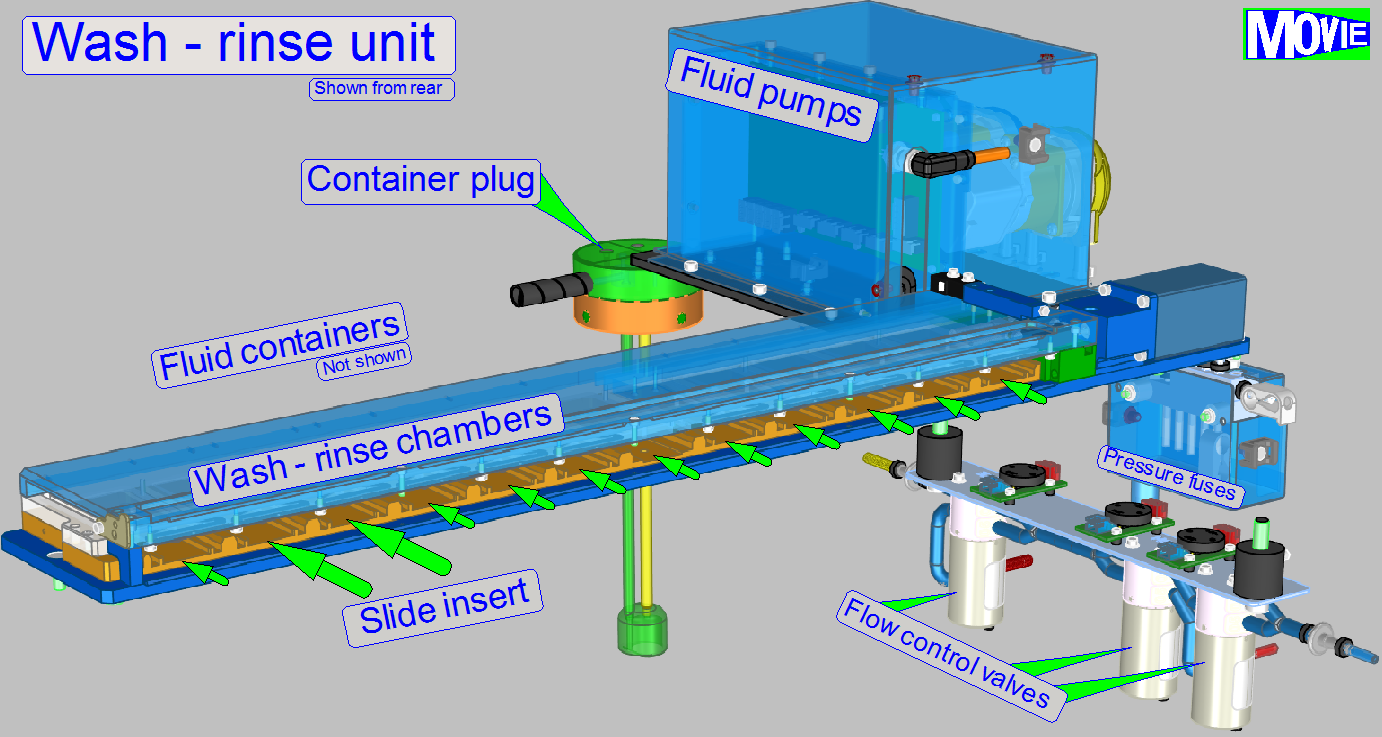

Wash and rinse unit; iSaCS

For

technicians and partly for sales managers

The

following chapter handles principles, tasks and components of the fluid control

during the washing and rinsing procedure of the 3DHISTECH iSaCS.

The

following chapter handles principles, tasks and components of the fluid control

during the washing and rinsing procedure of the 3DHISTECH iSaCS.

If the sample received the staining fluid during the

staining procedure, the incubation will be done in the chamber of its origin

place.

If the incubation time of the stain is over, the

specimen is moved to a free wash and rinse chamber.

Contents

Tasks

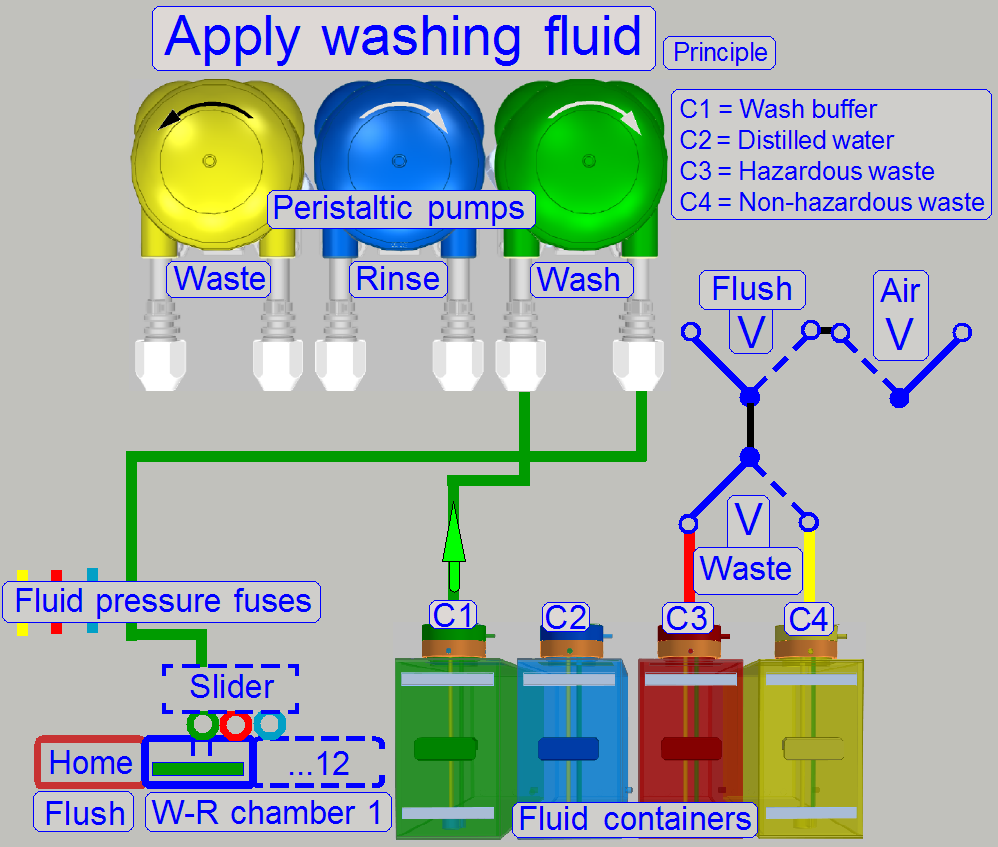

After finishing the incubation of staining, the

staining reagent has to be removed from the sample to stop the staining

process.

This task is done with the wash and rinse unit.

Before the wash - rinse procedure starts, the slide

with specimen is moved by the transporter from its origin place into a free

WR-chamber.

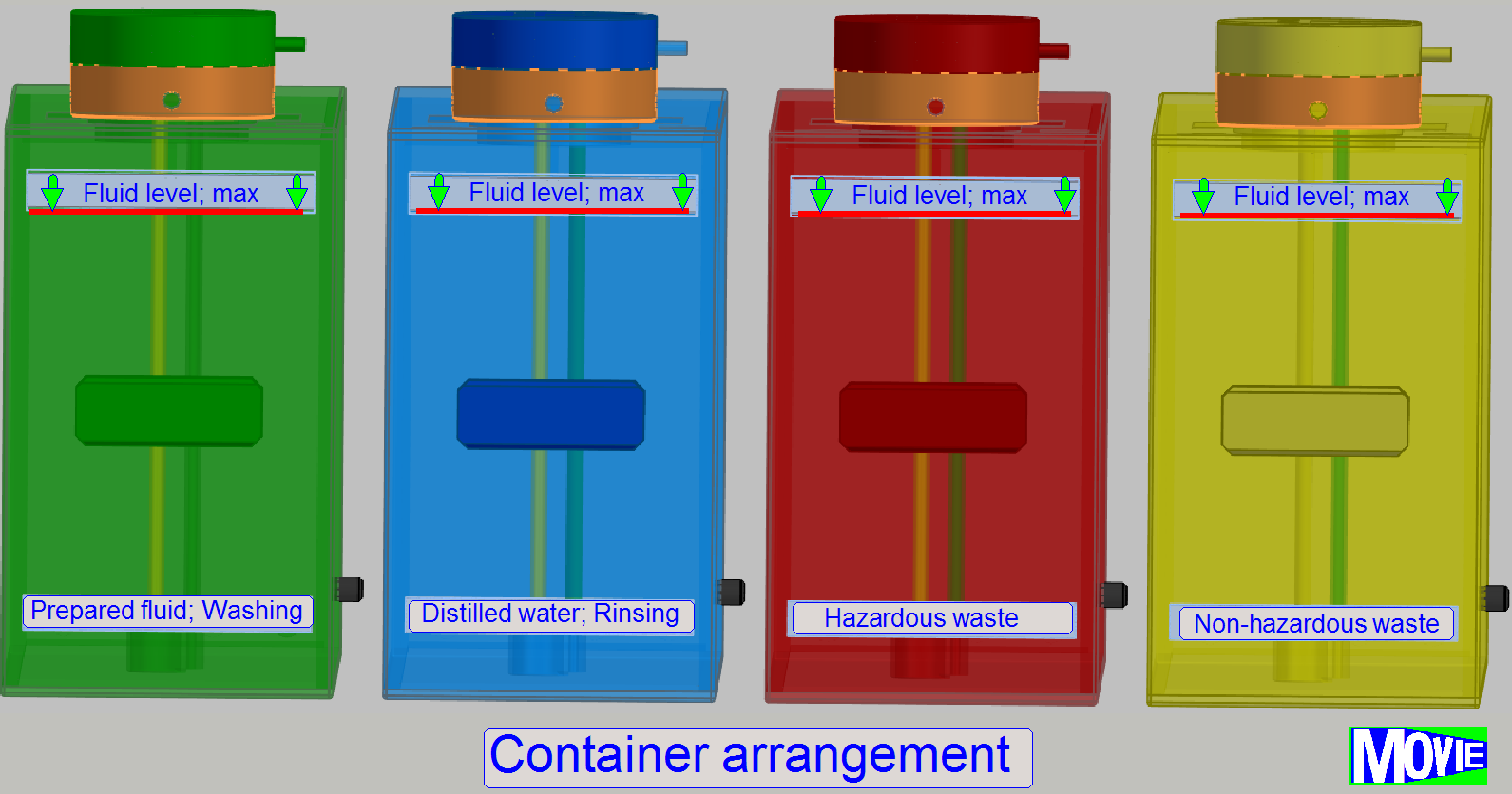

The washing fluid is based on distilled water and

contains chemicals to fix the properties of the stain.

When the washing procedure is finished, the waste

washing fluid is moved into a "waste” container (C3 or C4).

The rinsing of the tissue is done with distilled water

(C2); the waste fluid is moved into the appropriate "waste" container

(C3 or C4).

Thereafter, the slide is moved from the “Wash-Rinse”

chamber, to the “Air wiper” bay.

Finally, the fluid, remained on the specimen (slide

surface) will be blown off the sample surface by the “Air wiper”; so, the

sample surface will be dry. The slide is moved to its original place and waits

there for cover slipping or the staining procedure can be repeated with another

stain.

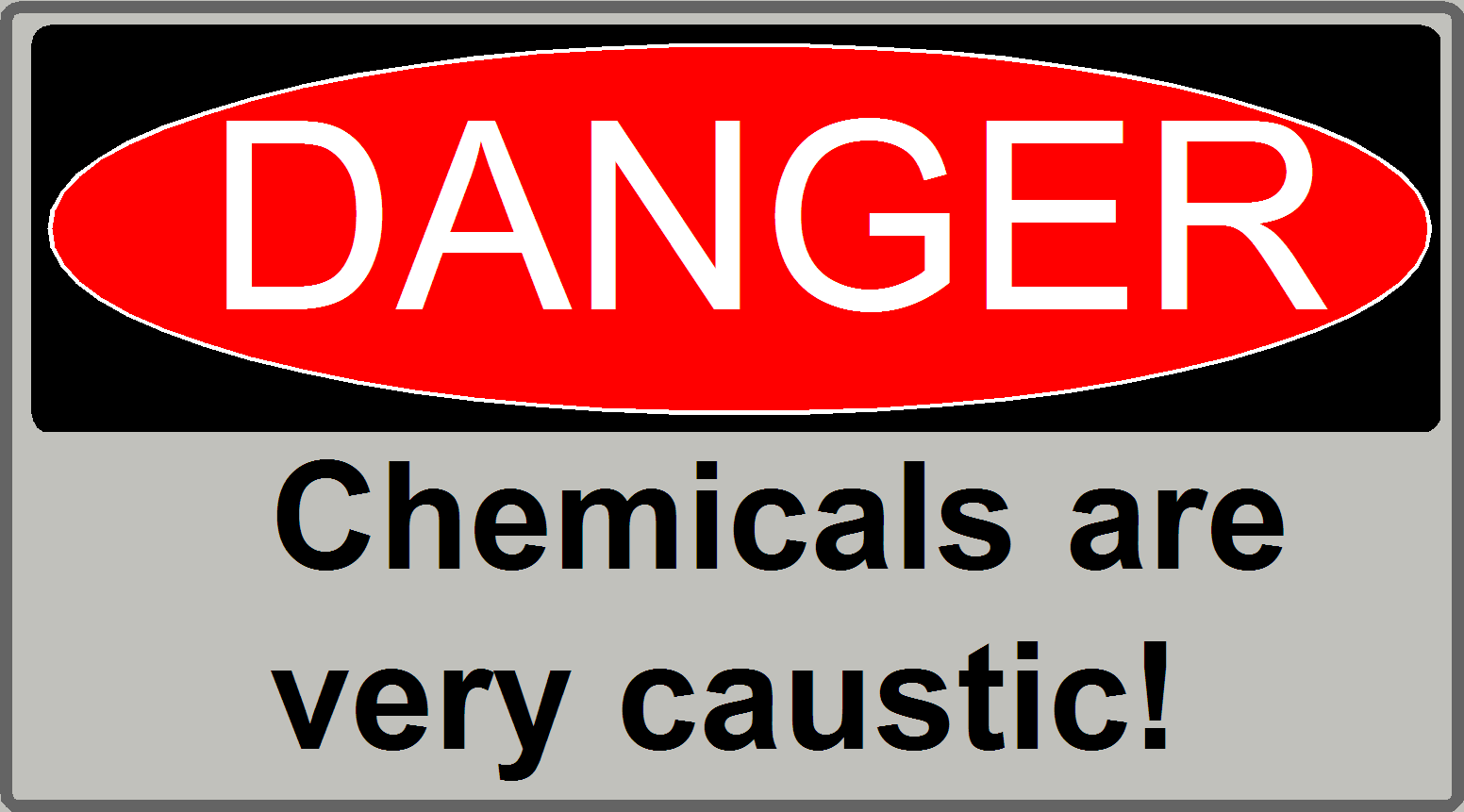

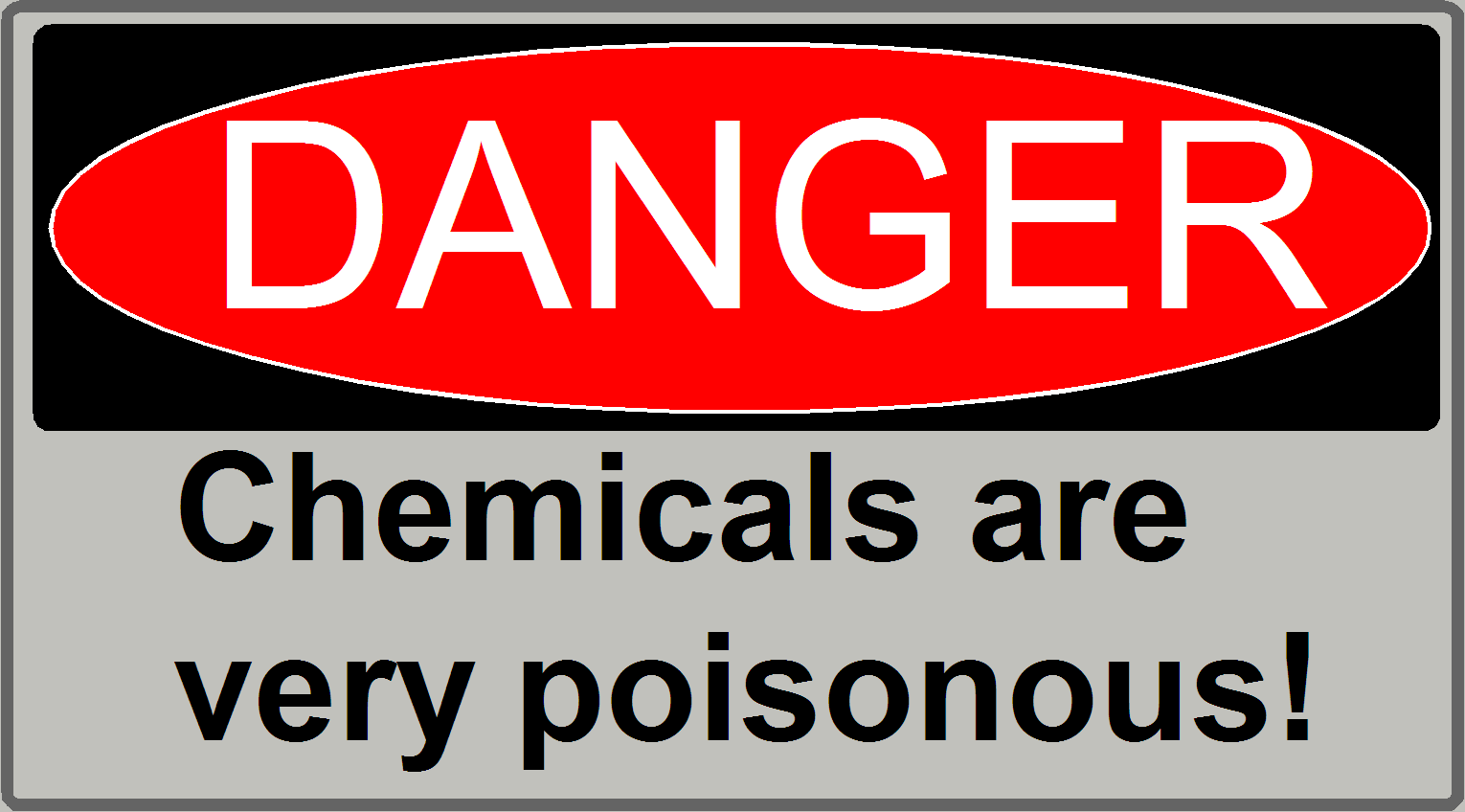

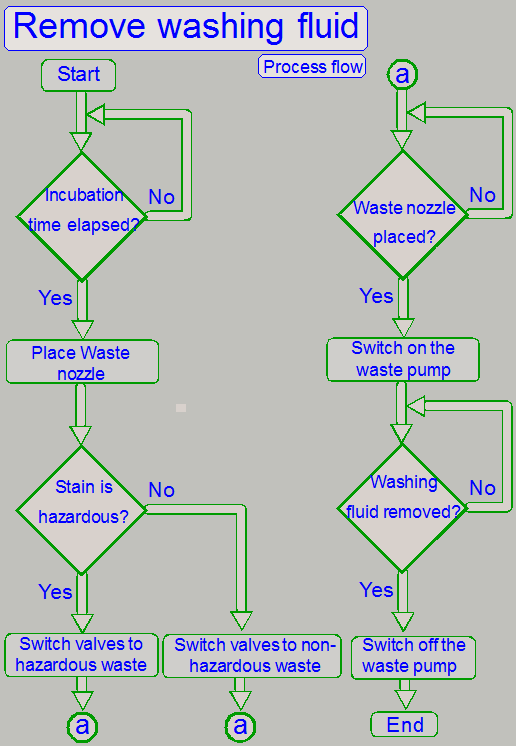

Hazardous and non-hazardous waste

In all cases, the selected fluid path depends on the

stain, used during the staining procedure.

