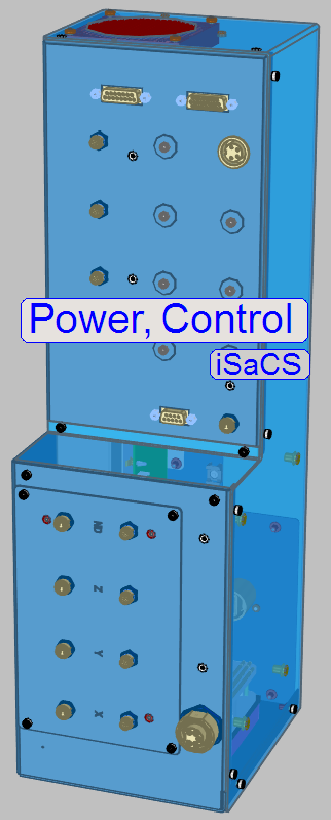

Power, control; iSaCS

For technicians and

partly for sales managers!

The scanner

3DHISTECH iSaCS has modified power supply and electronics compare to the

Pannoramic 250. These modifications are required because the scanner is based

on a modular

The scanner

3DHISTECH iSaCS has modified power supply and electronics compare to the

Pannoramic 250. These modifications are required because the scanner is based

on a modular

·

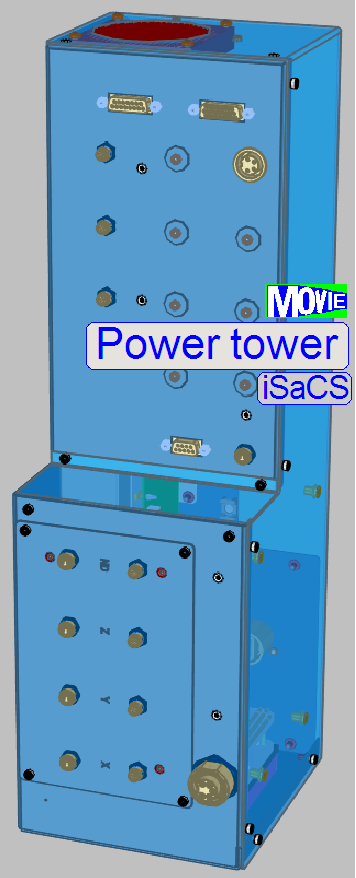

The entire power unit has also got a separate housing

and is arranged in a tower; the so-called “Power tower”.

·

The internal construction and used components are

derived from the scanner Pannoramic 250 Flash and the Pannoramic Confocal.

·

Control of the staining and cover slipping units are

realized by the main control electronics and the local electronic units.

·

Power for the main electronics and connected

components is supplied from the Power tower.

·

The power supply of the Lumencor SPECTRA light engine

is realized with an external power supply.

·

Software-related settings and checks are based on the

software version 1.20.

Important remark

- After maintenance

or service and tests of the scanner are 100% finished, protective ground

connections and other safety regulations related to hazardous voltage,

accessible conductive parts and dangerous to life parts have to be checked

(again).

- For safety regulations

regarding human health and scanner functionality please refer to: Precautions

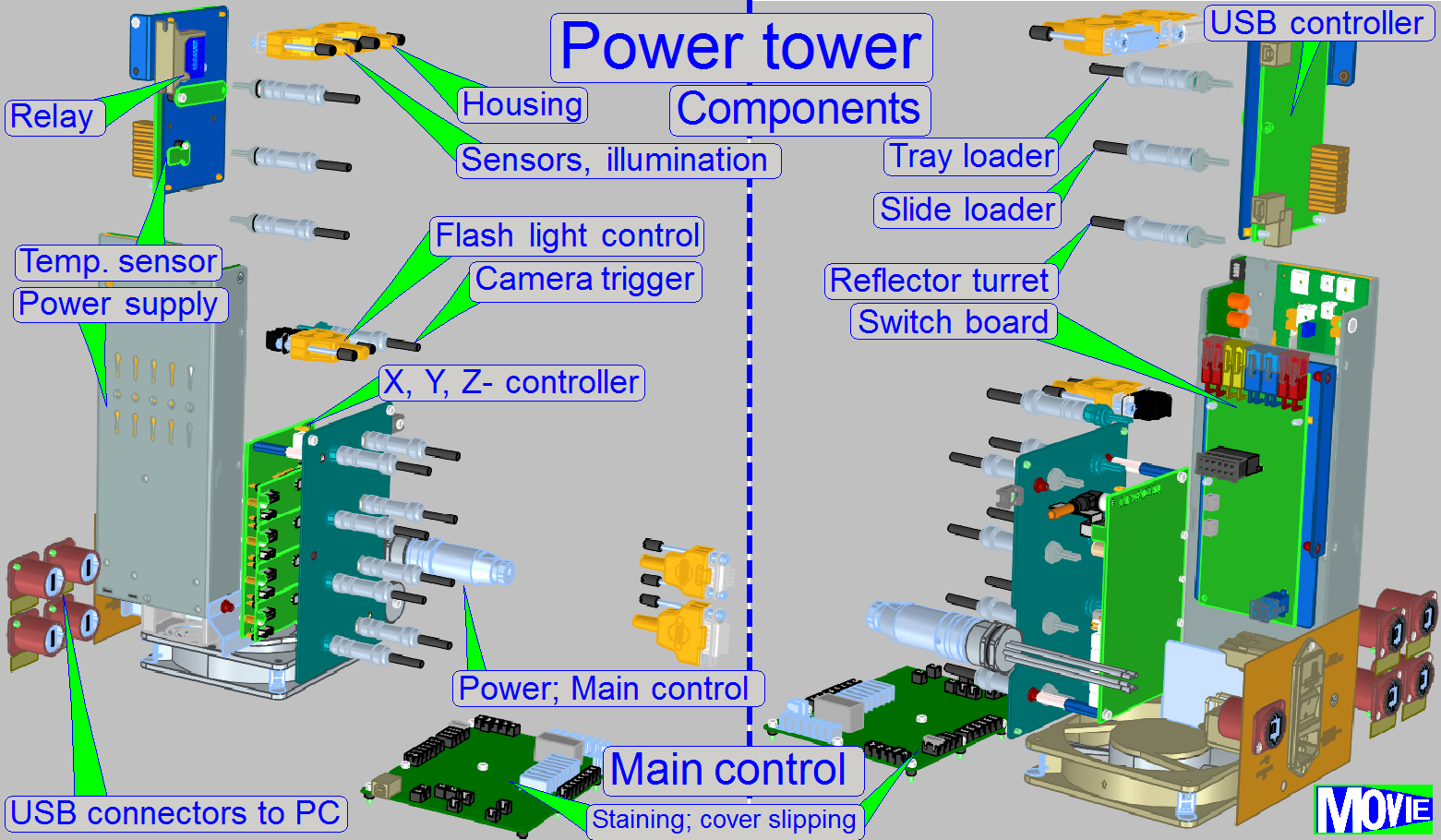

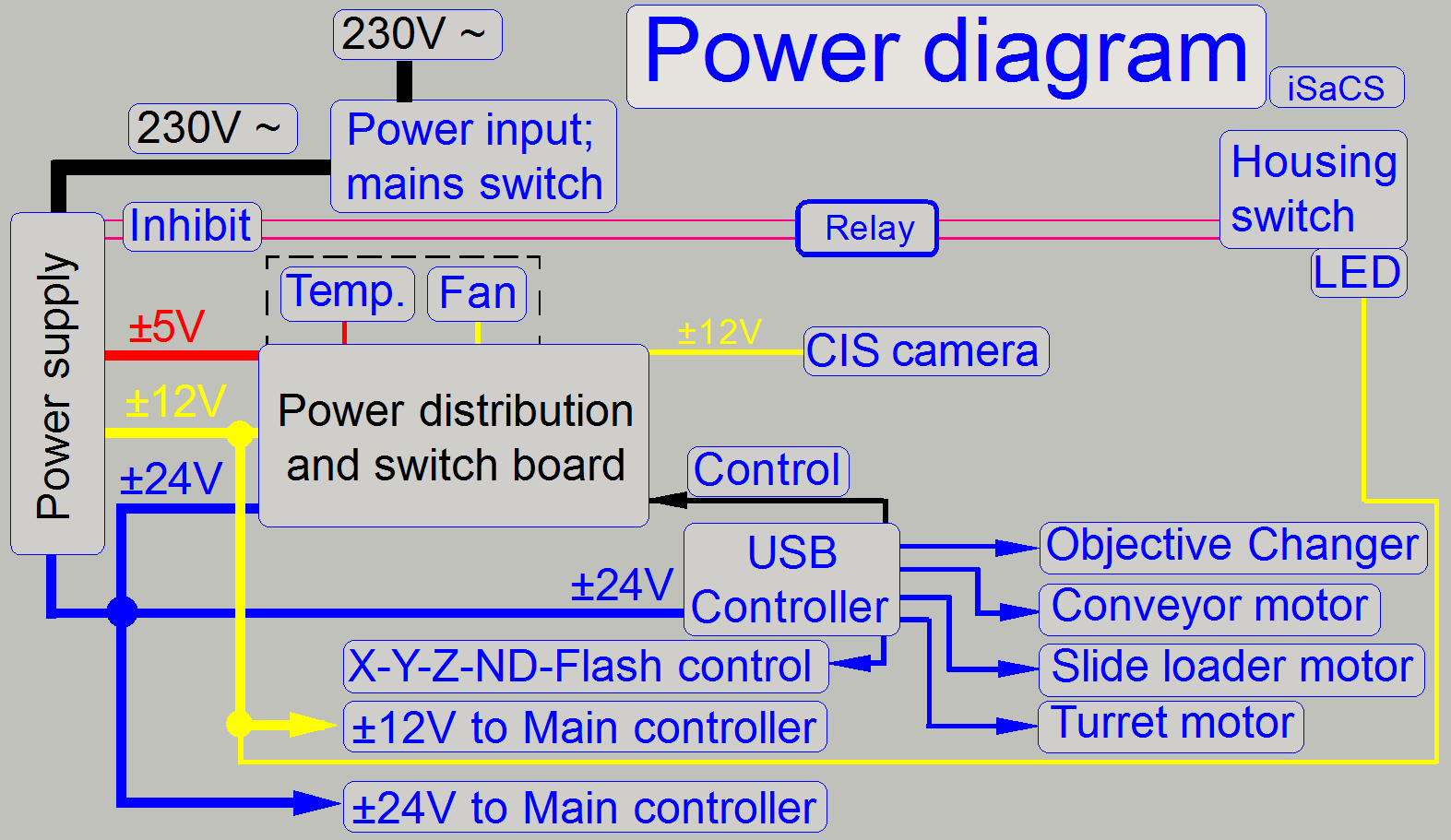

The power supply and control

electronics consist of the following components and units:

·

General

·

Scanner

·

Power distribution

and switch board

·

USB

Controller with EEPROM

Main control; Staining, Cover

slipping

Main modifications in

relation to the modular

Main modifications in

relation to the modular

·

The iSaCS power supply is realized as an internal OEM power supply

module.

·

The power distribution

for momentarily unused units or all units in emergency situations (overheating)

can be

switched off by the PIC controller firmware.

·

The focus unit stepper motor was changed to a motor

with higher resolution (6400 steps / revolution).

·

Control of the objective

changer.

·

The X-Y-Z stepper motors do not contain control

electronics; the control

electronics for these motors was separated.

·

Independent temperature-sensing

and regulation by the control of the fan’s speed.

·

Further

sensors are implemented.

·

Illuminated logo.

Configure electronics components

Since the software version 1.15 the units of the

scanner are configured in the file “MicroscopeConfiguration.ini”, section

[Microscope].

The actual version of the

electronic components in the scanner iSaCS is defined as follows:

[Microscope]

SerialNumber=xxxxxx

MicroscopeType=3DMic10

MicroscopeSubtype=SCS

PreviewCameraType=CVrmc_m8_pPro

BarcodeReaderType=PreviewCamera

LoaderType=SL_1Mag_12Slide_Sensor_Horizontal

CameraChangerType=CC_None

ReflectorTurretType=RT_None

BrightfieldLightSourceType=RGBLedLight

ObjectiveChangerType=OC_2Pos

ObjectGuideXYZType=OGXYZ_FLASH4

FlashUnitType=FlashUnit_Type2; see

also: X-,Y-,Z-controller

NDFilterType=ND_None

PreviewLightType=PreviewLightUnitType_Type2

PowerSwitchBoardType=PowerSwitchBoard_Type1 see also: Power distribution

and switch board

Remark

To enable the X-,Y-,Z-controller:

FlashUnitType=FlashUnit_Type2

Actually, the most recent

“Type2” is used.

To disable the X-,Y-,Z-,controller:

FlashUnitType=FlashUnit_None

To enable the switch board:

PowerSwitchBoardType=PowerSwitchBoard_Type1

Actually, the most recent

“Type1” is used.

To disable the switch board:

PowerSwitchBoardType=PowerSwitchBoard_None

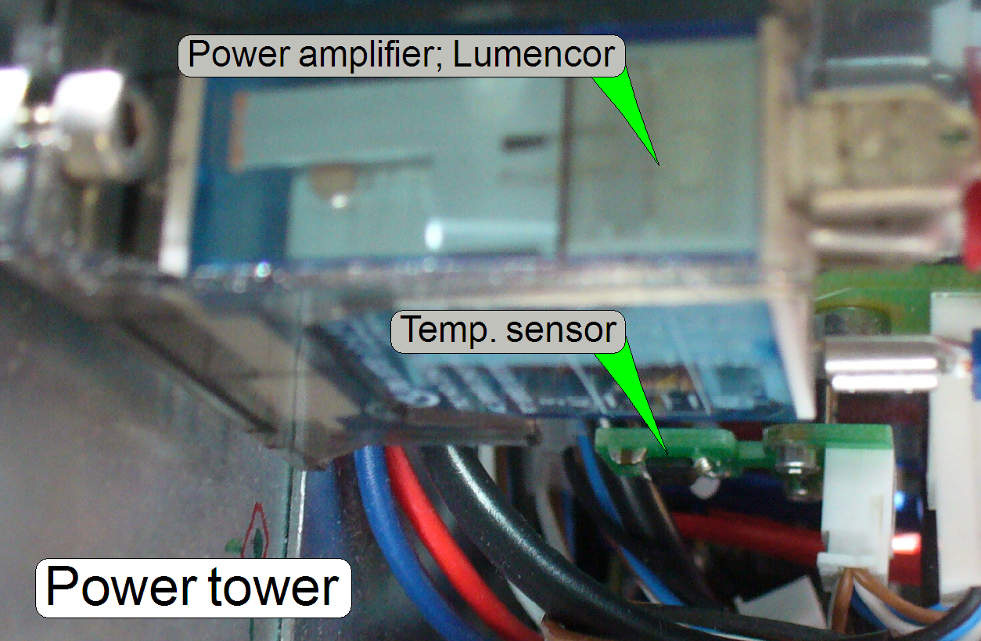

The main components of the

power supply and control electronics for the scanner are arranged in a “Power

tower”.

In the bottom part a fan with

particle filter is implemented, so the power supply and other electronic

components reach cooling.

A temperature sensor is

implemented to avoid probable overheating.

·

The entire power tower is mounted by 4 bolts to the

truss of the iSaCS.

More detailed information

about the internal construction can be found in the “Power

tower gallery”.

