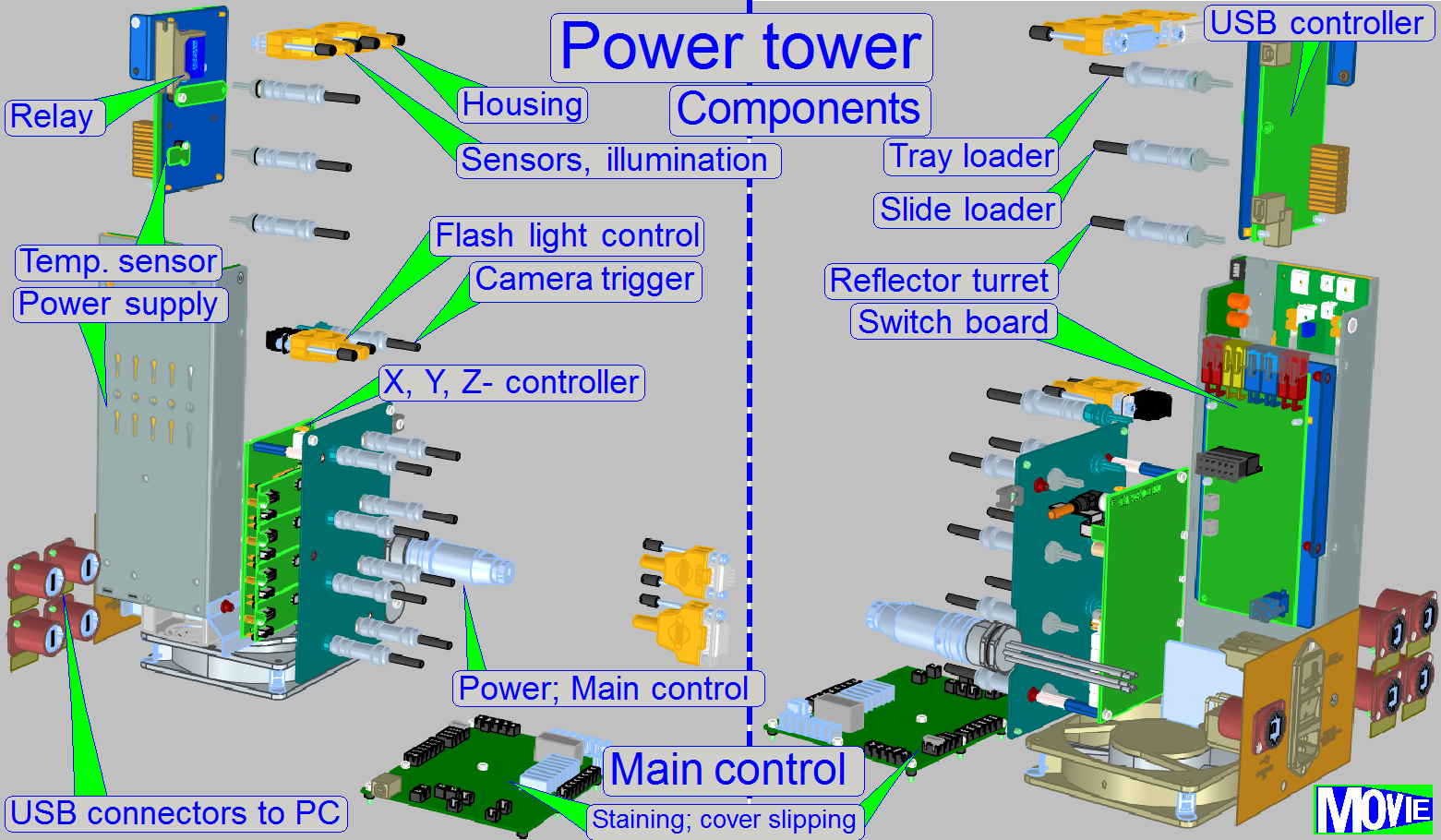

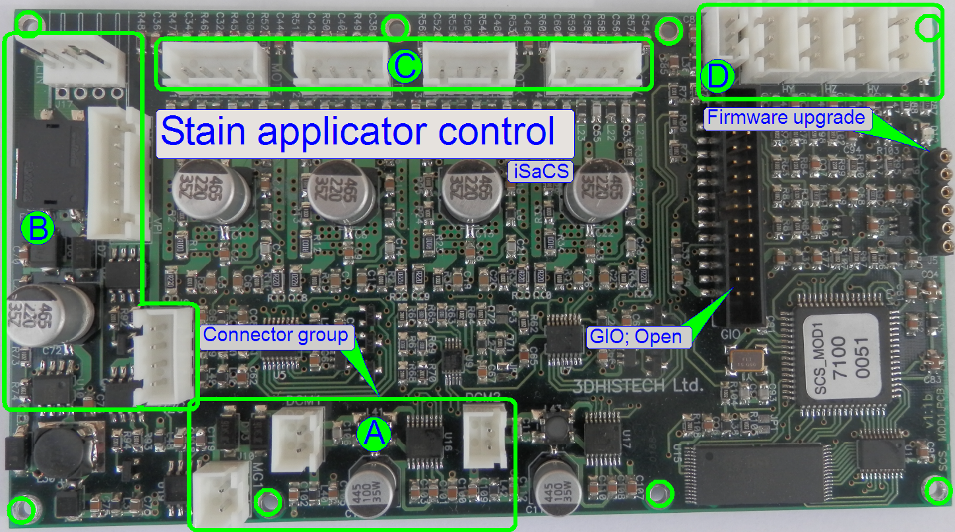

Control units;

iSaCS

For technicians

Main

control

Addresses of staining and cover slipping

|

Addresses SC units |

||

|

Unit |

Address |

Type |

|

Main control |

|

|

|

Transporter |

|

|

|

Stain applicator |

|

|

|

Reagent chain |

|

|

|

Cover slipping |

|

|

|

Wash rinse |

|

|

|

Legend: |

||

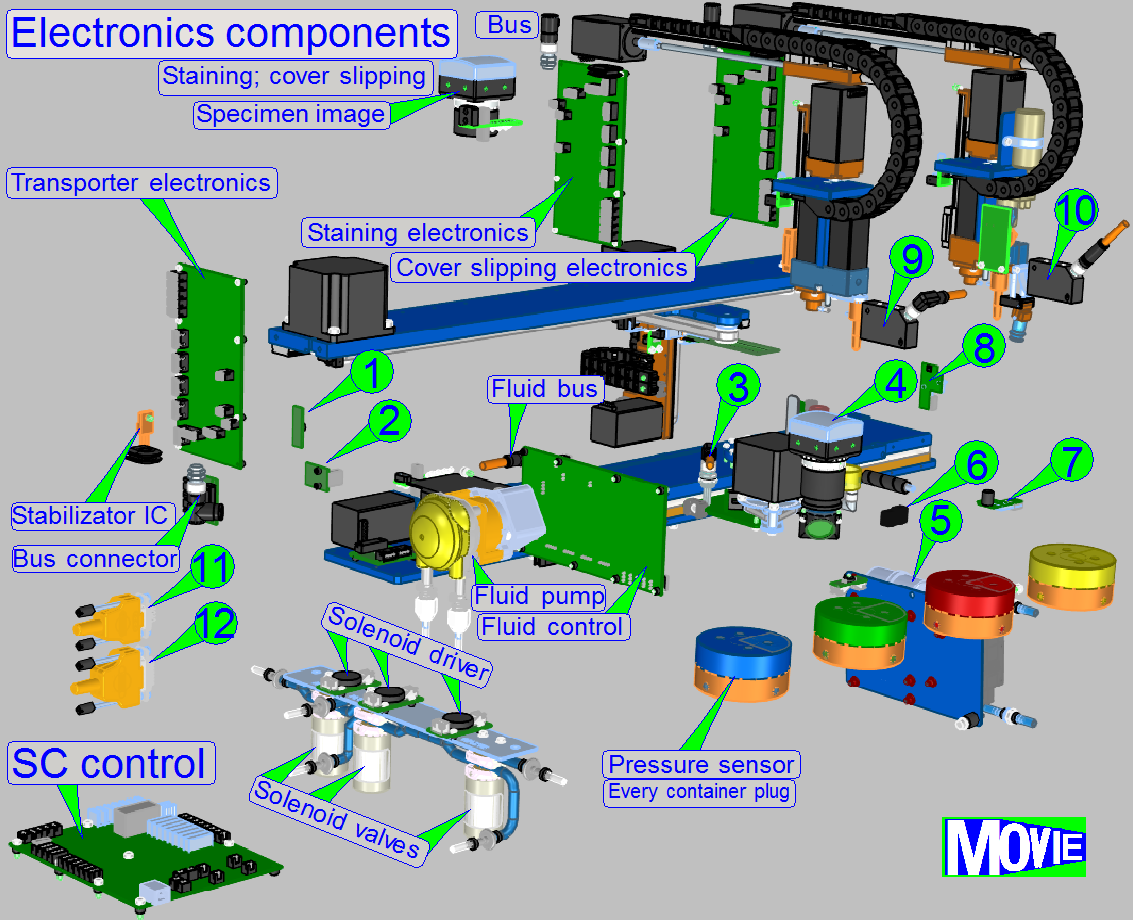

The entire staining and cover slipping part of the iSaCS is controlled

through a USB cable by the PC, different from the scanner part. The staining

and cover slipping part is divided into several control electronics, and

addresses are used to distinguish the data stream for the controllers.

The addresses are programmed into the unit, so each unit is unique in

the system. Several controllers are from the same construction.

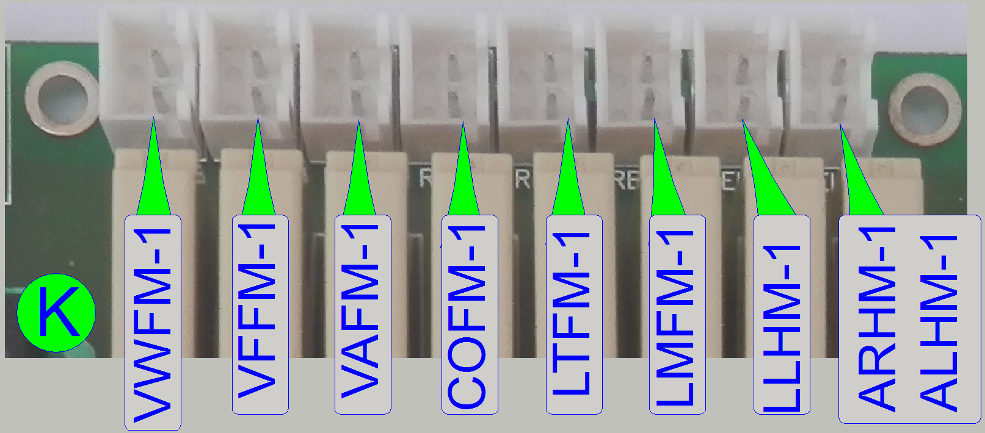

Wire

labels; names

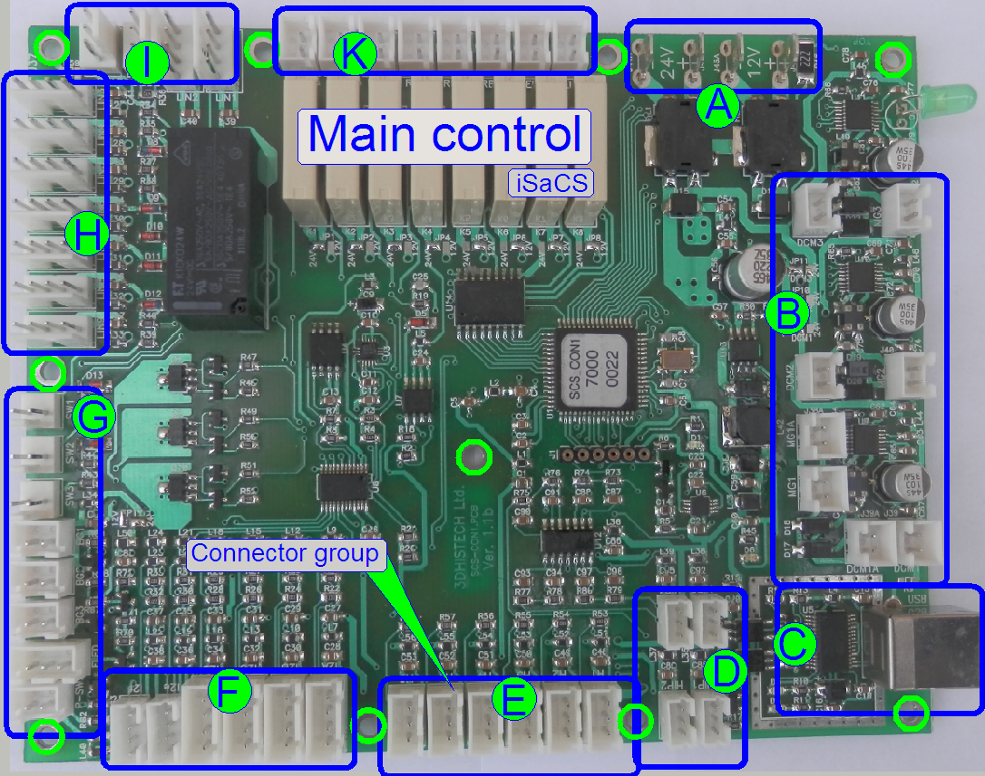

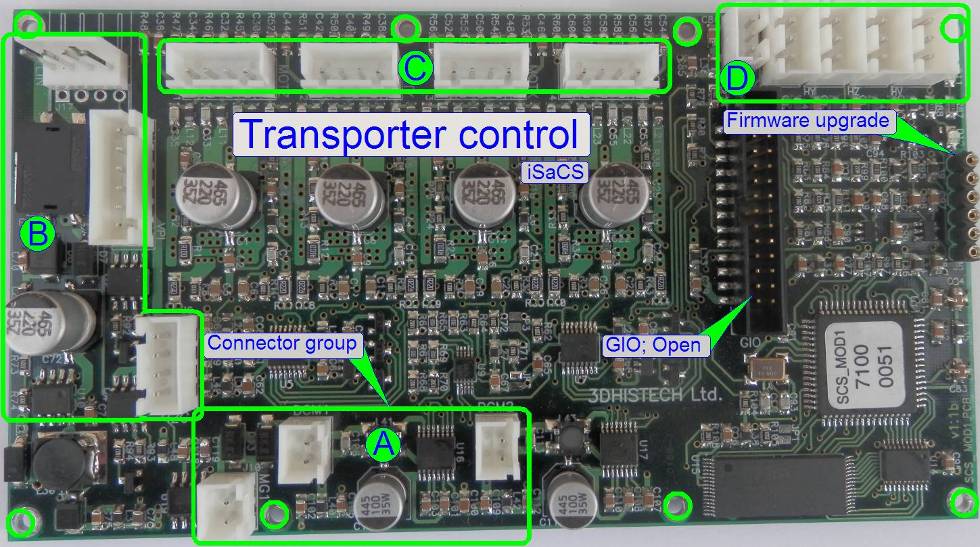

There are numerous connectors, so they are grouped to increase their

manageability.

