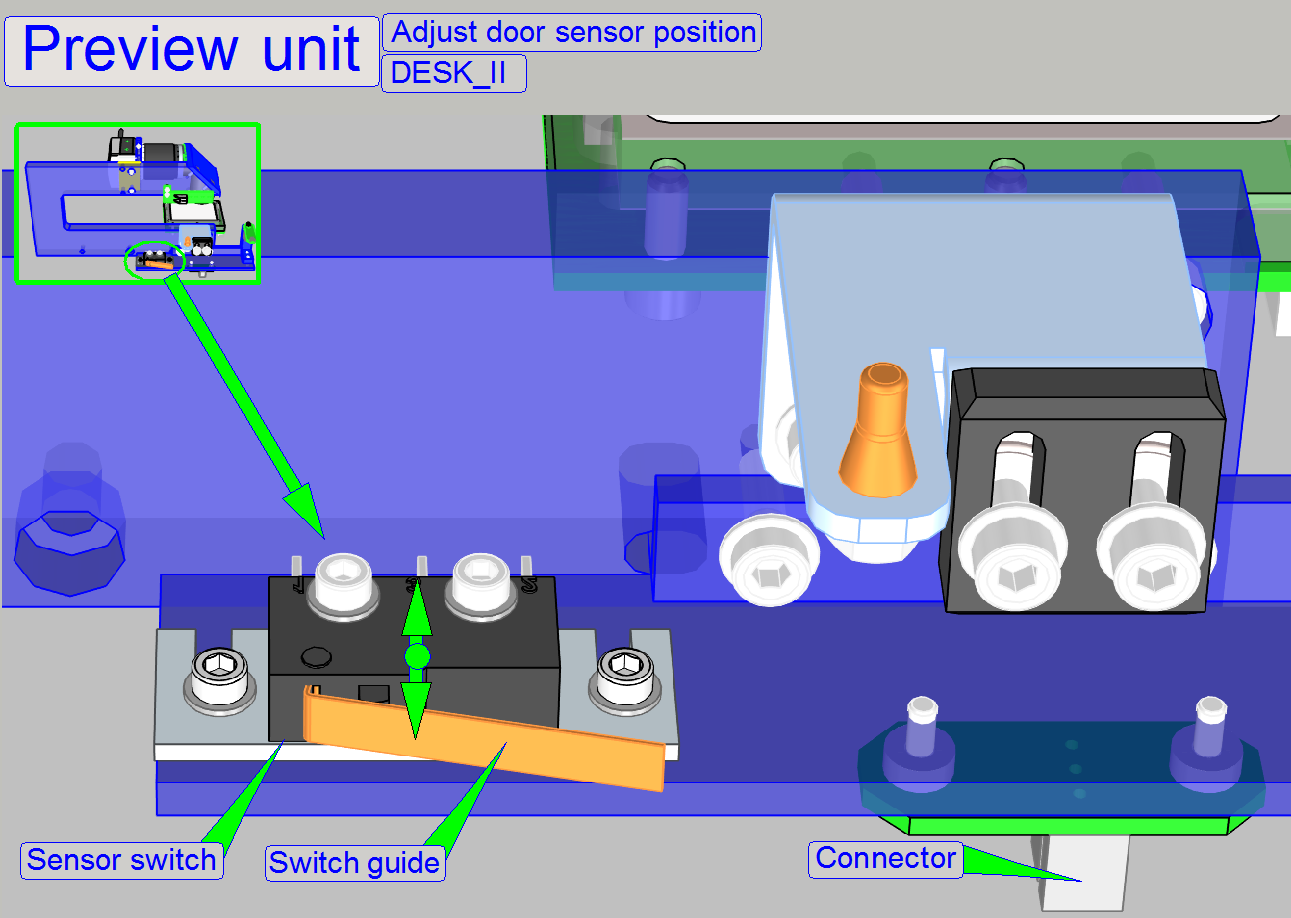

The door sensor should signal the “door closed” state safely, if the

door is closed; therefore the door sensor should acting about 1 ...

Adjust the door switch position

This adjustment should be done only, if there are problems with

recognizing of the “door closed” state, e.g. if the scan process is interrupted

without any interpretable reason; if the mountings or adjustment bolts was

loosened or the position of the scanner plate was adjusted or modified.

This adjustment assumes that the scanner plate position is correct, see

above “Adjust the scanner plate position”.

1.

Remove the upper cover (see above).

2.

Loosen the mounting or adjustment bolts.

3.

Move the switch to the front or to the rear as desired

and tighten the fixing bolts.

4.

Fit the upper cover as required for the normal work,

but do not drive in the cover mounting bolts.

5.

Check the “door closed”

position with the service program.

6.

Repeat from step 1 until the door closes correctly.

7.

Check this adjustment again if the upper cover is

fixed with the bolts.

Adjust the

specimen holder fixing

Adjust the

specimen holder fixing

This adjustment assumes that the scanner

plate position is correct, see above “Adjust the scanner plate position”.

- During these adjustment, the

parallelogram must not be strained!

Position

adjustment

1.

Loosen the bolts of "Adjust gap size"

2.

Set the X-Y-stage to the limits Y-min and X-min, (see

also “The X-Y-stage” and “Find the hardware limits for the

X-Y-carriage”).

3.