|

Connection |

Connector |

Identifier |

Pins |

||

|

Component |

|

+ |

- |

Signal |

|

|

Preview BF illumination |

LBSL-1 |

10 |

11 |

|

|

|

|

|

12 |

13 |

|

|

|

|

|

14 |

15 |

|

|

|

Barcode illumination |

LCSL-1 |

16 |

17 |

|

|

|

Tray sensor |

HTSL-1 |

3 |

1 |

2 |

|

|

Slide sensor |

HSSL-1 |

6 |

4 |

5 |

|

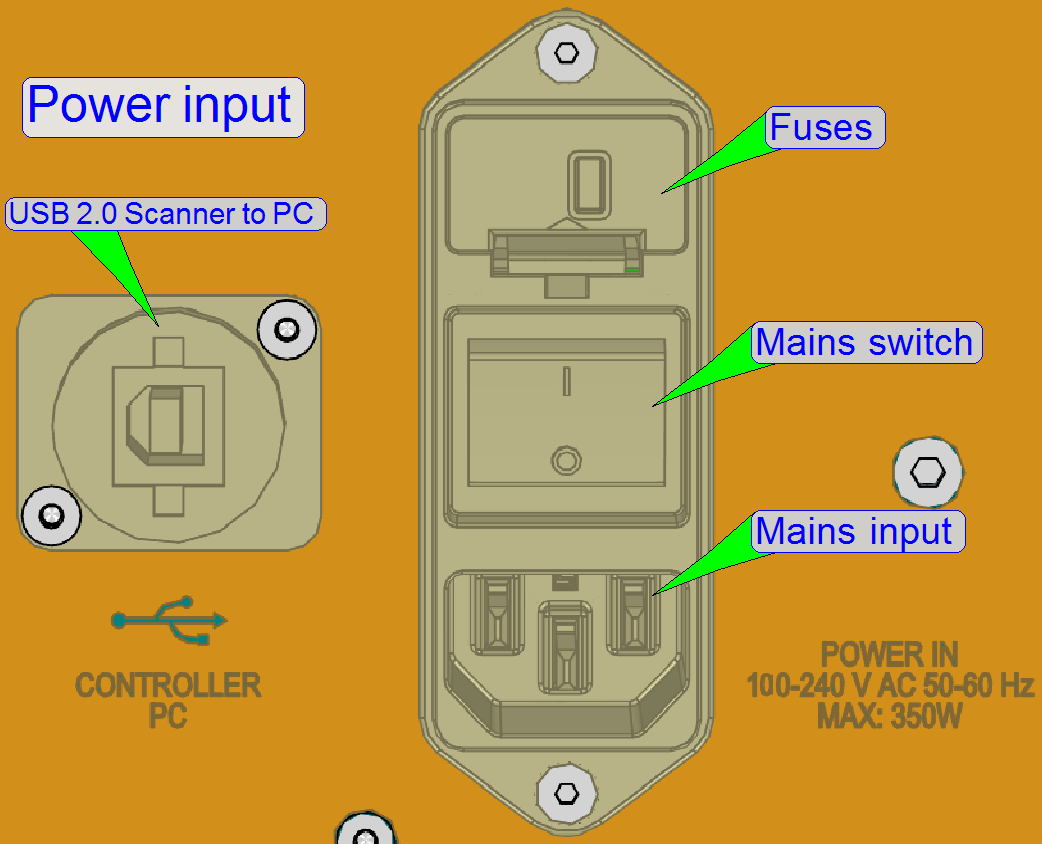

Power distribution

and switch board

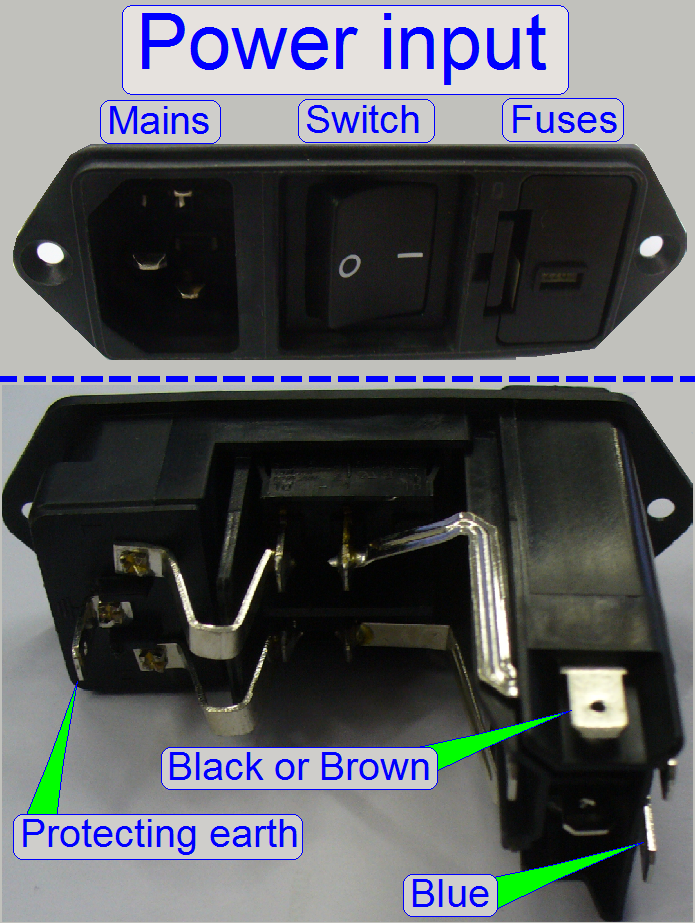

The power input connector and

mains switch consist of:

·

Power cord connector (Mains input)

·

Mains switch

·

Fuse housing with fuses

The double-pole mains switch disconnects

the mains power from the internal power supply.

Each pole is secured by a

slow-blow fuse of T3.15 A / 250V.

230V~

or 100V~

The alteration of

the mains power input in the range from 100V~ to 240V~ is reduced to the use of

the appropriate mains power cable (additionally, various connector outlet

constructions are used in different countries worldwide).

The alteration of

the mains power input in the range from 100V~ to 240V~ is reduced to the use of

the appropriate mains power cable (additionally, various connector outlet

constructions are used in different countries worldwide).

If the mains power is changed

from 230V~ to 100V~ or vice versa, no alterations are required inside the

scanner. The change of the mains power is fully handled by the input voltage

range of the power supply; ![]() “Power supply TDK -Lambda“.

“Power supply TDK -Lambda“.

More information can be found

in the “Power input gallery” and the “Power input slide show”.

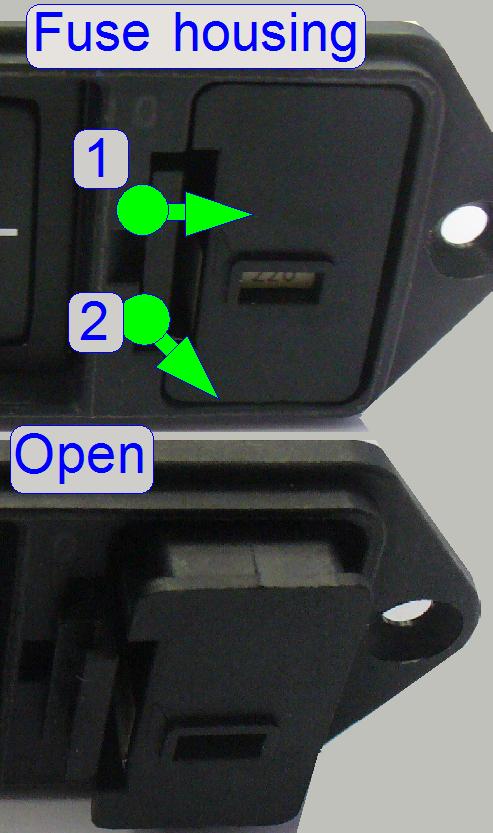

Check

or replace fuses

Disconnect the

power cable.

Disconnect the

power cable.

·

Open the fuse housing and remove the fuse container.

·

Push the fuse container lock guide (1) to the center

of the fuse container (for example with a flat screw driver).

·

Pull the container out (2) of the housing.

·

If the fuses are dismounted, use an Ohmmeter to check

the fuses.

·

If a fuse exchange is necessary, always use a

slow-blow fuse of T3.15 A / 250V (100V~ or 230V~ power input is unimportant).

More information can be found

in the “Power input gallery” and the “Power input slide show”.

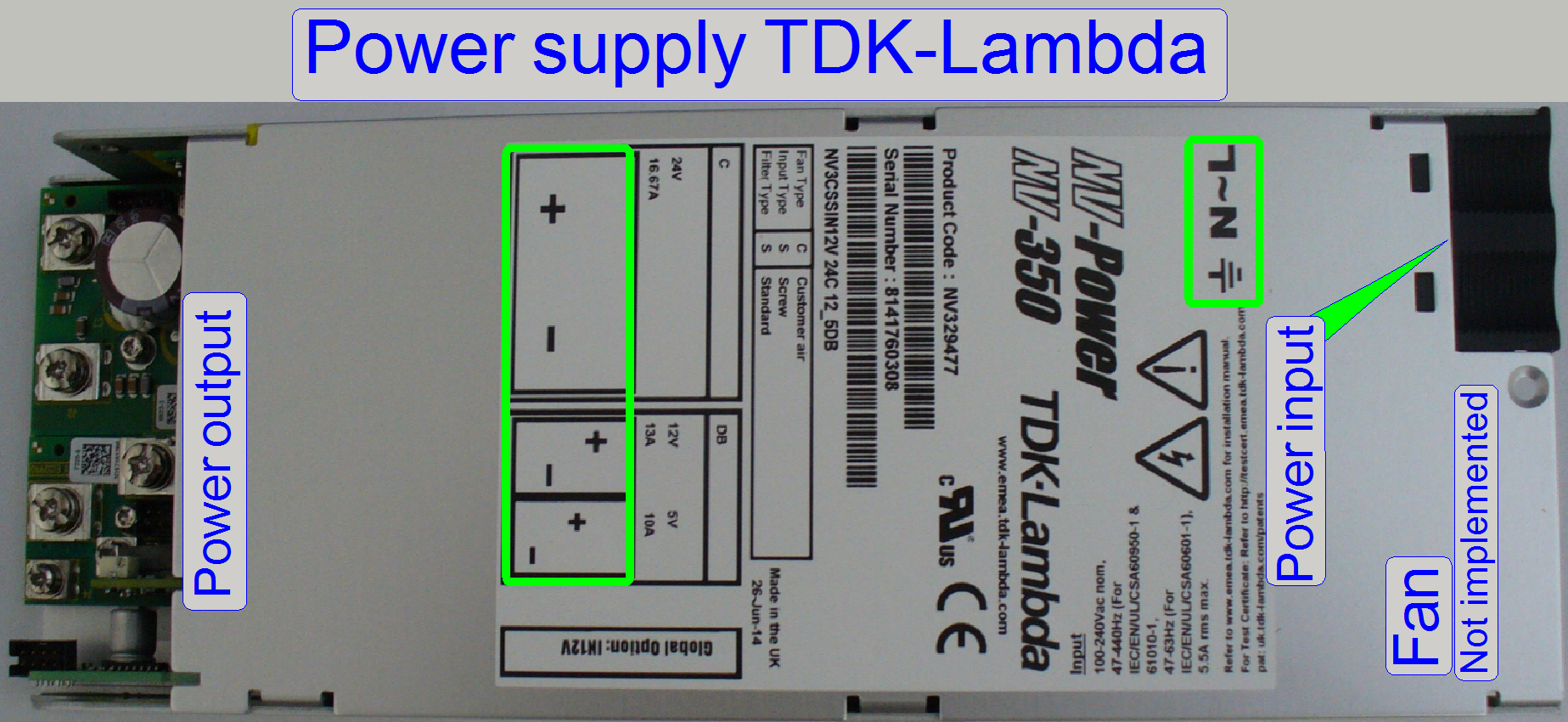

Power supply TDK -Lambda

The internal OEM power supply

TDK-Lambda with an input voltage range of 90V~ to 264V~ AC, an input frequency

of 47Hz ~ 63Hz and output voltages of 5V-, 12V- and 24V- DC supplies the

internal units of the iSaCS with power. Inside the controller units (USB, X-,

Y-, Z-motor controller, power distribution board and some stepper motors) a

local power supply is located and this create further, required voltages.

·

The power supply is short circuit-protected.

·

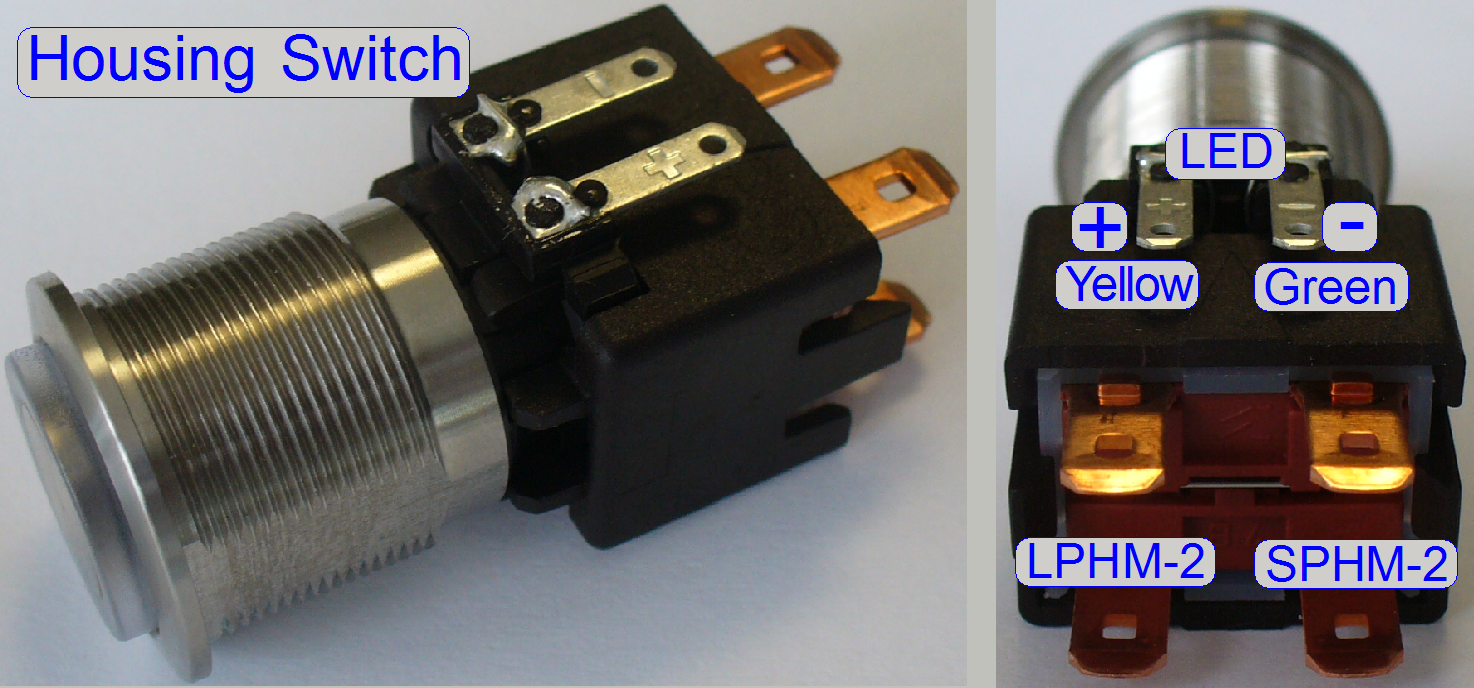

The “Housing Switch” is used to switch off the entire

scanner if mechanical malfunction or other emergency situation occurs.

·

If the input voltage is changed from 230V~ to 100V~ or

vice versa, no alteration is required inside the scanner.

Remark

The fan of the power supply

is removed in the iSaCS; the cooling of the components is done by the central fan of the power tower.

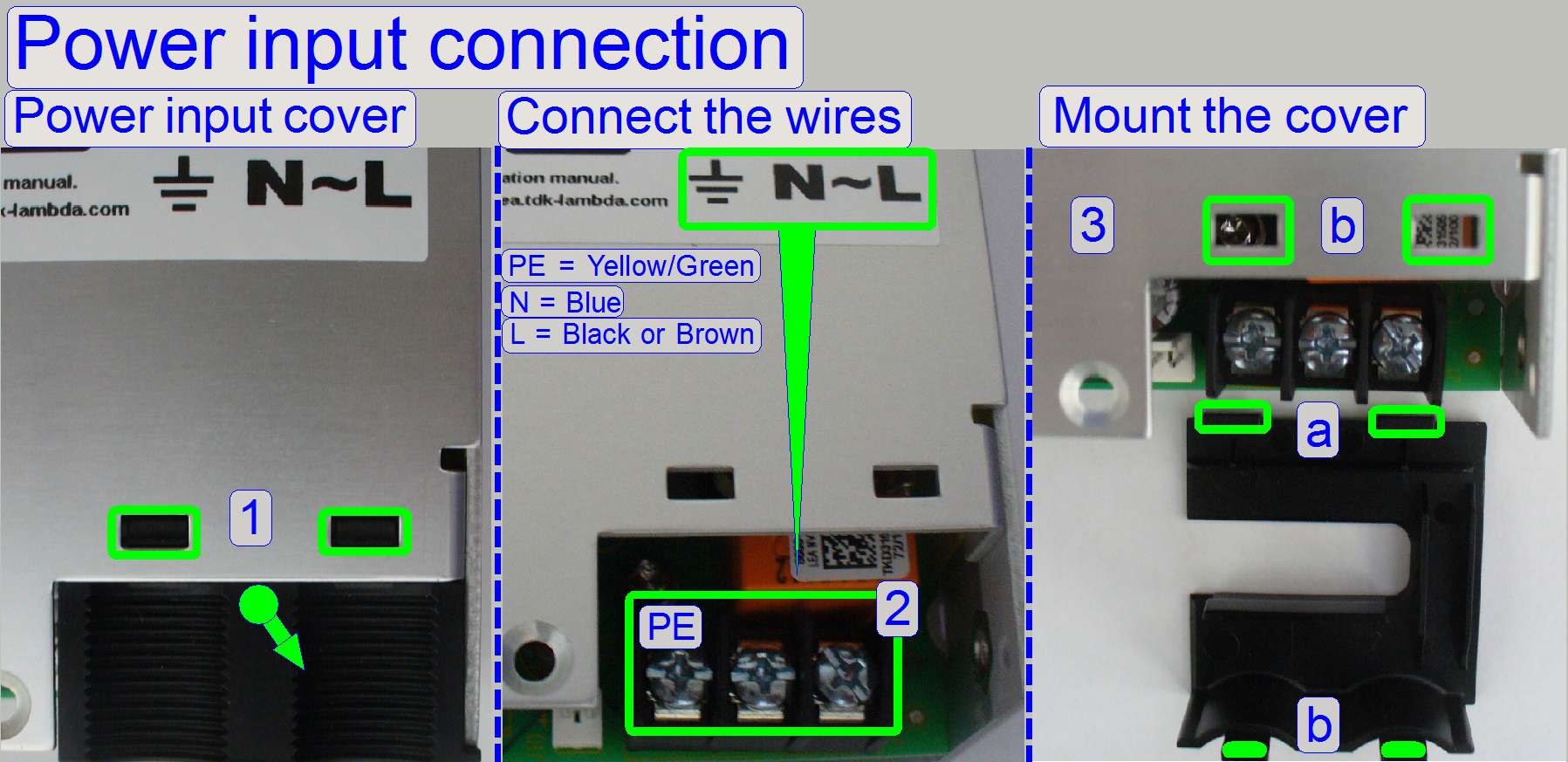

Power input

·

Press the power

input cover a bit downward until the clamps (1) are disconnected from the upper

housing part and remove the cover.

Press the power

input cover a bit downward until the clamps (1) are disconnected from the upper

housing part and remove the cover.

·

Connect the power wires as shown (2).

·

Fit the parts (a) into the slots of the base cover and

the clamps (b) into the appropriate slots of the top cover.