If the stain to be removed is poisonous and / or

caustic, the waste washing and also the rinsing fluid is always collected in

the "Hazardous waste" container.

If the stain to be removed is nonpoisonous and no

caustic, the waste washing and rinsing fluid is always collected in the

"Non-hazardous waste" container.

Washing as well as rinsing fluid itself is not

declared as caustic or poisonous,

therefore these fluids are always collected in the "Non-hazardous

waste" container (during software start).

There are some situations, where the kind of fluid can

not be decided e.g. in the overflow system. In such cases, the fluid has to be

disposed always as "Hazardous waste".

Wash

buffer

The wash buffer is based on distilled water and contains

salts and additional chemicals.

The wash buffer is based on distilled water and contains

salts and additional chemicals.

The used chemicals are mainly independent of the stain

type.

- Differences will be equalized by the incubation time of the washing

fluid.

For

TBS pH 7.4 dilution required ingredients

Tris base 120.825g

NaCl 75g

HCLcc ~38.75 ml

Distilled

water: add to the shown ingredients

distilled water until the capacity of 1000ml is reached.

o A 5l

wash buffer needs of course 5x quantities.

Information about main components and recipes of

washing fluids can be found in …………...

- Washing fluid

itself is declared as non-hazardous!

Distilled

rinsing water

The rinsing water is distilled water. Fill single

distilled water into the container.

· 40ml Tween-20 detergent

fluid is required for 1000ml of rinsing water.

- Rinsing fluid

itself is declared as non-hazardous!

Non-hazardous

waste

The fluid, removed as a result of the washing or

rinsing procedure after a non-hazardous reagent (stain) was used is stored

here.

- The container

content may be discharged as domestic waste water.

Hazardous

waste

The fluid, removed as a result of the washing or

rinsing procedure after a hazardous reagent (stain) was used is stored here.

- Hazardous waste has to be disposed into appropriate collecting

containers.

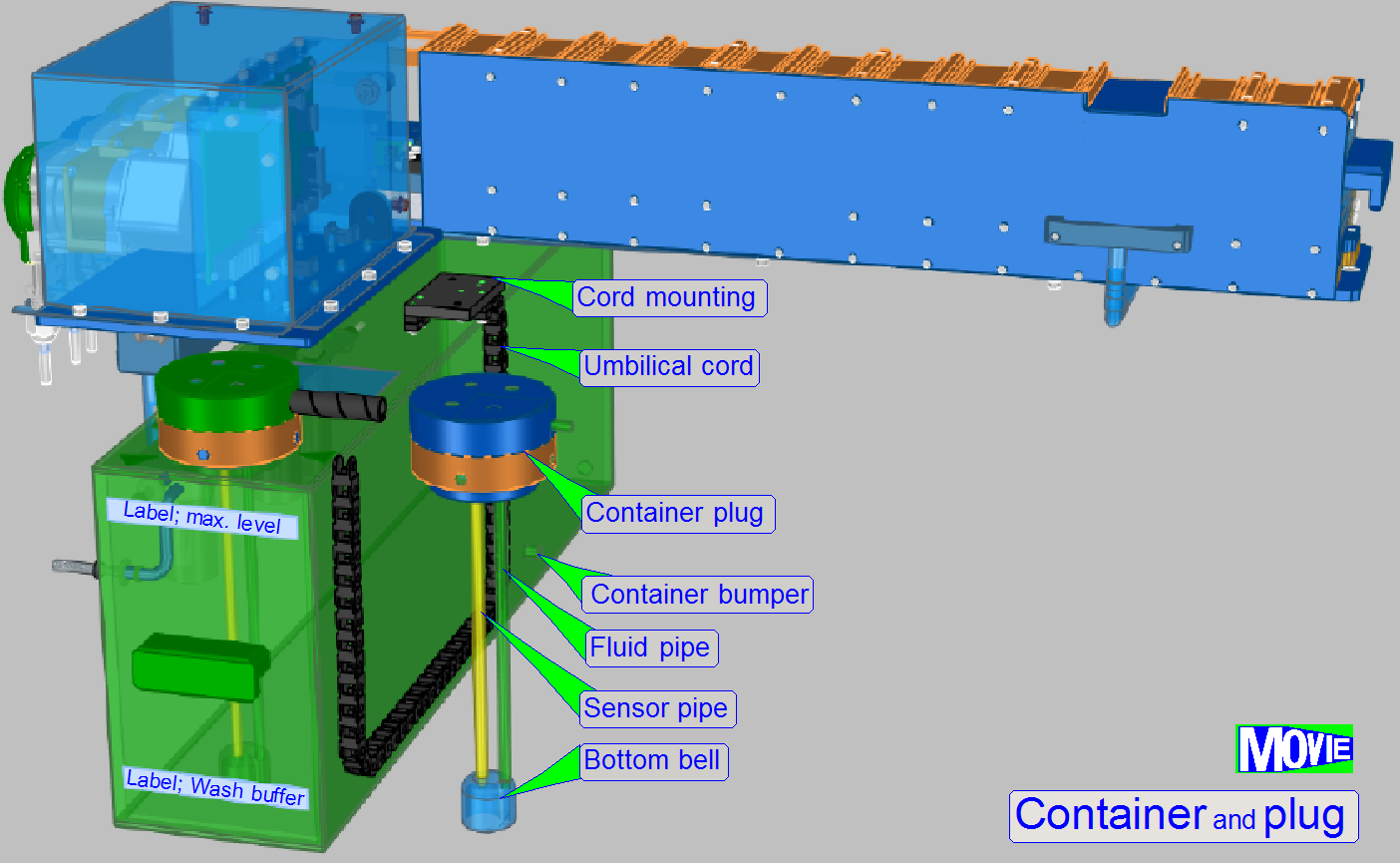

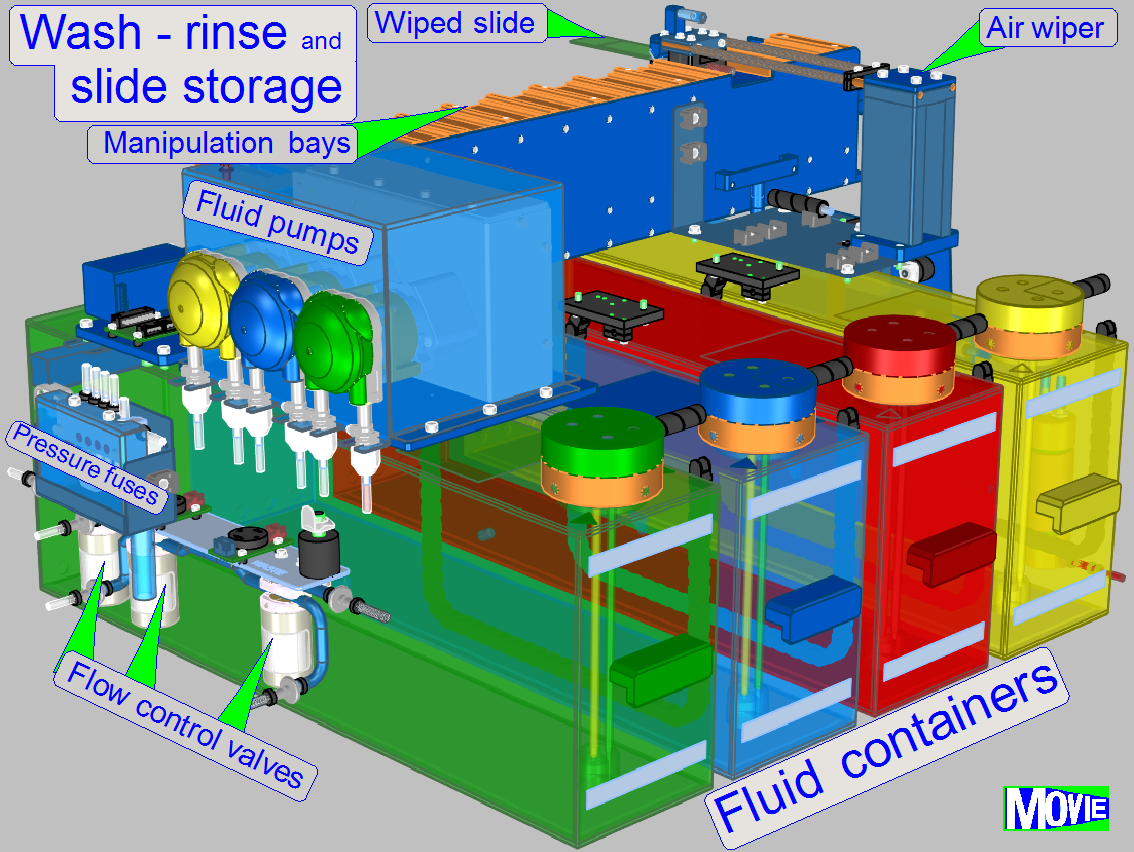

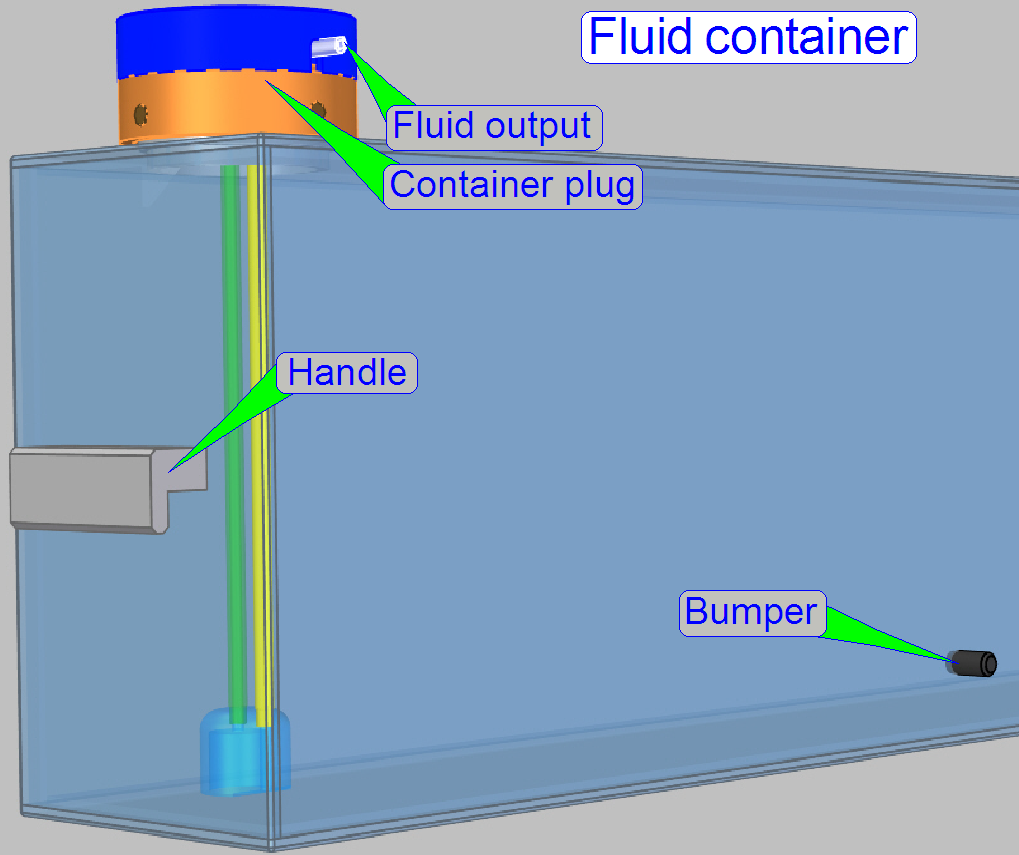

The

containers are arranged in the iSaCS as shown.

The

containers are arranged in the iSaCS as shown.

· The

sequential arrangement of the containers and so the fluid is important.

· Each

container may contain 5l of the appropriate fluid; filled until the lower edge

of the “Fluid max. label”.

·

Fill the container (

·

A minimum of 300ml fluid content in the

container is required; the system can not use fluid below this level for

washing or rinsing procedures

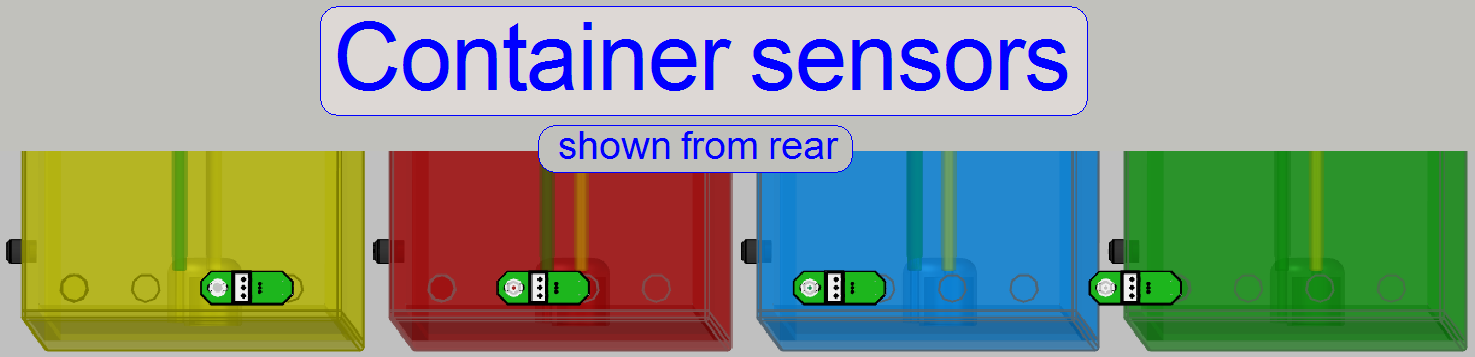

· The

states Container “empty”, “full” and “fluid present” are detected by a pressure

sensor in the plug.

· The

position of the containers is recognized by Hall sensors on the rear.

· The

user fills the containers for the wash and rinse process manually with the

appropriate fluid.

· The

content of the waste containers is disposed manually to appropriate collecting

containers.

· Each

container has its own plug to move the fluid out of the container (

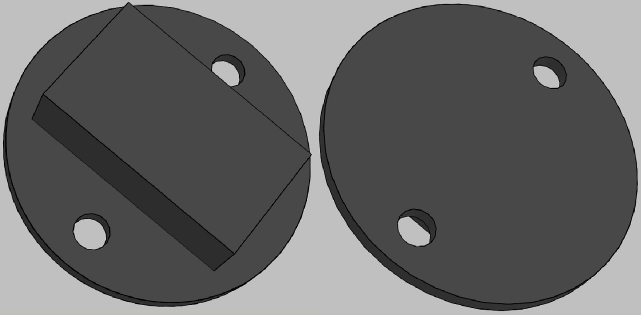

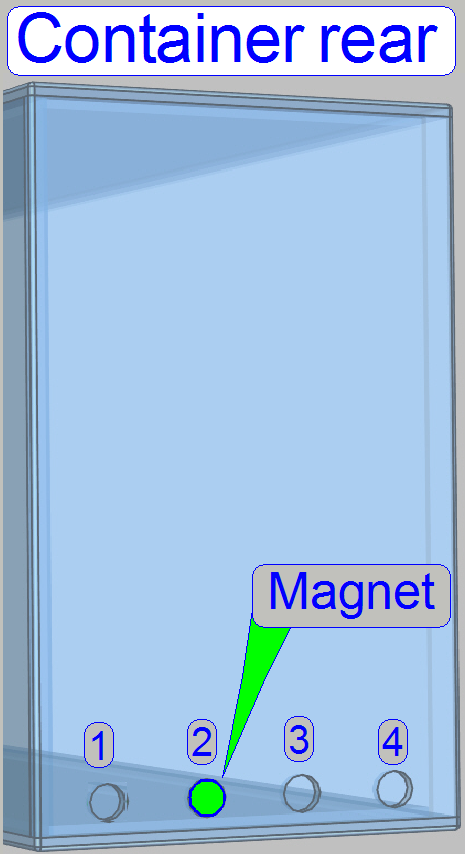

On the rear of the container, positions to hold a permanent

magnet are defined. By implementing (bonding) the permanent magnet at the

specified position, the container content (kind of fluid) and its position in

the arrangement is defined.

On the rear of the container, positions to hold a permanent

magnet are defined. By implementing (bonding) the permanent magnet at the

specified position, the container content (kind of fluid) and its position in

the arrangement is defined.

· This

way, each container has always the same position and an interchange of the

fluids is avoided!

Important

If the container was filled by mistake with incorrect

fluid, please clean and rinse the container and its plug with distilled water;

especially the container for the Rinse process!

By using sensors behind the containers, the position

and the fluid kind of the container are defined.

· If the

Hall sensor does not recognize a container, the container is missed (the

container position is empty) the container is not fully pushed to the rear (the

acting position of the sensor is not reached) or the container is in a wrong

place.