Groups of connections

Groups of connections

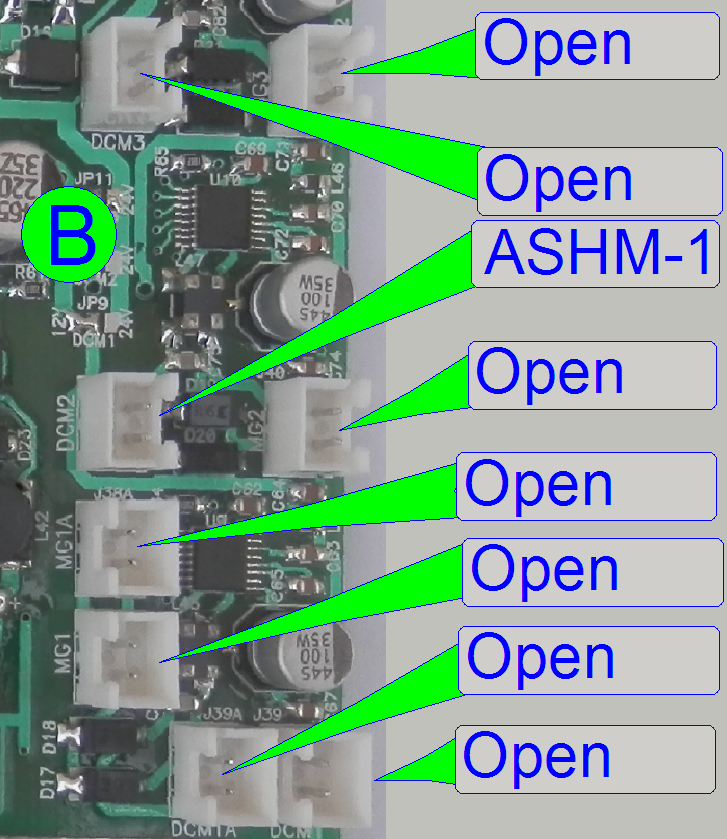

· A

= Power supply

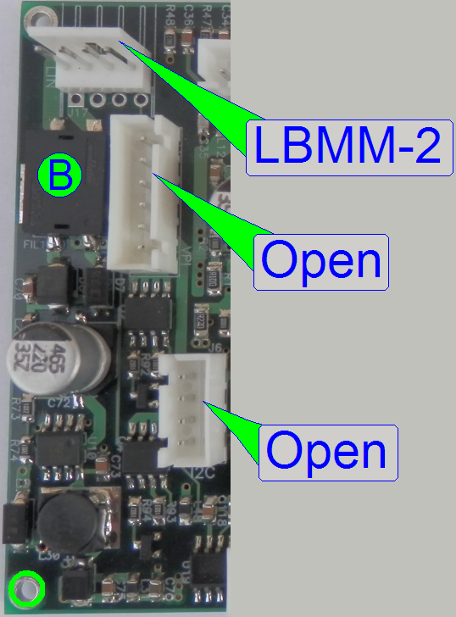

· B

= Housing

· C

= USB communication

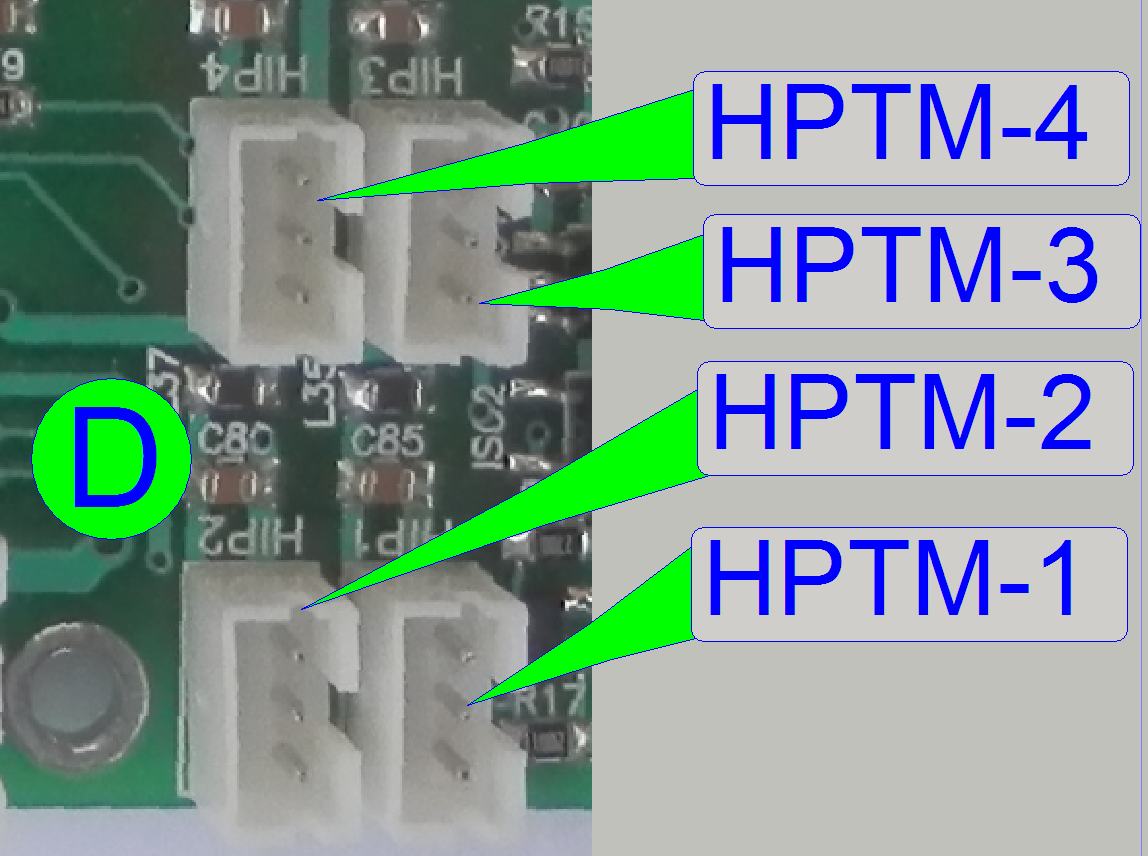

· D

= Plug sensors

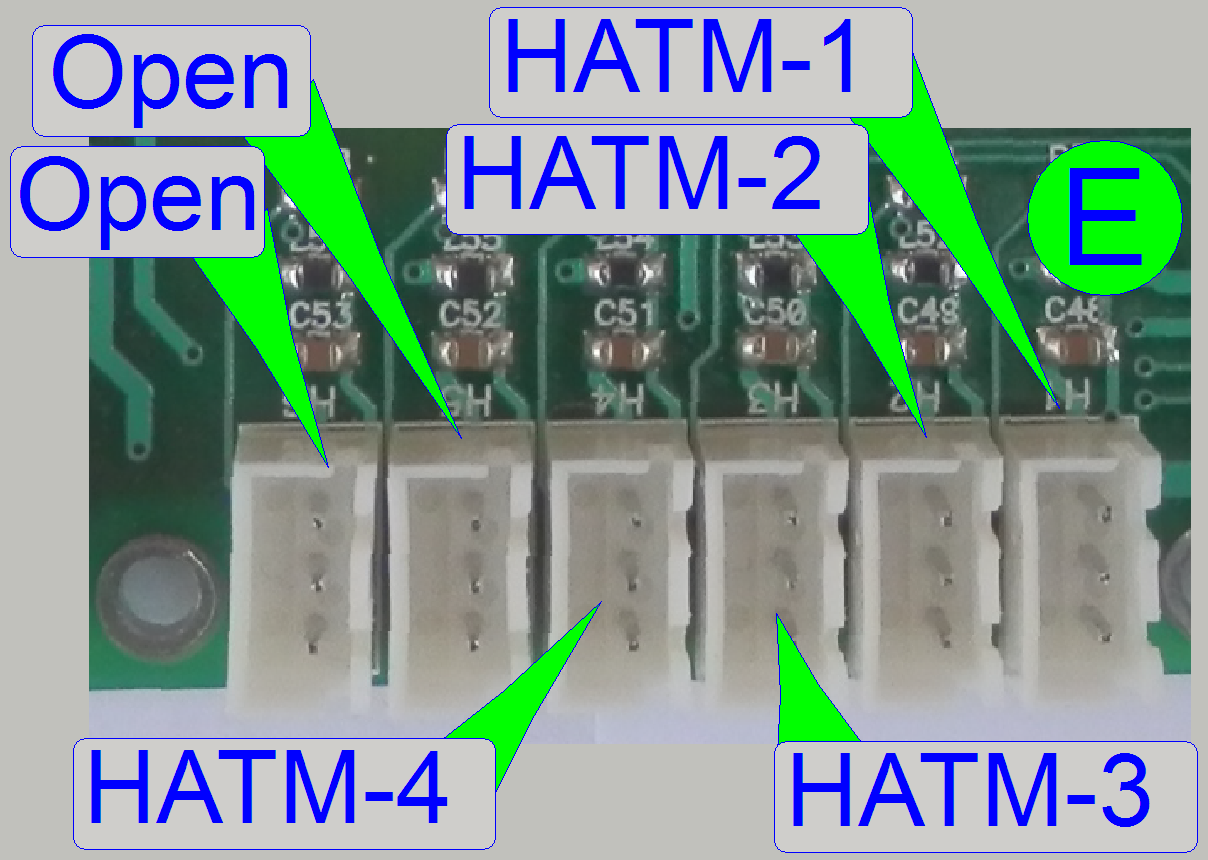

· E

= Container sensors

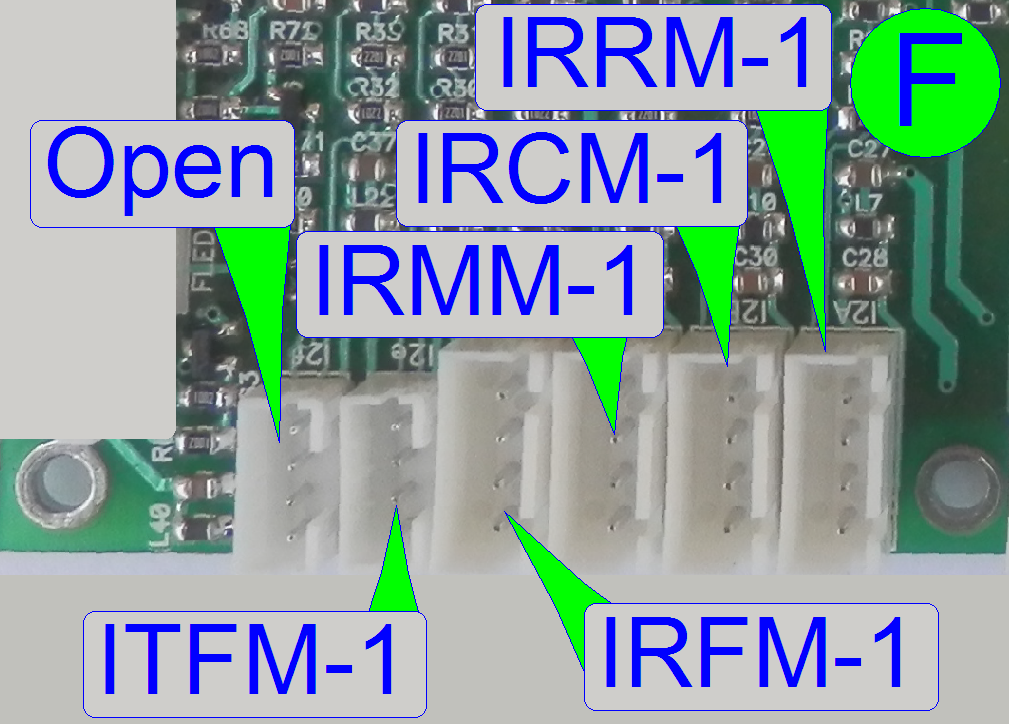

· F

= Optical sensors

· G

= Switches

· H

= Bus connections

· I = Micro switches

· K

= Relay outputs

|

Connections of the

“Main control” board |

||||

|

Name |

Type |

Group |

Source or Target |

Description |

|

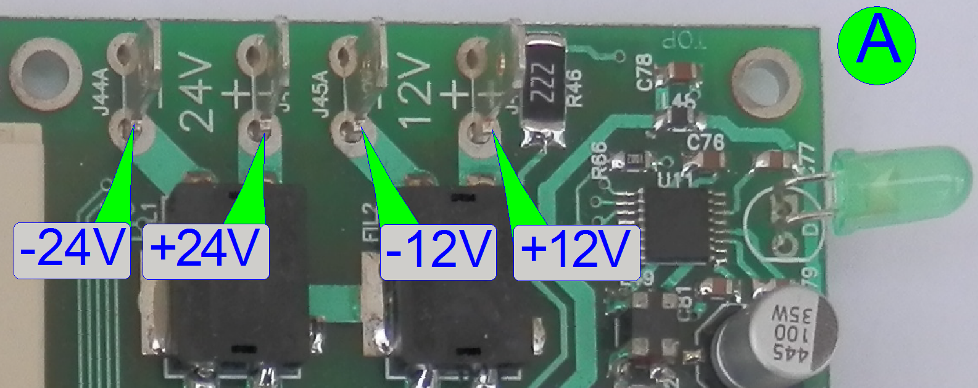

±12V |

Power |

Power tower |

Through connector “Power

Main electronics” |

|

|

±24V |

Power |

|||

|

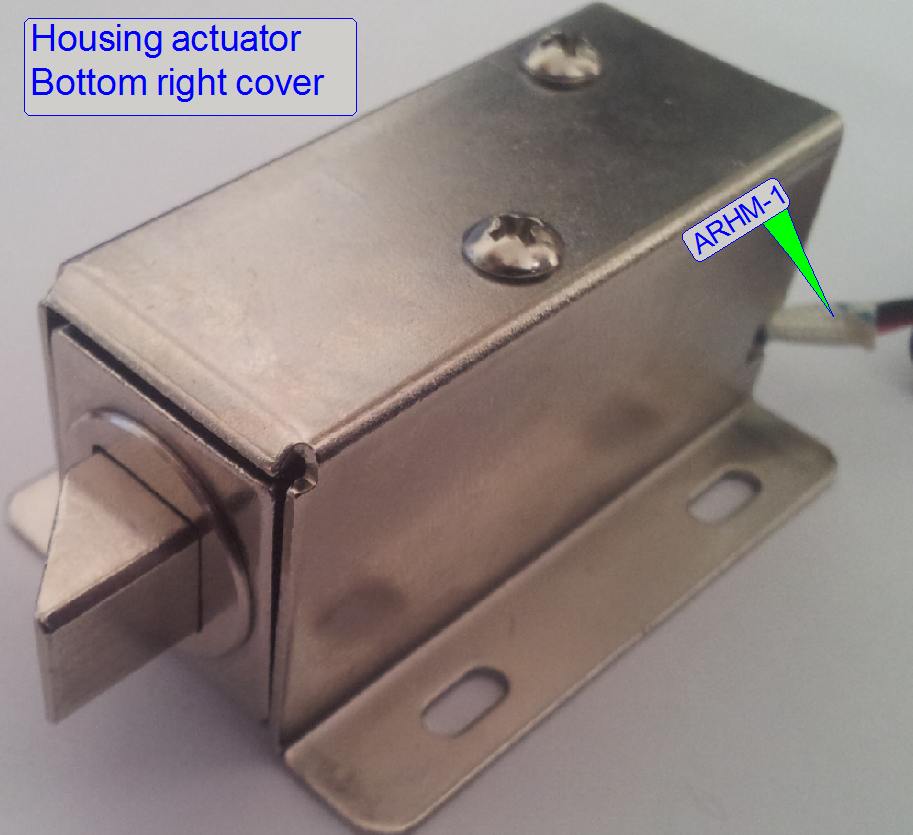

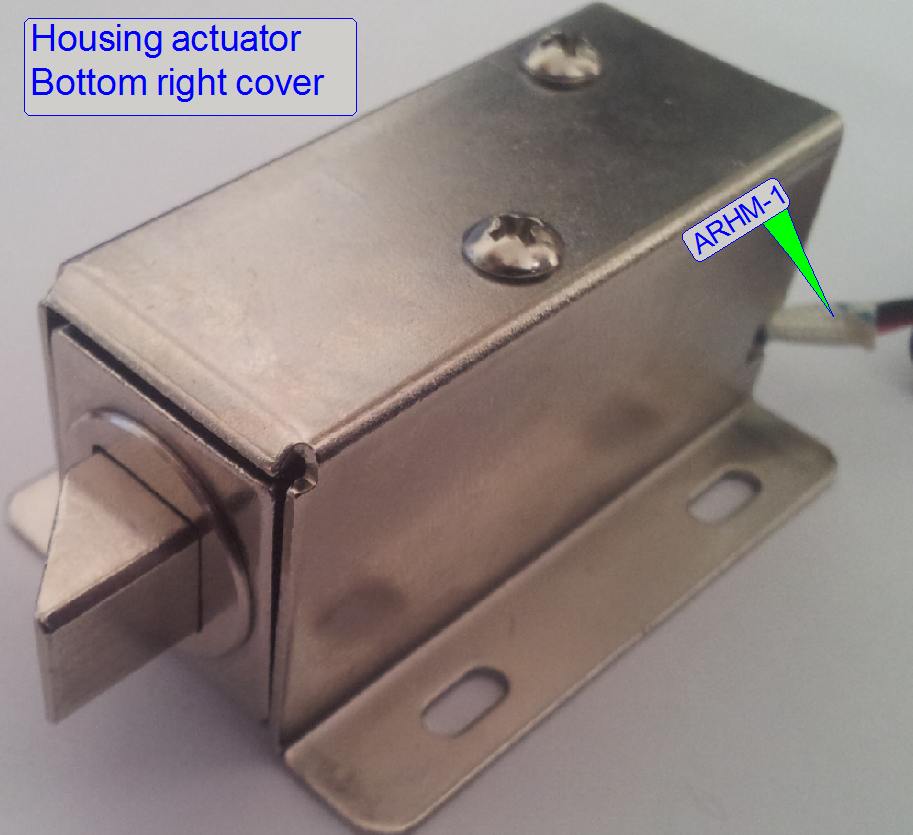

ASHM-1 |

Container door |

Bottom right cover |

Locked “Off” / Released

“On” Solenoid latch locks the

lower right cover |

|

|

USBM-1 |

USB bus |

USB I/O board |

Software communication;