![]() “Installation manual” (in more languages); stored in this

description

“Installation manual” (in more languages); stored in this

description

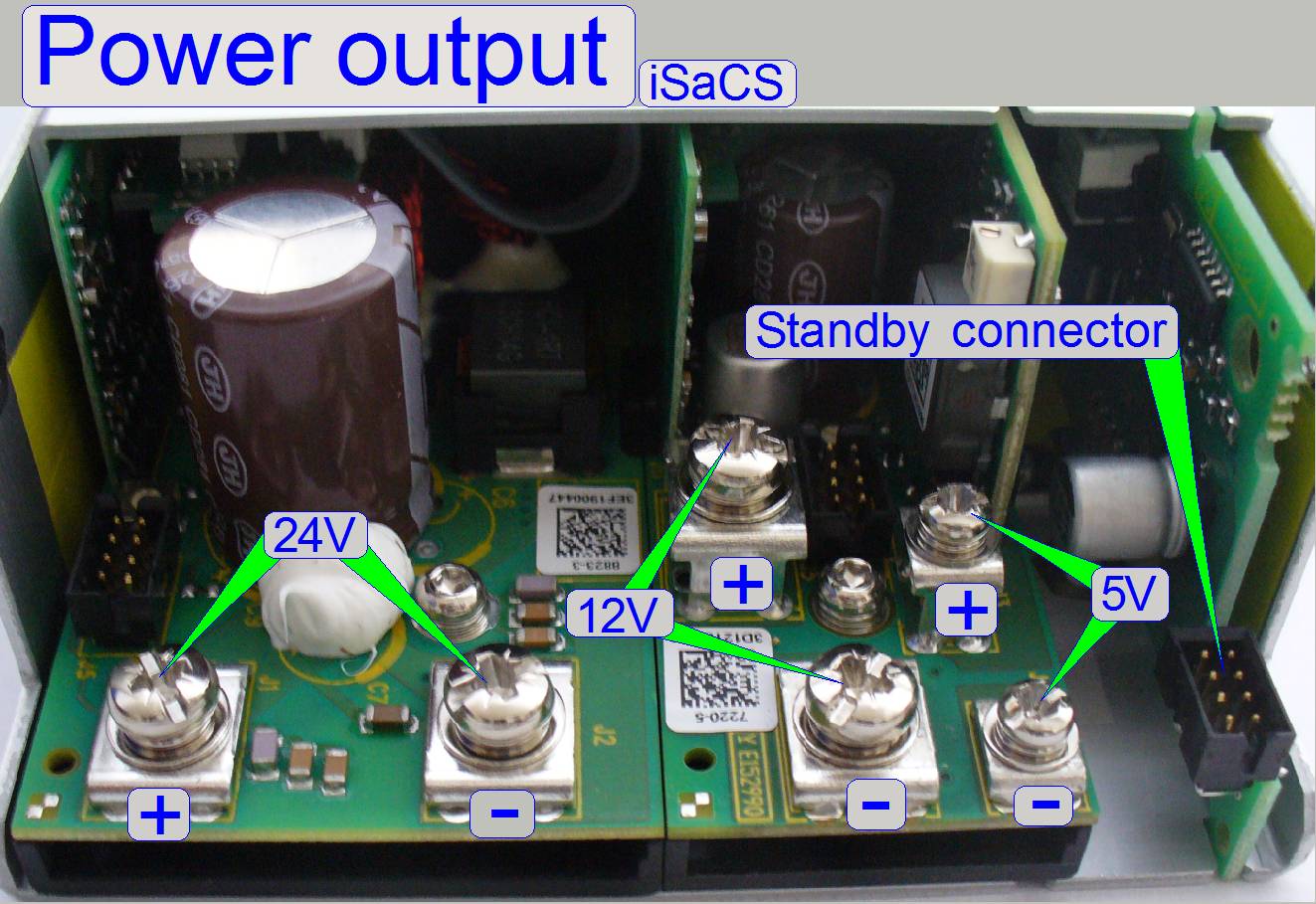

Output

voltages; power

·

5V- /10A DC

5V- /10A DC

·

12V- / 13A DC

·

24V- / 18.75A DC

The outputs are short

circuit-protected and are ground independent (the minus pole is not connected to GND) so each

voltage has a plus (+) and a minus (-) pole.

![]() Power_supply_tdk_Lambda_Data_Sheet.pdf (stored) and

Power_supply_tdk_Lambda_Data_Sheet.pdf (stored) and

Power_supply_tdk_Lambda_App.

Notes.pdf (stored)

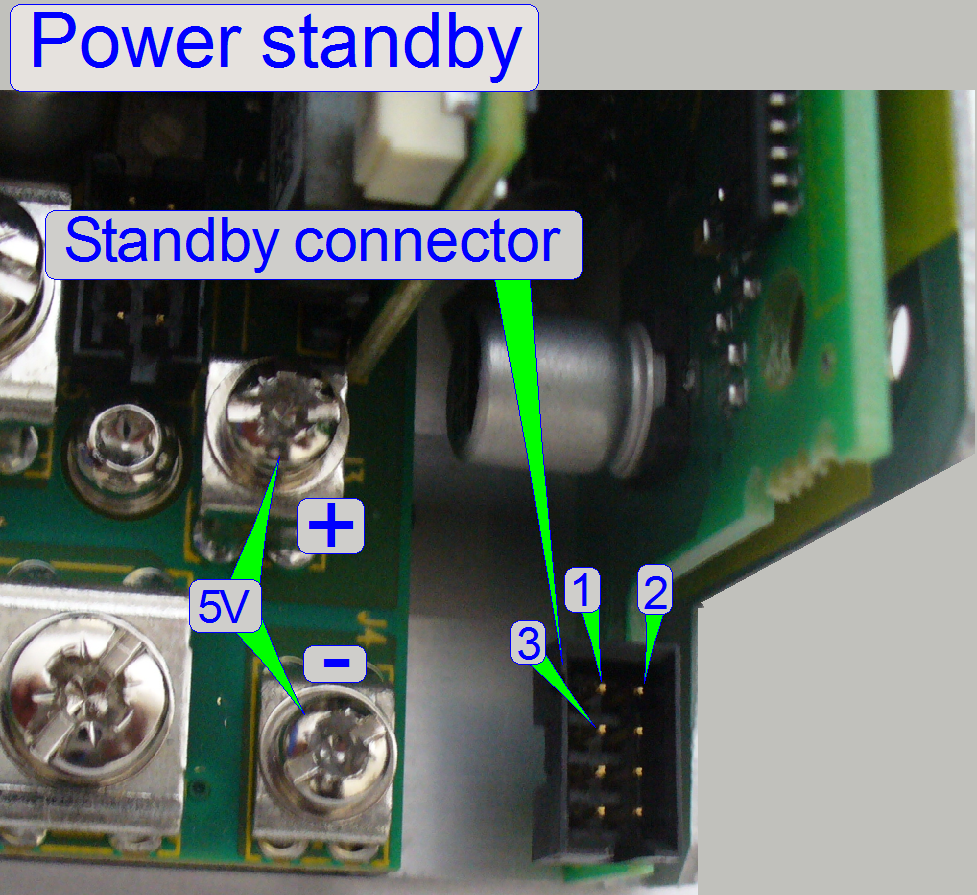

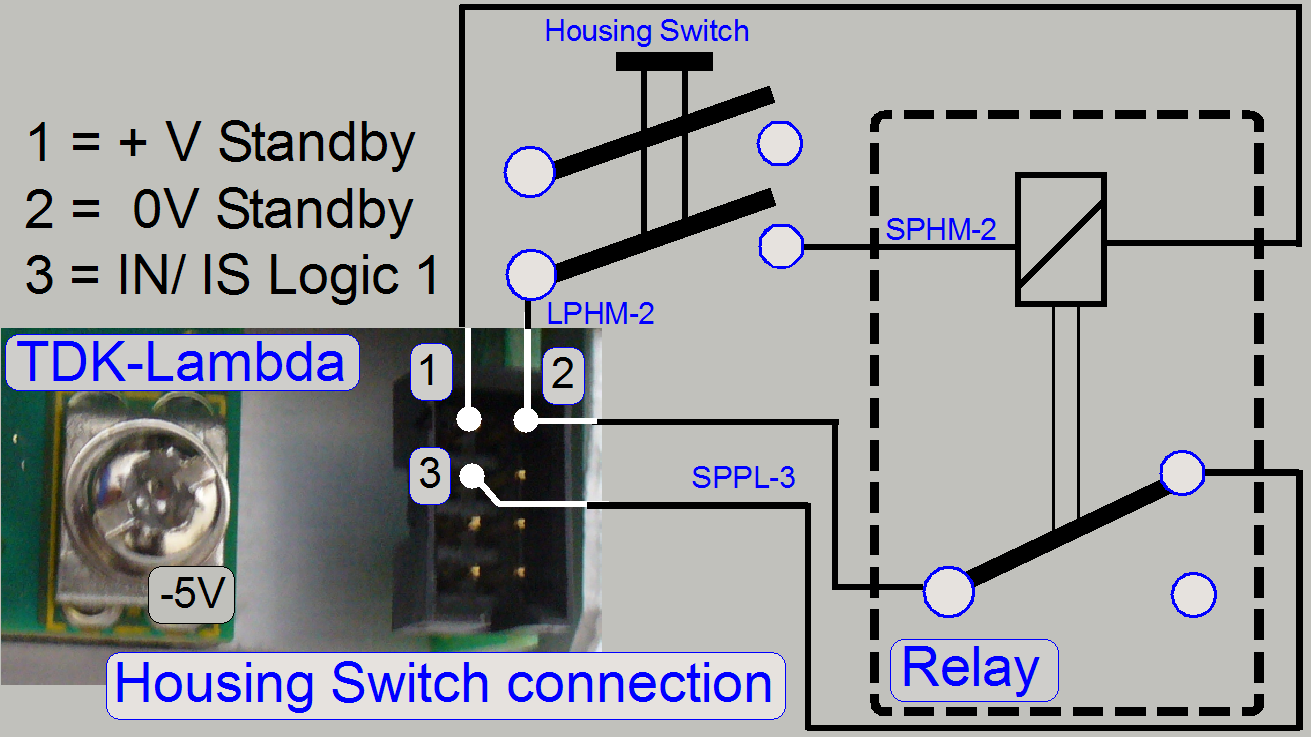

Housing Switch and standby

The Housing Switch

inhibits and stops the switching power supply by the help of a relay, but the

mains voltage of 100V~ or 230V~ is not interrupted; the power supply goes to

standby.

The Housing Switch

inhibits and stops the switching power supply by the help of a relay, but the

mains voltage of 100V~ or 230V~ is not interrupted; the power supply goes to

standby.

By shorting the pins “

If there is no connection

between the two pins (or the standby option is not used), the power supply is

running continuously.

·

These two pins will be shorted via a relay, if the

“Housing Switch” is active and closed.

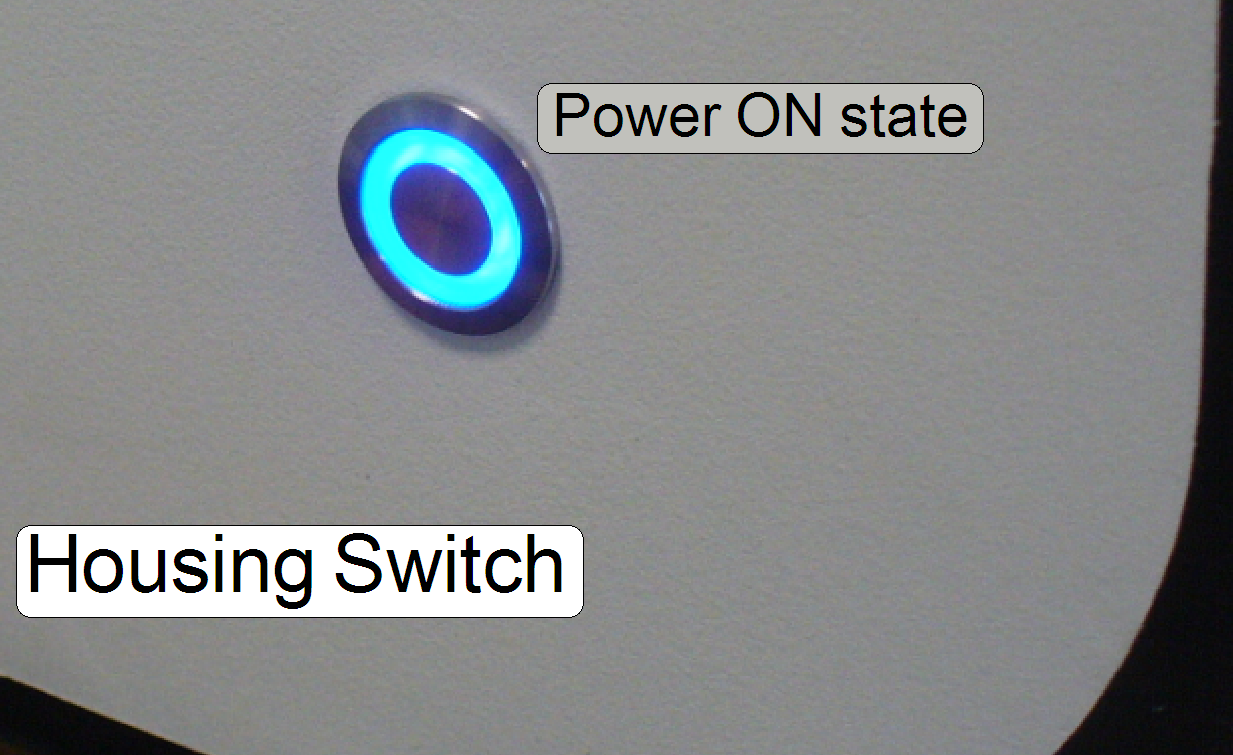

Housing Switch

The Housing Switch

is situated in the left handed side wall of the scanner and is used to inhibit the

power supply. The power distribution is interrupted and all movements are

stopped immediately.

The Housing Switch

is situated in the left handed side wall of the scanner and is used to inhibit the

power supply. The power distribution is interrupted and all movements are

stopped immediately.

·

If the power is supplied again to the scanner, the software has to be

started again.

![]() “Housing

Switch” and “Power LED”.

“Housing

Switch” and “Power LED”.