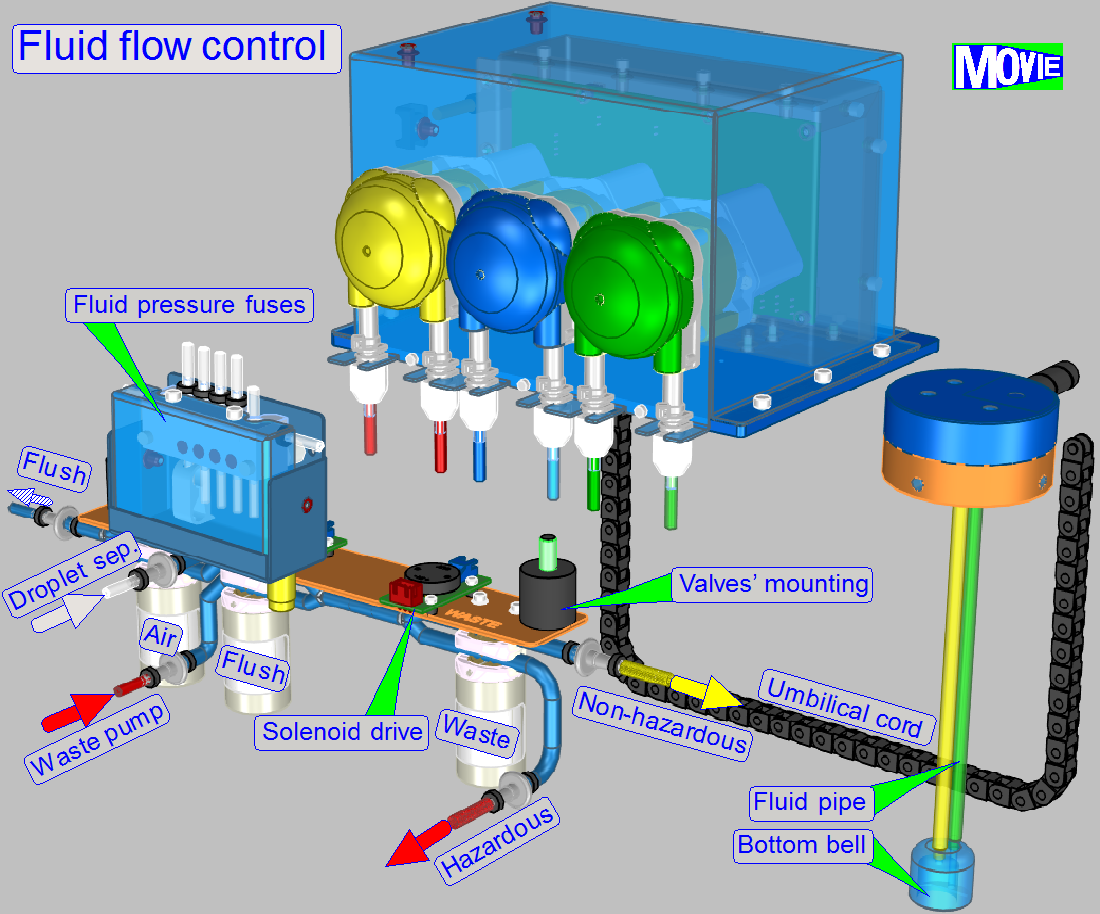

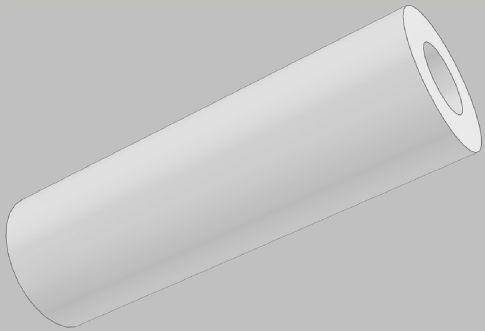

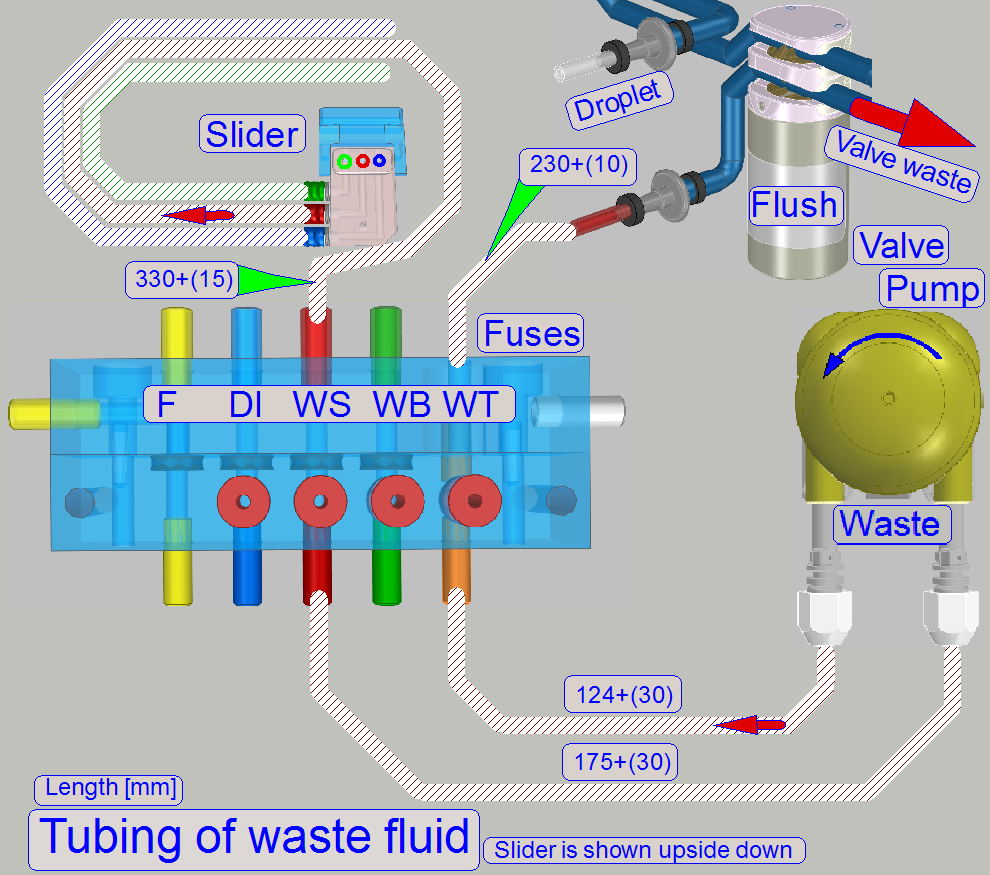

The

so called “umbilical cord” contains the flexible fluid pipe and the wires for

the pressure sensor. Both are covered by an energy chain.

Cord mounting

Fixes the fluid pipe, the sensor wires and is used as

mounting for the energy chain.

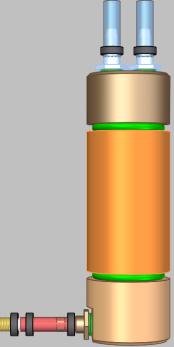

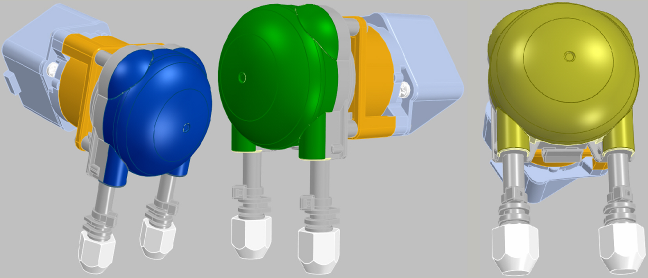

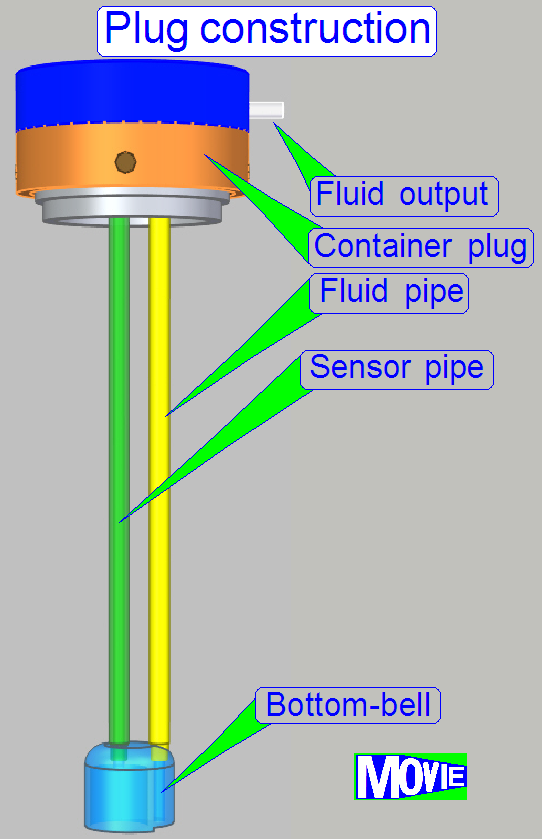

Container plug

The container plug contains the pressure sensor and

realizes the fluid flow from the container to the destination or waste fluid

into the container.

See also: “Container plug”

The

container plug and its construction allow the flow of the fluid out of the

container (washing and rinsing) or used fluid can be moved into the waste

container.

The

container plug and its construction allow the flow of the fluid out of the

container (washing and rinsing) or used fluid can be moved into the waste

container.

A pressure controlled sensor detects the states

“container empty”, “container full” and “fluid in the container”.

· Depending

on the fluid level in the container, the air in the sensor pipe will be

compressed or decompressed and so, the required fluid level states can be recognized.

By calibrating the pressure sensor, other container

fluid states like 1/4 full, 1/2 full and 3/4 full can be detected and

displayed.

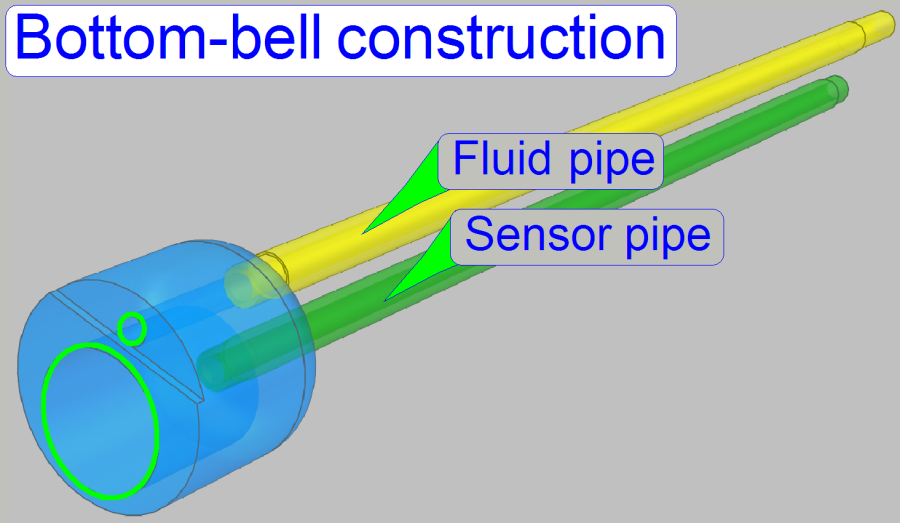

· If the

plug is inserted into the container vertically, the bottom-bell is filled with air

and so, the fluid will not stay in the sensor pipe. This way, the accuracy of

the sensor’s state is increased.

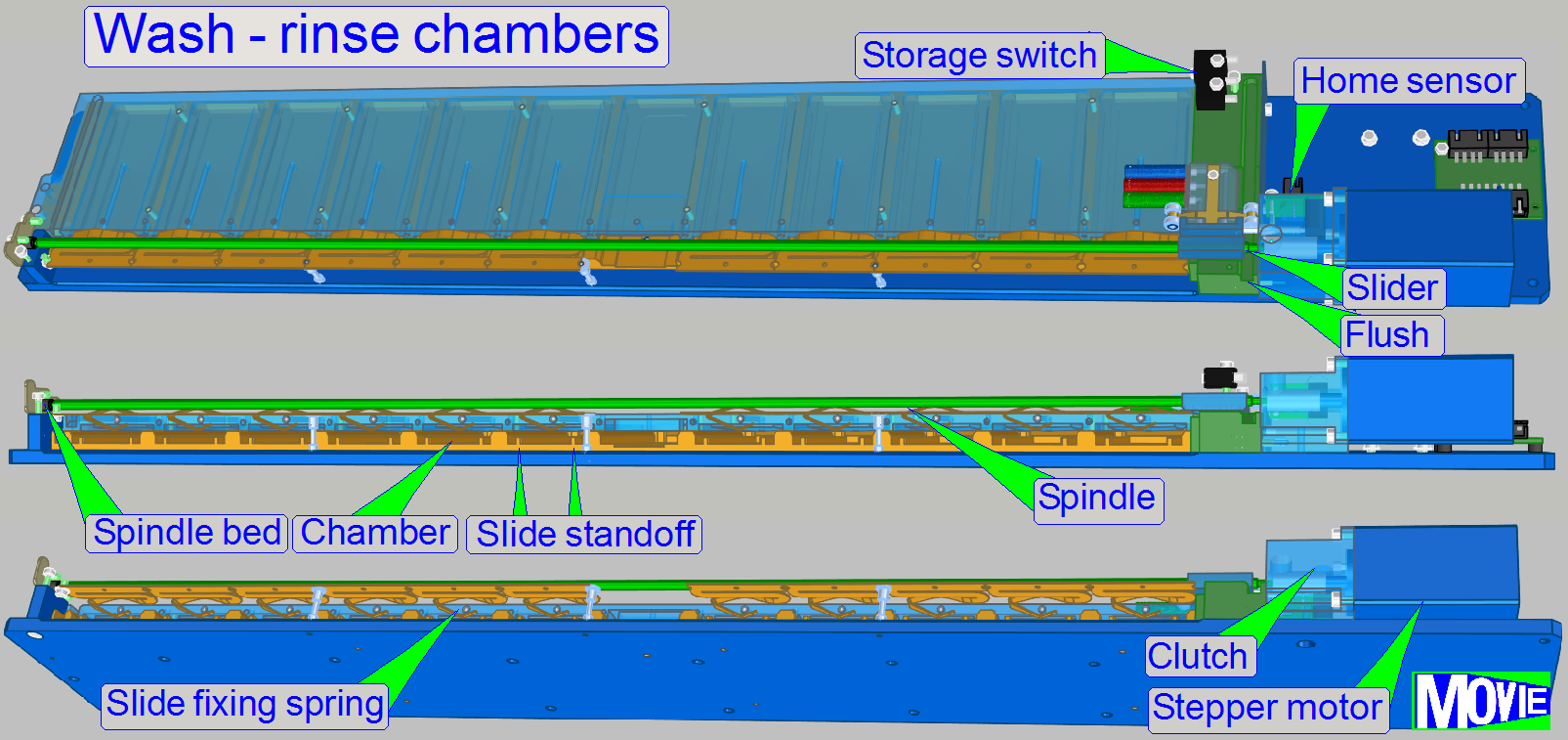

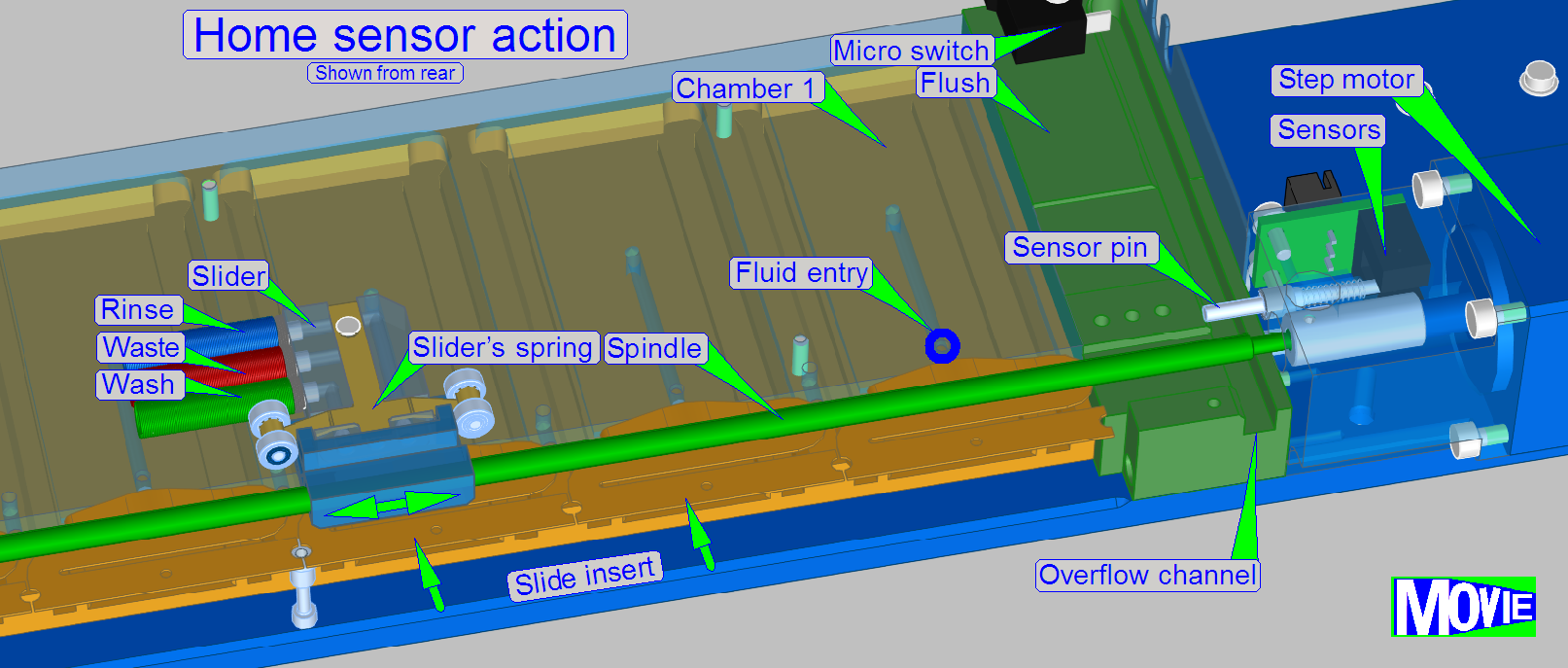

The spindle has 4 threads, so a very high precision of

longitudinal movement can be reached.

This precision is required to positioning the

appropriate nozzle to the fluid entry of the wash – rinse chamber.