located below the left side service door |

|

|

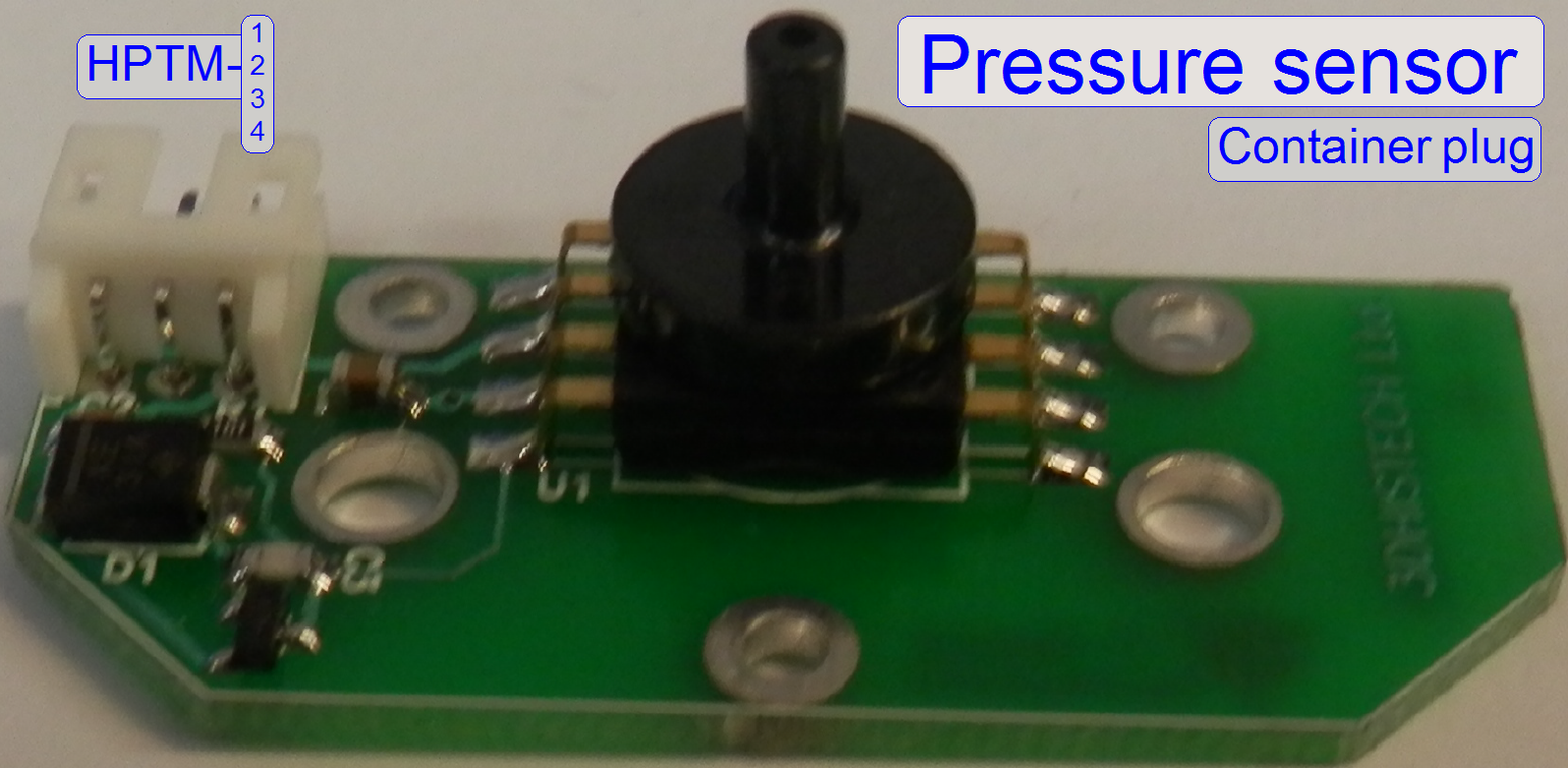

HPTM-1 |

Pressure sensor |

Plug “Wash buffer” |

Through these container

sensors, the fluid level is recognized |

|

|

HPTM-2 |

Pressure sensor |

Plug “Distilled water” |

||

|

HPTM-3 |

Pressure sensor |

Plug “Hazardous waste” |

||

|

HPTM-4 |

Pressure sensor |

Plug “Non-hazardous waste” |

||

|

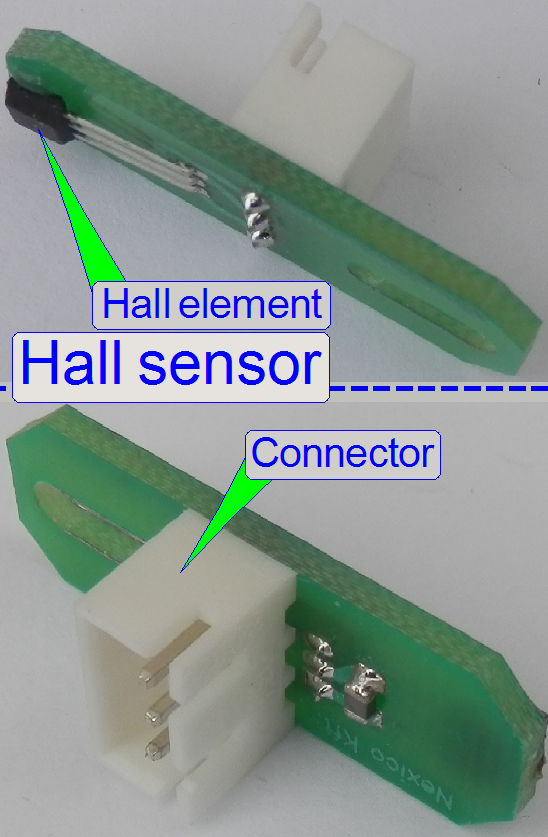

HATM-1 |

Hall sensor |

Position “Wash buffer” |

Container position

recognized, if the sensor shows active state |

|

|

HATM-2 |

Hall sensor |

Position “Distilled water” |

||

|

HATM-3 |

Hall sensor |

Position “Hazardous waste” |

||

|

HATM-4 |

Hall sensor |

Position “Non-hazardous

waste” |

||

|

IRCM-1 |

Optical sensor |

Pipette tip sensor |

IR sensor for staining;