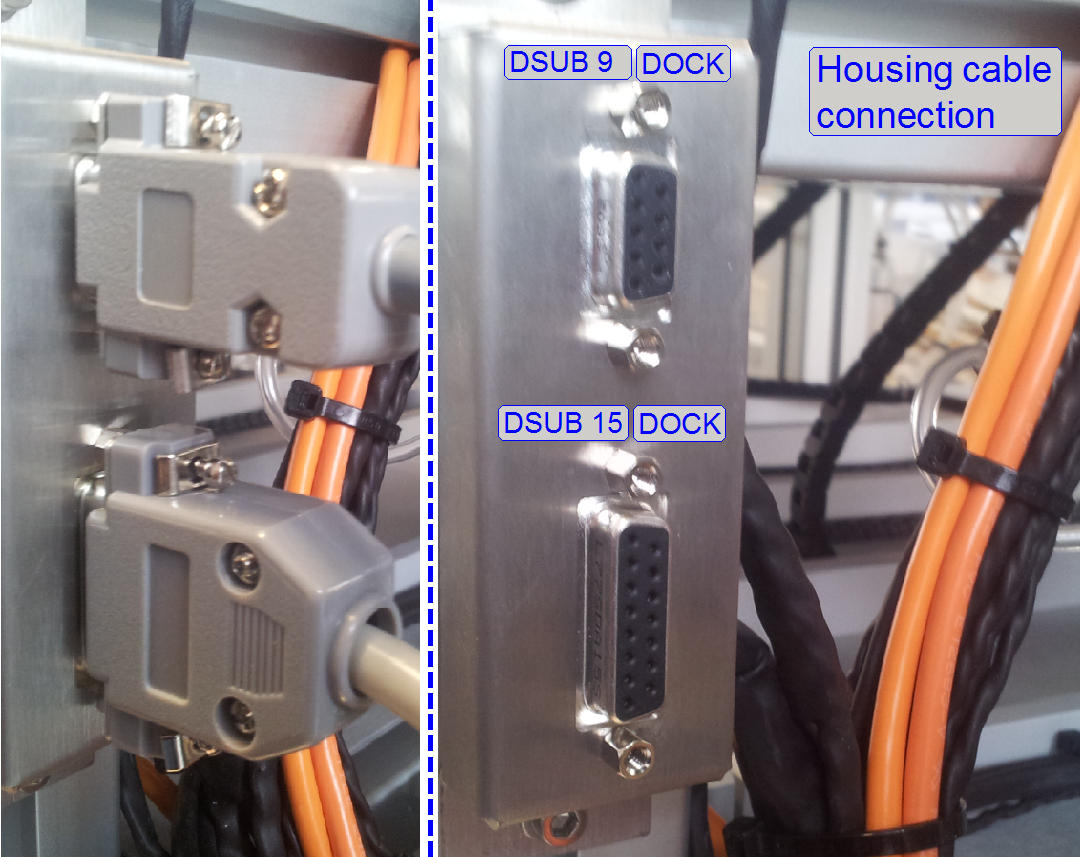

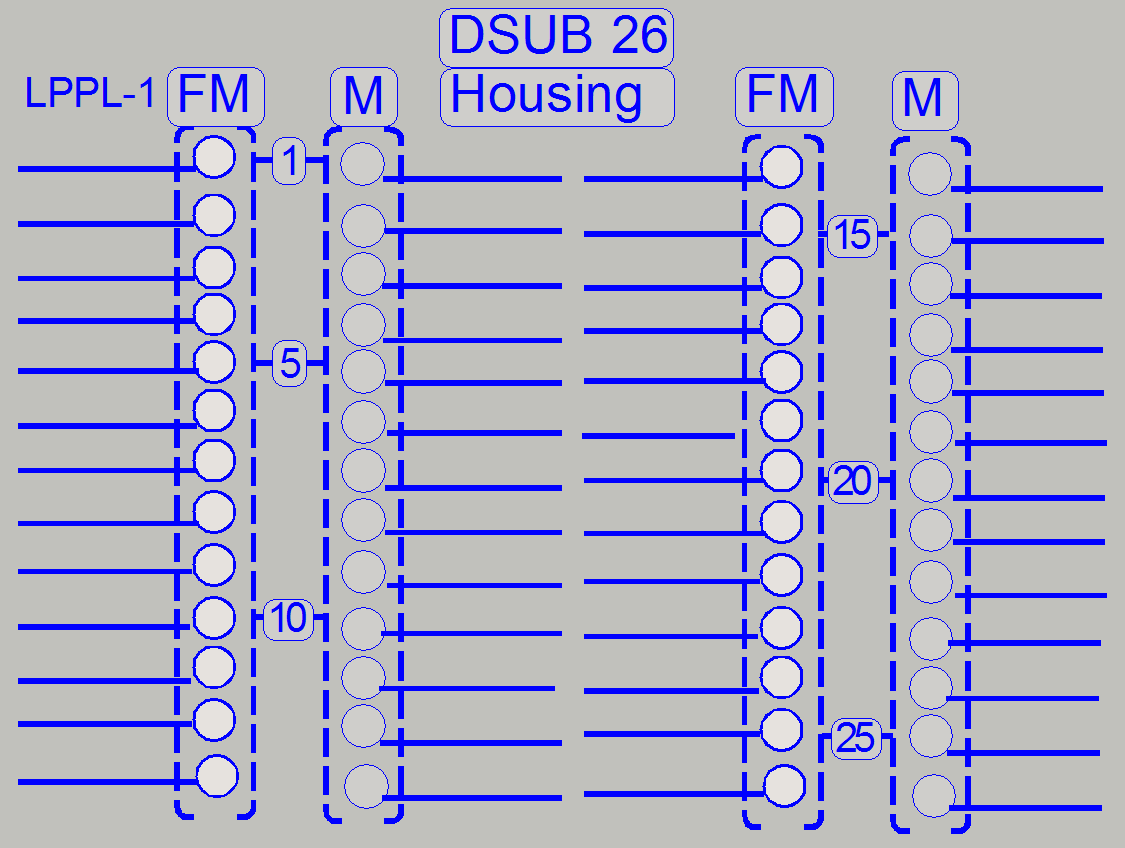

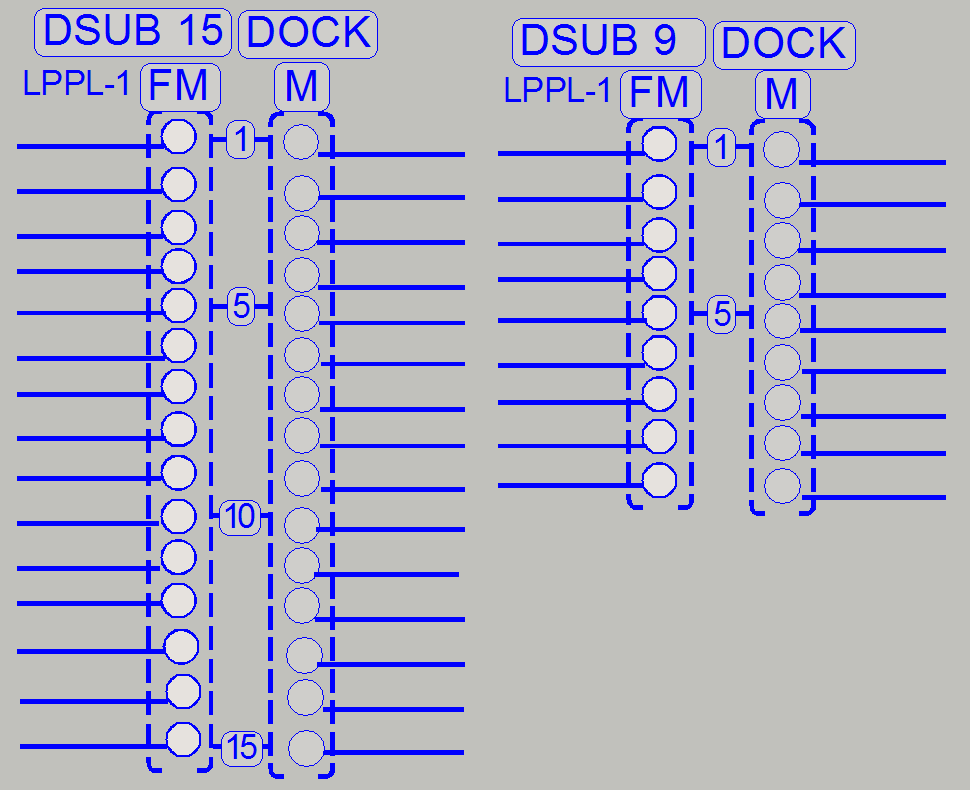

Housing

connectors

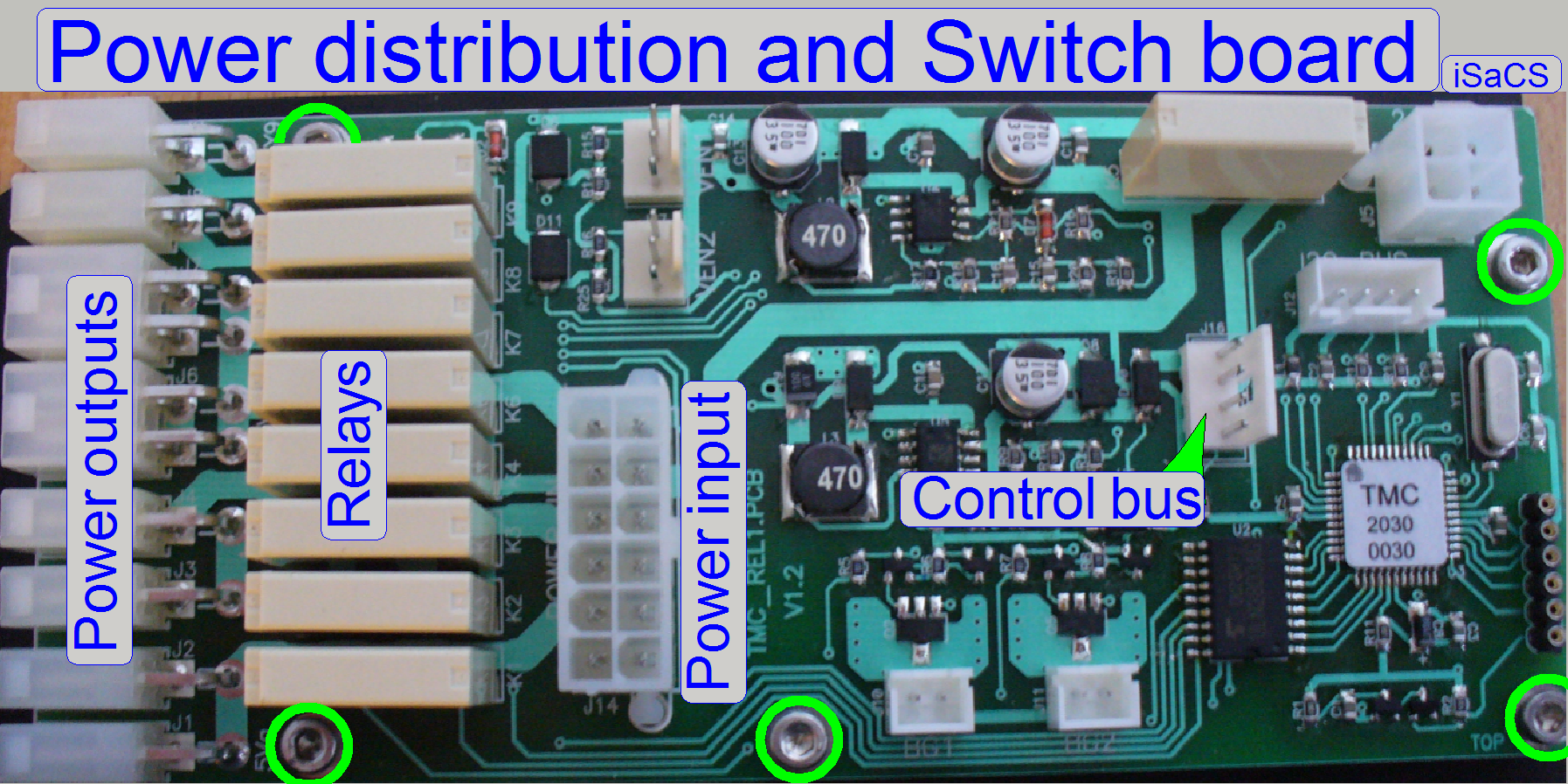

Power distribution and

switch board

The power outputs can be

switched by software; so momentarily unused units can be switched off, or if

any emergency event occurred, all outputs may be disabled.

The outputs are switched by

the use of relays.

The communication between

software and the power distribution board is realized with the control bus

connector; this is connected to the USB controller and is used to switch on /

off the power outputs and to transfer status information to the USB-controller.

The temperature sensor input

controls the fan output directly, without any scan software control, bat the

temperature value and the fan speed can be read from the software; see also the

service program, Low level service, power supply. The fan speed is controlled

via the PIC on this switch board, depending on the sensed temperature value.

Enable or disable of the switch board

For technical enhancements

and upgrades, the type of the entire “Power distribution & switch board”

can be defined or the board might be disabled.

The relevant parameter and

value is found in the section [Microscope] of the file “MicroscopeConfiguration.ini”.

To enable the switch board:

PowerSwitchBoardType=PowerSwitchBoard_Type1

Actually, the most recent

“Type1” is used.

To disable the switch board:

PowerSwitchBoardType=PowerSwitchBoard_None

Usually, the board is

enabled.

Usually, the board is

enabled.

If the entire “Power distribution

and switch board” is disabled, the power supply for the camera and all other

connected units is disabled; the scanner will not start correctly or the

powering of the appropriate units have to be realized otherwise; e.g. with

external power supplies.

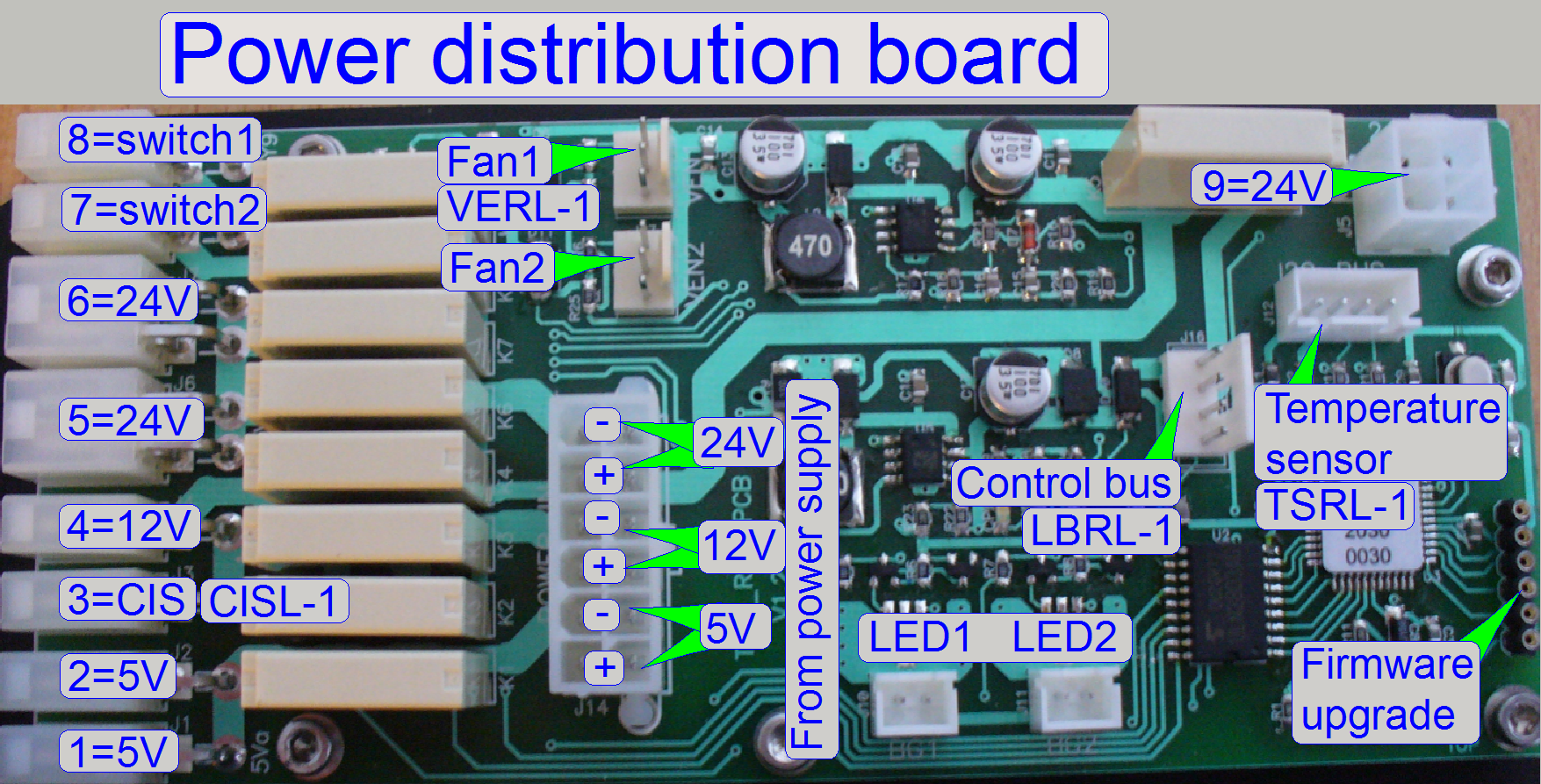

1= reserve 5V- output

2= reserve 5V- output

3= Power output 12V- CIS main camera; CISL-1

4= Power output 12V-

5= Power output 24V-

6= Power output 24V-

7= reserve switch1

8= reserve switch2

9= reserve 24V- output

5V= Power input from the

TDK-Lambda power supply

12V= Power input from the

TDK-Lambda power supply

24V= Power input from the

TDK-Lambda power supply and LPPL-1

The switched outputs are

ground independent (the minus pole is not connected to GND) so each voltage has

a plus (+) and a minus (-) pole.

The board is found in the

“Power tower” see also: Distribution

and switch board

Connectors Fan1 and Fan2

Via the connector “Fan

Temperature sensor input

The temperature sensor input

is an I2C bus input and the temperature sensor is connected via the

line “TSRL-

The temperature

inside the Power tower is sensed via a temperature sensor by the help of the

PIC on the switch board.

The temperature

inside the Power tower is sensed via a temperature sensor by the help of the

PIC on the switch board.

Probably errors may be:

·

Temperature sensor is not connected; any wire is

broken or has no contact.

·

Sensor is defective.

·

Power distribution and switch board is defective.

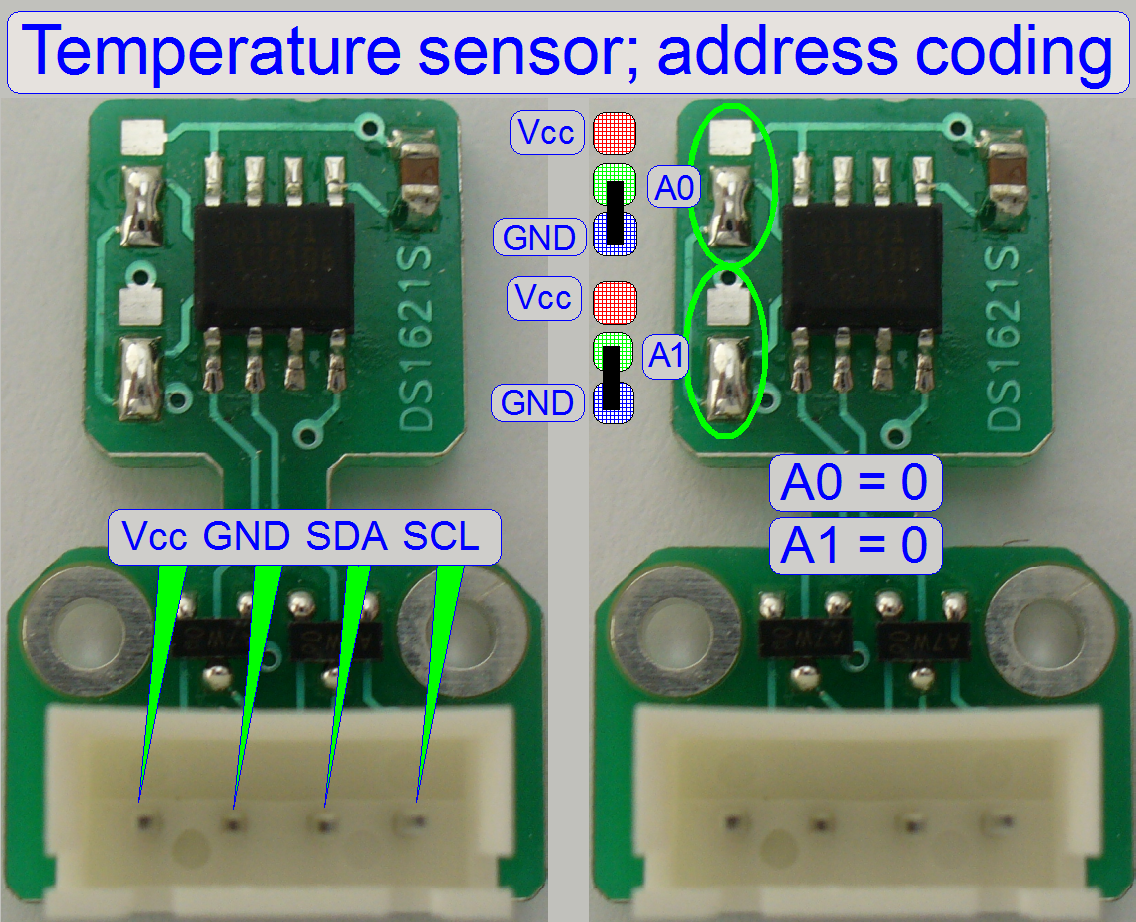

Temperature sensor;

TSRL-1

Temperature sensor;

TSRL-1

The temperature inside the

Power tower is sensed via a temperature sensor by the help of the PIC on the

switch board.

Probably errors may be:

- The

temperature sensor is not connected; any wire is broken or has no contact.

- Sensor is

defective.

- Power

distribution and switch board is defective.

- Wrongly

defined address of the sensors

(after exchange).