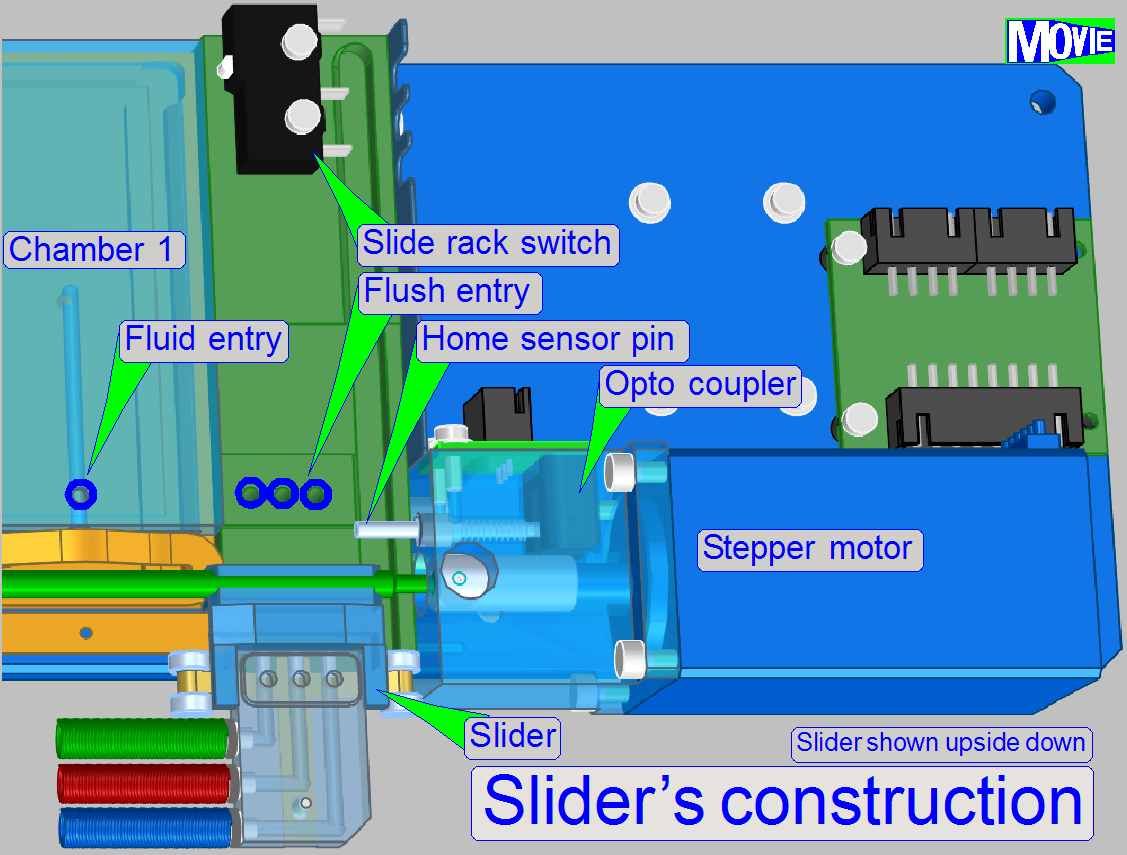

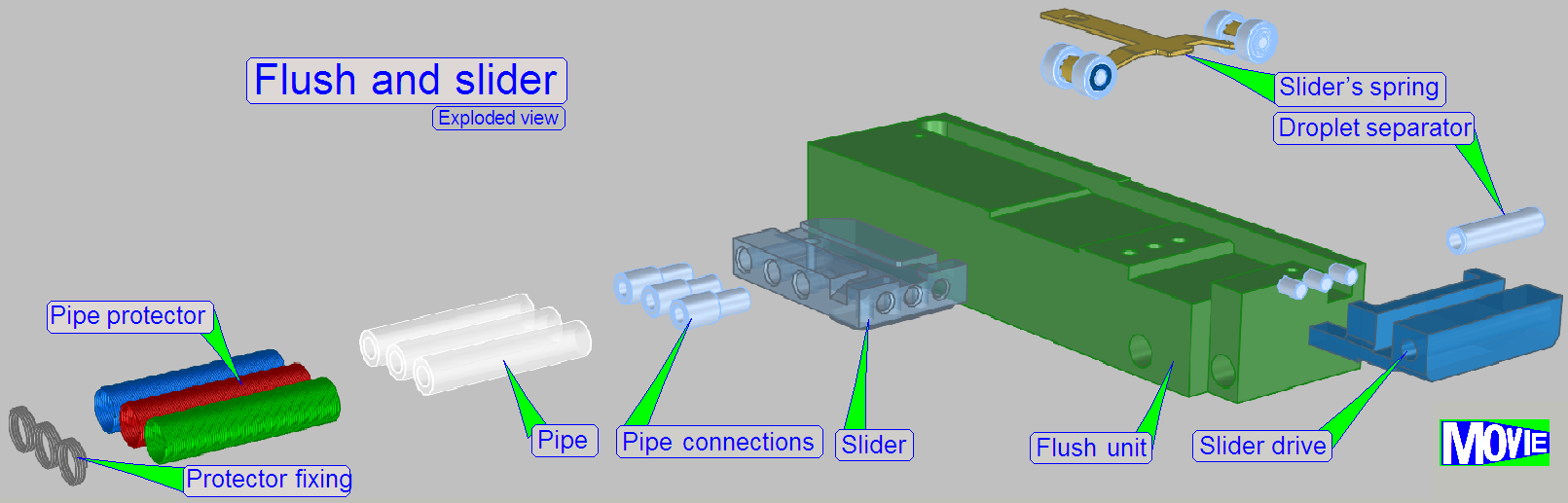

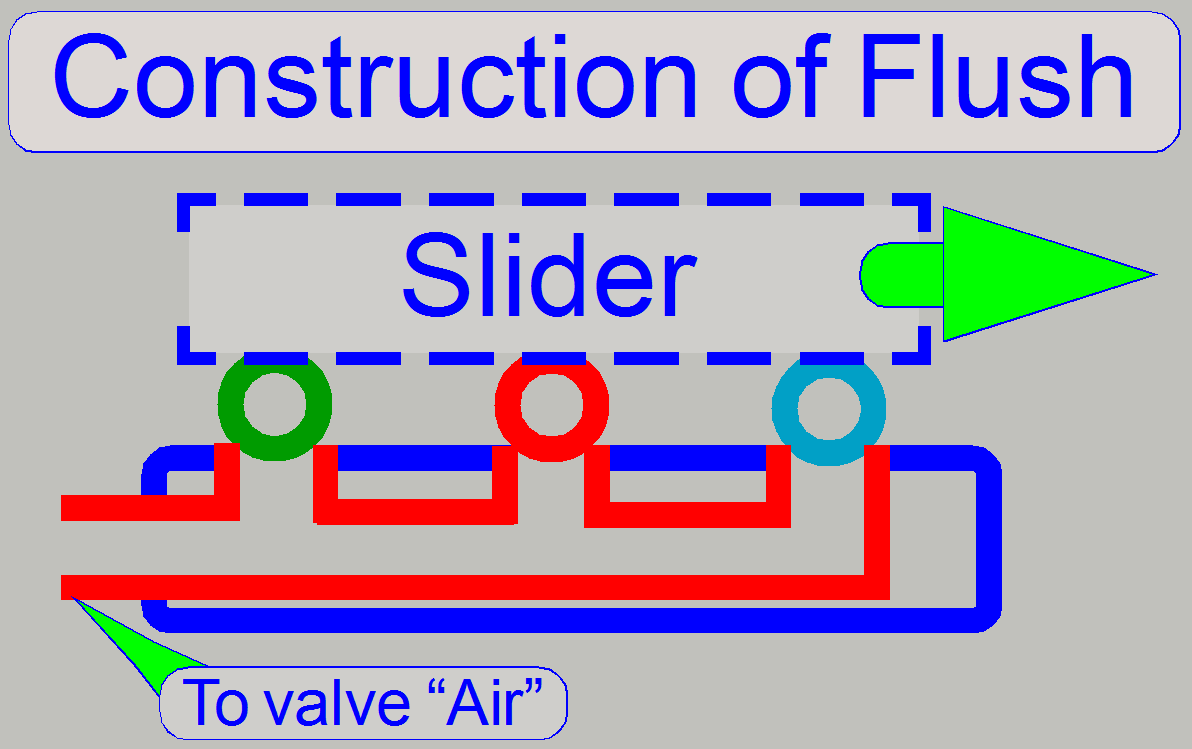

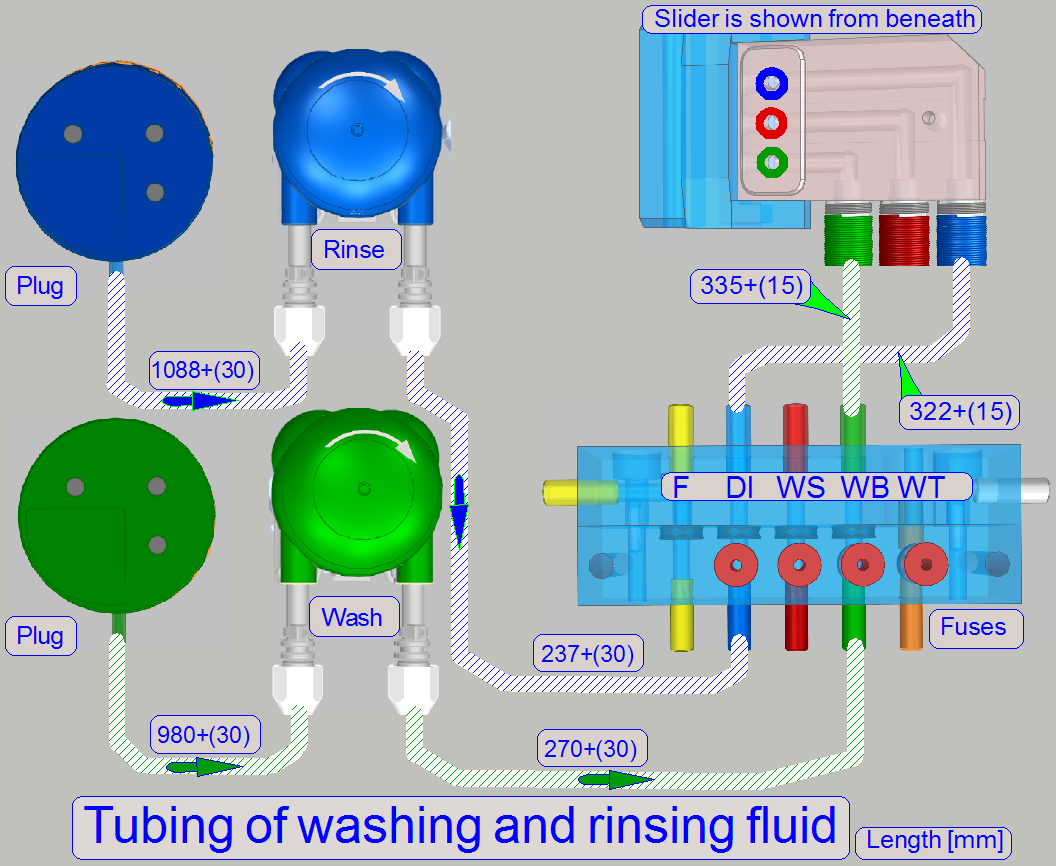

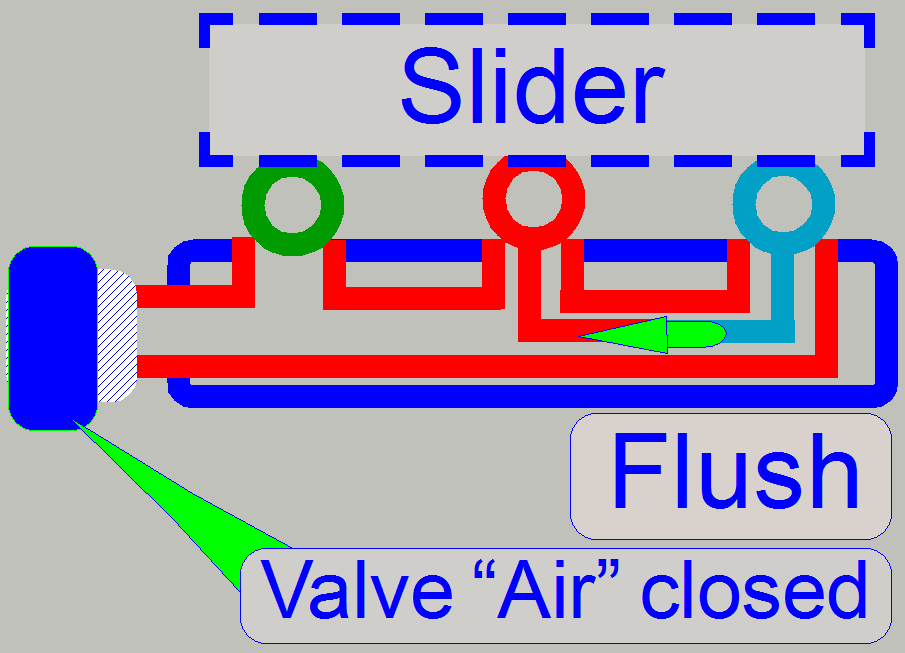

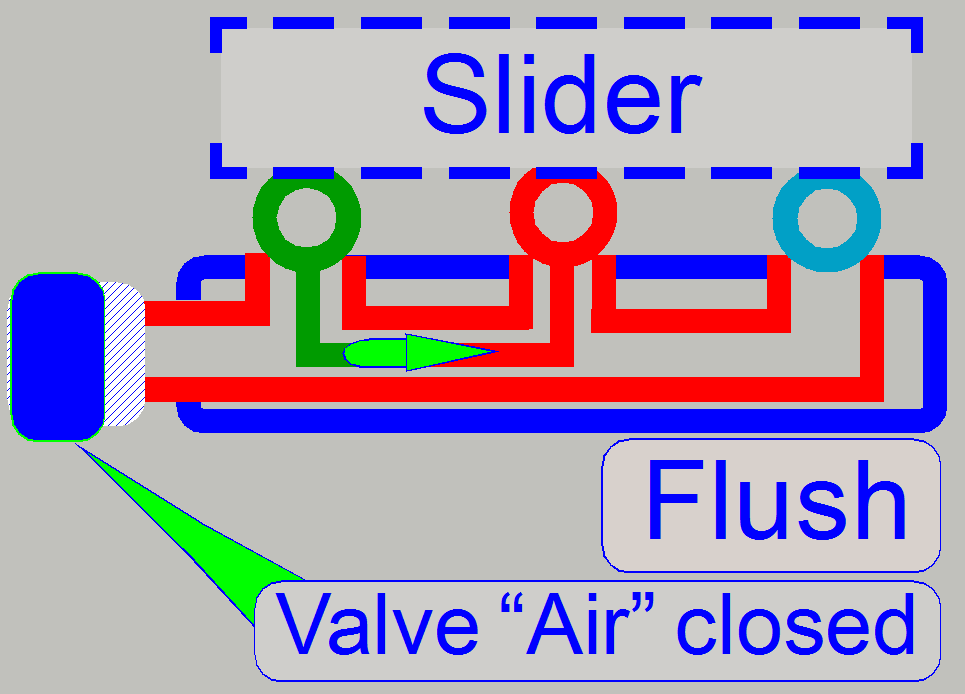

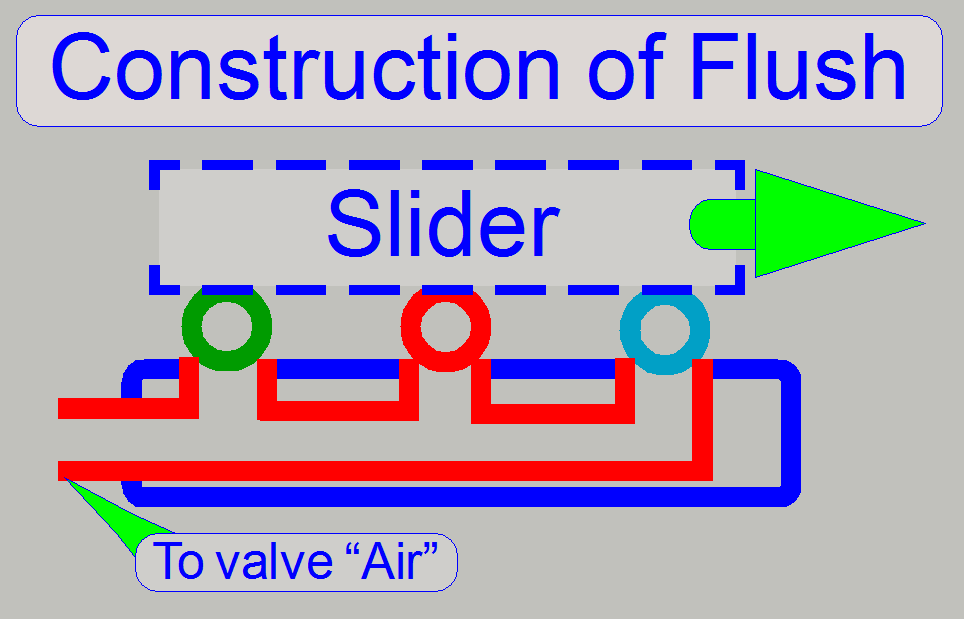

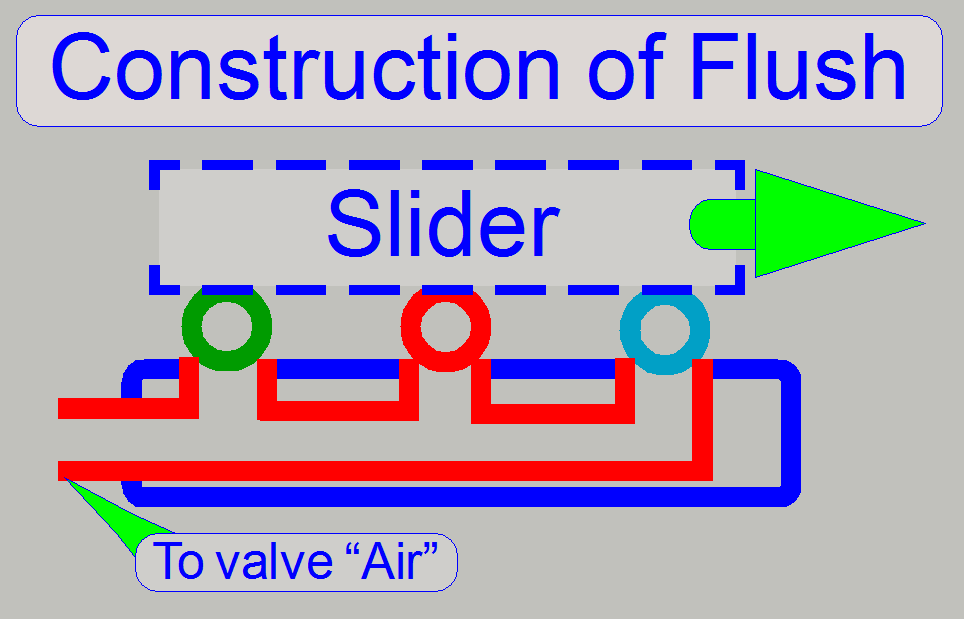

Slider

The slider is slippage free mounted to the spindle, so

a misalignment of the nozzles can not occur if the movement direction of the

slider is changed.