for used pipette tip |

|

|

IRRM-1 |

Optical sensor |

Reagent changer |

IR sensor for vials |

|

|

IRFM-1 |

Pipette tip checker |

Cover slipping |

IR sensor for mounting

medium |

|

|

IRMM-1 |

Optical sensor |

Slide handling |

Slide present or absent |

|

|

ITFM-1 |

Slide sensor |

Slide mover |

IR sensor; present or

absent |

|

|

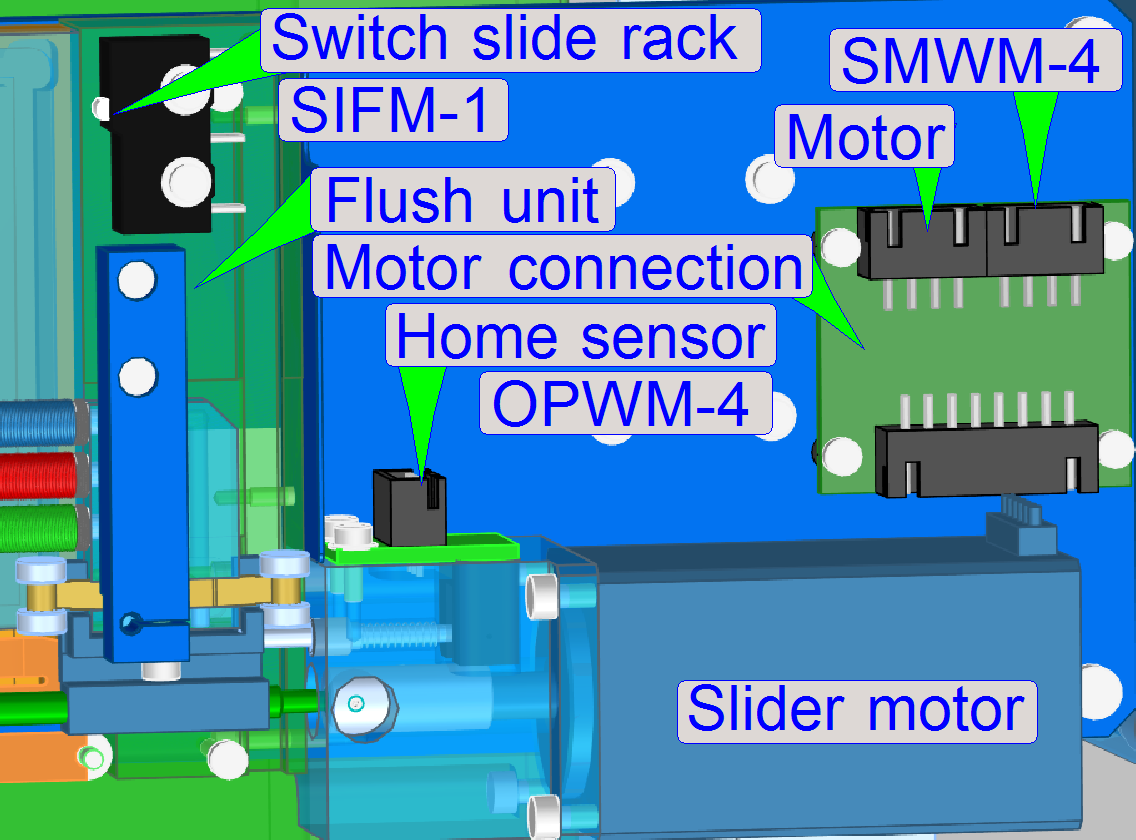

SIFM-1 |

Micro switch |

Slide rack; wash-rinse |

Rack inserted correctly |

|

|

SCFM-1 |

Micro switch |

Reagent tray |

Tray inserted correctly |

|

|

STHM-1 |

Tank switch |

|

|

|

|

LTDM-1 |

Illumination |

DF illumination for slide

image |

Front: “On” or “Off” |

|

|

LMDM-1 |

Illumination |

DF illumination for slide

image |

Rear: “On” or “Off” |

|

|

LLDM-1 |

Illumination |

For barcode in slide image |

“On” or “Off” |

|

|

LZHM-1 |

“On/Off” front |

Main switch for the entire

iSaCS |

Front of upper cover |

|

|

SZHM-1 |

“On/Off” front |

|||

|

LBRM-1 |

Vial chain |

Control board “Vial chain

control” |

Internal control bus |

|

|

LBWM-1 |

Wash-rinse |

Control board “Wash rinse” |

Internal control bus |

|

|

LBMM-1 |

Transporter |

Control board

“Transporter” |

Internal control bus |

|

|

LBCM-1 |

Cover slipping |

Control board “Cover

slipping” |

Internal control bus |

|

|

LBPM-1 |

Reagent applicator |

Control board “Reagent

applicator” |

Internal control bus |

|

|

SRHM-1 |

Reagent switch |

|

|

|

|

SSHM-1 |

Slide switch |

|

|

|

|

FSHM-1 |

Float sensor |

Overflow basin |

Fluid level sensing in

overflow basin |

|

|

VWFM-1 |

Valve “Waste” |

State of the valve paths |

Path open or closed |

|

|

VFFM-1 |

Valve “Flush” |

|||

|

VAFM-1 |

Valve “Air” |

|||

|

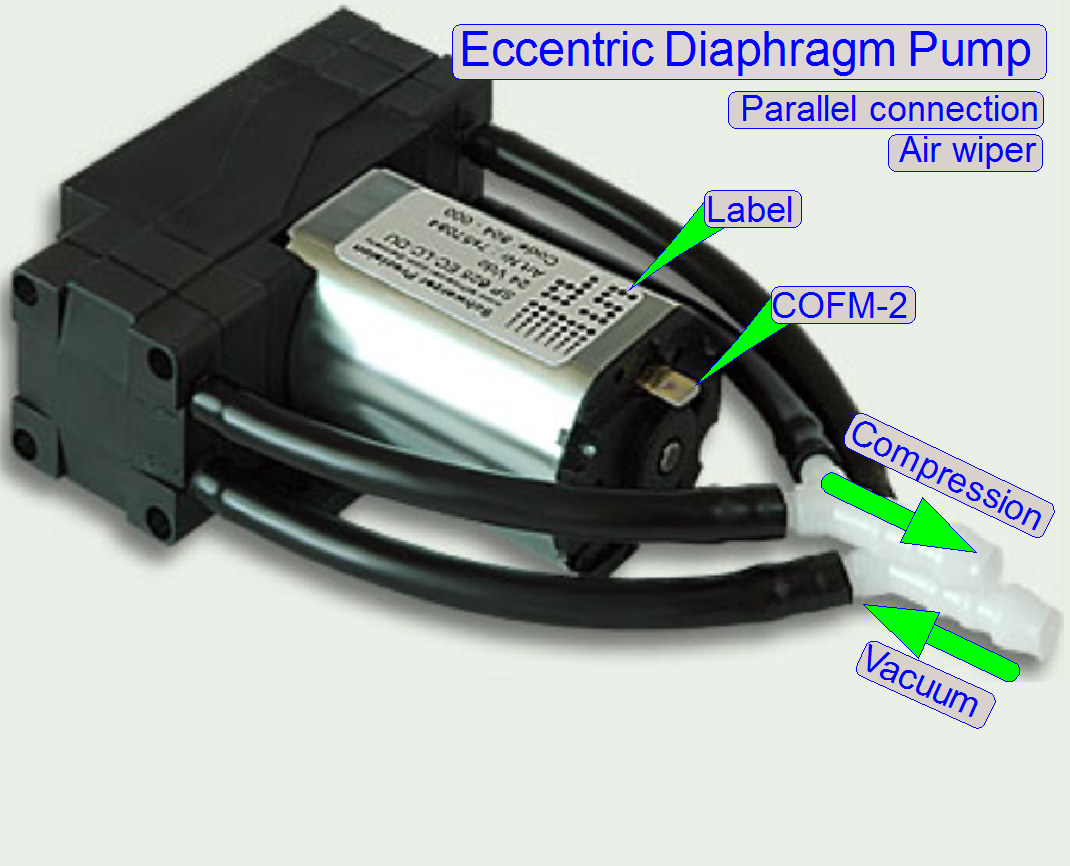

COFM-1 |

Wipe Compressor |

Beside non-hazardous waste

container |

“On” or “Off” |

|

|

LTFM-1 |

Transp. LED line |

Internal units

illumination; |

“On” or “Off” |

|

|

LMFM-1 |

Top LED line |

|||

|

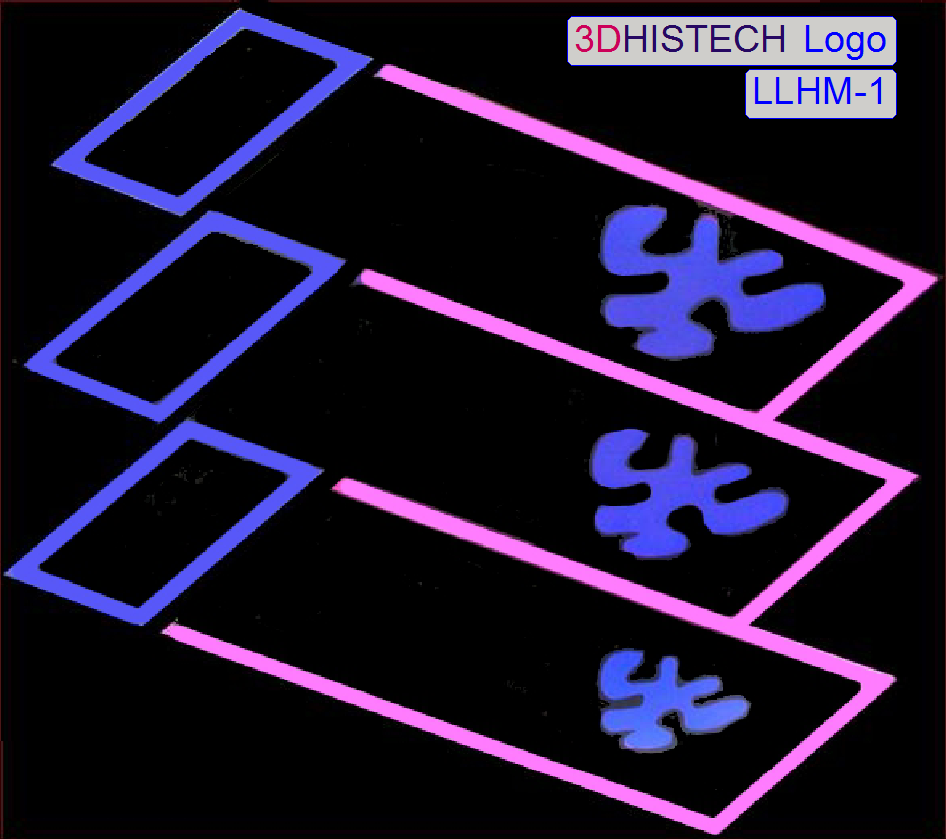

LLHM-1 |

Logo illumination |

Upper left cover front |

Switch Logo on or off |

|

|

ARHM-1 |

Upper cover right |

Solenoid latch locks the

covers during processes in progress |

Upper covers always

released at same time |

|

|

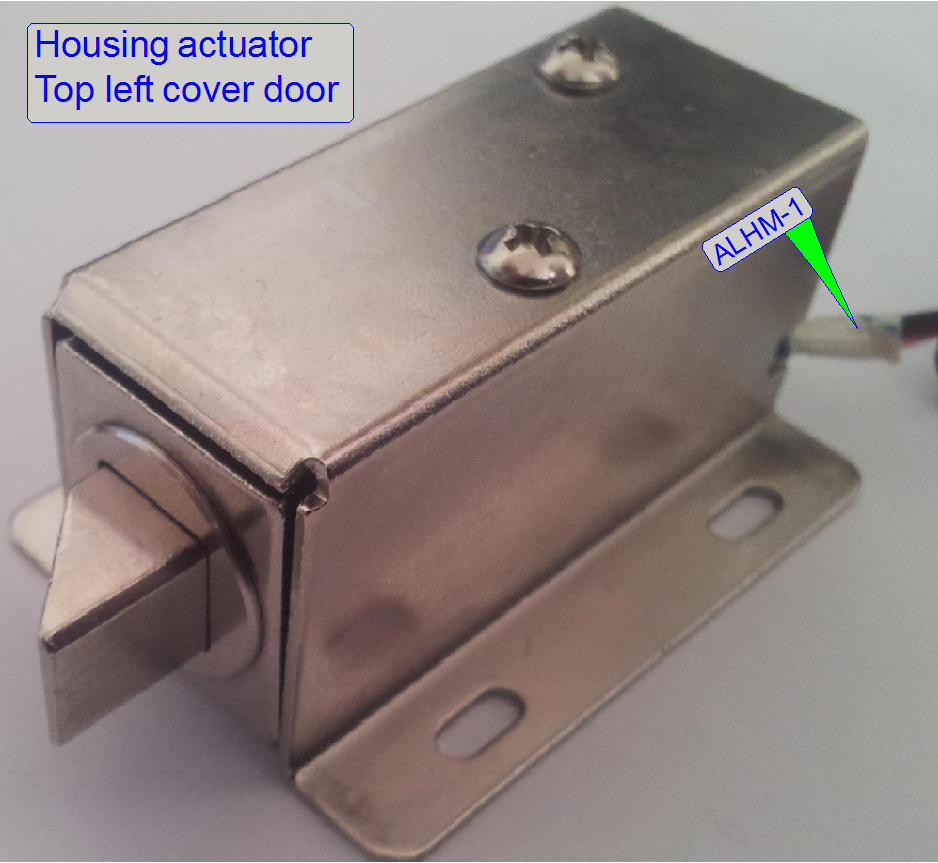

ALHM-1 |

Upper cover left |

|||

Power supply

The power supply

of the main control board is realized by the ±24V and the ±12V line; supplied

directly from the power tower’s power supply TDK Lambda through the connector

“Power, Main electronics”.

The power supply

of the main control board is realized by the ±24V and the ±12V line; supplied

directly from the power tower’s power supply TDK Lambda through the connector

“Power, Main electronics”.

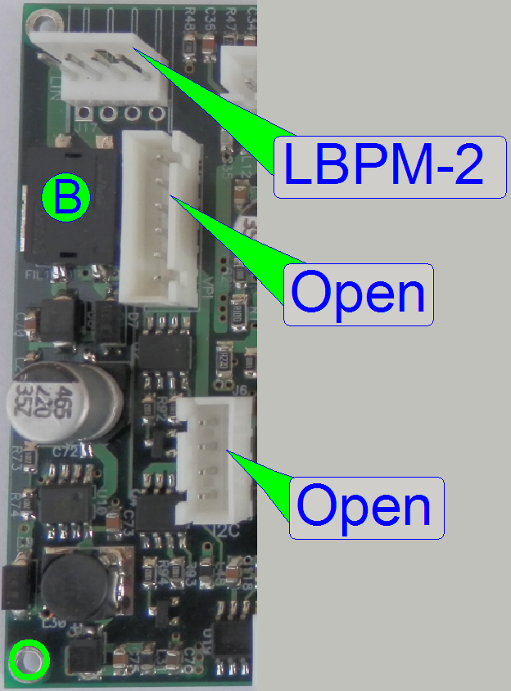

Housing

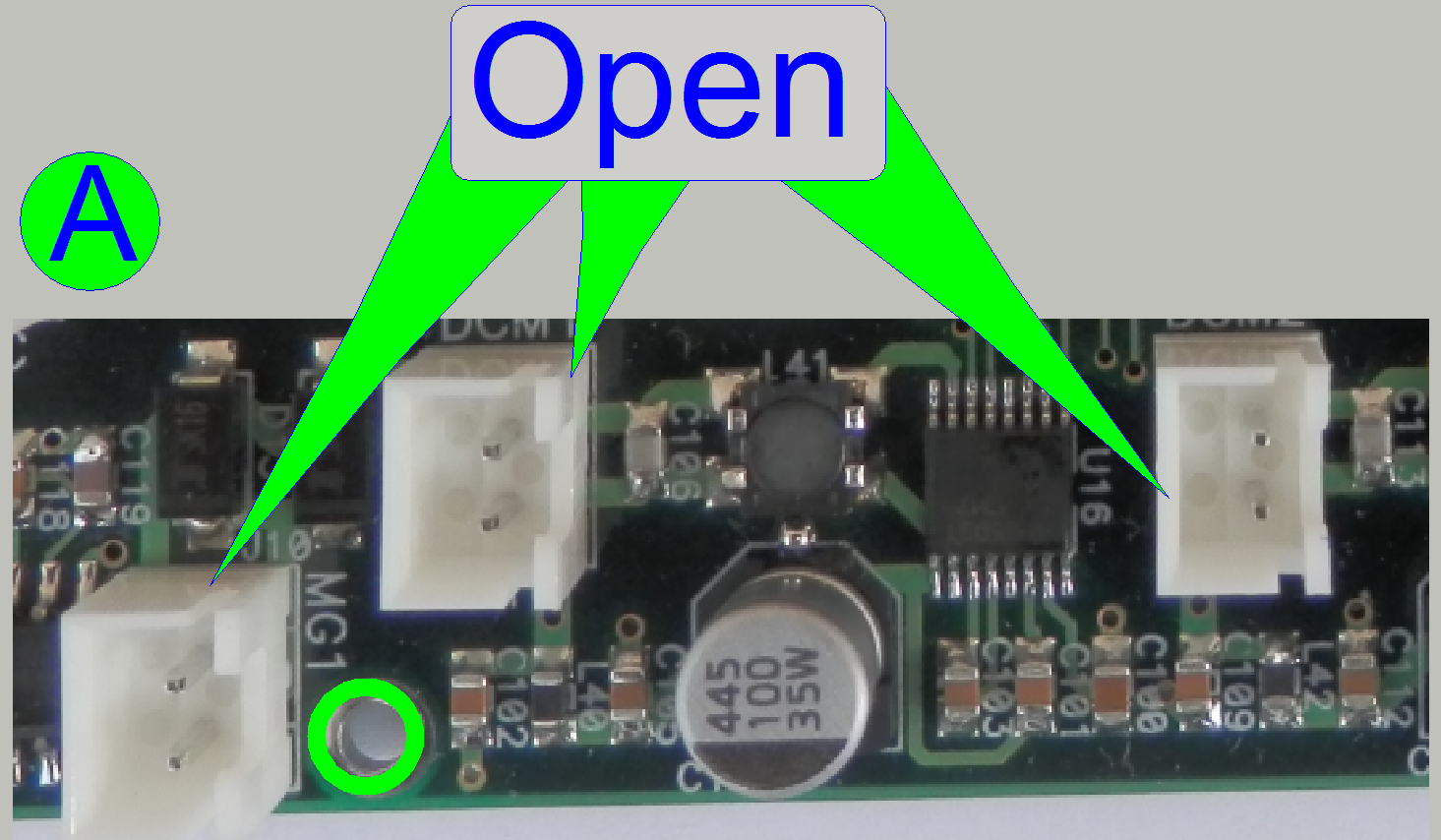

Open

This connector is left unconnected; it may be used in later versions.

ASHM-1

The bottom right

cover door is locked or unlocked by controlling this output.

The bottom right

cover door is locked or unlocked by controlling this output.

USB2.0

communication

By the use of an internal USB2.0 cable, the Main control unit is

connected to the computer’s USB2.0 port via the “USB connector board”

Plug

sensors

The pressure controlled sensors of each plug is connected here; plug the

sensor connector into the right position; see also: “Containers”.

HPTM-1

HPTM-1

Wash buffer

HPTM-2

Distilled water

HPTM-3

Hazardous waste

HPTM-4

Non-hazardous waste

Container

position

The sensors are used to distinguish the containers and to check their

correct position; see also: “Containers”

HATM-1

HATM-1

Wash buffer

HATM-2

Distilled water

HATM-3

Hazardous waste

HATM-4

Non-hazardous waste

Optical

sensor

IRRM-1

IRCM-1

IRMM-1

IRFM-1

Pipette tip checker; Cover slipping; tip holder

ITFM-1

IR sensor in the slide mover; Slide in the slide clamp or not

Units’

switches

Open

This connector is actually left unconnected; it may be used in later

versions.

SIFM-1

Connection to the

micro switch “Slide Rack Switch”; it signals the correct presence of the slide

rack.

Connection to the

micro switch “Slide Rack Switch”; it signals the correct presence of the slide

rack.

SCFM-1

Switch Reag. tray

STHM-1

Tank switch

LTDM-1; LMDM-1

Darkfield slide

illumination to make the „Slide view“

Darkfield slide

illumination to make the „Slide view“

The LEDs are arranged in an angle of ~45° in relation to the slide

surface and illuminating so the slide from beneath.

· The both led rows

are always switched on or off together.

LLDM-1

Barcode illumination LEDs for he slide during

“Slide view” capturing.

· Te LEDs are

illuminating only the barcode part of the slide

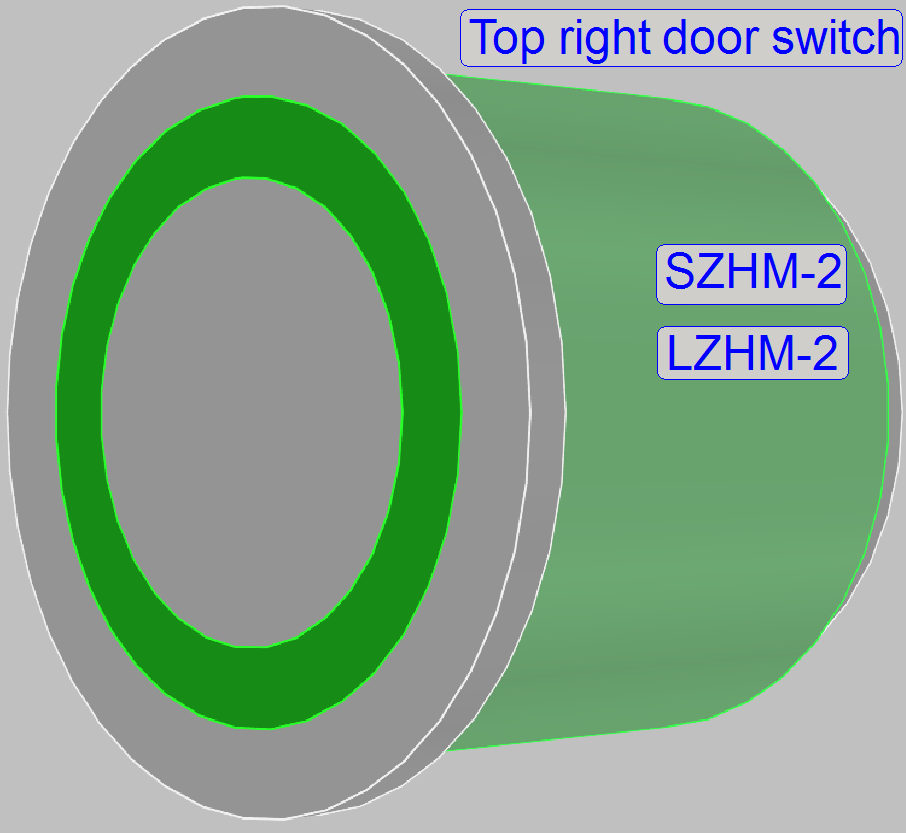

LZHM-1; SZHM-1

In front of upper

cover; by acting the cover switch, the software stops current processes and

allows the opening of the top covers.

In front of upper

cover; by acting the cover switch, the software stops current processes and

allows the opening of the top covers.

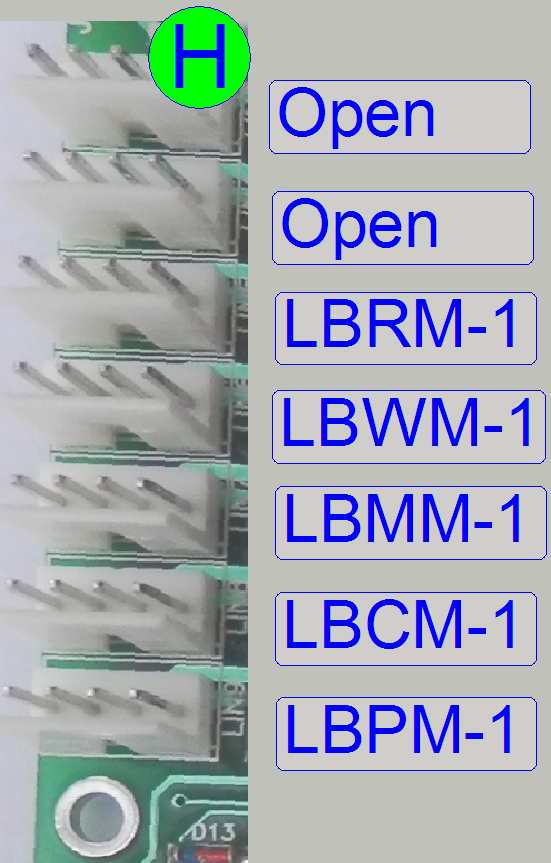

Bus

Connections

The connector

group distributes the I2C bus to the local controllers inside the staining and

cover slipping unit.

The connector

group distributes the I2C bus to the local controllers inside the staining and

cover slipping unit.

Open

This connector is actually left unconnected; it may be used in later

versions.