Voltage: 3.6V ~ 5.5V max

Data sheet: DS1621S

Temperature sensor, fan and fan control

Because the fan of

the power supply is removed and cameras needs cooling (their temperature must

not exceed 60º C (140º F)), temperature sensing and active

cooling of the scanner is required.

Because the fan of

the power supply is removed and cameras needs cooling (their temperature must

not exceed 60º C (140º F)), temperature sensing and active

cooling of the scanner is required.

The sensed temperature value

is used to control the speed of the fans directly; without any interaction of

the scan software “SlideScanner.exe”.

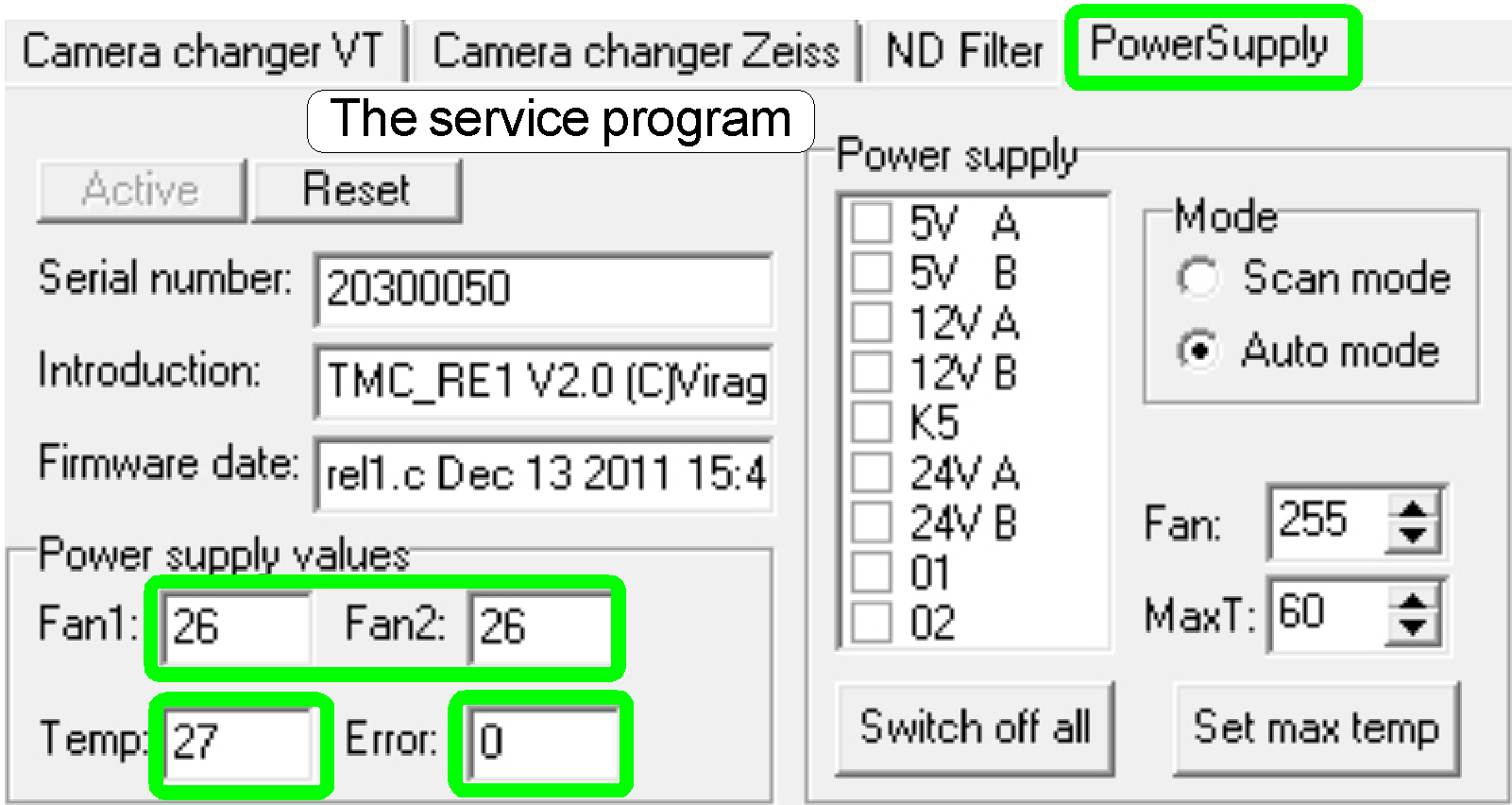

In the service program, the

sensed temperature is shown in [ºC], the fan speed is shown in a value

between 1 and 255; 255 is the full speed of the fan.

·

The sensed temperature value and the fan speed can be

read with the service program any time.

If the field “Error” is

different from zero, a HW error exists in the temperature sensor and fan

control electronics; depending on the error code.

Error codes

16 Fan error; the

spinning speed of the fan is too slow; the fan blades moving too strong; they

have too much resistance in the bearing.

32 Fan error; the

blades of the fan are not spinning; check cabling, connection; try to rotate

the fan blades manually; check for any mechanical reason also.

64 The temperature of

60º C (140º F) reached; check and clean the dust filter of the fan;

check the fan’s connection and the movement of the blades also.

128 Power tower

overheated; the relays are switching off; the power to the connected units is

interrupted; the temperature reached 70º

C.

·

Because the error bits are arranged in a byte, other

values are possible if more errors existing at the same time; e.g. 96= 64 + 32.

·

If the units are switched off by overheating, the scan

software SlideScanner.exe shows the error message

“Error occurred”

and stops working.

The spinning of the

blades is recognized by the PIC.

The spinning of the

blades is recognized by the PIC.

Probably fan errors may be:

·

The signal of the fan spinning sensor (situated inside

the fan) is not recognized by the fan control logic, because the fan is not or

not well connected; the fan blades does not rotate (any mechanical or cabling

reason) or the fan is defective.

·

If the fan speed is too slow please check and clean

the dust and particle filters or the fan blades moving too strong; they have

too much resistance in the bearing (fan goes defective).

·

The power distribution and switch board is defective.

![]() “The

fan”

“The

fan”

The Fan with dust filter is

found in the “Power tower” from beneath; see also: Construction_2

Nominal “wire to board”

connections

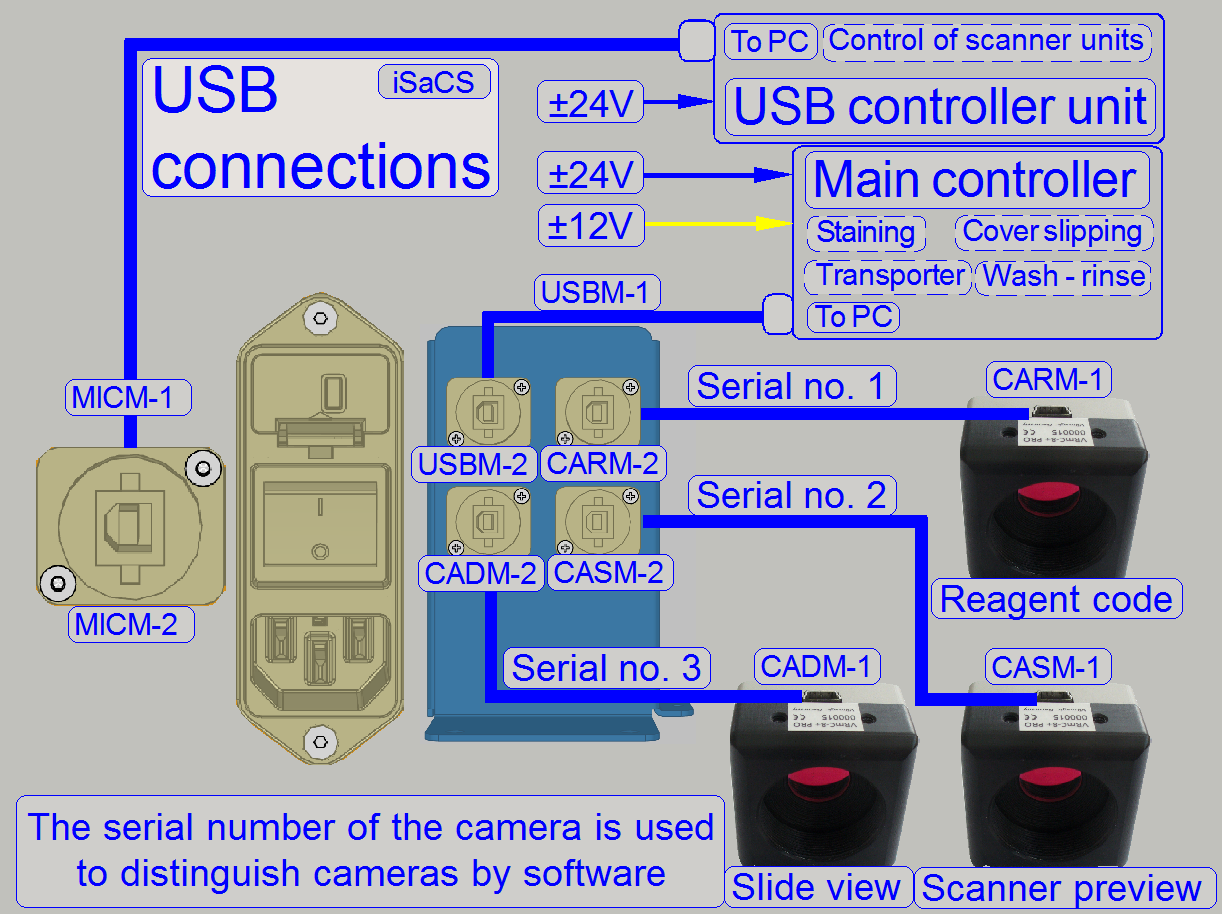

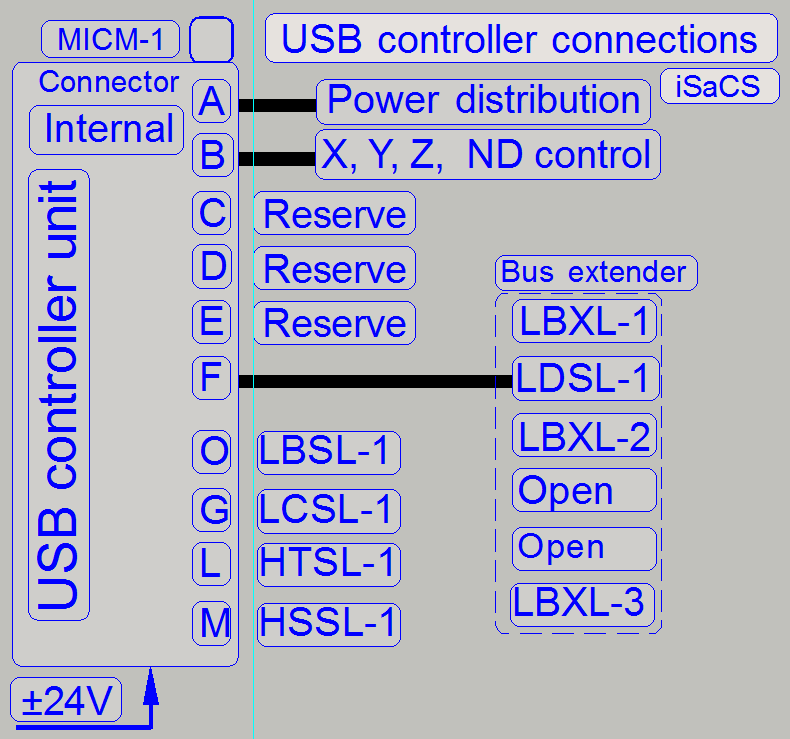

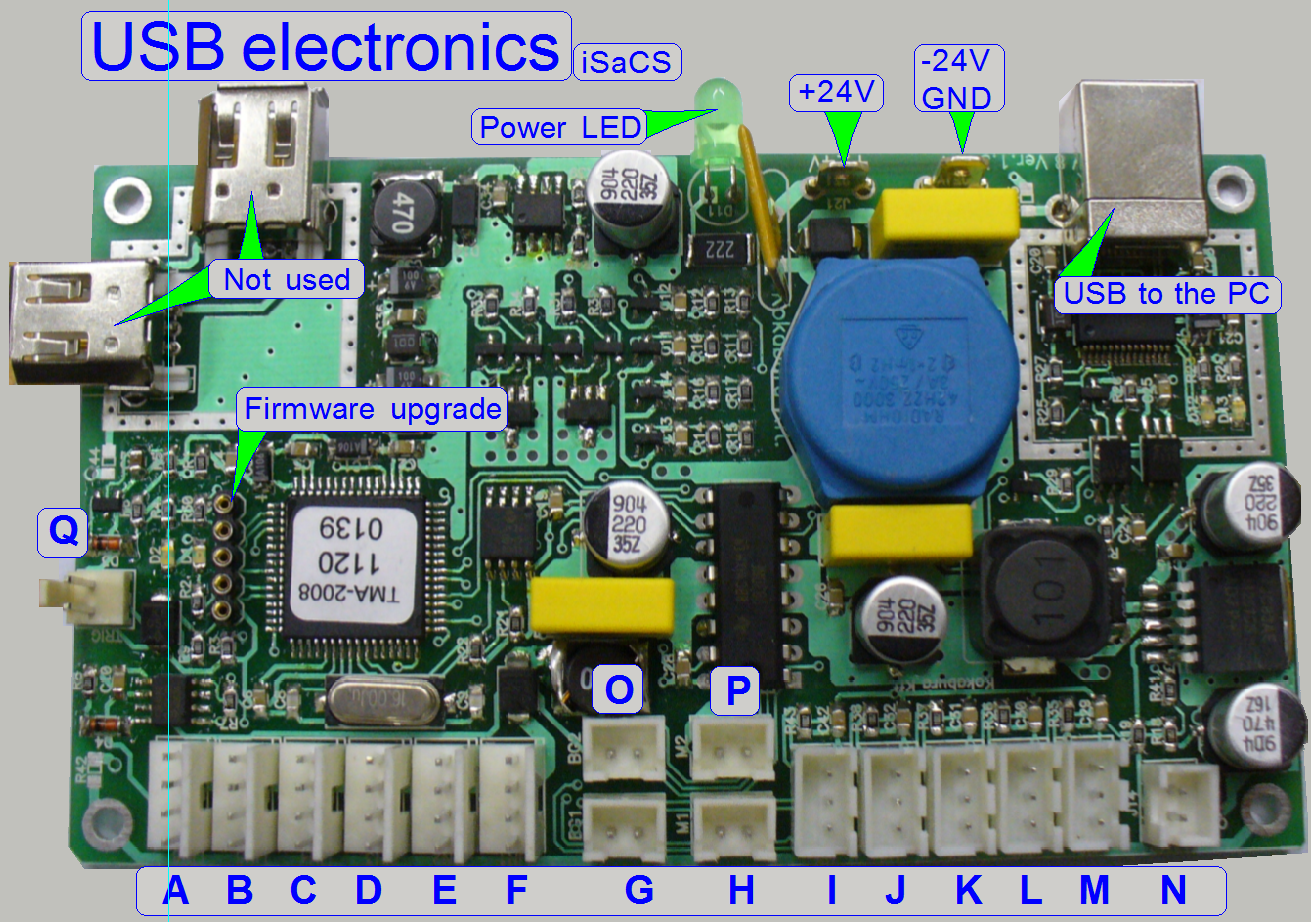

The USB controller connects,

supplies and controls all the addressable units and outputs; these are:

·

Power distribution

& switch board

·

Objective changer

unit (OC)

·

The USB controller gets its +-24V power directly from

the tdk lambda OEM

power supply.

The USB controller receives

the command for the units from the program SlideScanner.exe (the scan program)

or the SlideScannerService.exe (the service

program) via the USB control port of the PC and the USB cable.

All units contain separate

electronics and are connected via a bus system. To differentiate the units,

connected to the USB controller, all stepper motor electronics and the

unit-controller as well has an address.

Each data transfer starts with the specified address for the unit and is listen

by all units at the same time, but only this unit receives the message, which

internal address and the message address is identical. The stepper motor

electronics can receive commands (number of steps to go and direction) and can

send status information (desired position reached and the status of the sensors

Home1 and Home2). The status information

is sent via the USB cable to the software, hereby the address of the unit is

used also.

With this solution it is

possible to change the “Hirschmann” connection with another “Hirschmann” cable

(Connectors A ...F; e.g. for fault detection) without any risk or functional

restrictions. The label of the cable for digital electronics has no reason in

functionality; it differentiates the cables from each other instead, because

some cables are shorter than others.

Important

The construction of the controller powering on the board does allow the

drive of maximal 3 stepper motors at the same time!

·

Please take this into account, if you

are working with the service program and the batch test program module!

Nominal

“wire to board” connector positions

Nominal

“wire to board” connector positions

A = LBRL-1 Power distribution and switch board

B = LBFL-1 X-Y-Z-motor control

C = Reserve

D = Reserve

E = Reserve

F = LISL-1 Bus extender TMC_LIN 1 (1)

G = LCSL-1 Barcode illumination; CF01D

H = Reserve

I = Reserve

K = Reserve

L = HTSL-1 Tray sensor = TMC-HAL1(2) CF01E

M = HSSL-1 Slide sensor = TMC-HAL1(1) CF01F

N = Reserve

O = LBSL-1 Brightfield preview (background)

illumination; CF01A

P = Reserve

Q = Reserve

·

The USB controller gets its +-24V power directly from the tdk lambda OEM

power supply; the minus pole (-) is connected to the pin, named as GND!