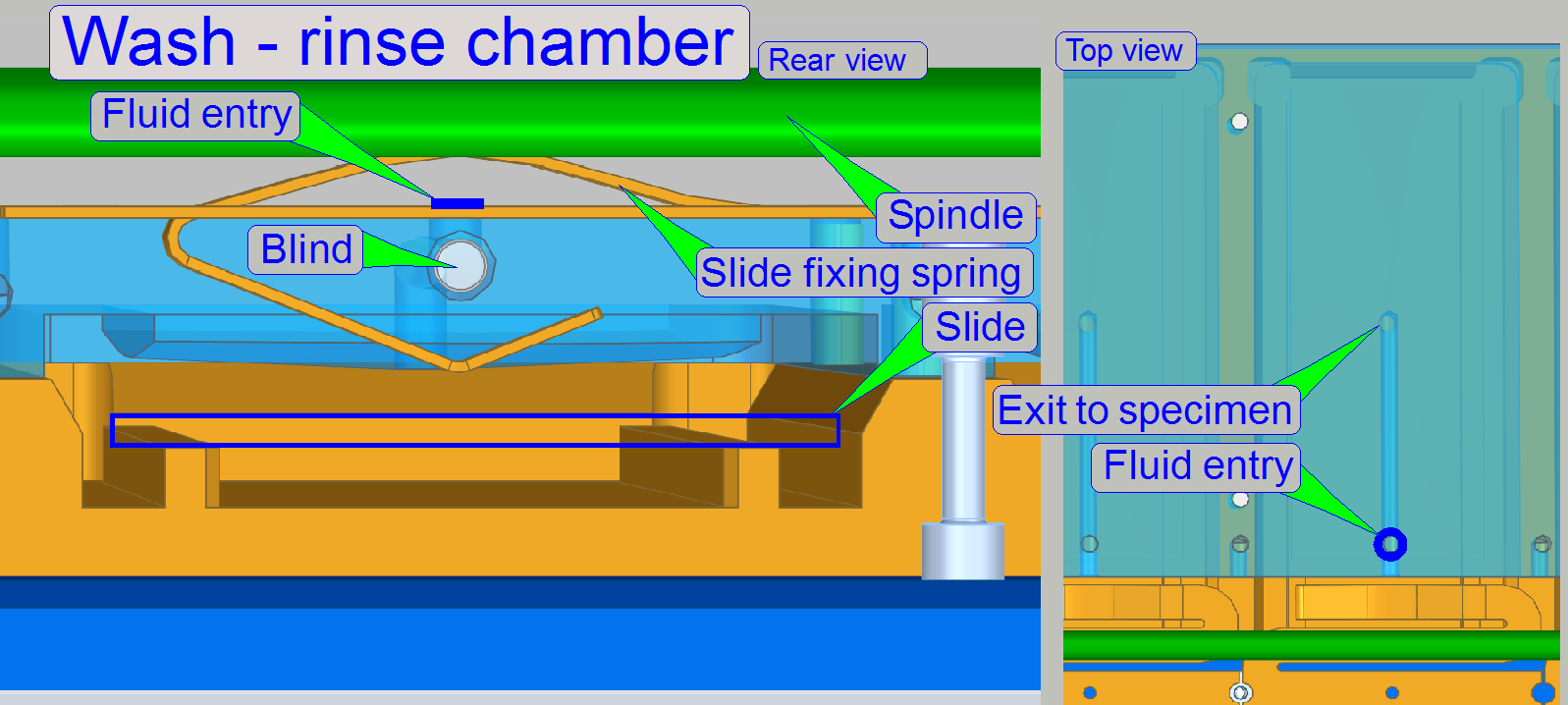

Chamber’s construction

Fluid

entry

On the top side of the chamber there is the Fluid

entry hole through which the fluid flows into the center of the slide’s

specimen area.

The “blind” is permanently fixed to the rear end of this fluid path in

order to block the way of the fluid to that direction.

Slide

holding spring

As the slider arriving to the chamber, the slide fixing spring is pushed

downward and fixes so the slide in its position for the appropriate procedure.

The spring will be released as the slider moves to the next chamber.

Slide rack switch

The

"Slide rack switch" (storage switch) is used to signal the presence

of the slide rack.

· If the

slide rack is present and inserted correctly, the switch is closed.

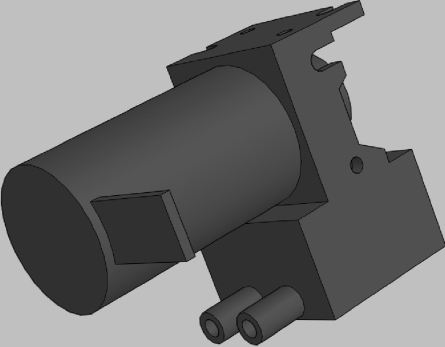

Stepper motor

The stepper motor rotates the spindle and moves so the slider over each

chamber or to the flush position.

The longitudinal movement resolution of the spindle

driven construction is 1μm so the nozzles can be moved accurately to the

fluid entry of the chamber.

· During

the processes “Apply fluid” and “Remove fluid” the nozzles are exactly placed

by software.

Home sensor

As the slider moves in direction to the spindle clutch

the slider arrives to the “Home sensor pin” and moves it in direction to the

opto-coupler. If the acting position of the opto-coupler is reached, the

optical path of the sensor is broken and the software will stop the slider’s

movement by switching off the stepper motor.

The fluid entry positions of the chambers are defined

in motor steps, counted from the home position.

The nozzle position of the slider is a number of motor

steps, relatively defined to the fluid

entry position of the chamber.

The slider contains the nozzles for the fluids; each fluid

type has its own nozzle.

The slider can be moved over each wash and rinse chamber.

The slider can be moved over each wash and rinse chamber.

If the slide arrived over the chamber, the slider

moves the wash nozzle over the fluid entry of the chamber and the washing fluid

will be placed onto the specimen area.

If the incubation time of the washing fluid is over,

the nozzle with the waste tube will be moved to the fluid entry of the chamber

and the washing fluid will be removed from the sample surface; the fluid is

stored in the appropriate container (C3 or C4).

Now, the nozzle with the distilled water tube will be

moved to the fluid entry of the chamber and the rinsing process starts.

The rinsing fluid will be removed from the slide

surface with the nozzle “waste” and the fluid is stored in the appropriate

container (C3 or C4).

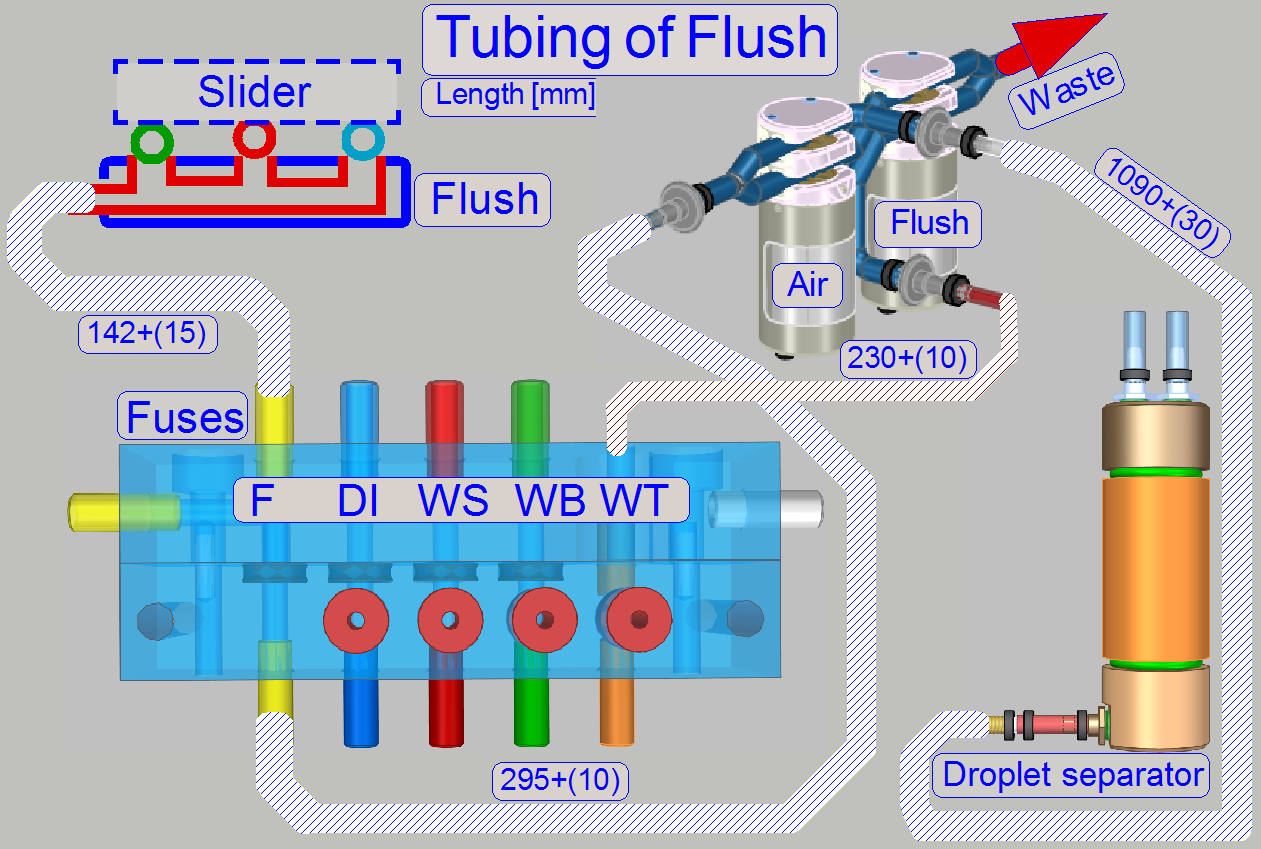

The flush unit is found at the home position of the

slider. It is used during software startup and software exit. The unit is

smaller than a slide chamber because only the nozzles are connected to each

other. In special conditions (software exit) the flush unit allows the removal

of the droplet separator’s fluid via the valve air.

See also “Start up software” and “Shut down software”.

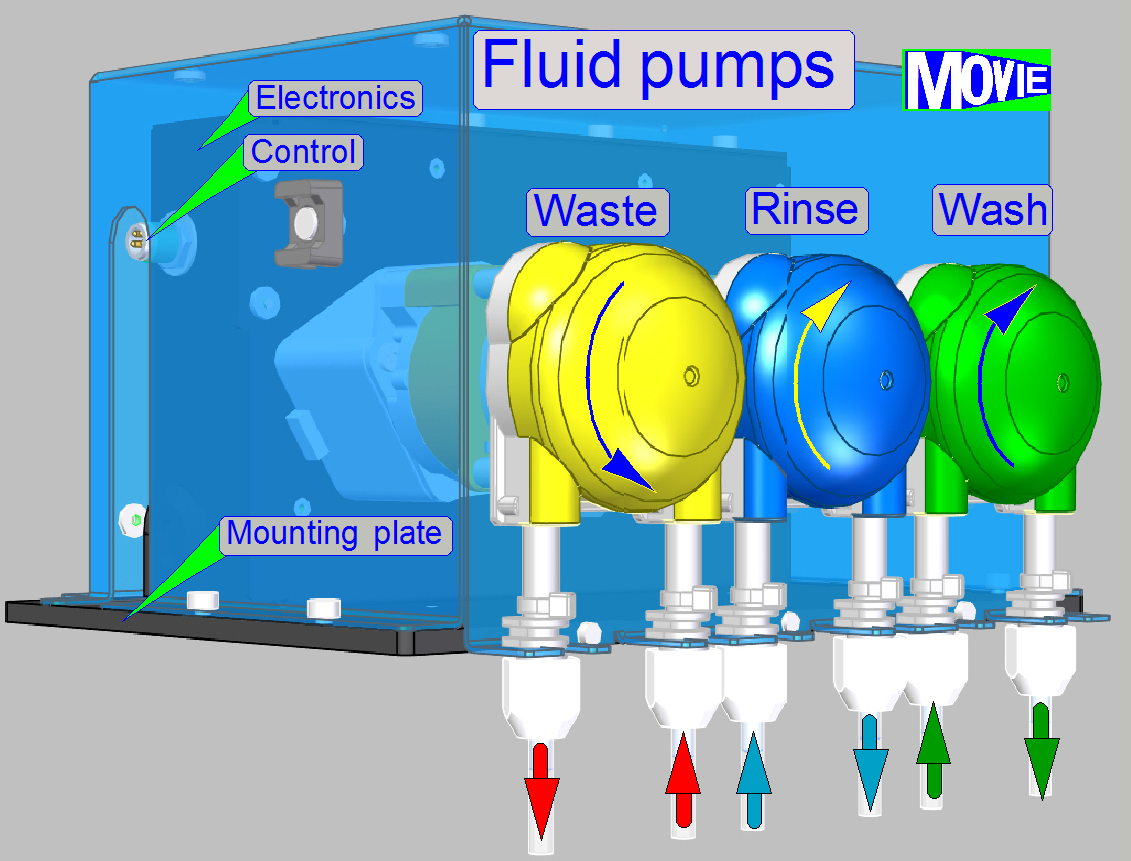

To avoid contaminating of the liquids washing, rinsing and waste,

the appropriate fluid is moved by a dedicated peristaltic pump.

The amount of

fluid to be carried is controlled by the pump. The pump is driven by a stepper

motor. The number of steps (the rotation angle of the pump's shaft) controls

the quantity of fluid and the time, elapsed between 2 step pulses is used to

control the speed of the carried fluid.

· If the

pump is switched off, the fluid path is broken; the pump’s behavior is like a

closed valve.

As the shaft rotates, the amount of the fluid is moved

from the tube input along the tube by the speed of the rotor until the fluid

amount arrives to the output.

See also “Materials”.

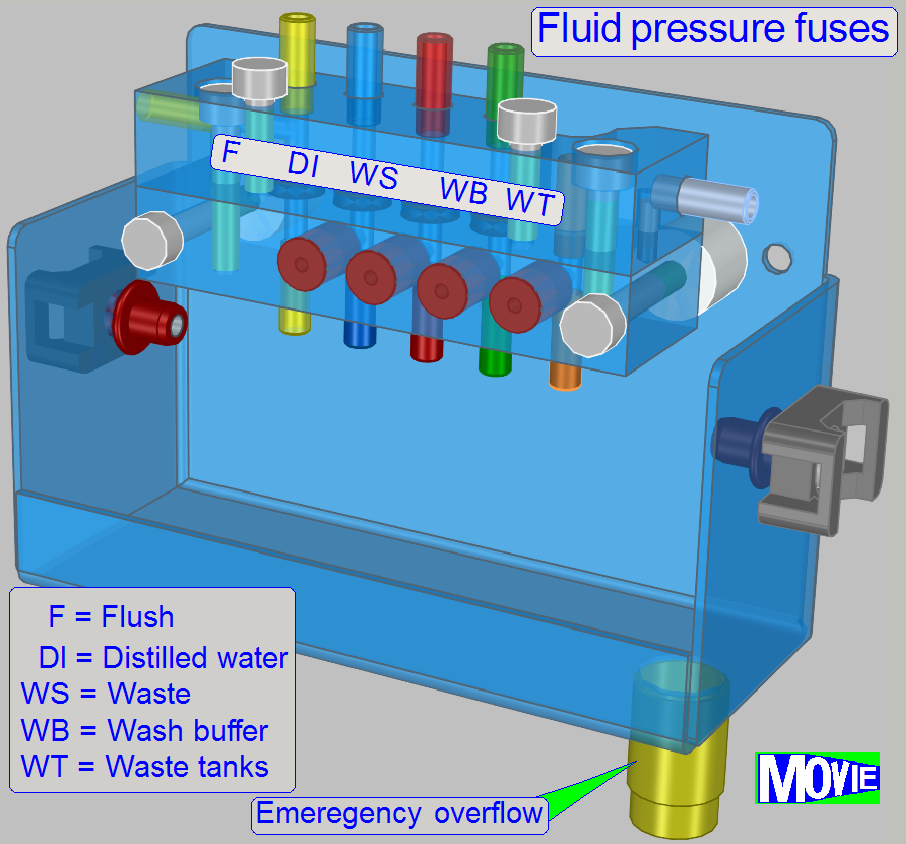

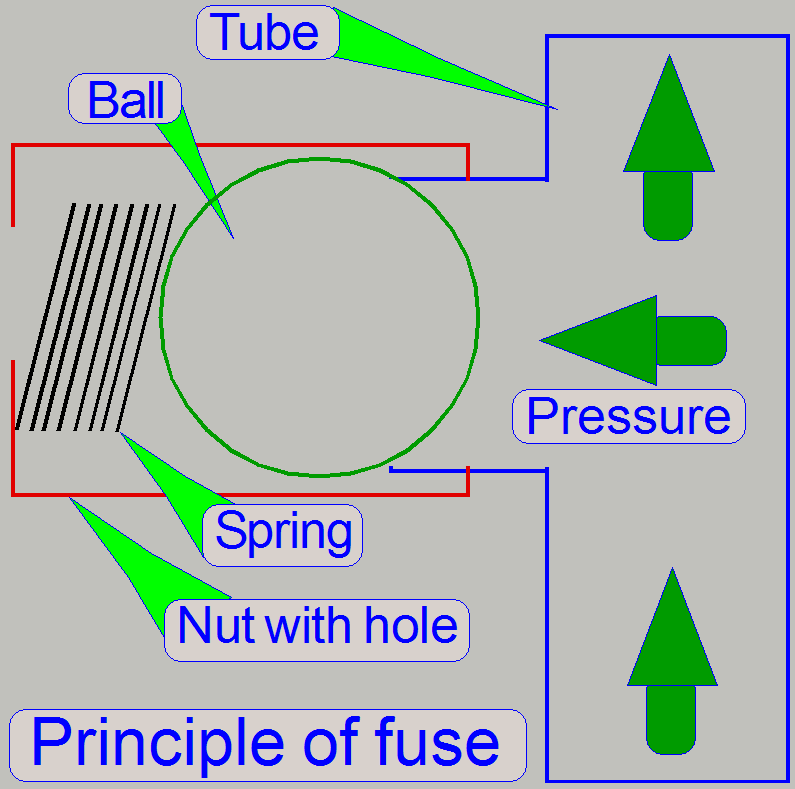

· Normally,

the fuses do not act, the fluid flows vertically thru the appropriate part of

the fuse unit.

Exception

· If the

fluid flow in the tube get obstruction for some reason (or the valves are wrongly

handled in the service program), the pressure in the tube system increases.

· To

avoid damaging of internal components and parts by aggressive fluids, the fuse

will act.

· Every

tube path has its own fuse.