LBRM-1

Control board “Vial chain control” Internal control bus

LBWM-1

Control board “Wash rinse” Internal control bus

LBMM-1

Control board “Transporter” Internal control bus

LBCM-1

Control board “Cover slipping” Internal control

bus

LBPM-1

“Control board “Reagent applicator Internal control bus

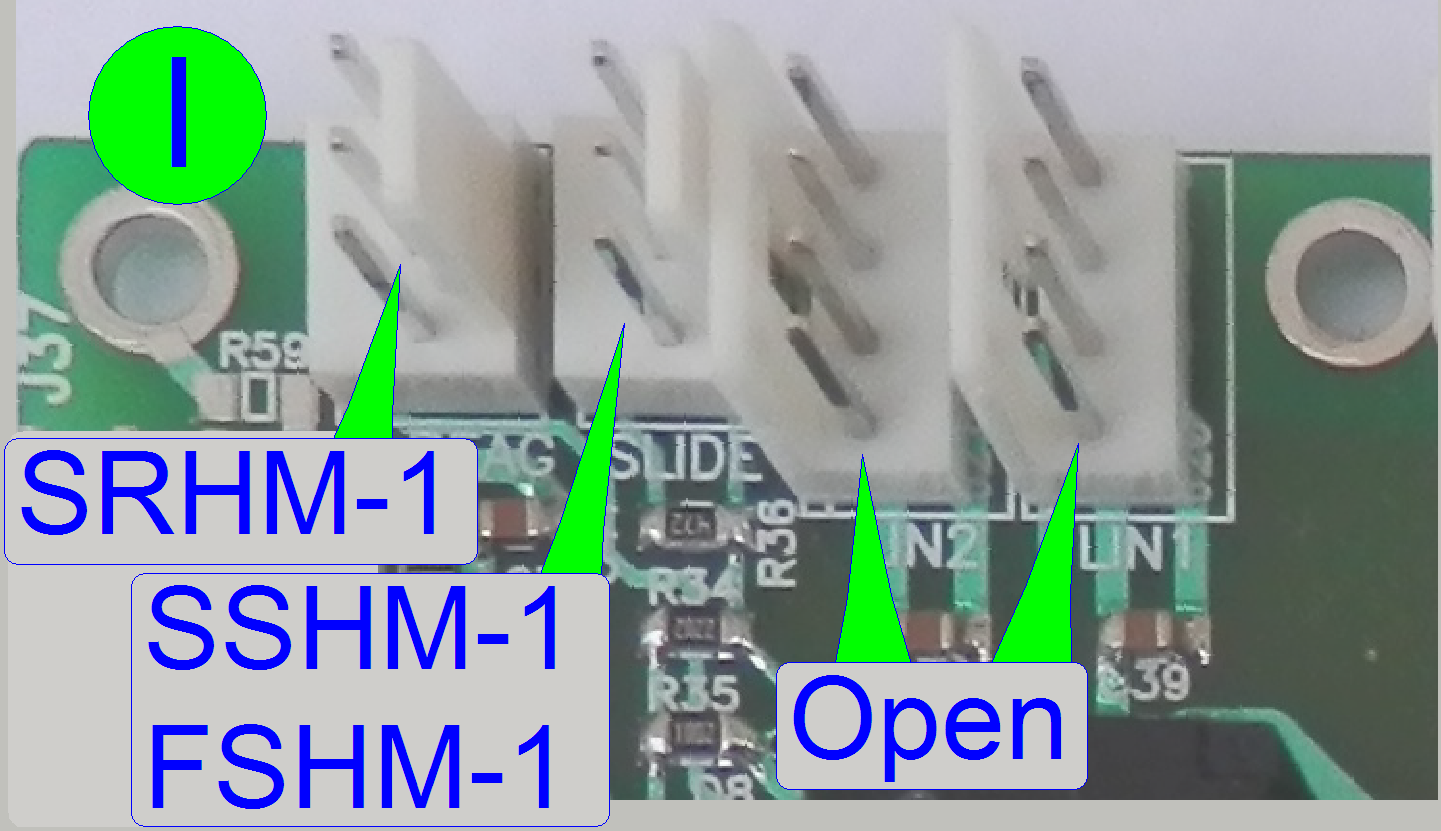

Micro

switches

SRHM-1

Reagent switch

SSHM-1

Slide switch

FSHM-1

Float sensor

Relay

outputs

VWFM-1

VWFM-1

Valve “WASTE” is controlled by this output.

VFFM-1

Valve “FLASH” is controlled by this output.

VAFM-1

Valve “AIR” is controlled by this output.

COFM-1

COFM-1

After the “Hirschmann” connector, the wire label is named as COFM-2

LTFM-1

LED is controlled by this output.

LMFM-1

LED is controlled by this output.

LLHM-1

The 3DHISTECH

illuminated logo is controlled by this output.

The 3DHISTECH

illuminated logo is controlled by this output.

ARHM-1

The top right

cover door is locked or unlocked by controlling this output.

The top right

cover door is locked or unlocked by controlling this output.

ALHM-1

The top left cover

door is locked or unlocked by controlling this output.

The top left cover

door is locked or unlocked by controlling this output.

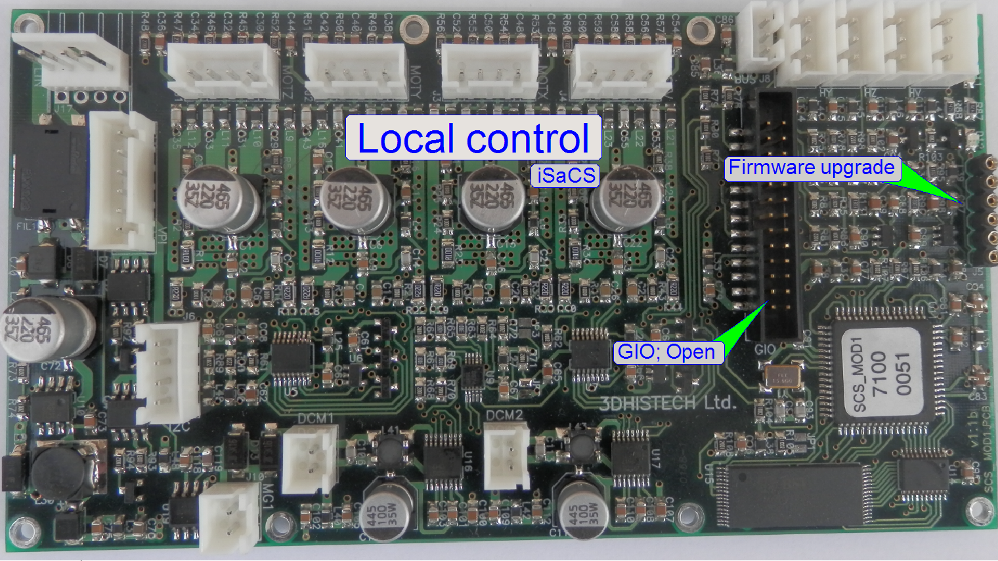

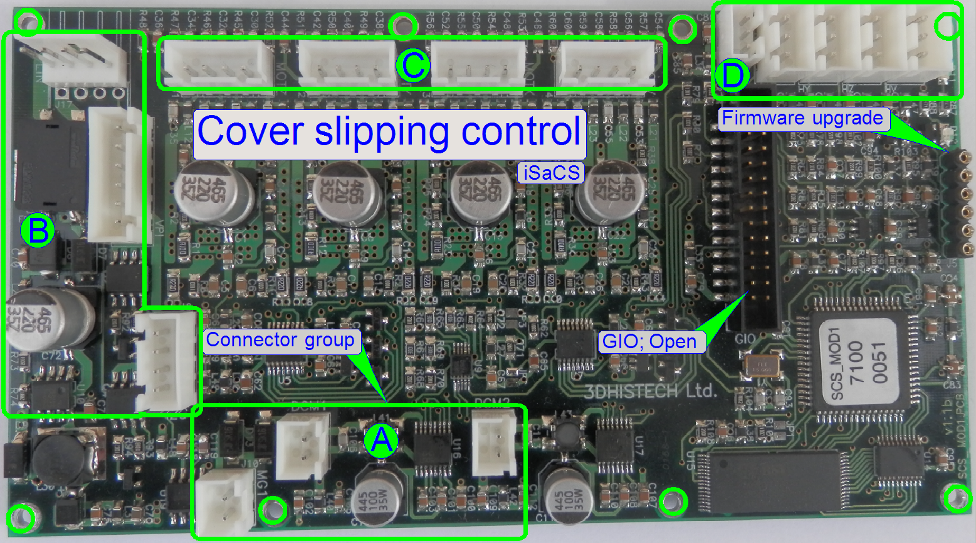

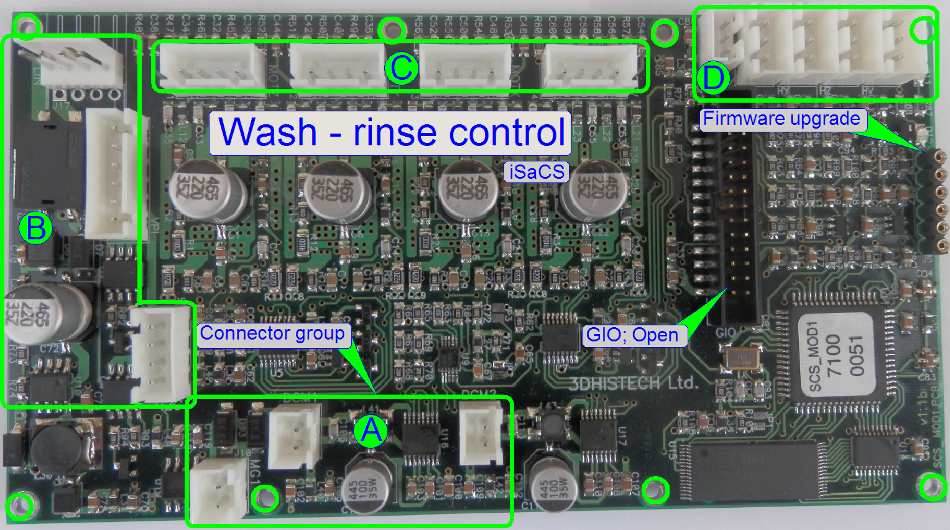

Local

control

The shown electronics board is used to control the

· transporter

· stain applicator

· cover slipping

· wash - rinse

The board exists 4x in the staining and cover slipping units;

differences are given in the address of the board and connected units; the

board itself is identical; the firmware also.

Remark

Because the address is different for each board, an interchange of the

board between the named units without address modifying is impossible!