The USB controller unit is

found in the “Power tower” see also: USB

and Construction_3

USB to PC

The USB connection

to the rear connector is realized with an internal USB cable, see also: “USB” and “Left side wall”

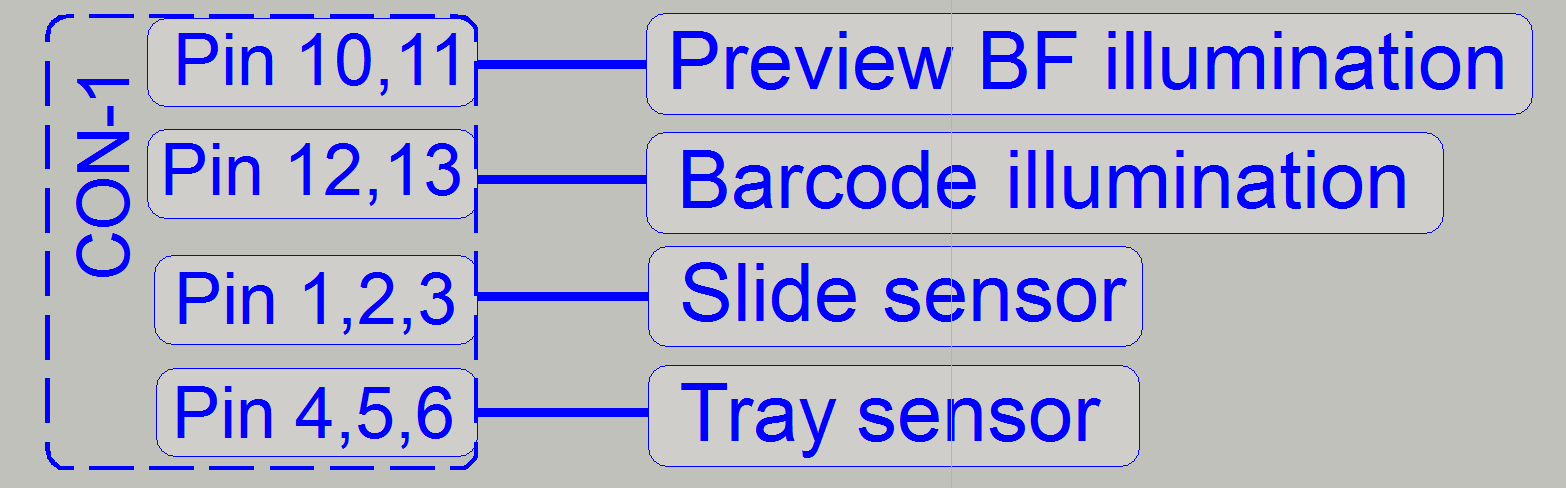

Output and sensor connections

|

Connection |

Connector |

Identifier |

Pins |

||

|

Component |

|

+ |

- |

Signal |

|

|

Preview BF illumination |

LBSL-1 |

10 |

11 |

|

|

|

|

|

12 |

13 |

|

|

|

|

|

14 |

15 |

|

|

|

Barcode illumination |

LCSL-1 |

16 |

17 |

|

|

|

Tray sensor |

HTSL-1 |

3 |

1 |

2 |

|

|

Slide sensor |

HSSL-1 |

6 |

4 |

5 |

|

·

The length of the cables is so

dimensioned, that only the specified unit can be reached easily.

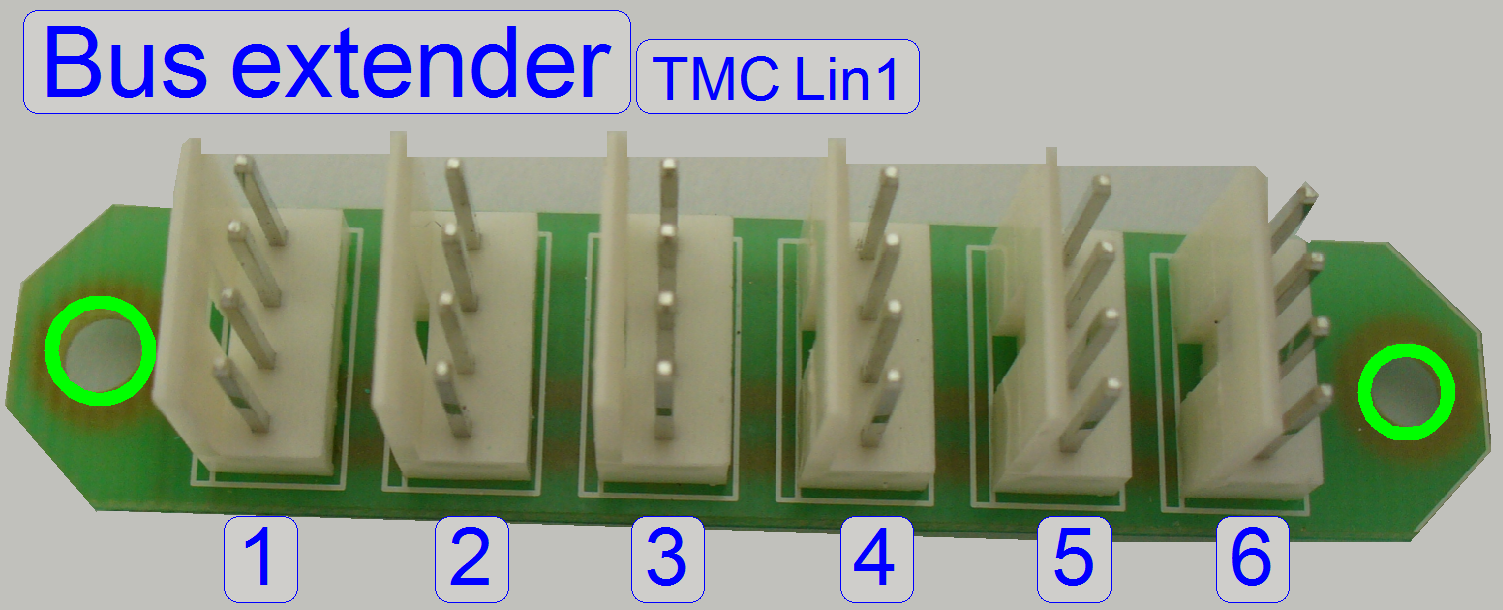

The addressable units are also

connected via the “Bus extender” because the number of connected units

increased. The bus contains the power supply for the unit (24V-) and the serial

bus (I2 C). Via the

serial bus the connected units are addressed, receive command and control

information and returns status information.

Each connected unit contains

a local power supply to create further, required voltages.

Nominal

connections of TMC LIN1

1 = LXBL-1 Tray

loader motor

1 = LXBL-1 Tray

loader motor

2 = LISL-1 Connector

“D” of the “USB

controller”

3 = LBXL-2 Slide

loader motor

4 = Open

5 = Open

6 = LBXL-3 Turret

motor

·

Positions may be changed without any functional risk

or restrictions!

The Bus extender is found in

the “Power tower” see also: “Bus

extender”

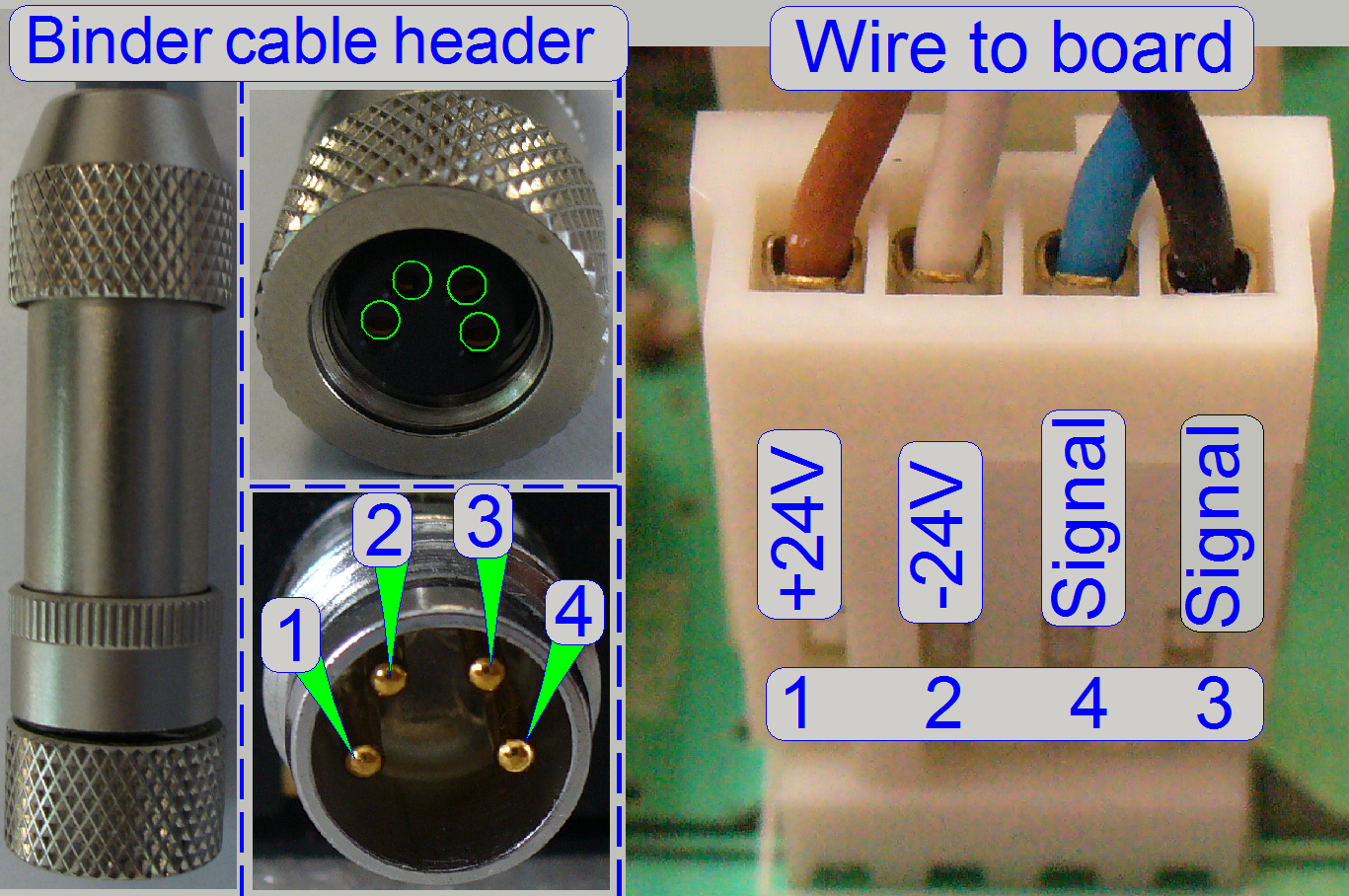

The addressable units are

connected with the “Binder” connector (except the Power distribution and switch

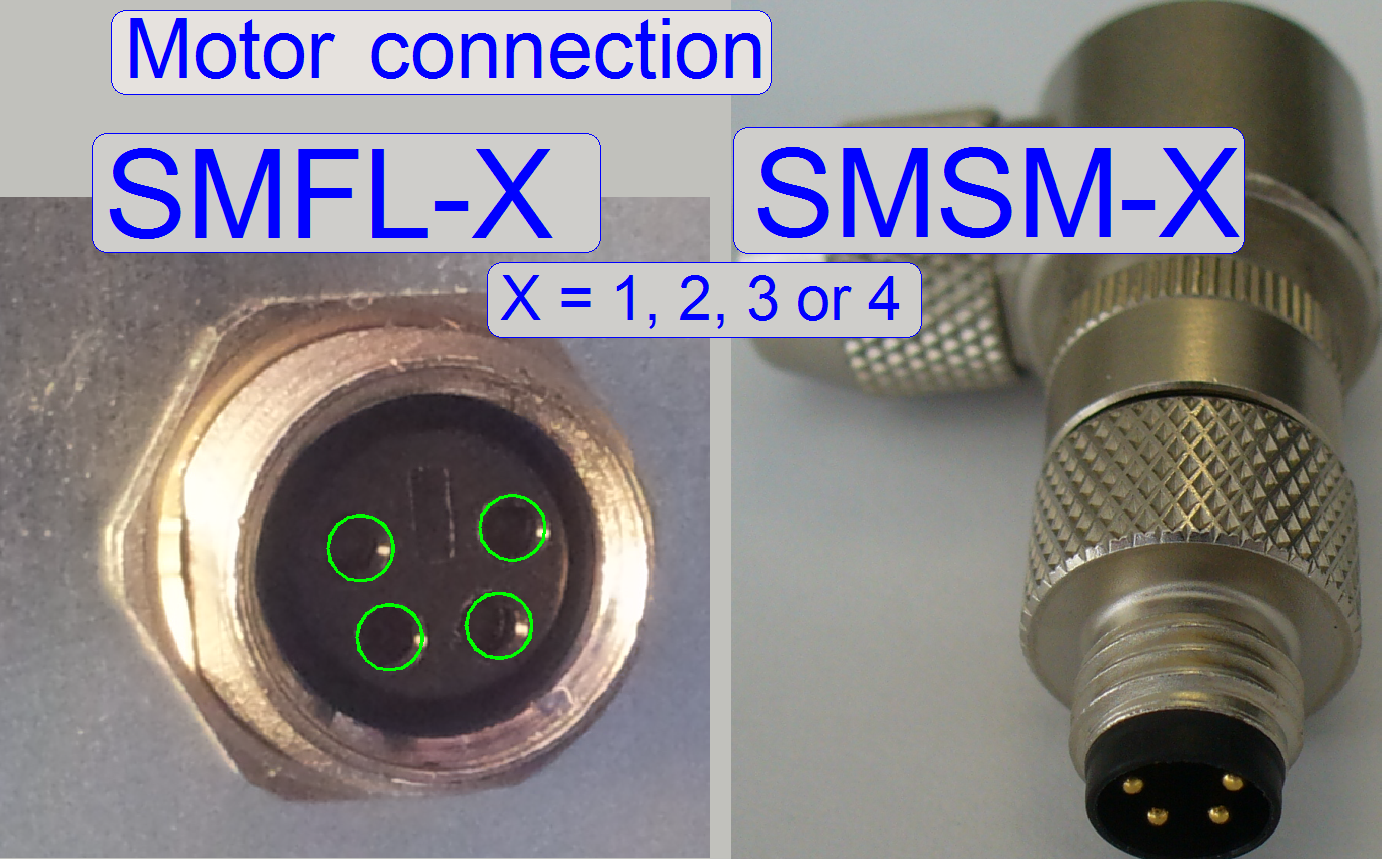

board); the connection is secured with a knurled nut. On the other end of the

cable a “wire to board” connector is used.

Important

Please do not use pliers to

loosen or tighten the cable header lock nut. If there is too much force used on

the connectors, the soldering of the connector may be destroyed and broken and

the appropriate motor or unit will not work.

|

Addresses of scanner

units |

||

|

Unit |

Address |

Type |

|

X-Y-Z

control |

00 |

C_P |

|

USB-controller |

01 |

All |

|

DC-controller |

02 |

P_S_M_D

|

|

X-motor |

03 |

S_M_D |

|

Y-motor |

04 |

S_M_D |

|

Z-motor |

05 |

S_M_D |

|

Turret

unit |

06 |

S_M_P |

|

Tray

loader motor |

07 |

M_C |

|

Slide

loader motor |

08 |

M_C |

|

Objective

changer |

09 |

C_P_S_M

|

|

Camera

changer |

10 |

P |

|

RGB

illumination |

11 |

C |

|

Reserve |

12 |

|

|

Immersion

liquid unit |

13 |

C |

|

Mechanical

shutter |

14 |

C |

|

Switch

board |

15 |

C_P |

|

Legend:

C=Confocal; P=P250; S=SCAN; M= |

||

The addresses are

used by the scan program and the service program to select the unit; these addresses

are programmed into the specified unit and can be changed via special software only. It is important,

that none of these addresses should exist twice inside of one Pannoramic

scanner, otherwise command and status mismatch occurs.

If data transfer

is in progress, all addressable units listen to the address of the data stream.

If the address of

the unit is identical with the address of the data stream, the addressed unit is

found and this receives the information.

·

The length

of the cables is so dimensioned, that every bus connector may be reached with

any bus cable header.

The length

of the cables is so dimensioned, that every bus connector may be reached with

any bus cable header.

·

Positions of the bus cables may be changed without any

risk or functional restrictions; e.g. for fault detection!