See also "Emergency overflow system"

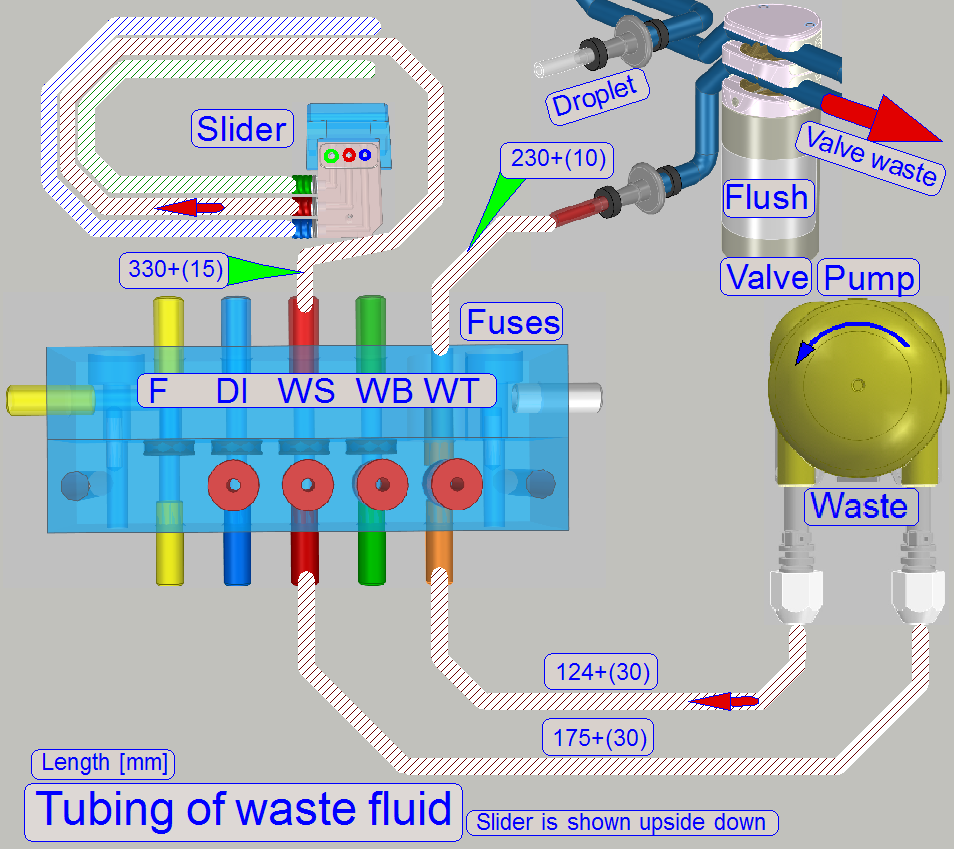

· Tubing

of fluid paths can be found in chapter “Fluid

paths”.

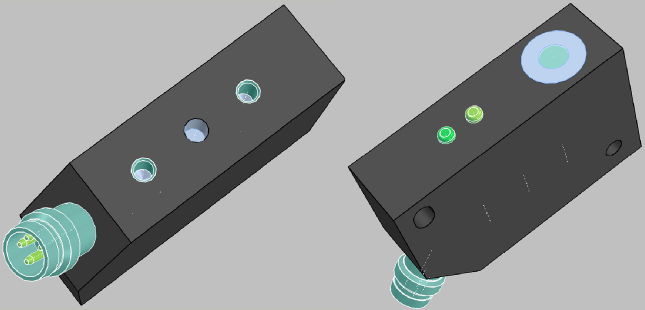

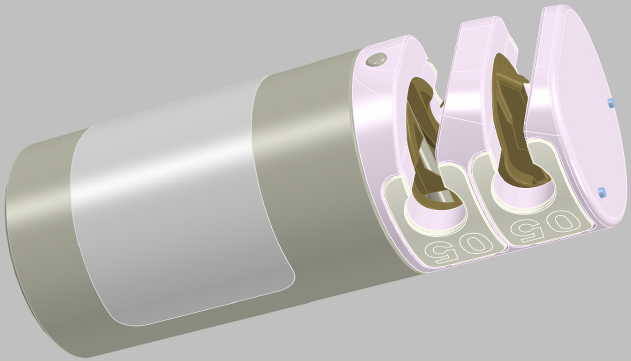

Principle of fuse

Principle of fuse

Normal

work

· Normally

the ball blocks the way in the direction to the nut's hole, and the fluid flows

vertically in the tube (as shown).

Exception

· As the

pressure in the tube increases and the force of the spring can not compensate

the pressure any more, the ball will not cover the tube stub and the fluid can

flow via the nut in the direction to its hole.

· After

this the fluid enters the fuse housing, gathers at the bottom of the housing

and flows out over the emergency overflow exit; see Fluid pressure fuses above.

See also "Emergency overflow system"