Transporter

control

|

Connections of

“Transporter control” |

||||

|

Name |

Type |

Group |

Source or Target |

Description |

|

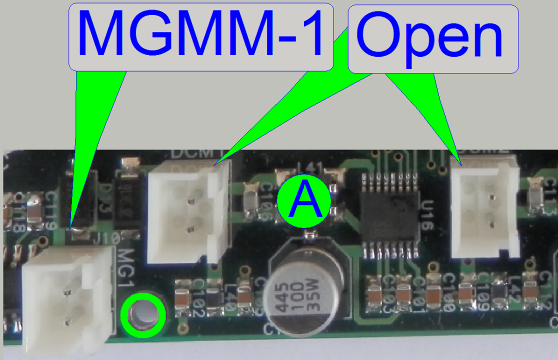

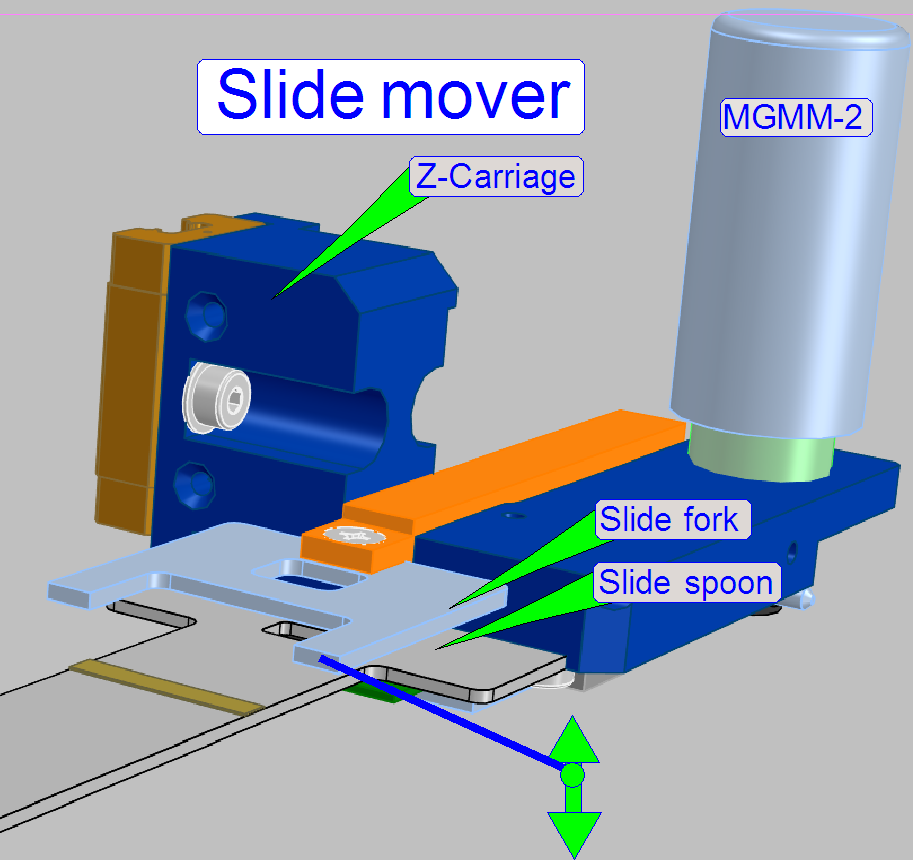

MGMM-1 |

Solenoid 15V; |

Slide fork |

Holds the slide |

|

|

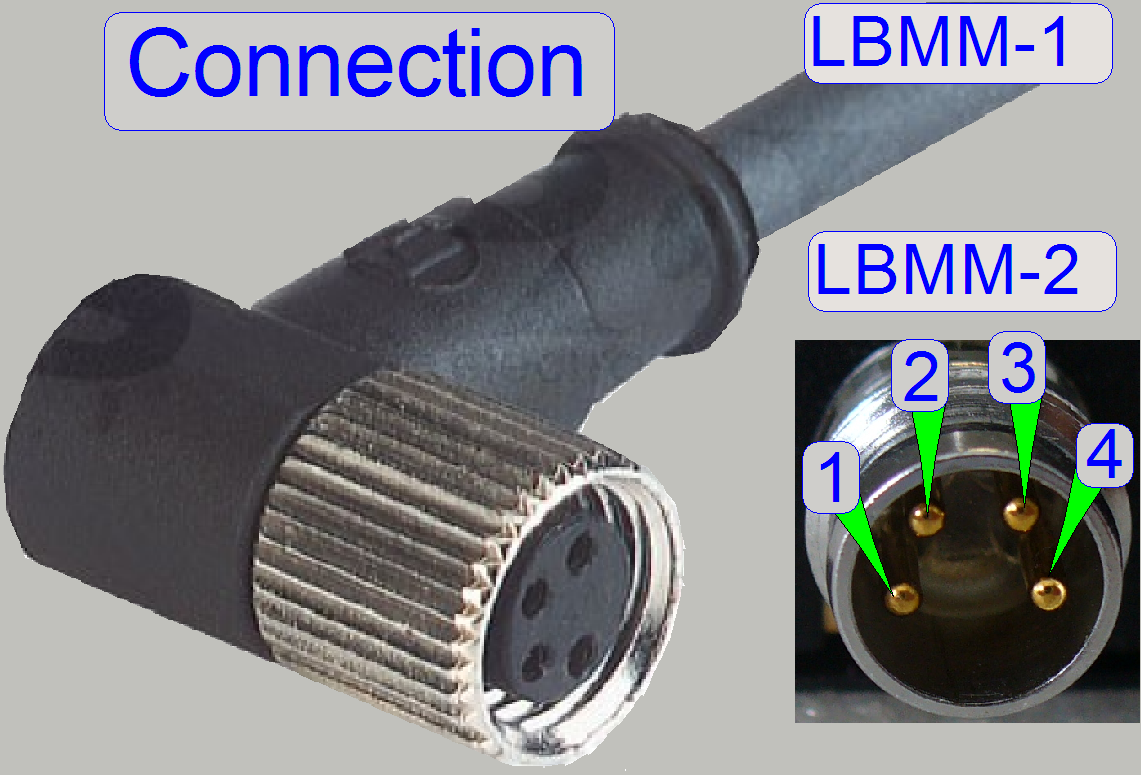

LBMM-2 |

Local communication bus |

Main control board |

Control of units |

|

|

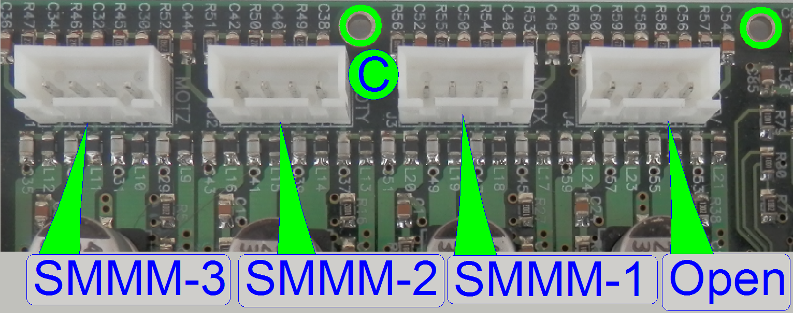

SMMM-3 |

Step motor in Z-direction |

Transporter |

Move slide along

mathematical axes |

|

|

SMMM-2 |

Step motor in Y-direction |

|||

|

SMMM-1 |

Step motor in X-direction |

|||

|

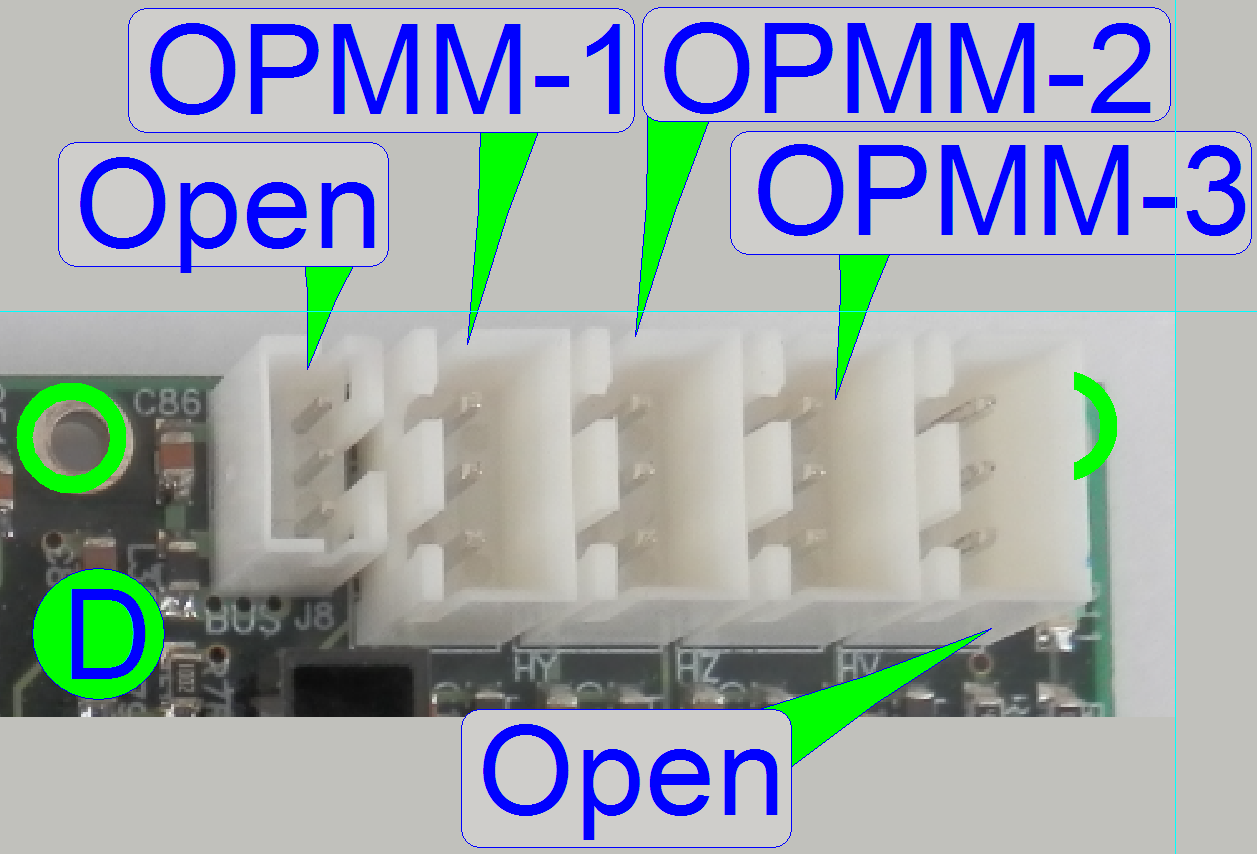

OPMM-1 |

Home sensor X-direction |

Transporter |

Detect home position for axis |

|

|

OPMM-2 |

Home sensor Y-direction |

|||

|

OPMM-3 |

Home sensor Z-direction |

|||

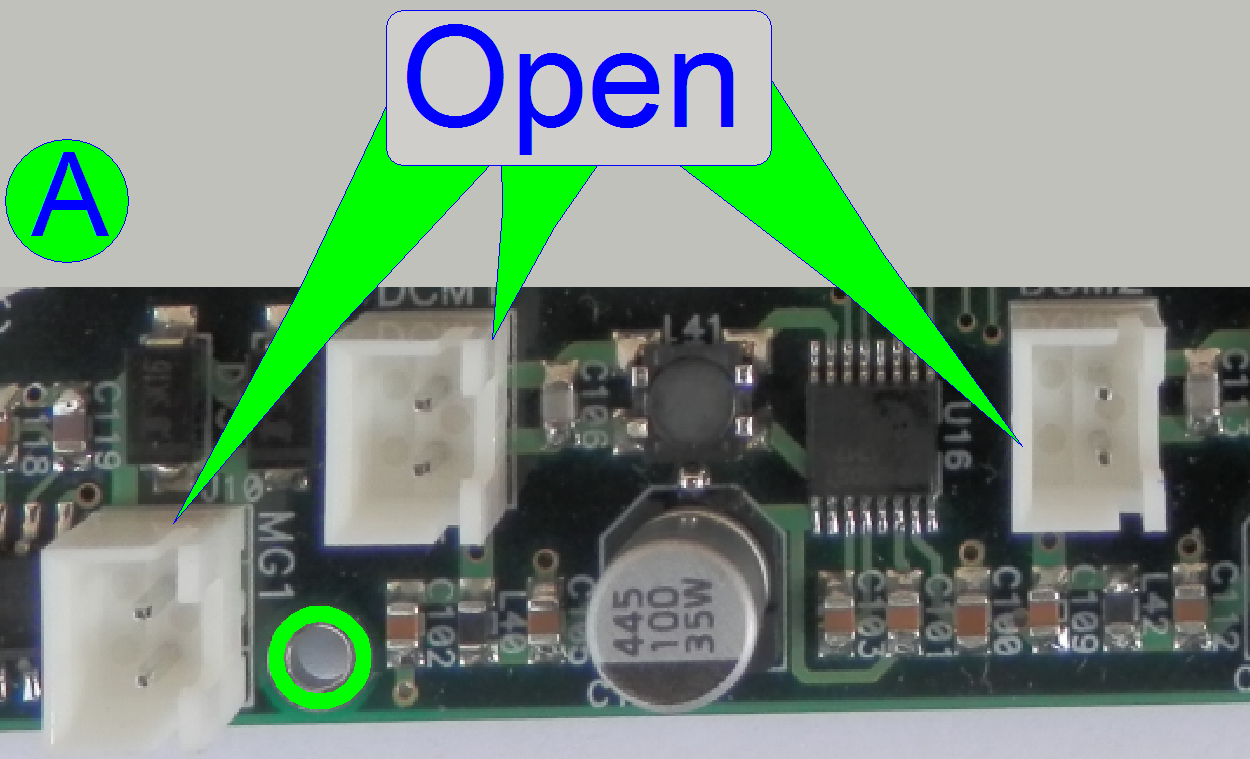

Open

This connector is actually left unconnected; it may be used in later

versions.

MGMM-1

Via a voltage stabilization IC of 15V the

slide fork of the slide mover is controlled.

Via a voltage stabilization IC of 15V the

slide fork of the slide mover is controlled.

LBMM-1; 2

Local communication bus

Open

This connector is actually left unconnected; it may be used in later

versions.

SMMM-3

SMMM-2

SMMM-2

SMMM-1

Open

This connector is actually left unconnected; it may be used in later

versions.

OPMM-3

OPMM-2

OPMM-2

OPMM-1

Open

This connector is actually left unconnected; it may be used in later

versions.

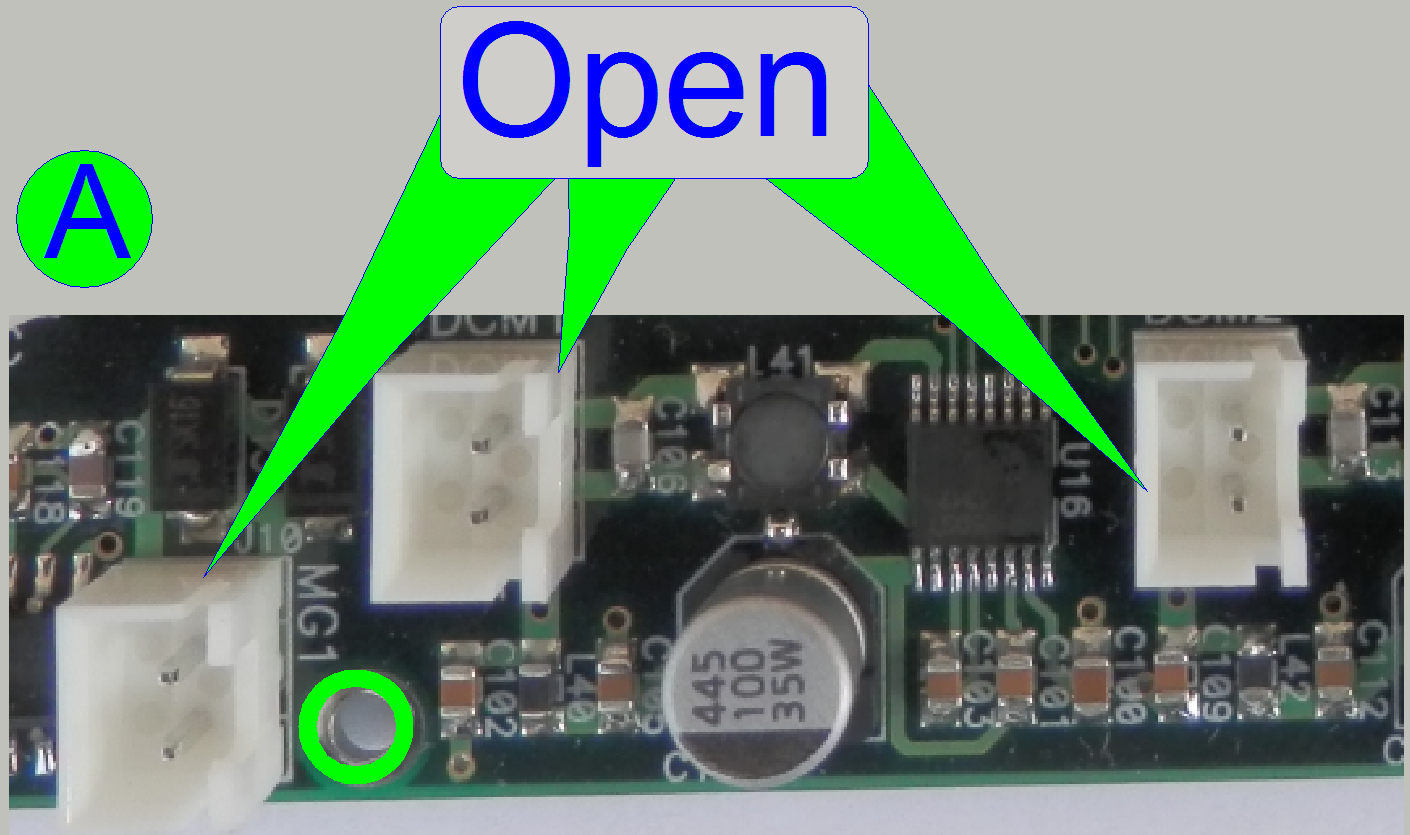

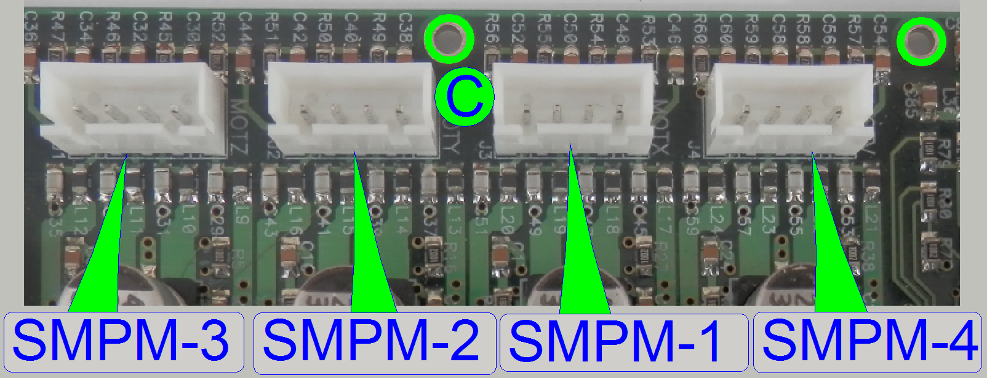

|

Connections of “Stain

applicator” |

||||

|

Name |

Type |

Group |

Source or Target |

Description |

|

Open |

Not used |

|

|

|

|

LBPM-2 |

Local communication bus |

Main control board |

Control of units |

|

|

SMPM-4 |

Step motor “Air pump” |

Applicator head |

Move tip acceptor along axes; Vacuum or pressure for tip |

|

|

SMPM-3 |

Lift motor in Z-direction |

|||

|

SMPM-2 |

Step motor in Y-direction |

|||

|

SMPM-1 |

Tip mover in X-direction |

|||

|

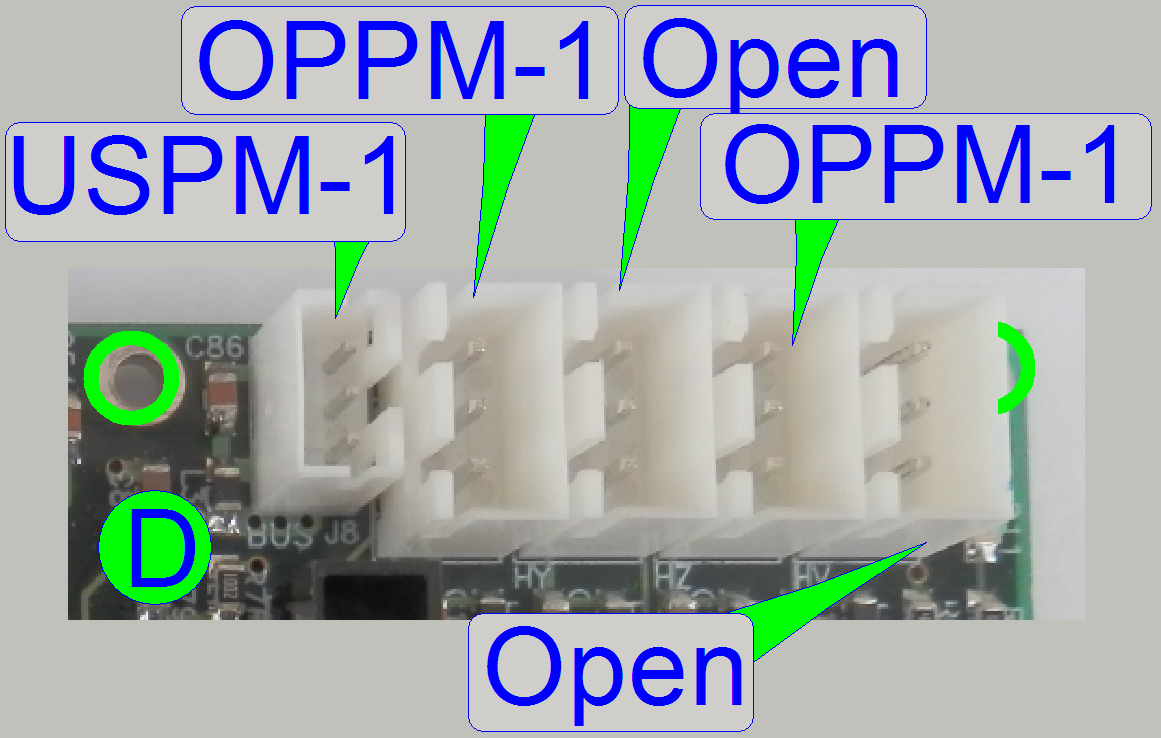

OPPM-1 |

Pressure sensor |

Pipette tip |

Vacuum; pressure |

|

|

USPM-1 |

Fluid level |

Reagent vial |

Reagent quantity |

|

Open

Open

This connector is actually left unconnected; it may be used in later

versions.

Group

“B”

LBPM-2

Open

This connector is actually left unconnected; it may be used in later

versions.

SMPM-1

SMPM-2

SMPM-3

SMPM-4

USPM-1

OPPM-1; OPPM-1

The wire has 2

connectors

The wire has 2

connectors

Open

This connector is actually left unconnected; it may be used in later

versions.