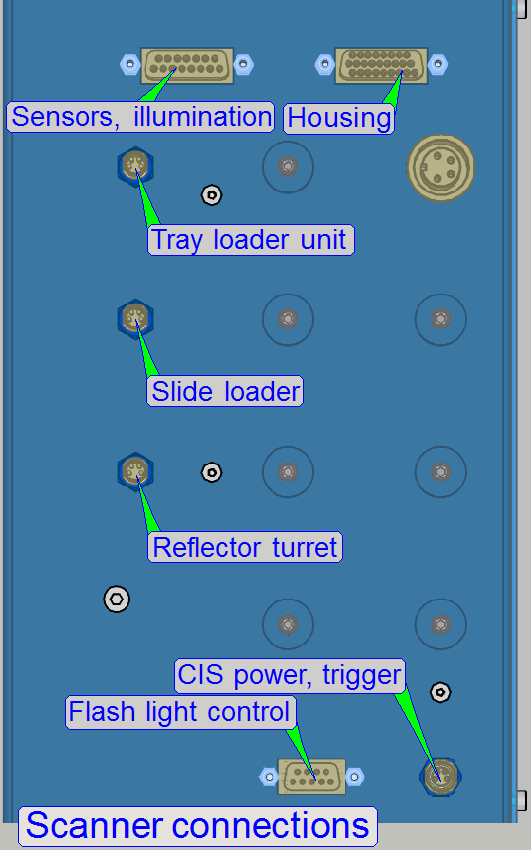

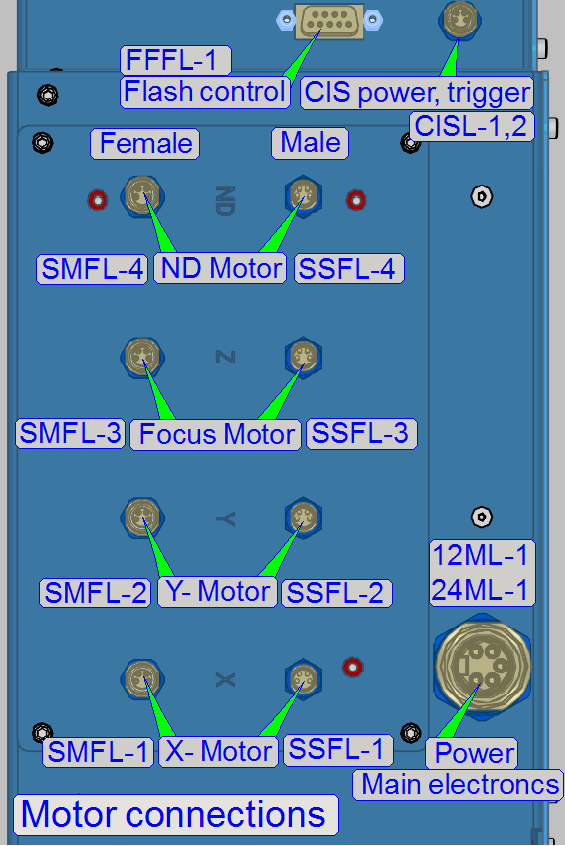

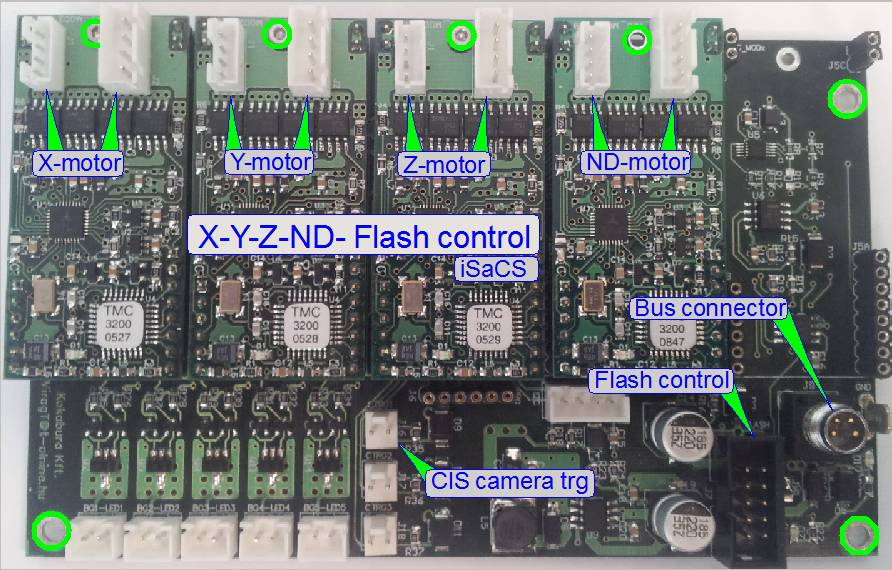

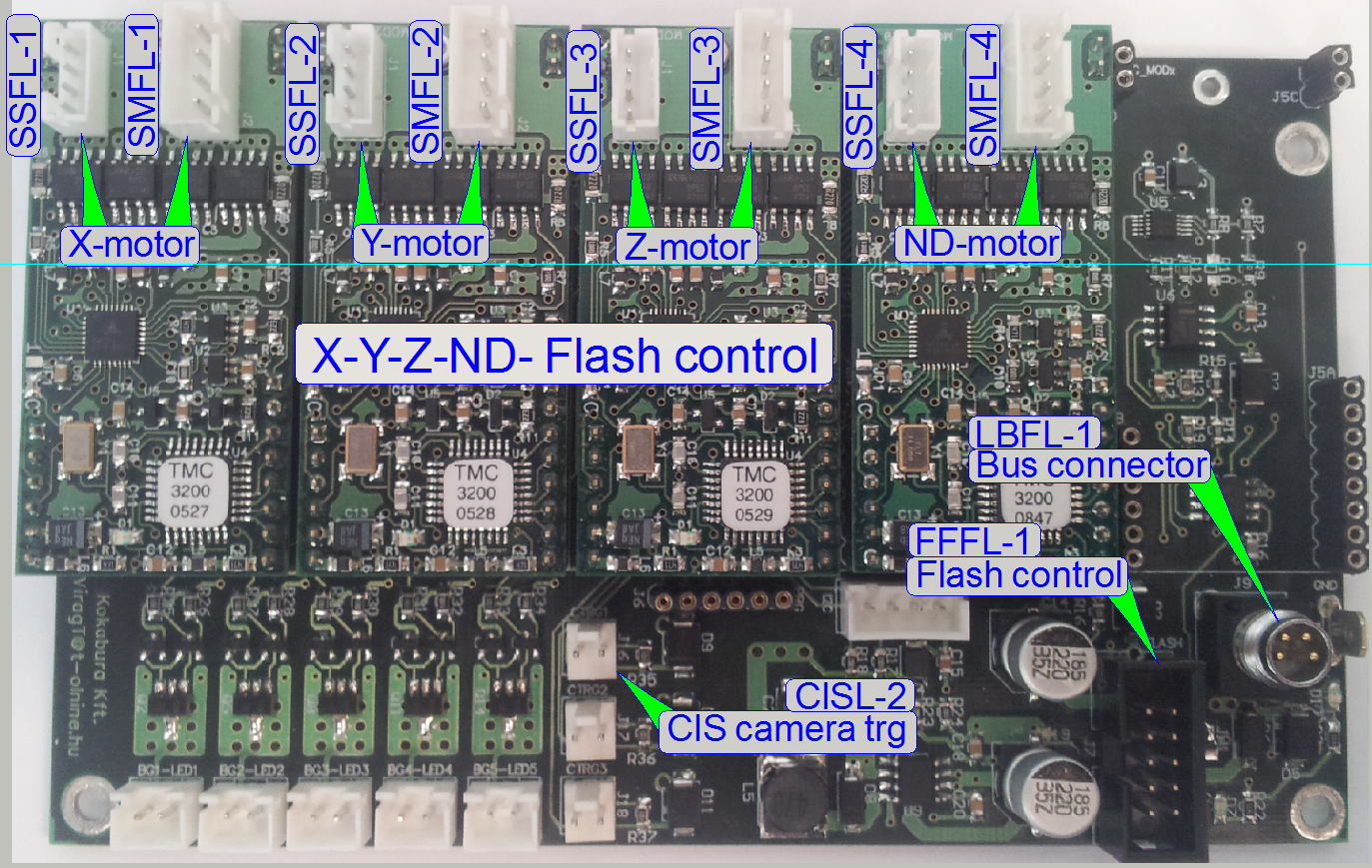

X-Y-Z-ND-motor and Flash

light control

Because in the P250 the

ND-motor is additionally implemented, the Flash light control has to be

resolved and the focus motor is of a different type, a new electronics box was

implemented.

Because in the P250 the

ND-motor is additionally implemented, the Flash light control has to be

resolved and the focus motor is of a different type, a new electronics box was

implemented.

The unit realizes the

control, connections and interfacing of the following units:

·

X-motor

·

Y-motor

·

Z-motor (focus)

·

ND-motor

·

Flash light

control for brightfield scan

·

Trigger connection of the CIS-camera

·

The power supply and the control of the addressable

unit are realized with the “Hirschmann” connector (Bus connector).

·

The X-, Y-, Z- and ND-stepper motor control

electronics is realized with the appropriate module; these motors itself does

not contain control electronics.

·

The motor modules are all from the same type and are

interchangeable without address modifying.

Flash light control

The arc frequency of

the Flash light source is controlled via the software.

The connector

“CIS-camera trg” is software controlled and defines the shutter time and pulse

width for the CIS-camera.

Darkfield illumination connector

·

The two connectors “DF illumination” provide the power

for the darkfield illumination and are interchangeable; the intensity can not

be affected.

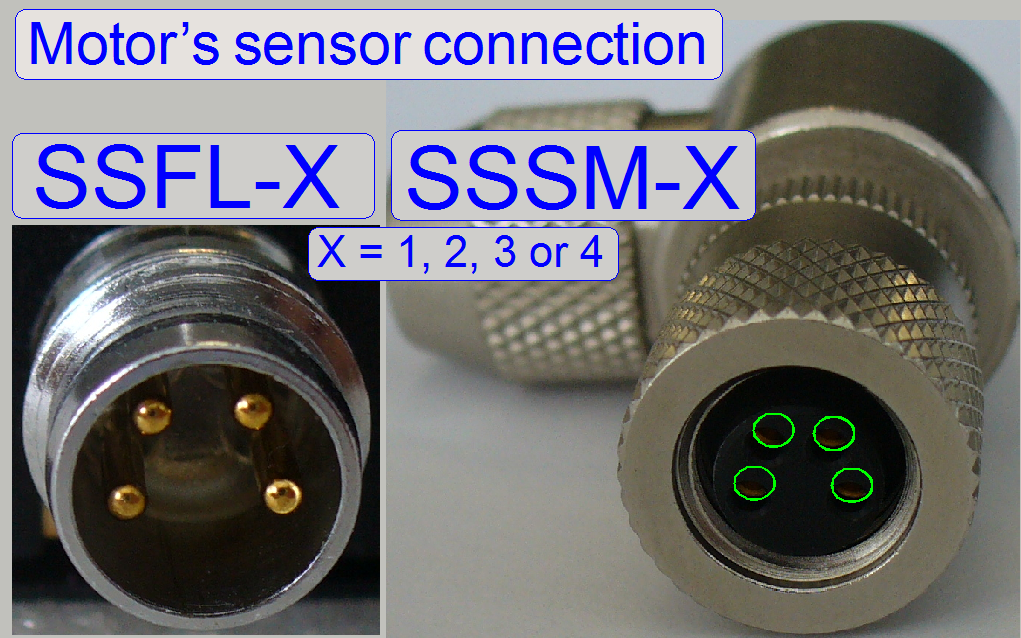

The wires of the appropriate

stepper motor as well as the wires of the sensors are directly connected to the

electronics via the motor cable headers.

The construction of the

connectors does not allow an interchanging of the two cables to each other, but

the motor can be connected to another module; e.g. for fault detection.

·

The sensors Home1 and Home2 are also connected via the

motor headers.

Important

Important

Please do not use pliers to

loosen or tighten the cable header lock nuts. If there is too much force used

on the connectors, the soldering of the connector may be destroyed or broken

and the appropriate motor will not work or may working very noisy.

Hint

·

For test purposes and fault detection, the motor cable header pair may be

connected to another motor output; e.g. the X-motor headers are connected to

the Y-motor output.

·

In this example, the service program Y-direction will be used to move

the X-stage!!

·

Before SlideScanner.exe will be started, the motor cable headers have to

be connected to their original, correct motor connection!

Addresses

of staining and cover slipping control

|

Addresses SC units |

||

|

Unit |

Address |

|

|

Main control |

5 |

|

|

Transporter |

2 |

|

|

Stain applicator |

1 |

|

|

Reagent chain |

4 |

|

|

Cover slipping |

0 |

|

|

Wash rinse |

3 |

|

|

|

||

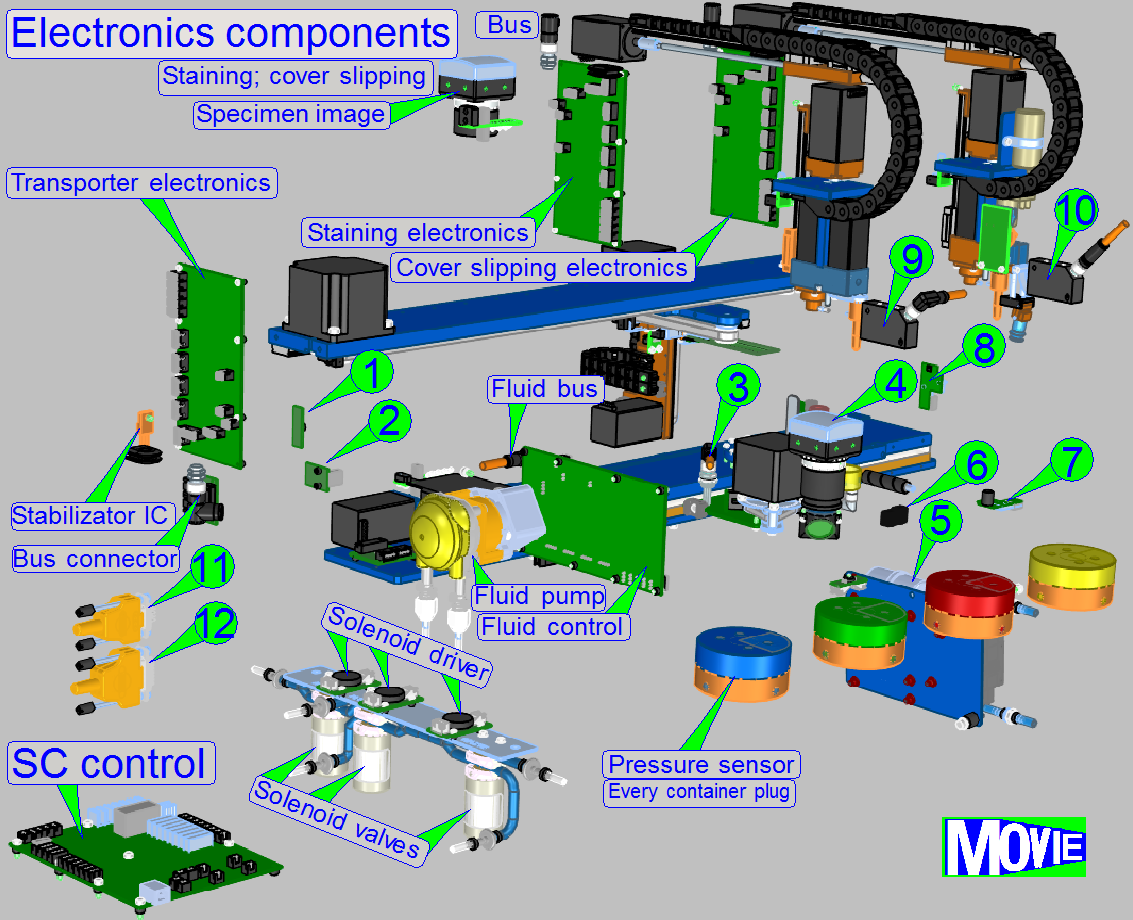

Because the entire staining

and cover slipping part of the iSaCS is controlled via an USB cable to the PC, different

from the scanner part, and the staining and cover slipping part is divided into

several control electronics, addresses are used to distinguish the data stream

for the controllers.

·

The addresses are programmed into the unit, so each unit

is unique in the system, nevertheless several controllers are from the same

construction!