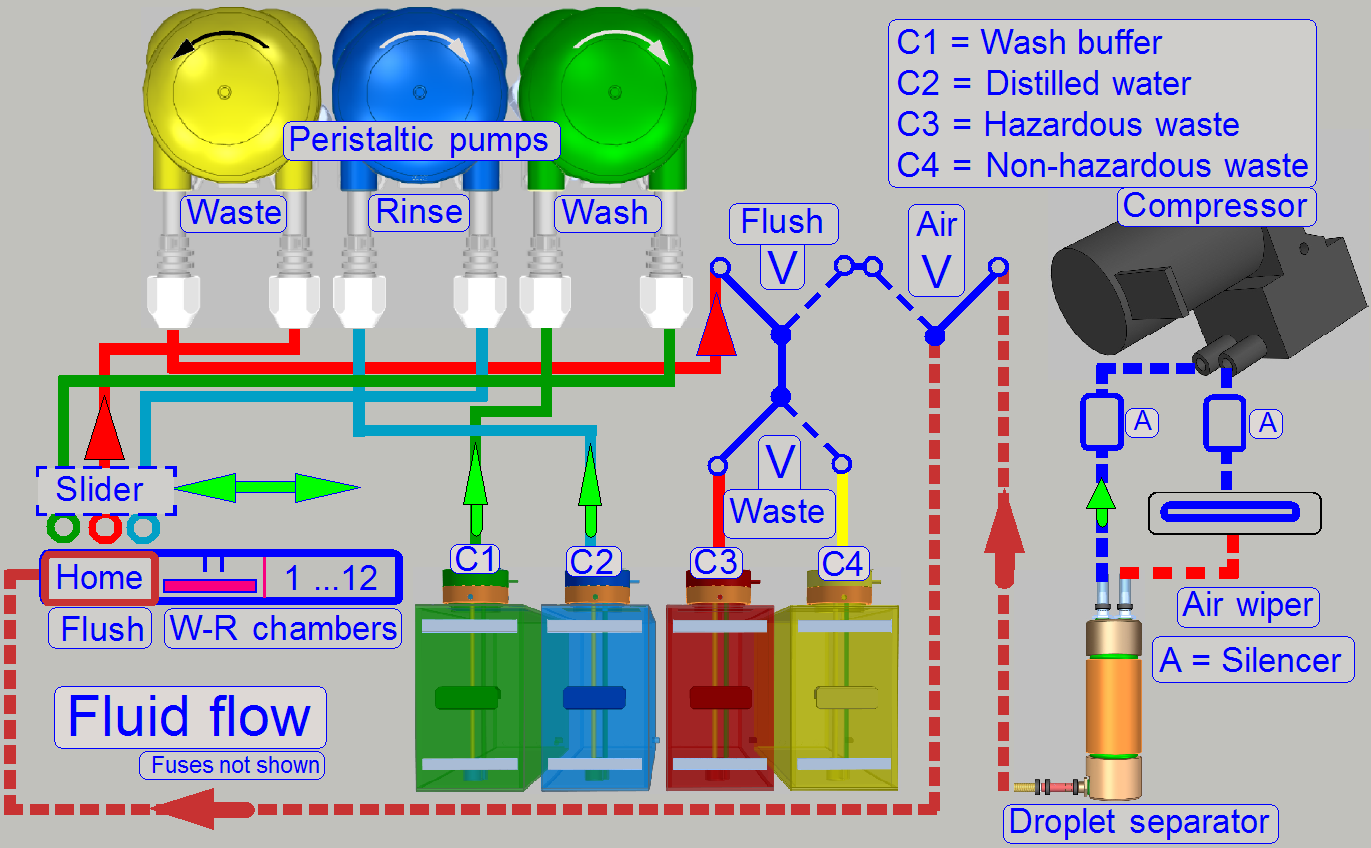

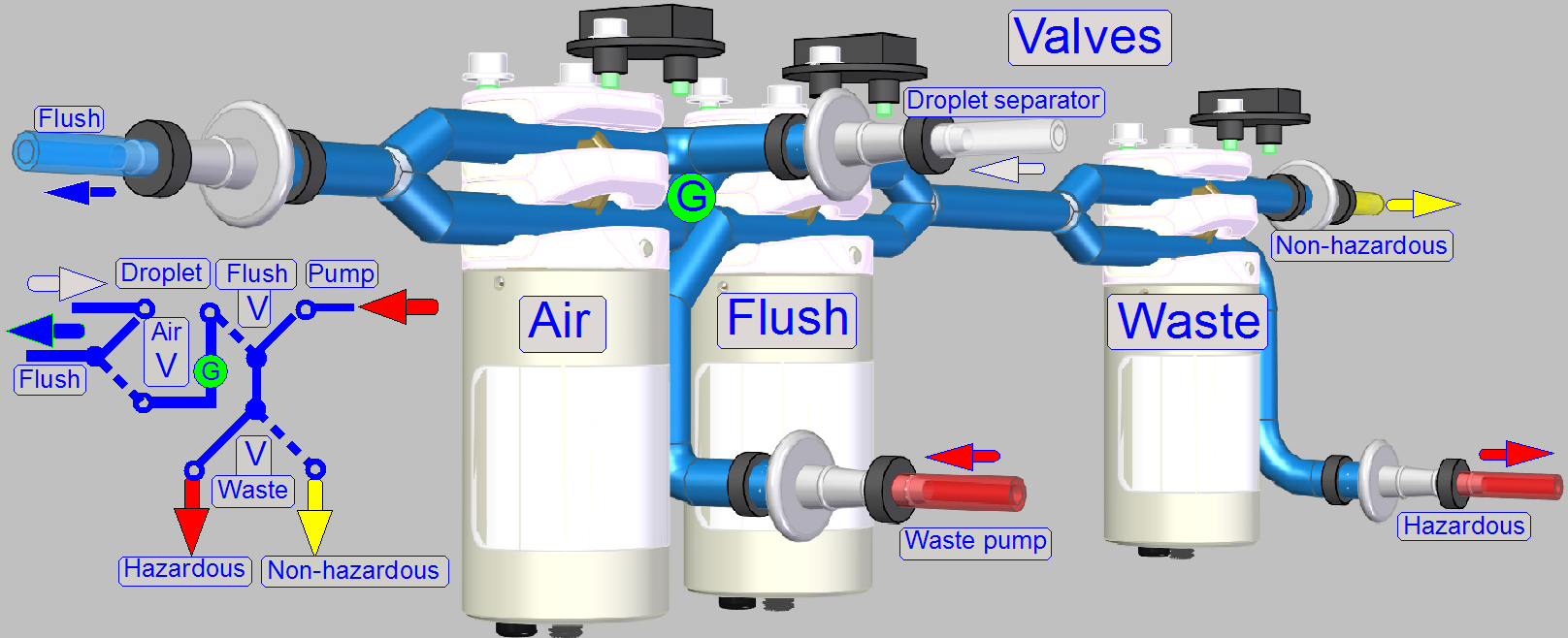

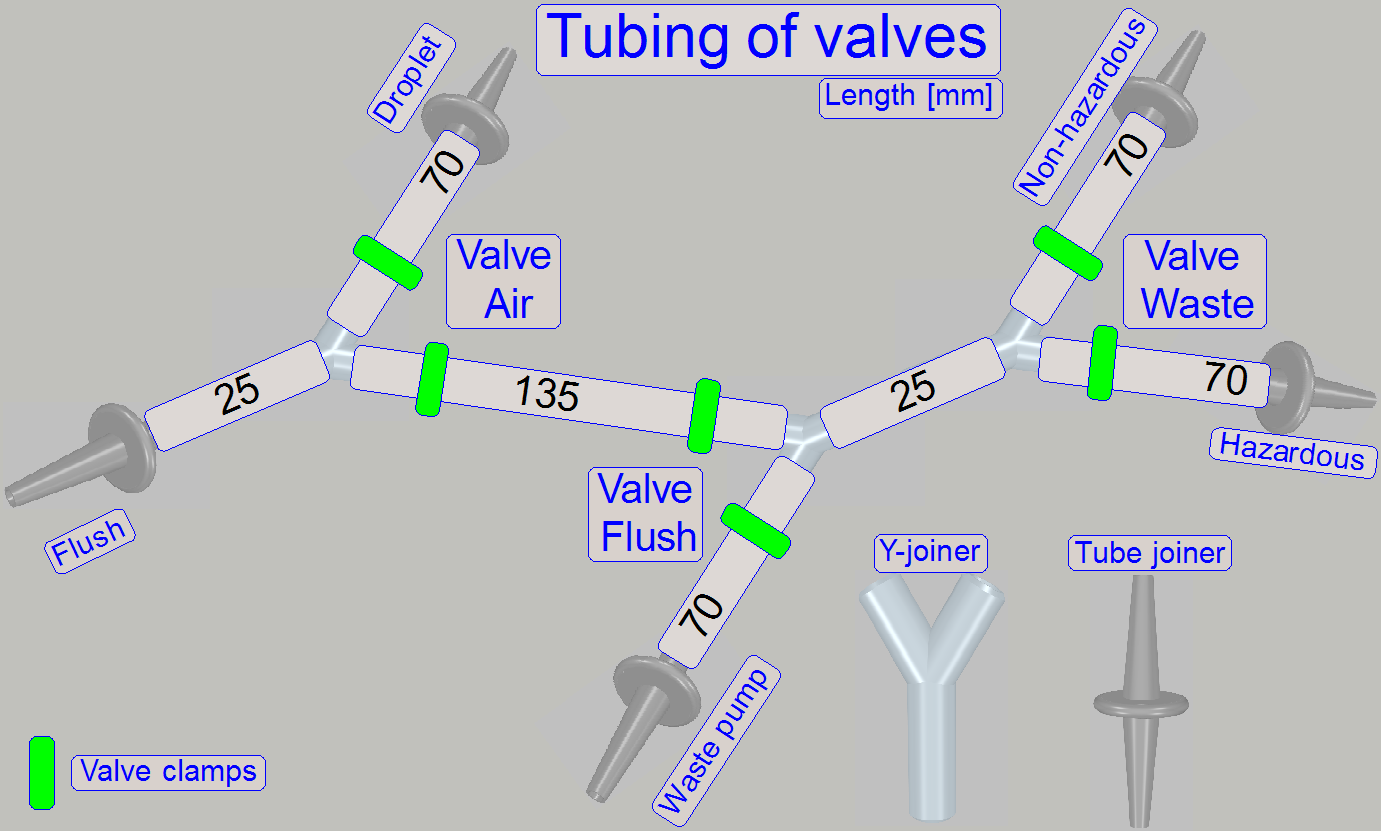

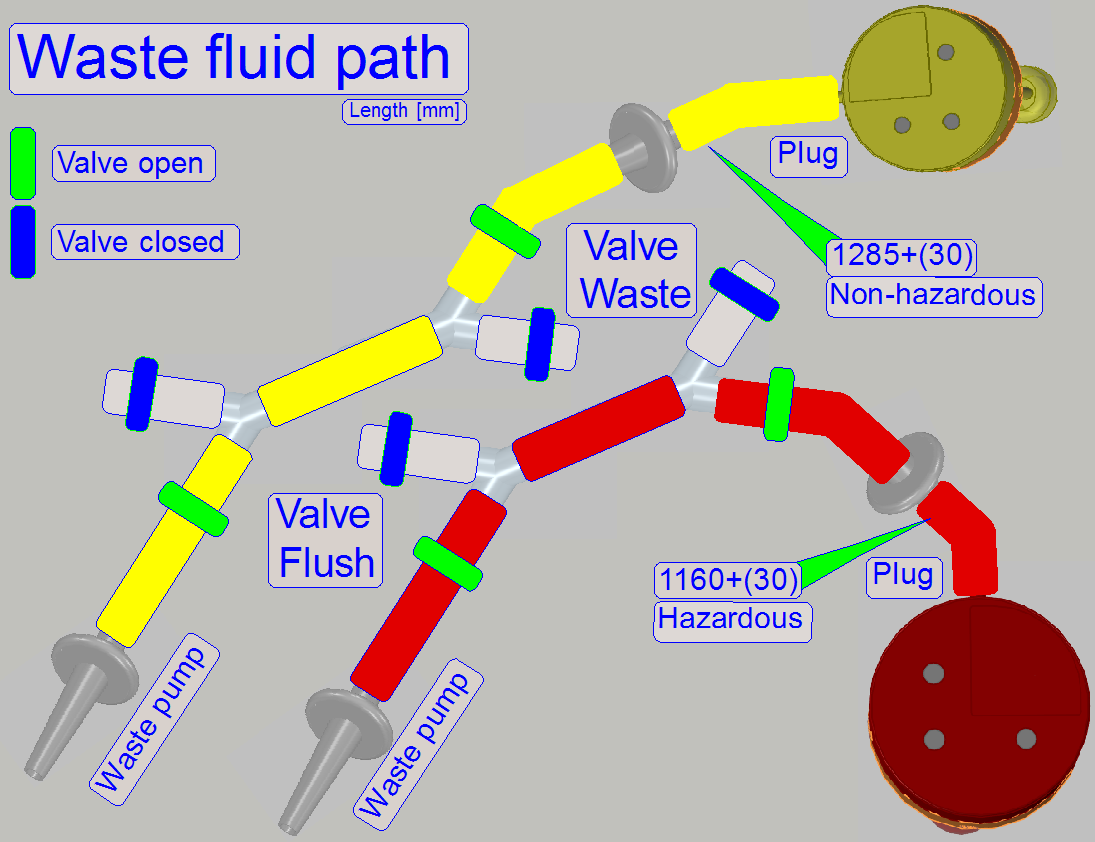

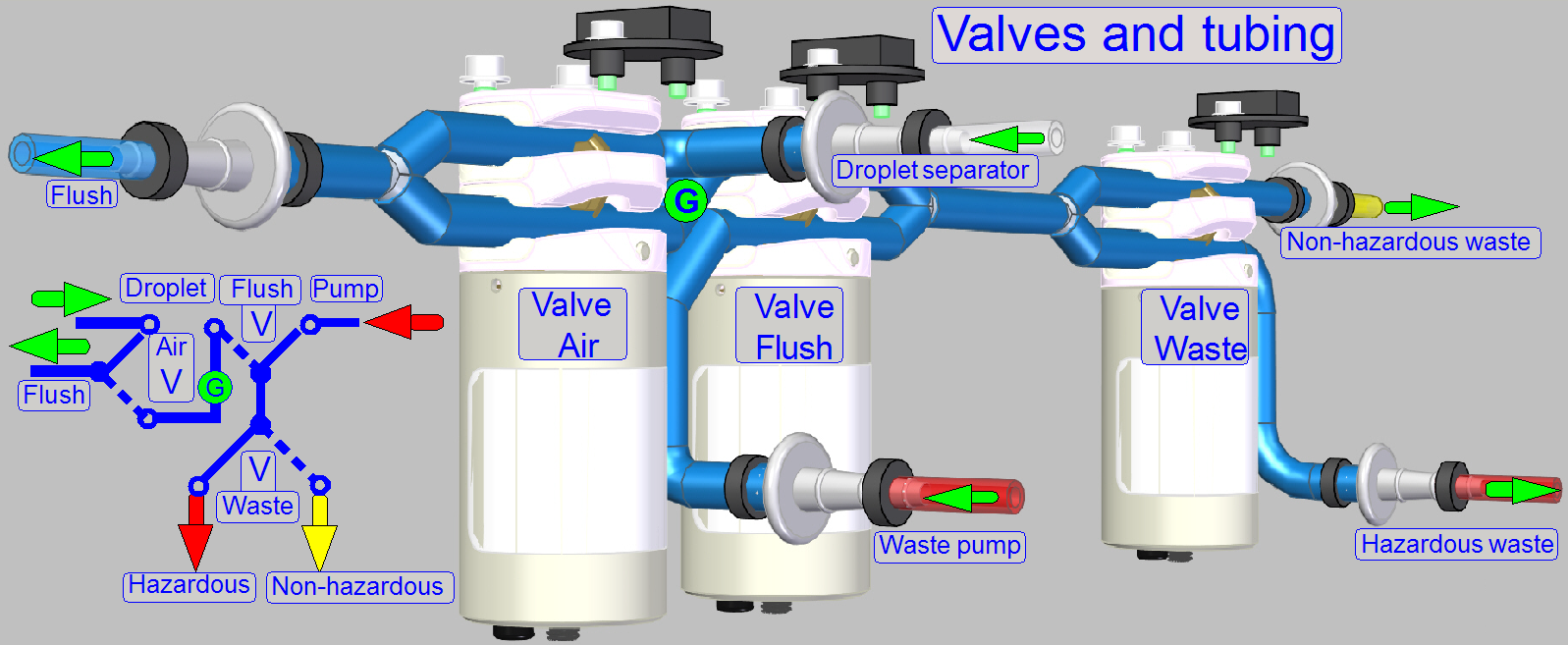

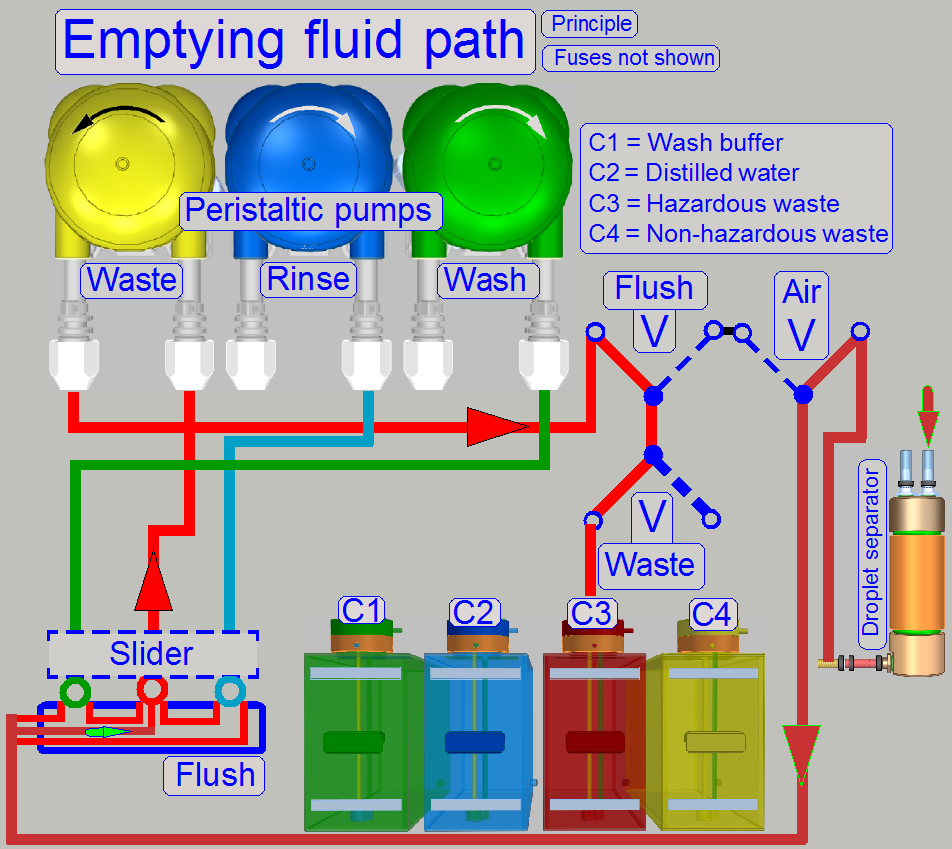

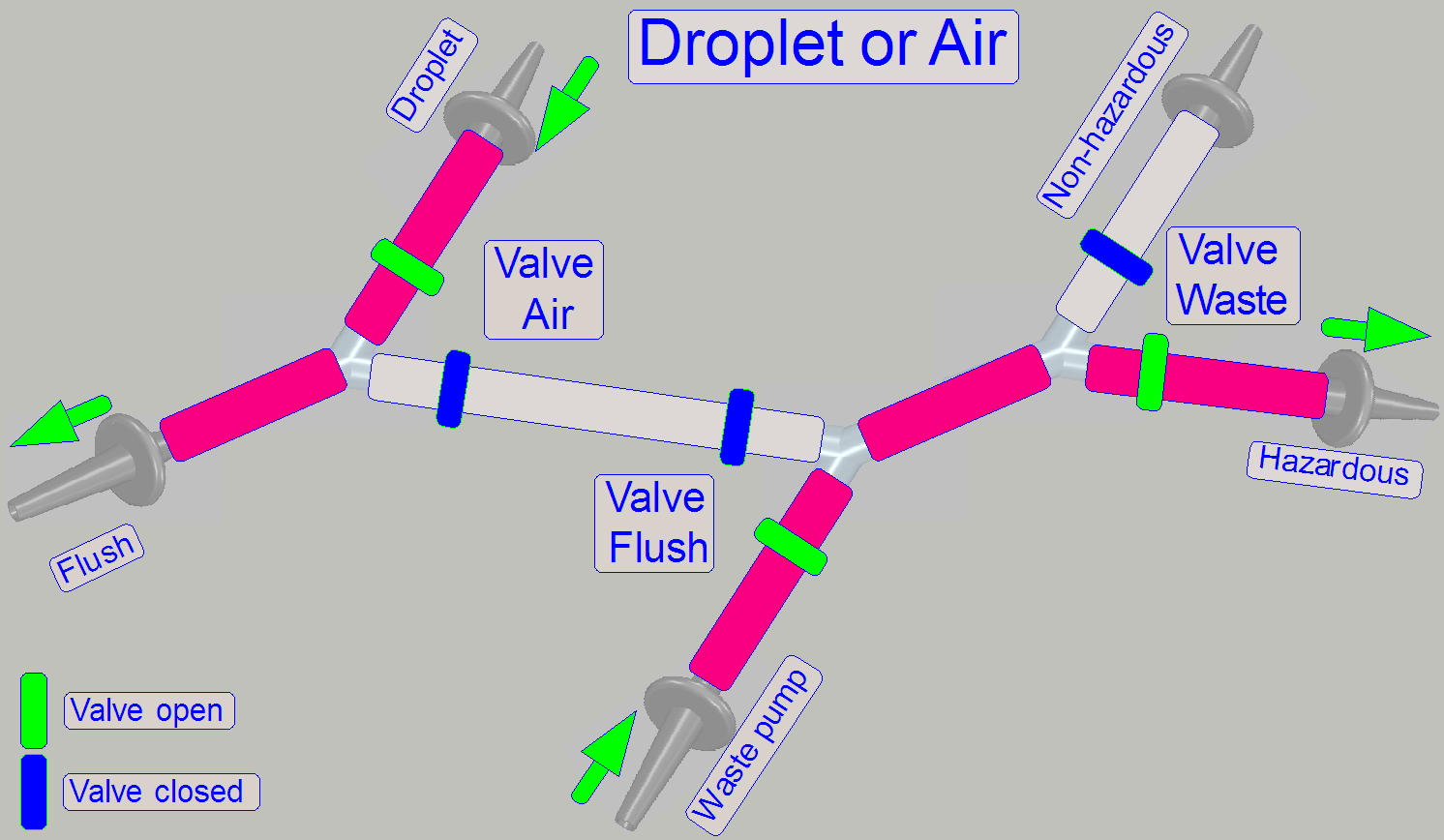

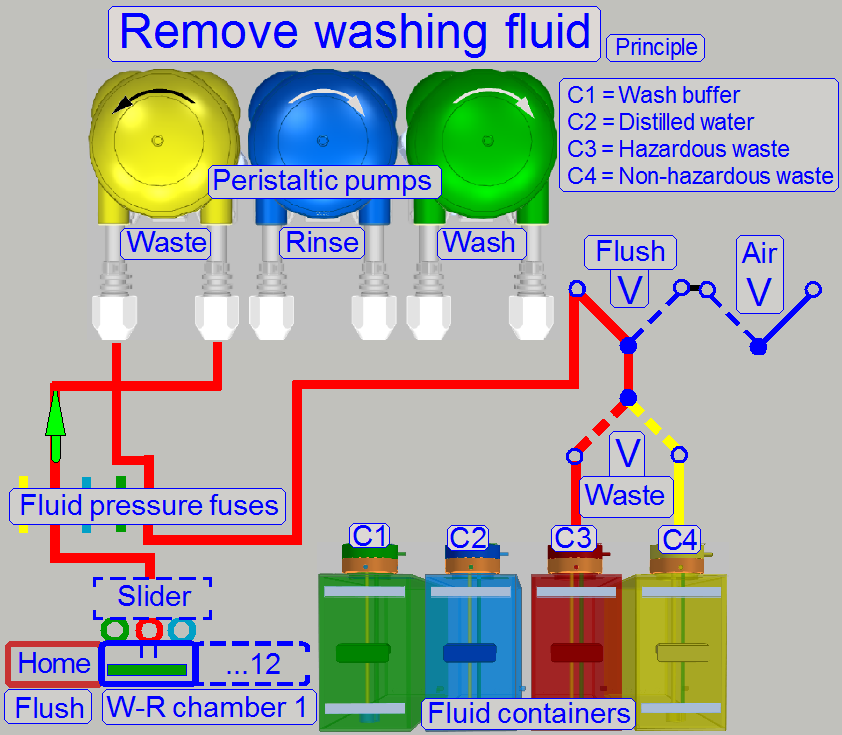

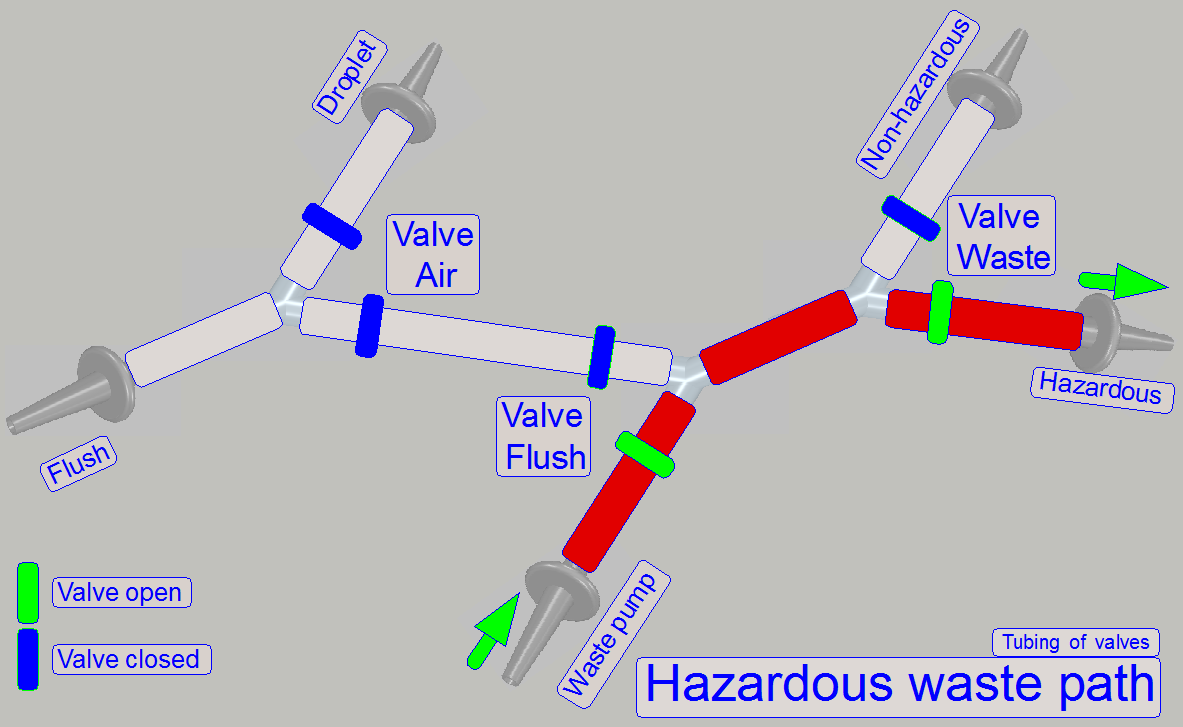

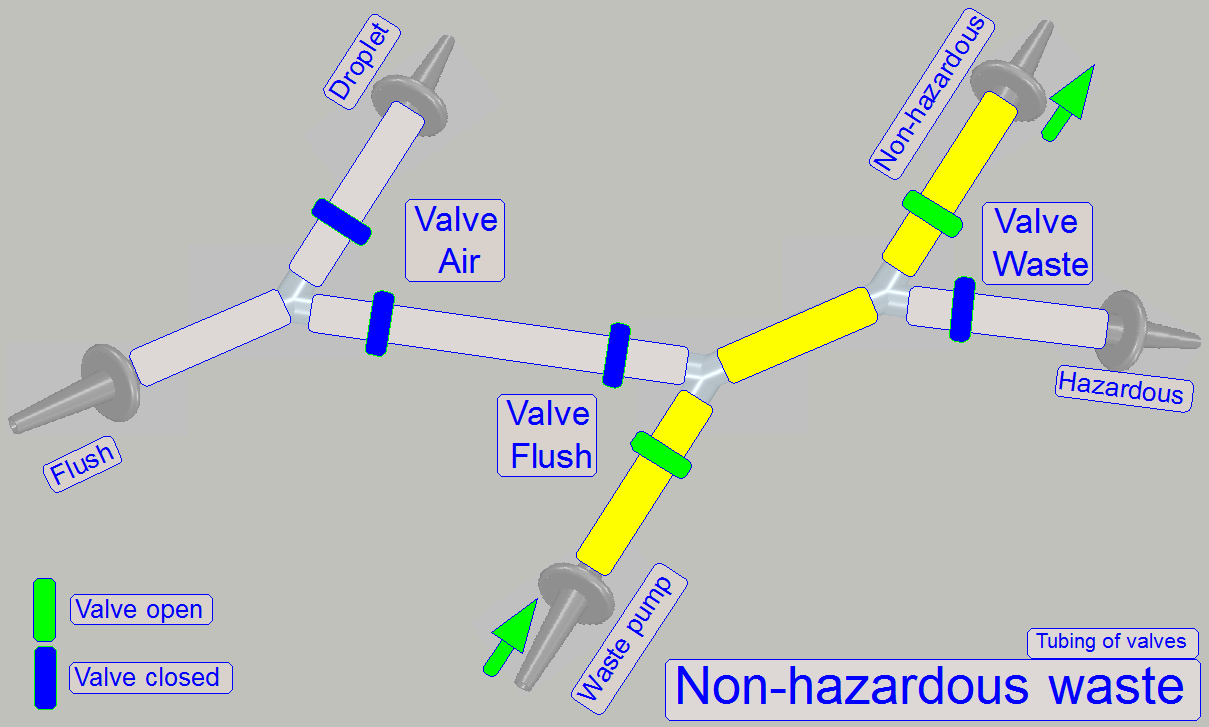

By using the 2-channel valves “Air”, “Flush” and

“Waste” and by switching on the peristaltic pump “Waste”, the flow direction of

the appropriate fluid can be controlled, depending on the task to be done and

kind of fluid to flow.

· The

valves are controlling always only the waste path of fluid!

· Tubing

of fluid paths can be found in chapter “Fluid

paths”.

By opening or closing the clamp(s) of the appropriate valve

the path will be controlled.

By opening or closing the clamp(s) of the appropriate valve

the path will be controlled.

· Tubing

of the valves to other components can be found in chapter “Fluid paths”.

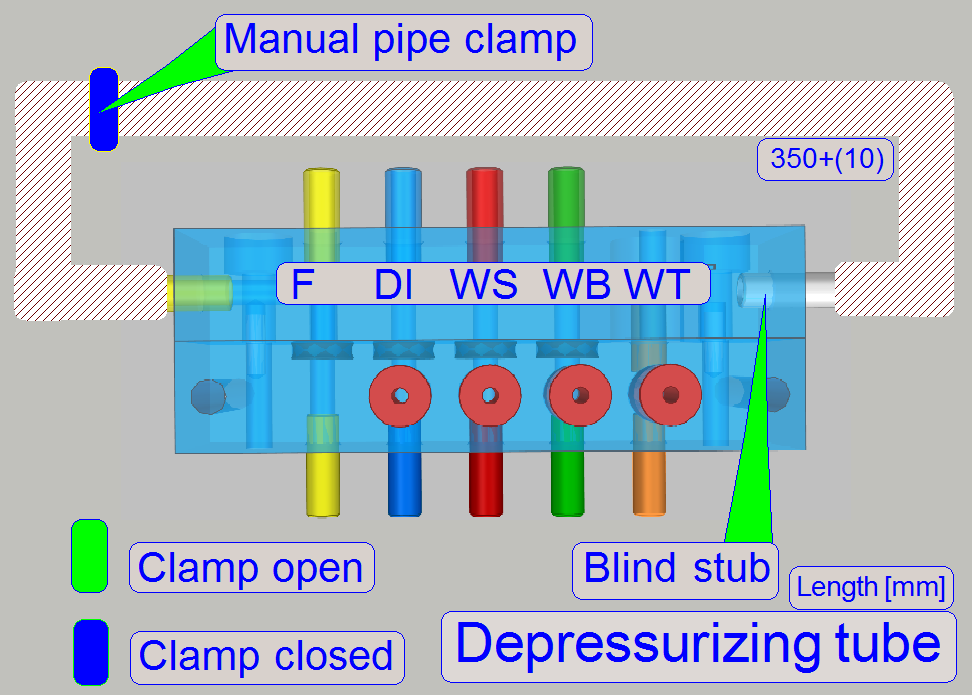

Depressurize flush path

By detaching

the pipe from its blind stub and moving this pipe end to the overflow basin and

opening the manual pipe clamp, the flush unit may be depressurized and fluid

can partly drained.

· If the

procedure is finished, please reconnect the pipe to its blind stub and close

the pipe clamp!

Flush path

Rinsing path

Washing path

Waste path

The path,

“Hazardous waste” and “Non-hazardous waste” depends always on the stain,

removed during the washing and rinsing procedure.

· If the

removed stain, removed during the washing process is not poisonous and not

caustic; the removed washing fluid will be routed to the non-hazardous waste

container.

· Rinsing

fluid will be drained to the hazardous waste container if the stain was

poisonous or caustic otherwise, the rinsing fluid is drained as non-hazardous

waste.