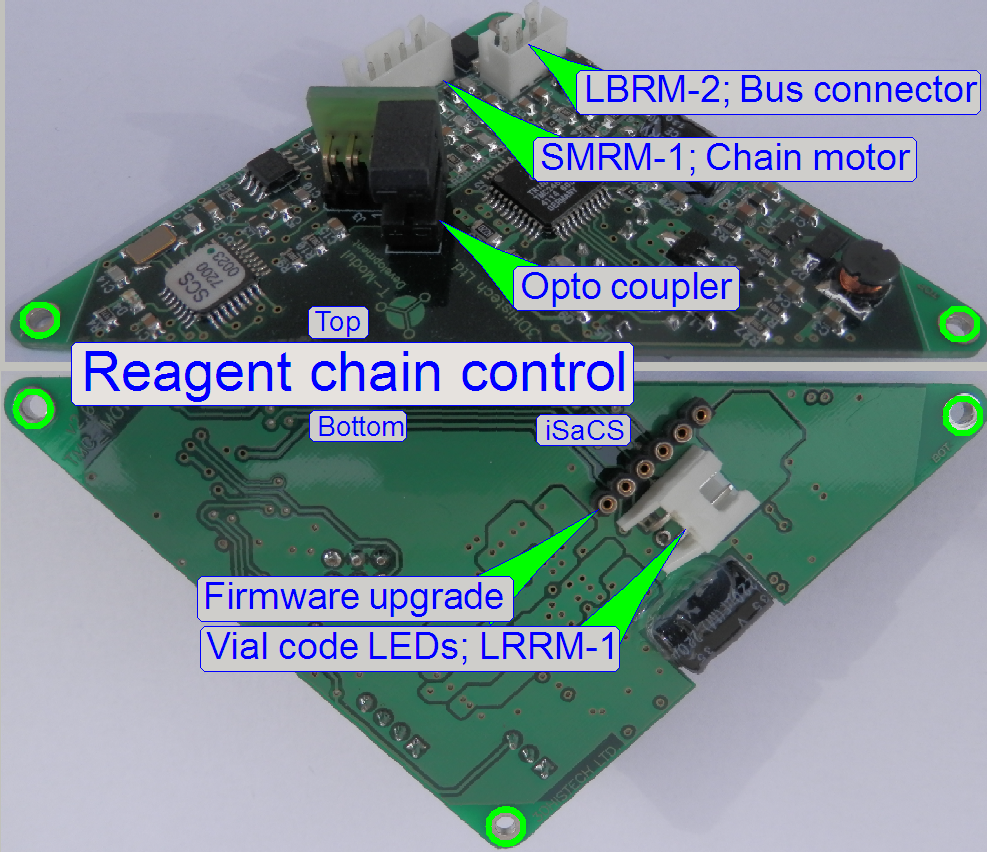

|

Connections of “Reagent

chain” |

||||

|

Name |

Type |

Source or Target |

Description |

|

|

LBRM-2 |

Local communication bus |

Main control board |

Control of units |

|

|

SMRM-1 |

Step motor |

Vial

chain |

Move circularly the vial chain |

|

|

LRRM-1 |

Illumination LEDs |

Reagent barcode |

Illumination |

|

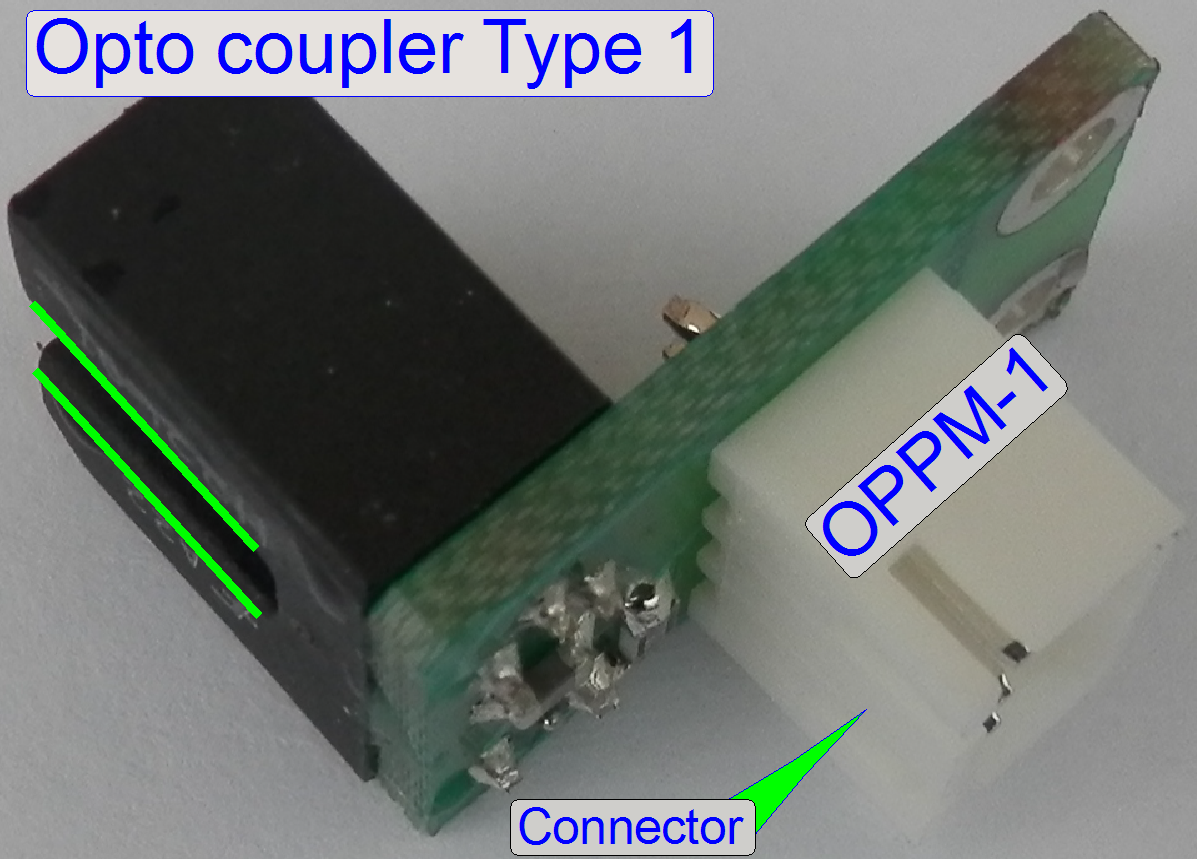

Vial

chain’s position sensor

Through the “Opto coupler” mounted on the PCB a disc half is rotated and

this is mounted onto the Maltese cross’ disc. With this solution the Home position

can be adjusted, so the vial chain link can be stopped in the correct vial

position for filling the pipette tip.