Position the entire specimen holder fixing so, that

the fixing guide of the specimen holder has a gap of about 0.1mm in the

hardware limit positions X-min and Y-min.

Adjust

the height

4.

Set the X-Y-stage to X-Home1,2 and Y-Home1,2.

5.

Insert a slide.

6.

Loosen the bolt "Adjust fixing height".

7.

Set the focus position to +1300 steps (SW position =

2650).

8.

Fit the height of the specimen holder fixing to the

specimen holder guide and tighten the fixing. To reach this, move the X-Y-Stage

in

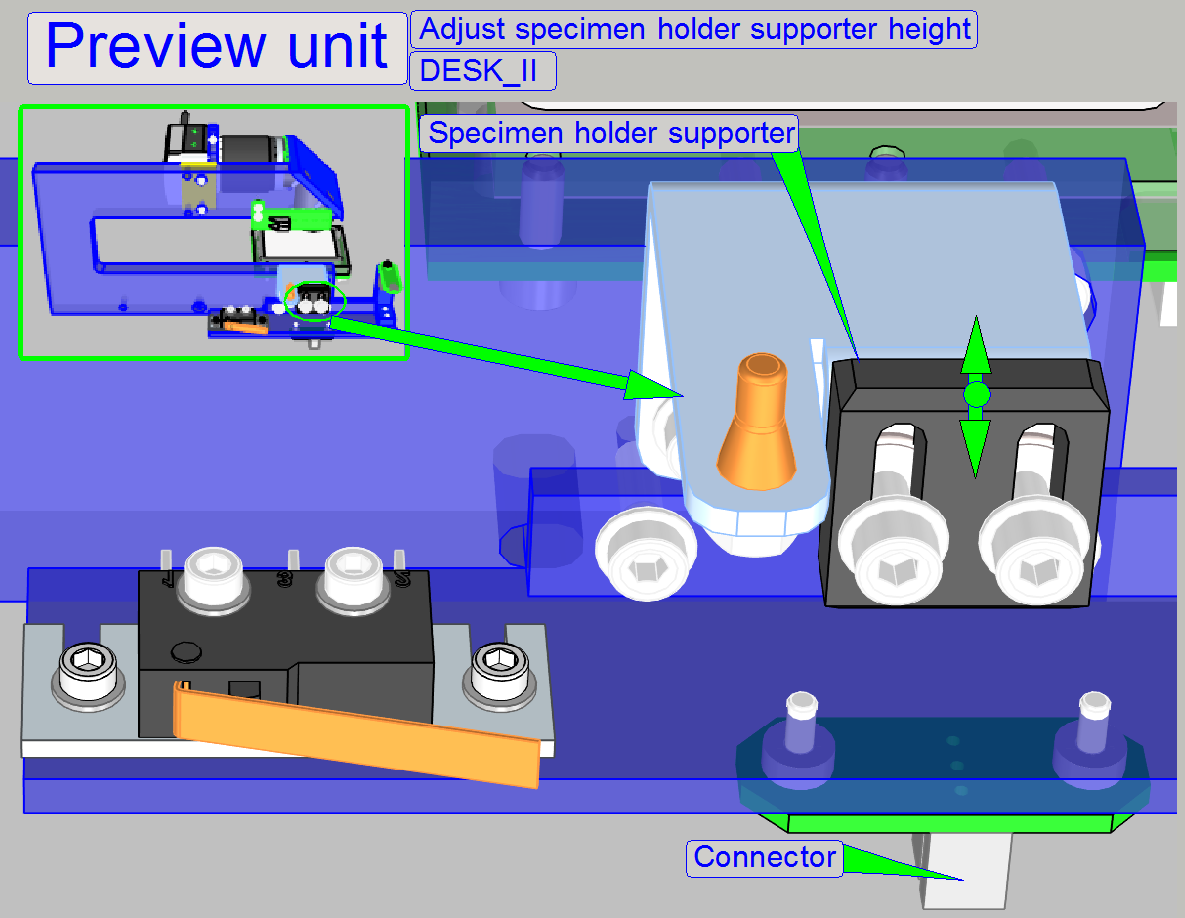

Adjust the supporter

This adjustment assumes that the specimen holder fixing position on the right

side is already adjusted.

9.

Loosen the supporter fixing bolts.

10. Set the X-Y-stage

to X-Home1,2 and Y-Home1,2.

11. Move the supporter

downward, then upward until the supporter part of the specimen holder is

reached; there should be no pressure against the specimen holder.

12. Tighten the

supporter fixing bolts.

Define the slide insert and remove parameters

The following parameter values defining the slide

insert and remove position for the specimen holder in the DESK. The values are

often 0, it means Home1,2; the values for the parameters “InsertSlide PositionX“, “RemoveSlide PositionX1“, and

“RemoveSlidePositionX2“ can be used to

adjust the specimen holder position to the housing, but the size of the gap is

not critical.

If any value would be more the 1000 steps, the scanner

plate position must be corrected (see above “Adjust the scanner plate

position”).

Relevant

parameters in the file “MicroscopeConfiguration.ini”

The shown values are for information only!

[SlideLoading]

InsertSlidePositionX=200

InsertSlidePositionY1=0

InsertSlidePositionY2=0

InsertSlidePositionY3=0

RemoveSlidePositionX1=200

RemoveSlidePositionX2=200

RemoveSlidePositionY=0