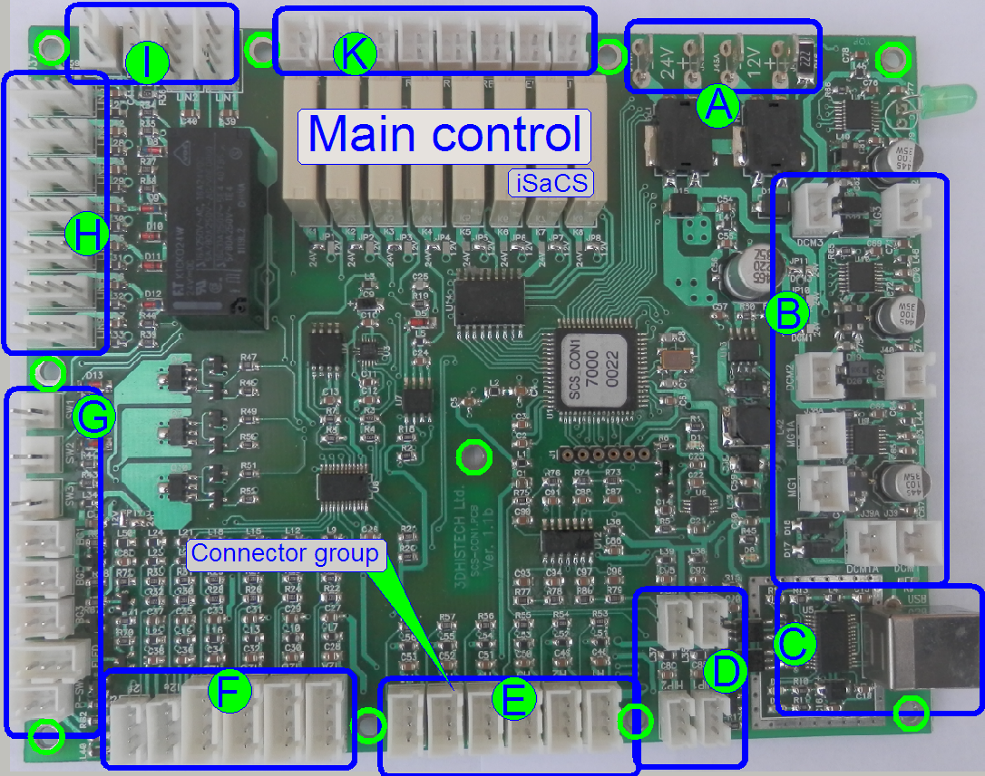

To

increase the manageability of the numerous connectors, these are grouped

·

A = Power supply

·

B = Housing

·

C = USB communication

·

D = Plug sensors

·

E = Container position

·

F = Optical sensors

·

H = Local bus

·

I

= Miscellaneous

·

K = Relay controlled outputs

·

To find the description

of connected units for the cable labels (Name), click the group link

|

Name |

Type |

Group |

Source or Target |

Description |

|

±12V |

Power |

Power tower |

Via connector

“Power Main electronics” |

|

|

±24V |

Power |

|||

|

ASHM-1 |

Container door |

Solenoid latch; locks the

lower right cover |

Latched “Off” Released “On” |

|

|

USBM-1 |

USB bus |

USB I/O board on the left

side |

Software communication |

|

|

HPTM-1 |

Pressure sensor |

Plug “Wash buffer” |

Via these container

sensors, the fluid level is recognized. |

|

|

HPTM-2 |

Pressure sensor |

Plug “Distilled water” |

||

|

HPTM-3 |

Pressure sensor |

Plug “Hazardous waste” |

||

|

HPTM-4 |

Pressure sensor |

Plug “Non-hazardous waste” |

||

|

HATM-1 |

Hall sensor |

Position “Wash buffer” |

Container position

recognized, if the sensor shows active state. |

|

|

HATM-2 |

Hall sensor |

Position “Distilled water” |

||

|

HATM-3 |

Hall sensor |

Position “Hazardous waste” |

||

|

HATM-4 |

Hall sensor |

Position “Non-hazardous

waste” |

||

|

IRCM-1 |

Optical sensor |

Pipette tip sensor |

|

|

|

IRRM-1 |

Optical sensor |

Reagent changer sensor |

|

|

|

IRFM-1 |

Pipette tip checker |

IR sensor cover slipping |

Mounting medium |

|

|

IRMM-1 |

Optical sensor |

Slide handling |

|

|

|

IRCM-1 |

Pipette tip checker |

IR sensor staining |

Used pipette tip |

|

|

ITFM-1 |

Slide sensor |

IR sensor in the slide

mover |

Present or absent |

|

|

SIFM-1 |

Switch Slide rack |

Micro switch in wash-rinse

unit |

Rack inserted corectly |

|

|

SCFM-1 |

Switch Reag. tray |

|

|

|

|

STHM-1 |

Tank switch |

|

|

|

|

LTDM-1 |

illumination |

DF illumination for slide

image |

Front: “On” or “Off” |

|

|

LMDM-1 |

illumination |

DF illumination for slide

image |

Rear: “On” or “Off” |

|

|

LLDM-1 |

illumination |

For barcode in slide image |

“On” or “Off” |

|

|

LZHM-1 |

“On/Off” front |

Main switch for

the entire iSacs |

Front of upper

cover |

|

|

SZHM-1 |

“On/Off” front |

|||

|

LBRM-1 |

Vial chain |

Control board “Vial chain

ontrol” |

Internal control bus |

|

|

LBWM-1 |

Wash-rinse |

Control board “Wash rinse” |

Internal control bus |

|

|

LBMM-1 |

Transporter |

Control board “Transporter” |

Internal control bus |

|

|

LBCM-1 |

Cover slipping |

Control board “Cover

slipping” |

Internal control bus |

|

|

LBPM-1 |

Reagent applicator |

Control board “Reagent

applicator” |

Internal control bus |

|

|

SRHM-1 |

Reag switch |

|

|

|

|

SSHM-1 |

Slide switch |

|

|

|

|

VWFM-1 |

Valve “Waste” |

State of the

valve paths |

Path open or

closed |

|

|

VFFM-1 |

Valve “Flush” |

|||

|

VAFM-1 |

Valve “Air” |

|||

|

COFM-1 |

Wipe Compressor |

Beside non-hazardous waste

container |

“On” or “Off” |

|

|

LTFM-1 |

Transp. LED line |

Internal units

illumination; |

“On” or “Off” |

|

|

LMFM-1 |

Top LED line |

|||

|

LLHM-1 |

Logo illumination |

Upper left cover front |

Switch Logo on or off |

|

|

ARHM-1 |

Upper cover right |

Solenoid latch locks the

covers during processes in progress |

Upper covers always

released at same time |

|

|

ALHM-1 |

Upper cover left |

|||

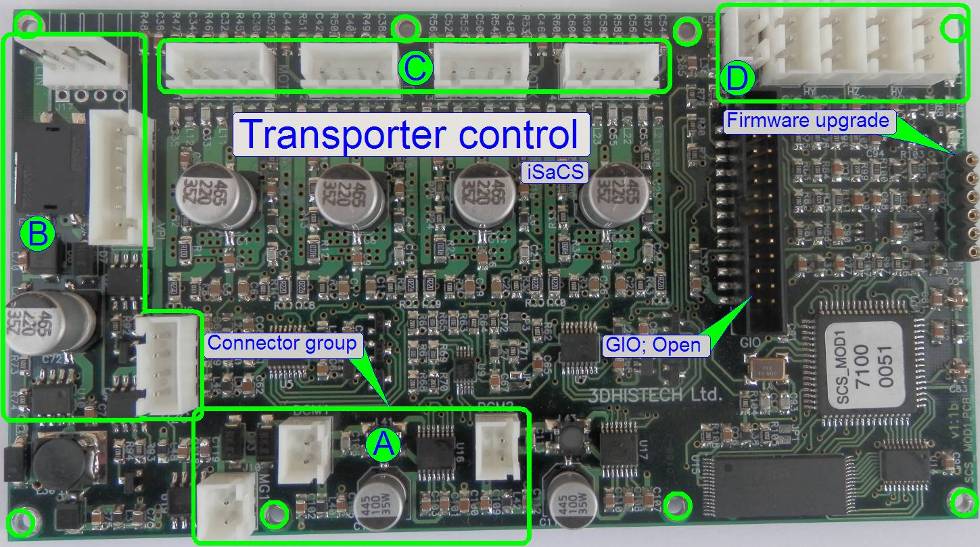

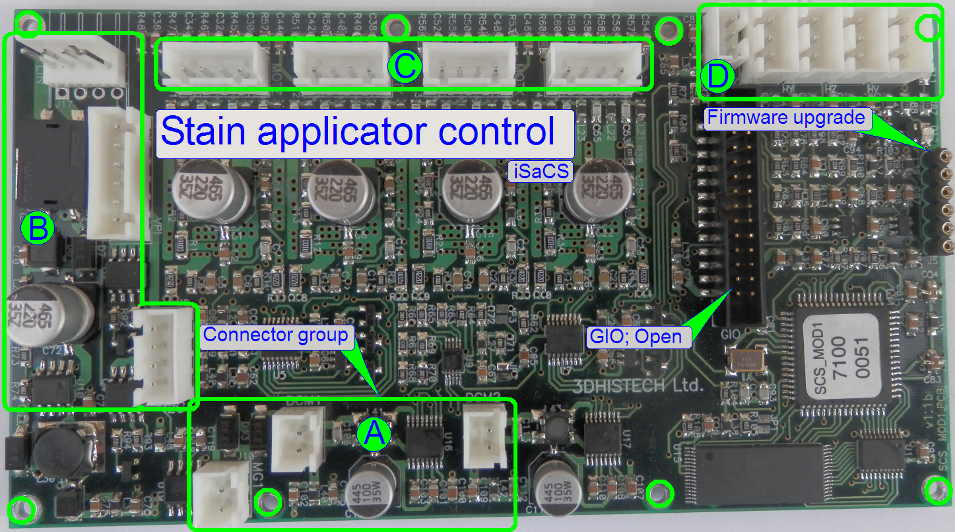

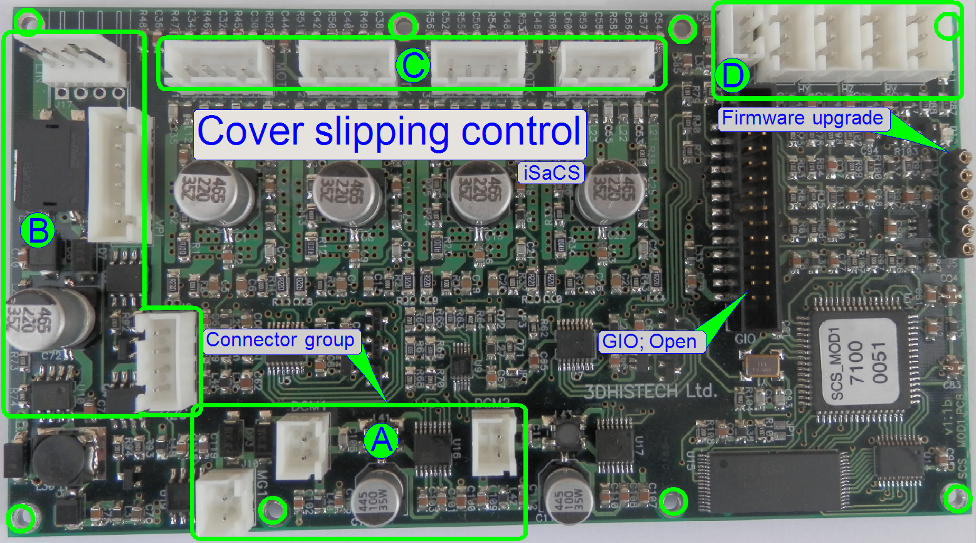

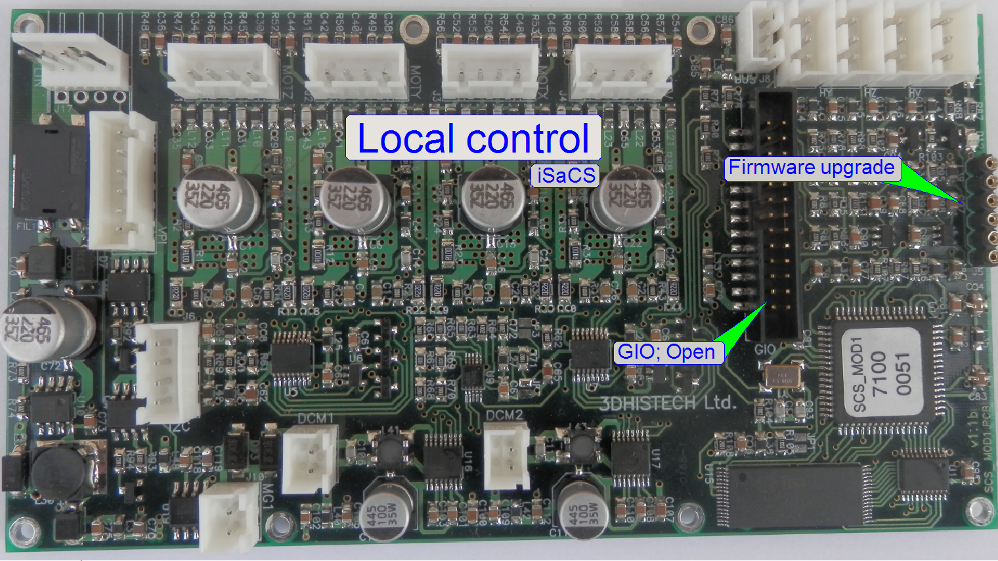

The shown

electronics board is used to control

The shown

electronics board is used to control

·

Transporter

·

Stain applicator

·

cover slipping

·

And

Differences are given in the

address of the board and connected units; the board itself is identical; the

firmware also.

Remark

Because the address is

different for each board, an interchange of the board between the named units

without address modifying is impossible!

·

To find the description

of connected units for the cable labels (Name), click the group link

|

Connections of “Transporter control” |

||||

|

Name |

Type |

Group |

Source or Target |

Description |

|

MGMM-1 |

Solenoid 12V driven by 15V |

Slide mover fork |

Holds the slide |

|

|

LBMM-2 |

Local communication bus |

Main control

board |

Control of units |

|

|

SMMM-3 |

Step motor in Z-direction |

Transporter |

Move slide

along mathematical axes |

|

|

SMMM-2 |

Step motor in Y-direction |

|||

|

SMMM-1 |

Step motor in X-direction |

|||

|

OPMM-1 |

Home sensor X-direction |

Transporter |

Detect home

position for axis |

|

|

OPMM-2 |

Home sensor Y-direction |

|||

|

OPMM-3 |

Home sensor Z-direction |

|||

·

To find the description

of connected units for the cable labels (Name), click the group link

|

Connections of “Stain applicator” |

||||

|

Name |

Type |

Group |

Source or Target |

Description |

|

Open |

Not used |

|

|

|

|

LBPM-2 |

Local communication bus |

Main control

board |

Control of units |

|

|

SMPM-4 |

Step motor “Air pump” |

Applicator

head |

Move tip

acceptor along axes; Vacuum or

pressure for tip |

|

|

SMPM-3 |

Lift motor in Z-direction |

|||

|

SMPM-2 |

Step motor in Y-direction |

|||

|

SMPM-1 |

Tip mover in X-direction |

|||

|

OPPM-1 |

Pressure sensor |

Pipette

tip |

Vacuum; pressure |

|

|

USPM-1 |

Fluid level |

Reagent

vial |

Reagent quantity |

|

|

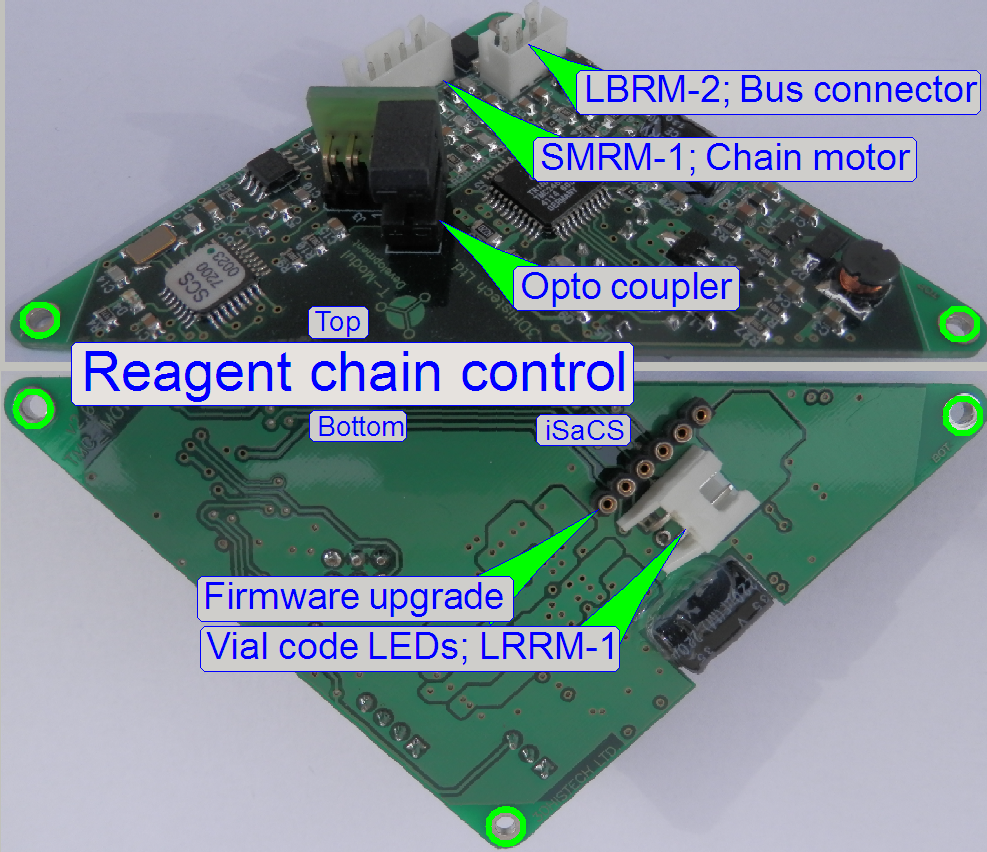

Connections of “Reagent chain” |

|||

|

Name |

Type |

Source or Target |

Description |

|

LBRM-2 |

Local communication bus |

Main control

board |

Control of units |

|

SMRM-1 |

Step motor |

Vial chain |

Move circularly

the vial chain |

|

LRRM-1 |

Illumination LEDs |

Reagent barcode |

Illumination |

·

To find the description

of connected units for the cable labels (Name), click the group link

|

Connections

of “Cover slipping” |

||||

|

Name |

Type |

Group |

Source or Target |

Description |

|

Open |

Not

used |

|

|

|

|

LBCM-2 |

Local

communication bus |

Main control board |

Control of units |

|

|

VPCM-1 |

Pressure

sensor |

Sensor; pump; Valve |

|

|

|

SMCM-4 |

Step

motor “V” |

Applicator

head |

Move tip acceptor

along Z-axis; Vacuum or pressure for

tip |

|

|

SMCM-3 |

Lift

motor in Z-direction |

|||

|

Open |

-------- |

|||

|

SMCM-1 |

Step

motor “X” ?? |

|||

|

OPCM-1 |

Opto

sensor |

Pipette tip |

Vacuum; pressure |

|

|

USCM-1 |

Fluid

level |

Mounting medium |

Medium quantity |

|

·

To find the description

of connected units for the cable labels (Name), click the group link

|

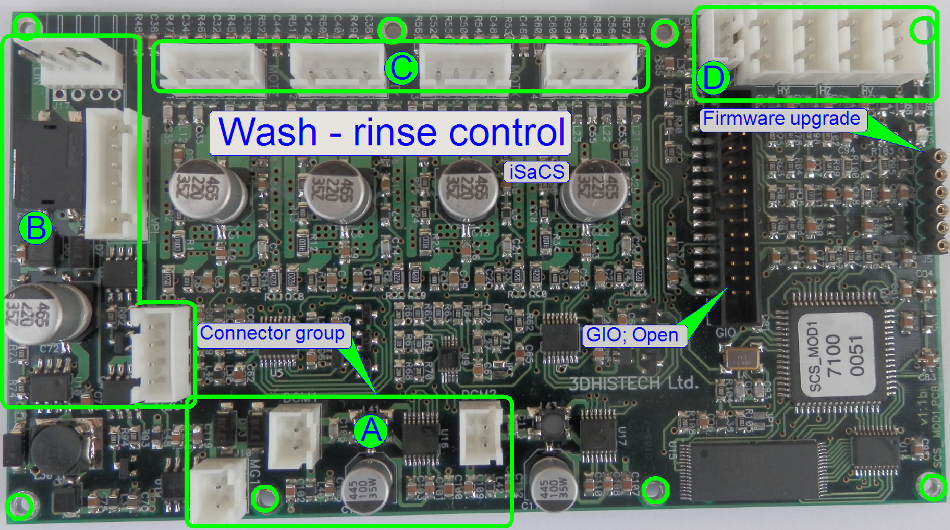

Connections

of “Wash-rinse” |

||||

|

Name |

Type |

Group |

Source or Target |

Description |

|

Open |

Not

used |

|

|

|

|

LBWM-2 |

Local communication bus |

Main control board |

Control of units |

|

|

SMWM-4 |

Step

motor “Slider” |

Wash-rinse chambers |

Move fluid nozzles |

|

|

SMWM-3 |

Pump

“WASTE” |

Pumps |

Move dedicated fluids |

|

|

SMWM-2 |

Pump

“Rinsing” |

|||

|

SMWM-1 |

Pump

“ |

|||

|

OPWM-4 |

Slider home sensor |

Wash-rinse |

Detect home position |

|