|

Connections of “Cover slipping” |

||||

|

Name |

Type |

Group |

Source or Target |

Description |

|

Open |

Not used |

|

|

|

|

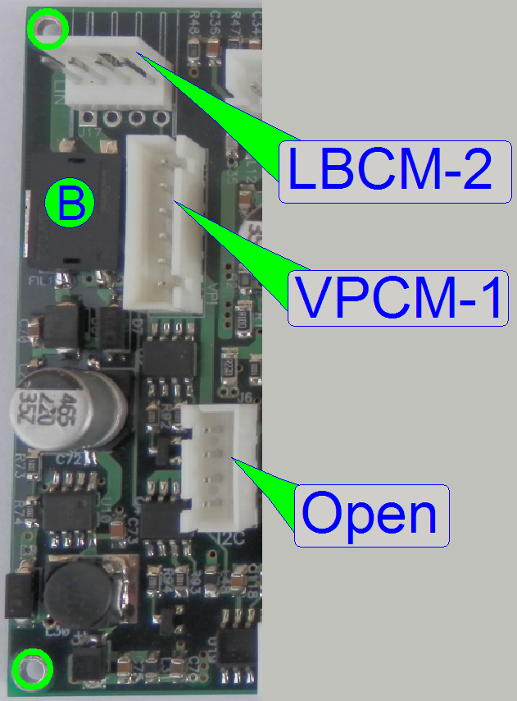

LBCM-2 |

Local communication bus |

Main control board |

Control of units |

|

|

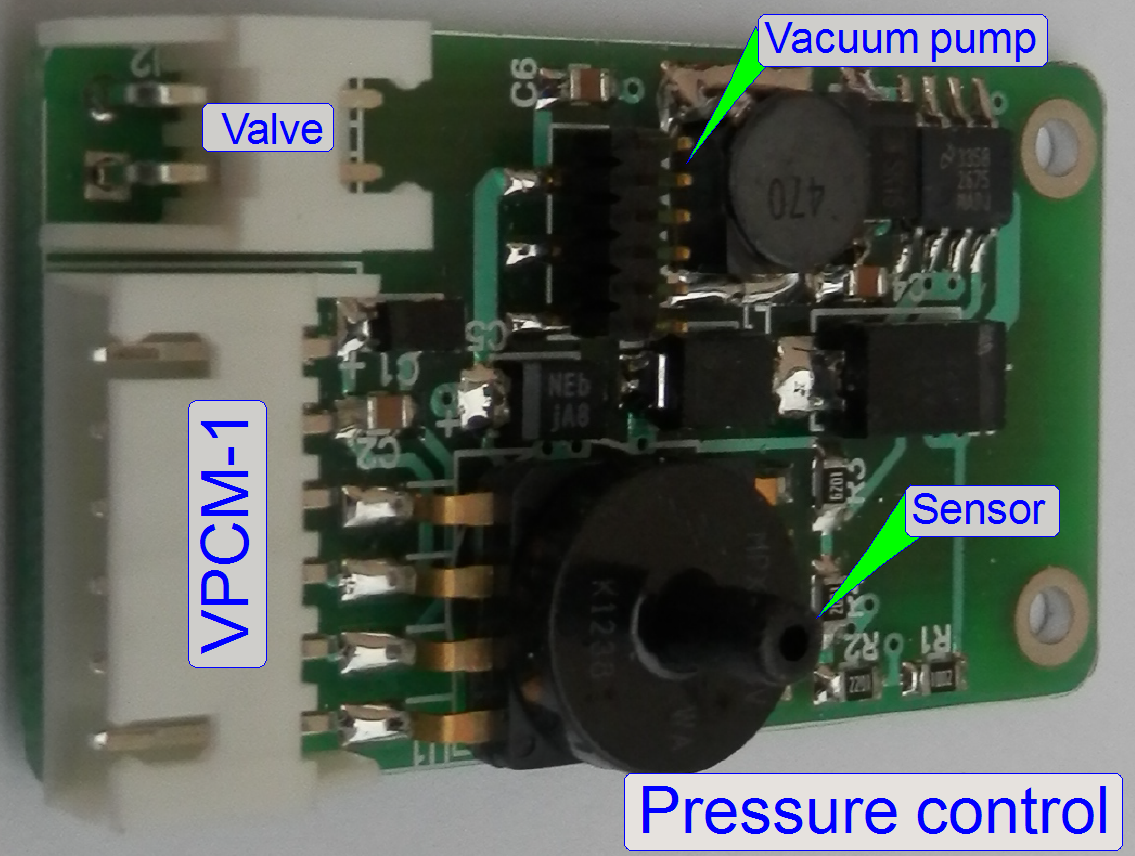

VPCM-1 |

Pressure sensor |

Sensor; pump; Valve |

Control components |

|

|

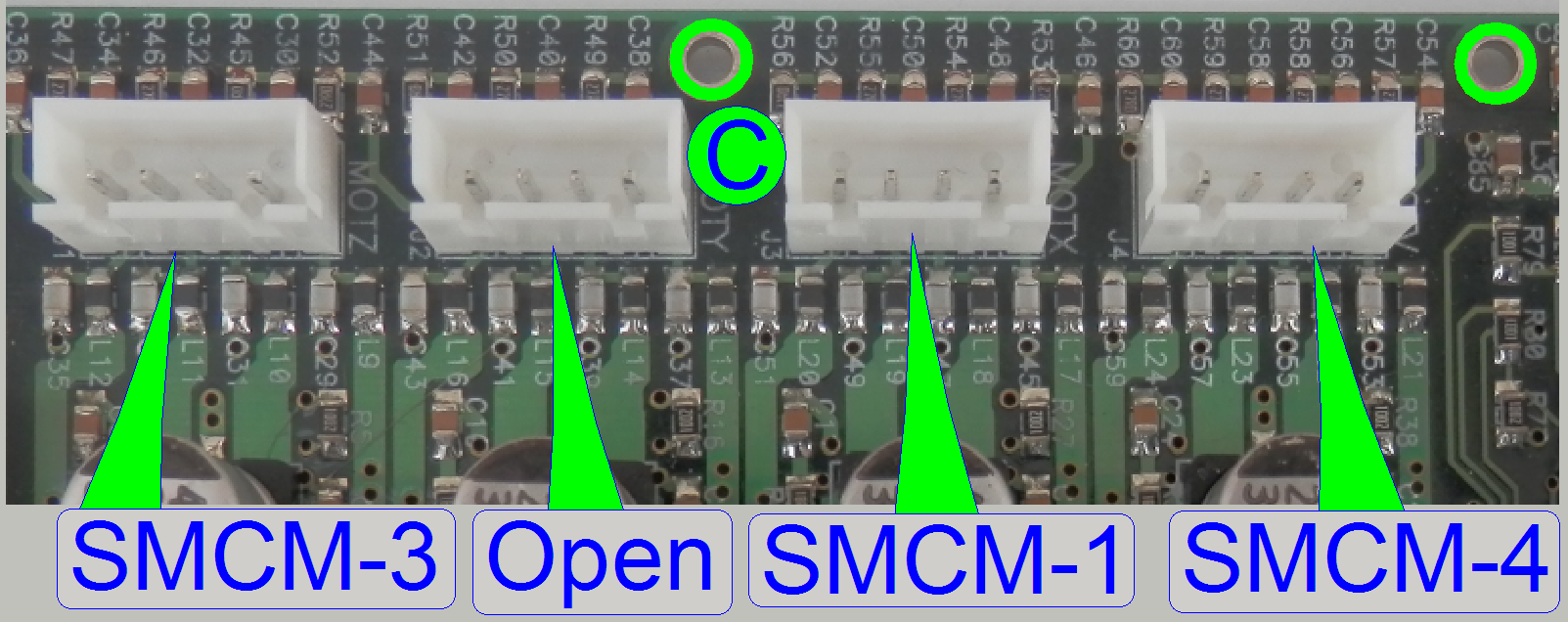

SMCM-4 |

Step motor “V” |

Applicator

head |

Move tip acceptor

along Z-axis; Vacuum or pressure for

tip |

|

|

SMCM-3 |

Lift motor in Z-direction |

|||

|

Open |

-------- |

|||

|

SMCM-1 |

Step motor “X” ?????????? |

|||

|

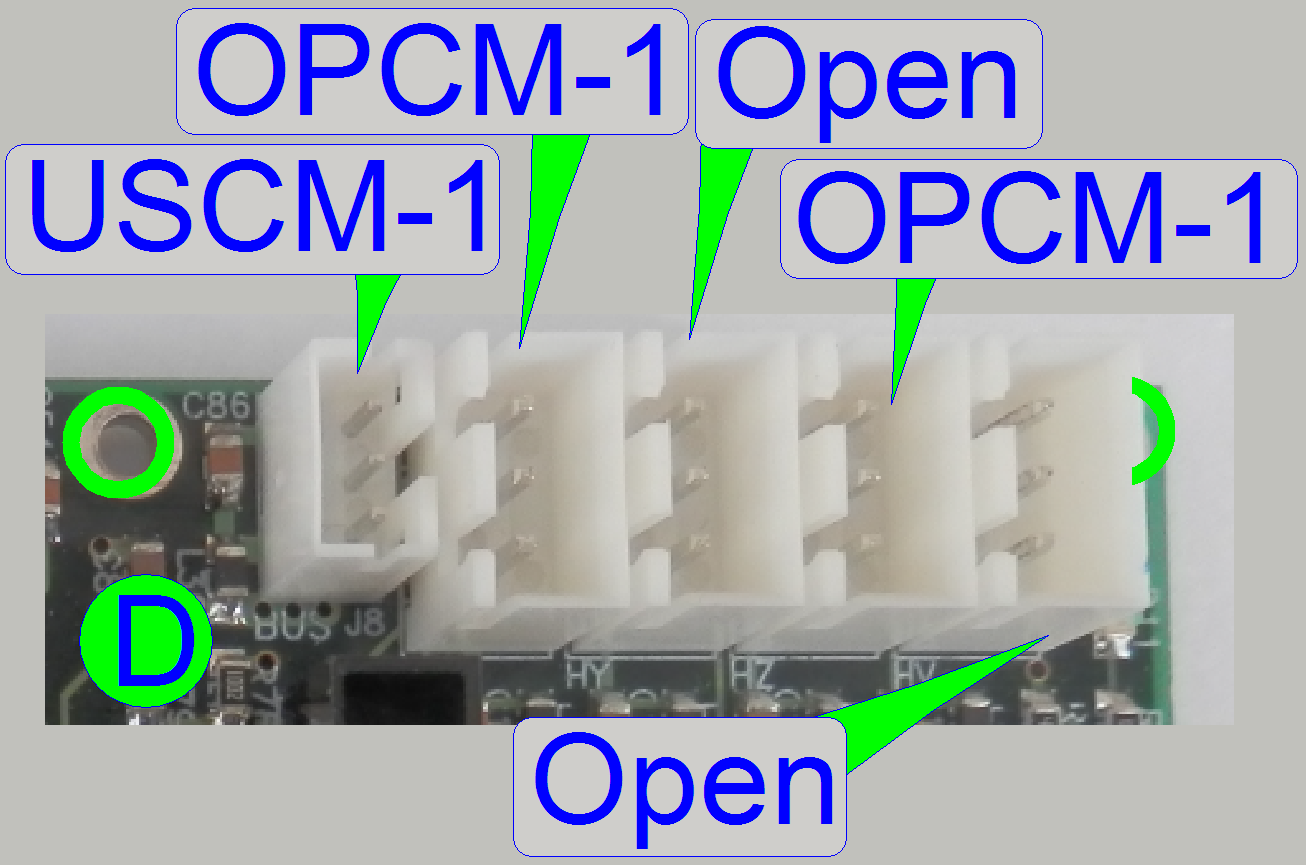

OPCM-1 |

Opto sensor |

Pipette

tip |

Vacuum; pressure |

|

|

USCM-1 |

Fluid level |

Mounting

medium |

Medium quantity |

|

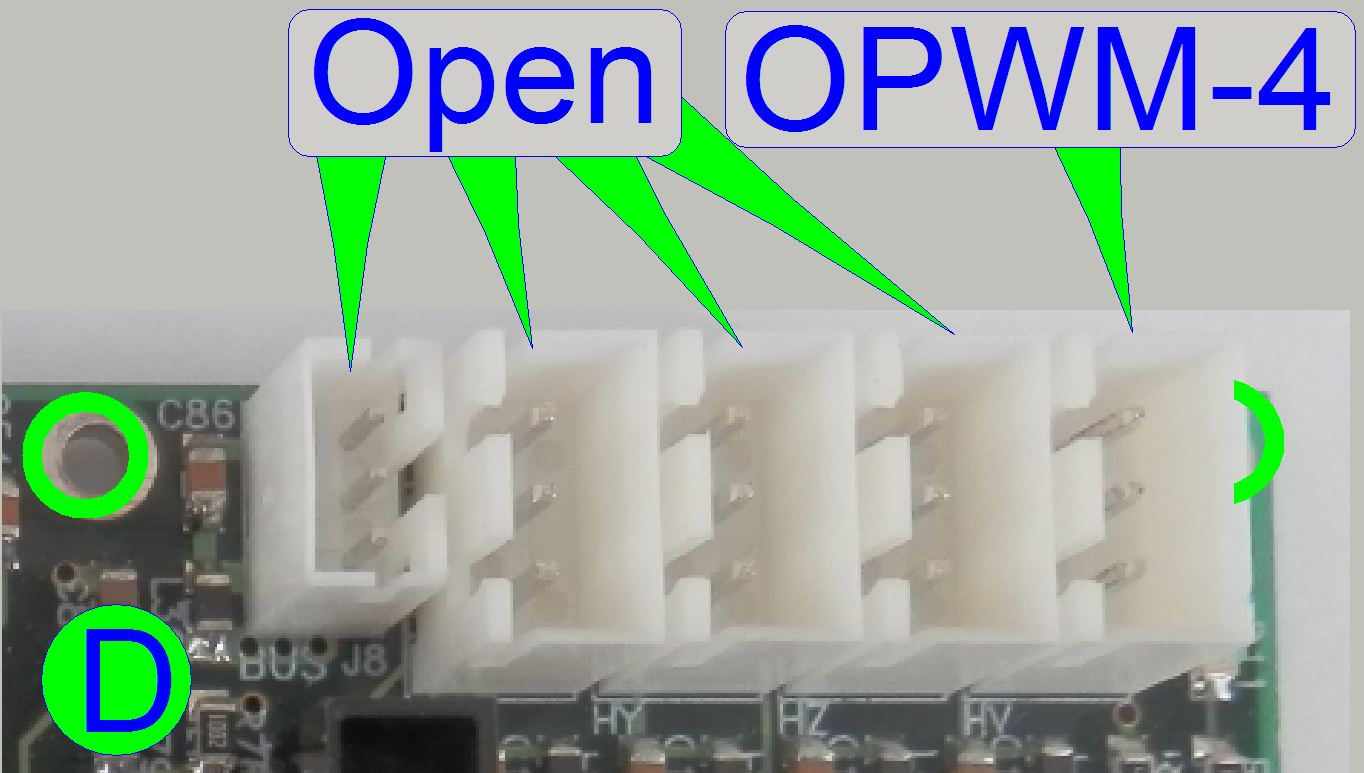

Open

This connector is actually left unconnected; it may be used in later

versions.

LBCM-2

VPCM-1

Open

This connector is actually left unconnected; it may be used in later

versions.

Group

“C”

SMCM-1

SMCM-1

SMCM-3

SMCM-4

Open

This connector is actually left unconnected; it may be used in later

versions.

USCM-1

OPCM-1; OPCM-1

The wire end has 2 connectors

Open

This connector is actually left unconnected; it may be used in later

versions.

|

Connections of “Wash-rinse” |

||||

|

Name |

Type |

Group |

Source or Target |

Description |

|

Open |

Not used |

|

|

|

|

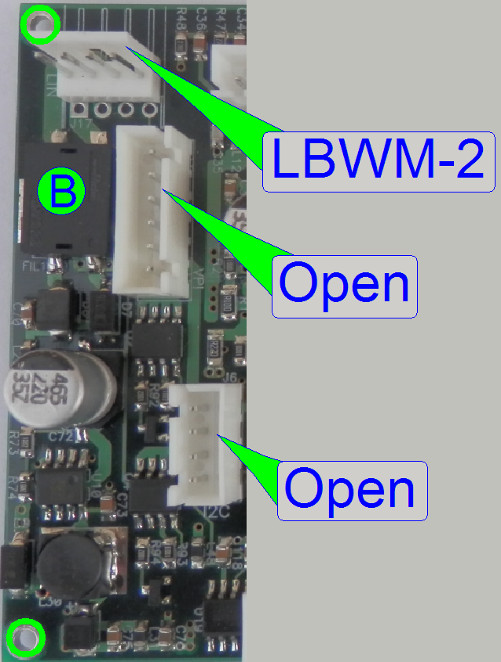

LBWM-2 |

Local communication

bus |

Main control board |

Control of units |

|

|

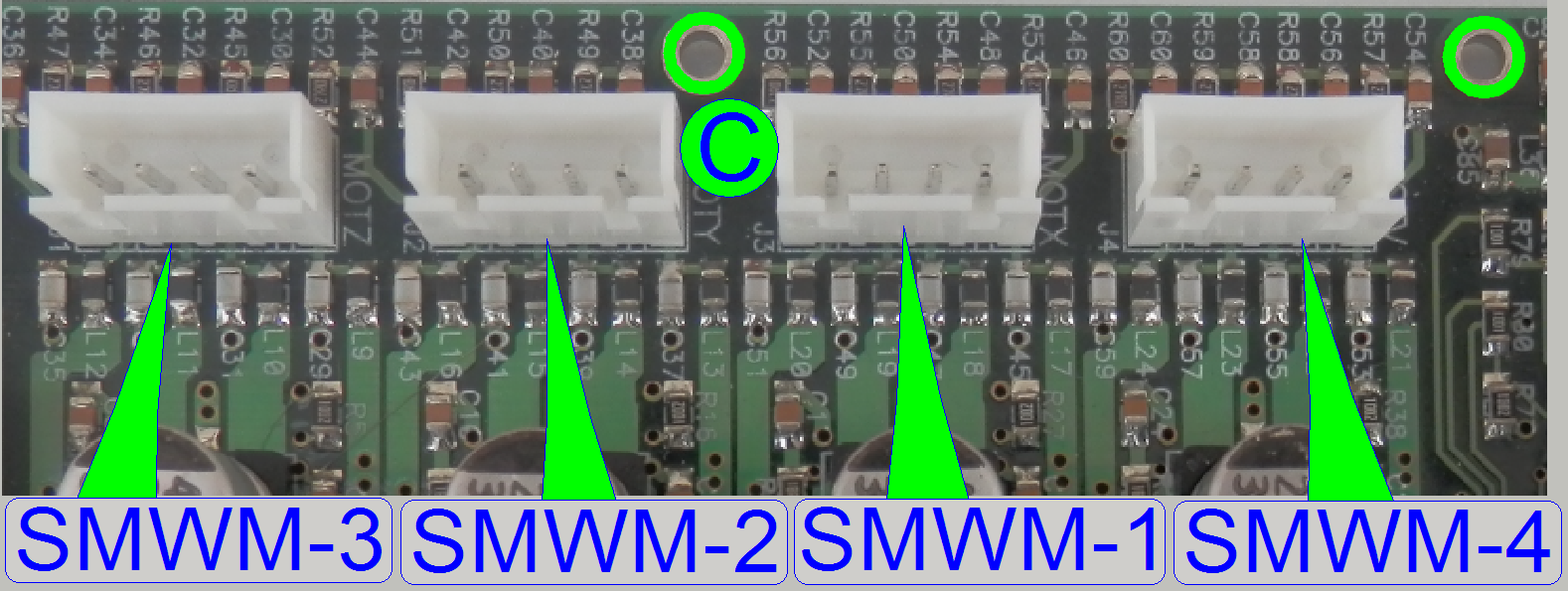

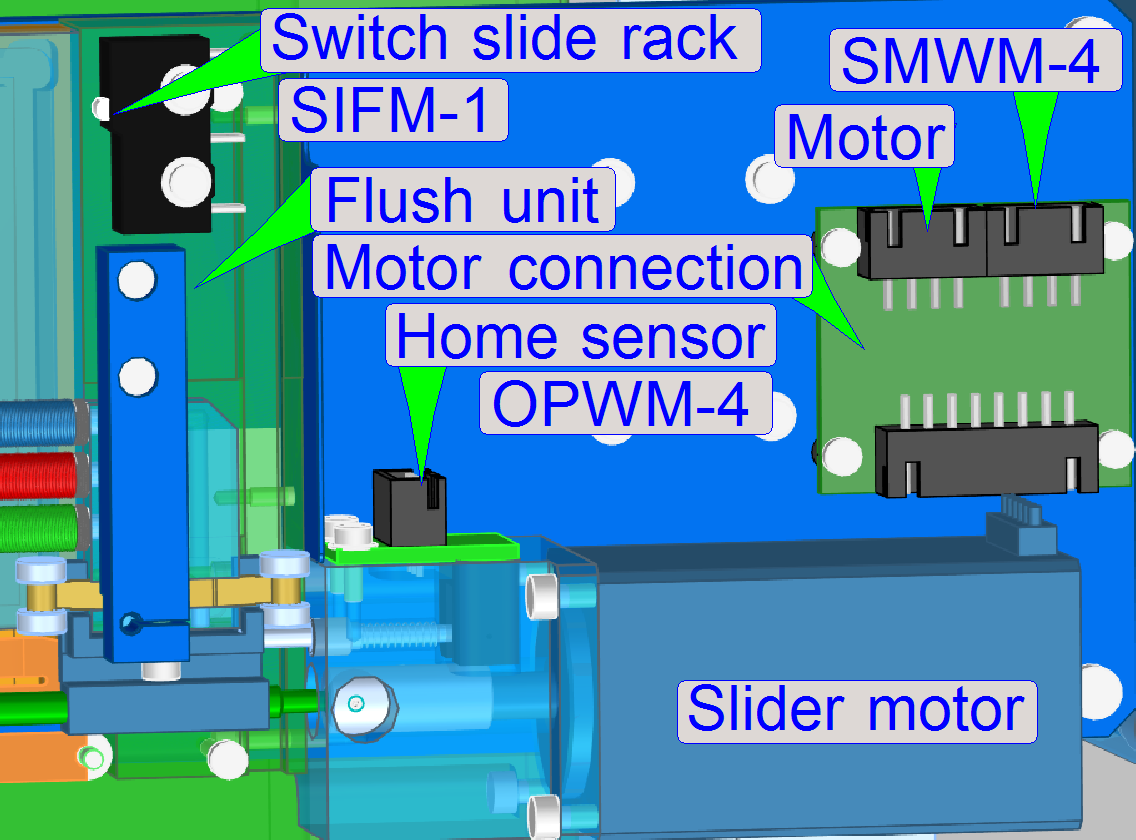

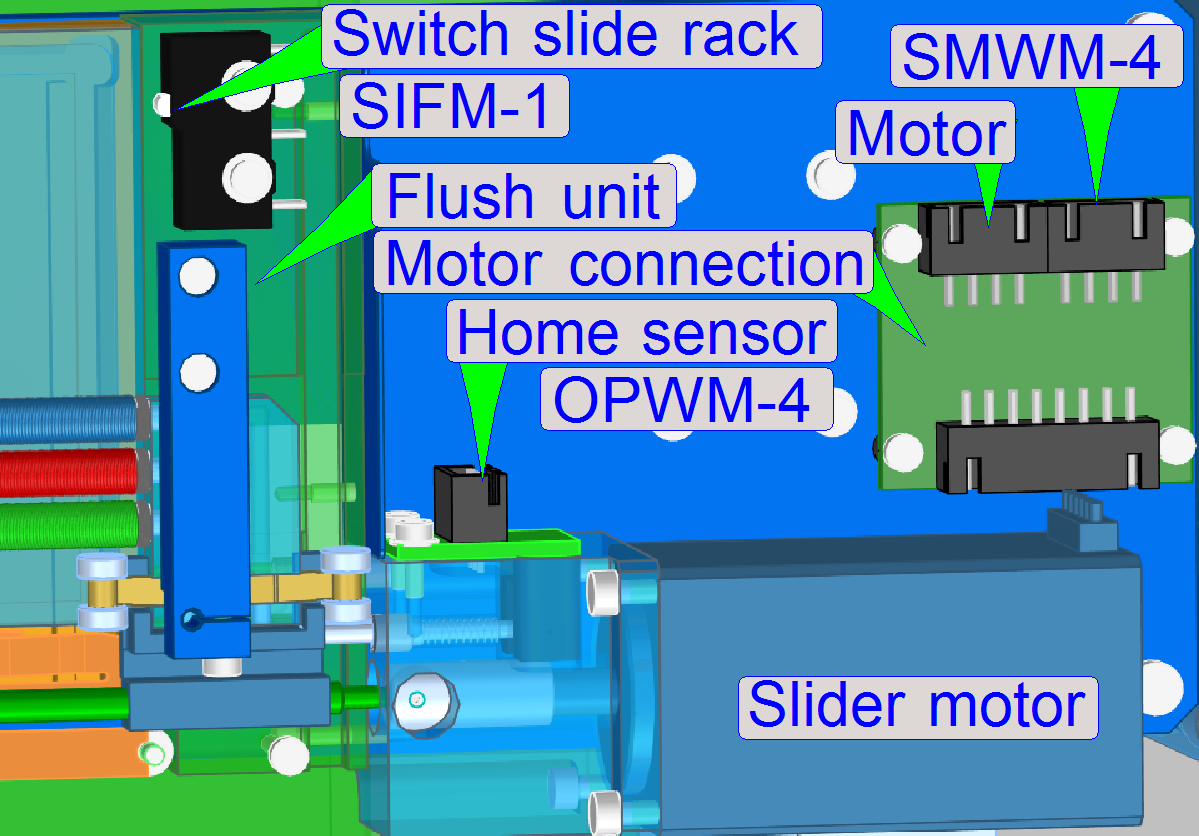

SMWM-4 |

Step motor “Slider” |

Wash-rinse chambers |

Move fluid nozzles |

|

|

SMWM-3 |

Pump “WASTE” |

Pumps |

Move dedicated

fluids |

|

|

SMWM-2 |

Pump “Rinsing” |

|||

|

SMWM-1 |

Pump “ |

|||

|

OPWM-4 |

Slider home sensor |

Wash-rinse |

Detect home position |

|

Open

This connector is actually left unconnected; it may be used in later

versions.

LBWM-2

Open

This connector is actually left unconnected; it may be used in later

versions.

SMWM-1

SMWM-2

SMWM-2

SMWM-3

SMWM-4

See “Motor connection” board on the right

Open

This connector is

actually left unconnected; it may be used in later versions.

This connector is

actually left unconnected; it may be used in later versions.

OPWM-4

Home sensor of the slider in the wash – rinse unit