The

fluid flow is usually divided into 4 phases

· Software

start

· Apply

fluid to the specimen

· Remove

fluid from the specimen

· software

exit

The fresh fluid will be driven directly from the fluid

container to the appropriate chamber in its dedicated pipe line system by its

own pump; so contamination of the fluid is avoided.

· During

startup the software, the slider will be moved to the Flush position (Home) and

the filling of the pipes with the appropriate fluid is done.

Because the waste path handles the fluid flow from

several possible sources and the waste fluid will be collected in 2 containers,

the source and destination path of the waste fluid will be selected by valves.

· During

exit the software, the fluid of the Air dropper will bee removed and then the

pipes of the valve system will be emptied (filled with air).

Because the pressure of the pump may be much more then

required “Fluid pressure fuses” are implemented; these fuses acting only in emergency

states.

In the

following, the fluid flow will be separated by source, destination and task.

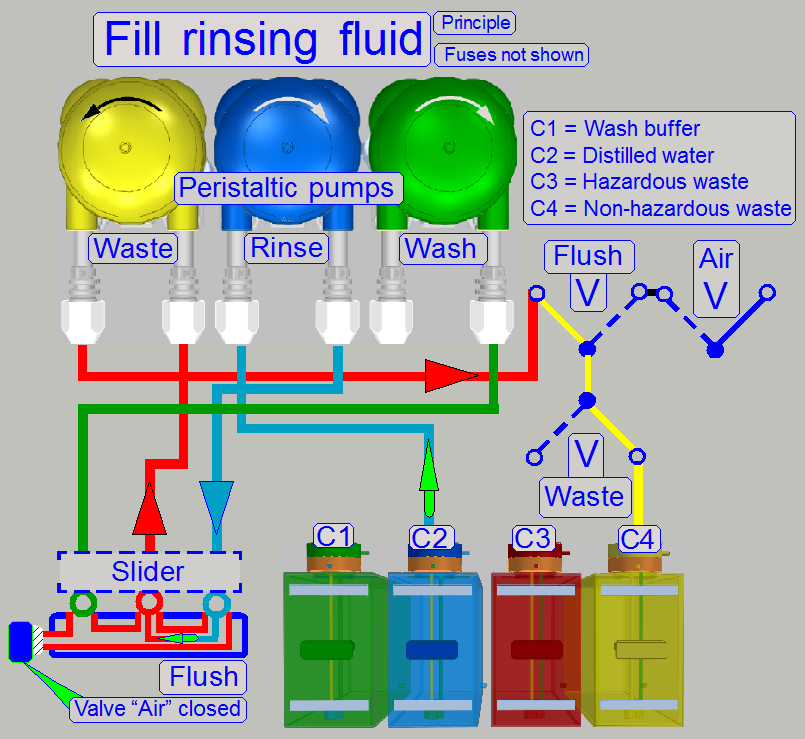

During the startup procedure of the software the tubes

and pumps for the washing and rinsing process have to be filled with water or

washing fluid respectively and the fluid supply tubes must not contain air

bubbles.

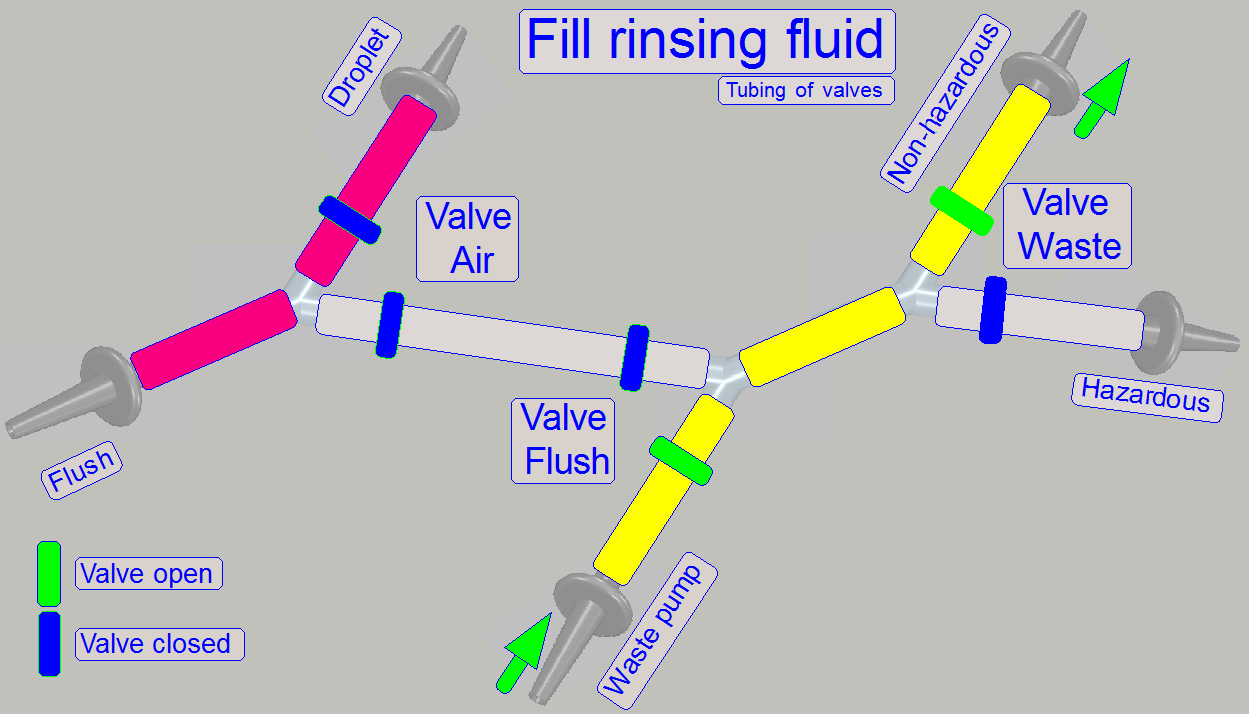

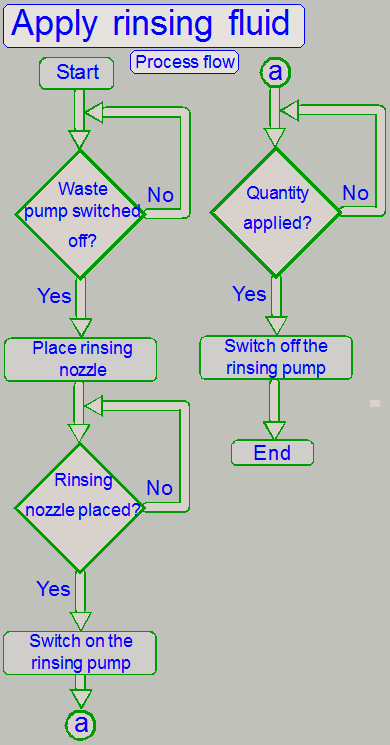

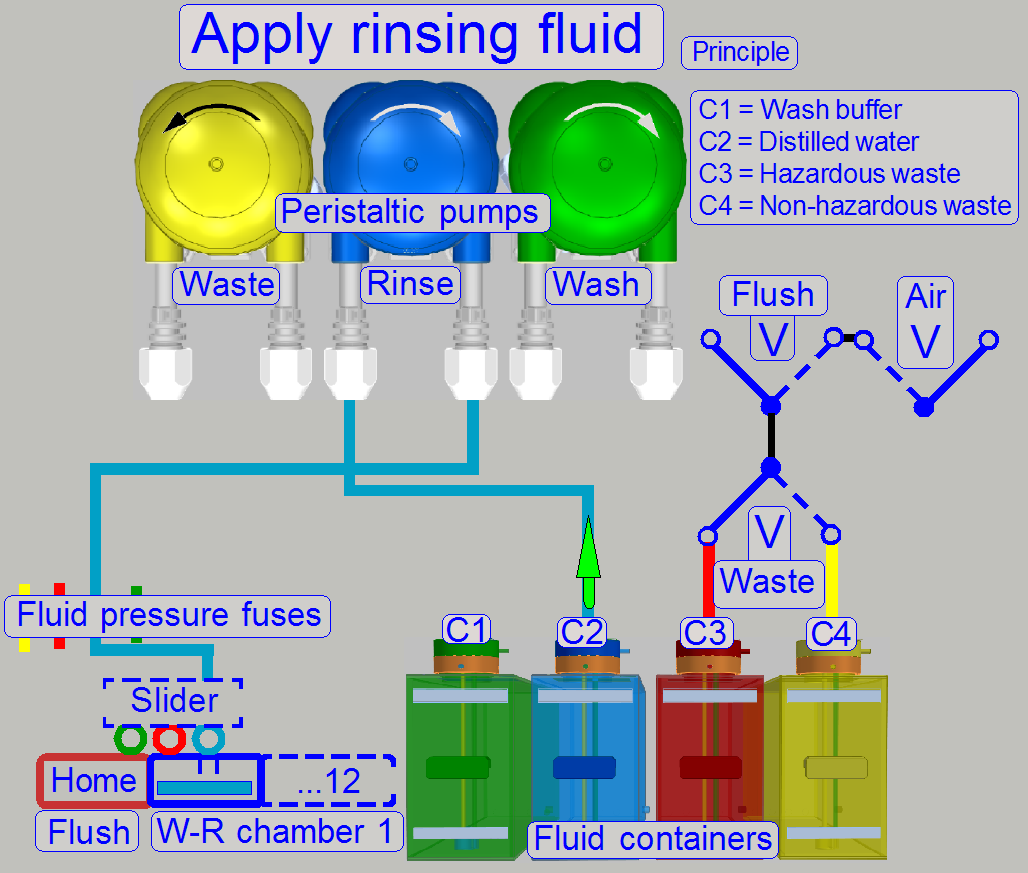

Fill rinsing fluid

First, the slider is moved to the flush (home)

position by the software. The rinsing pump and the waste pump are switched on.

The rinsing pipes will be filled with distilled water. The fluid moves through

the Rinse pump and the fuses to the slider. The flush path to the valve

"Air" is blocked.

Remark

· The

fuses are not shown on the image. For fuse implementing, see “Fluid pressure fuses”.

· The

piping of the container C1 is not shown, because it is excluded during this

operation.

· Because

the wash pump does not work, its behavior is like a closed valve.

The fluid is moved from the waste nozzle via the waste

fuse, the waste pump to the valves.

Rinsing fluid is non-hazardous, so the fluid is pumped

into the non-hazardous waste container.

The rinsing pump is switched on and pumps distilled

water to the appropriate slider opening. In the same time, the waste pump moves

the fluid into the non-hazardous waste container.

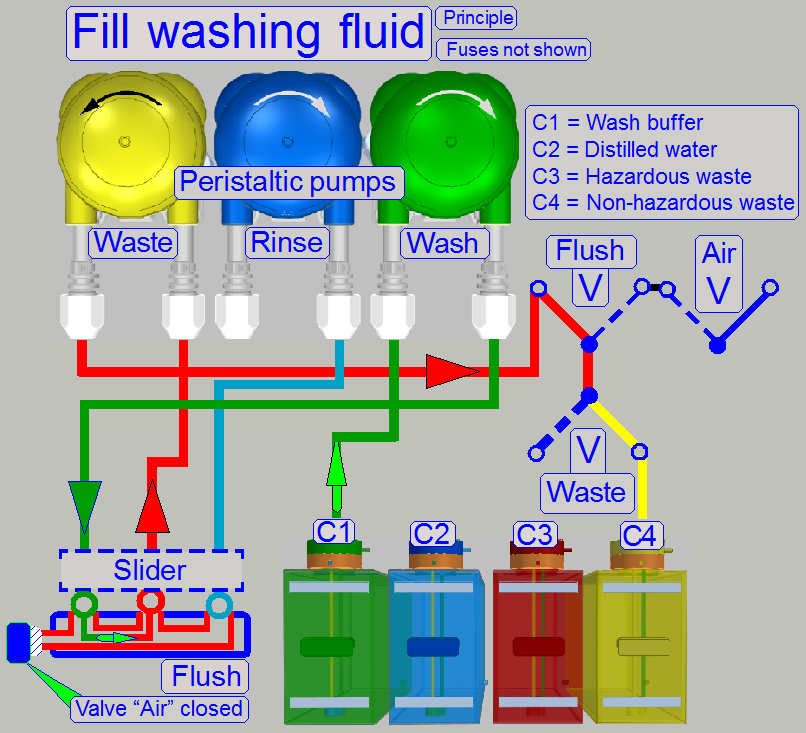

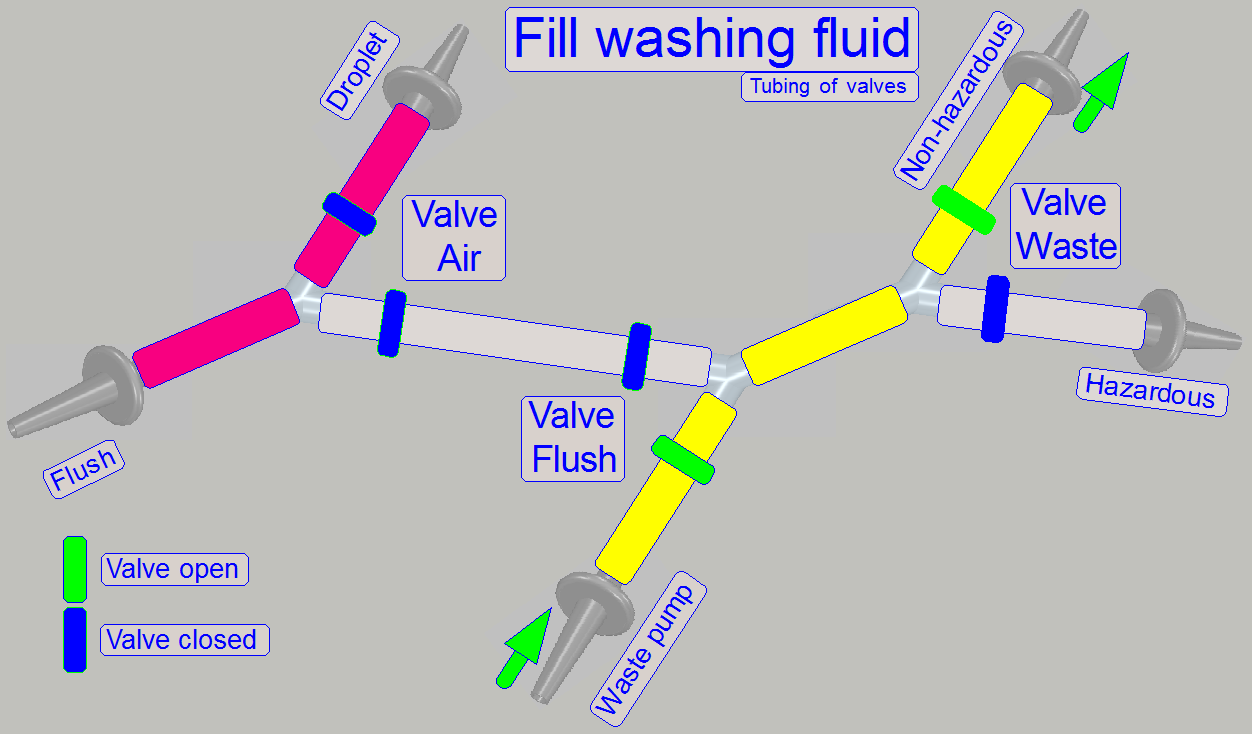

Fill washing fluid

Fill washing fluid

The slider stays in the flush (home) position. The

washing pump and the waste pump are switched on.

The pipes of the washing path will be filled from the

wash container via the wash pump.

The washing fluid arrives to the slider’s nozzle and

the fluid will be removed from the slider nozzle via the waste path.

The washing fluid itself is non-hazardous, so fluid is

pumped to the non-hazardous waste container.

Remark

· The

fuses are not shown on the image. For fuse implementing, see also “Fluid pressure fuses”.

· The

piping of the container C2 is not shown, because it is excluded during this

operation.

· Because

the rinse pump does not work, its behavior is like a closed valve.

The wash pump is switched on and pumps washing fluid

to the appropriate slider's opening, during the waste pump moves the fluid to

the non-hazardous waste container.

During this process the Air wiper’s droplet separator

fluid container will be emptied.

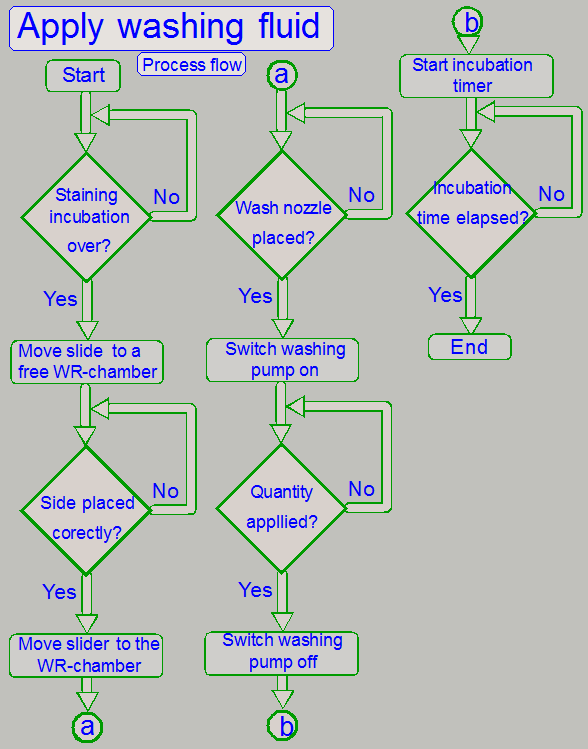

See the flowchart on the right; only components for

the process are shown.

The washing fluid remains on the specimen for 1 … 10 minutes, depending

on the stain properties; the exact time is defined in the process protocol.

· The incubation of

the washing fluid is done in the actual WR-chamber.

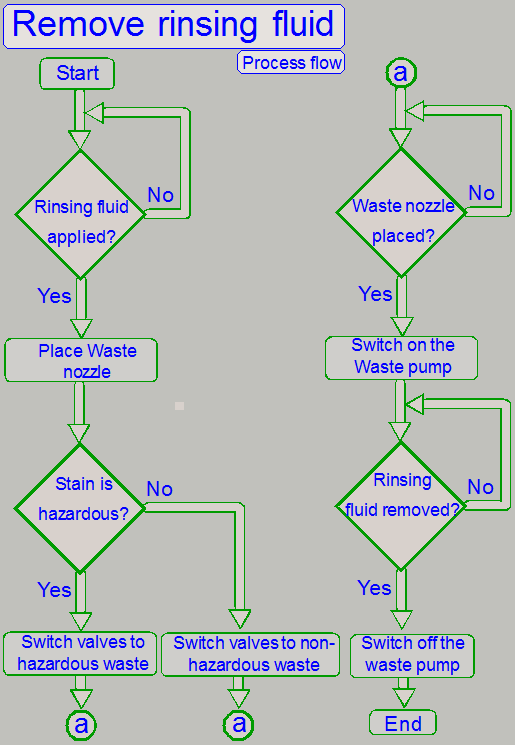

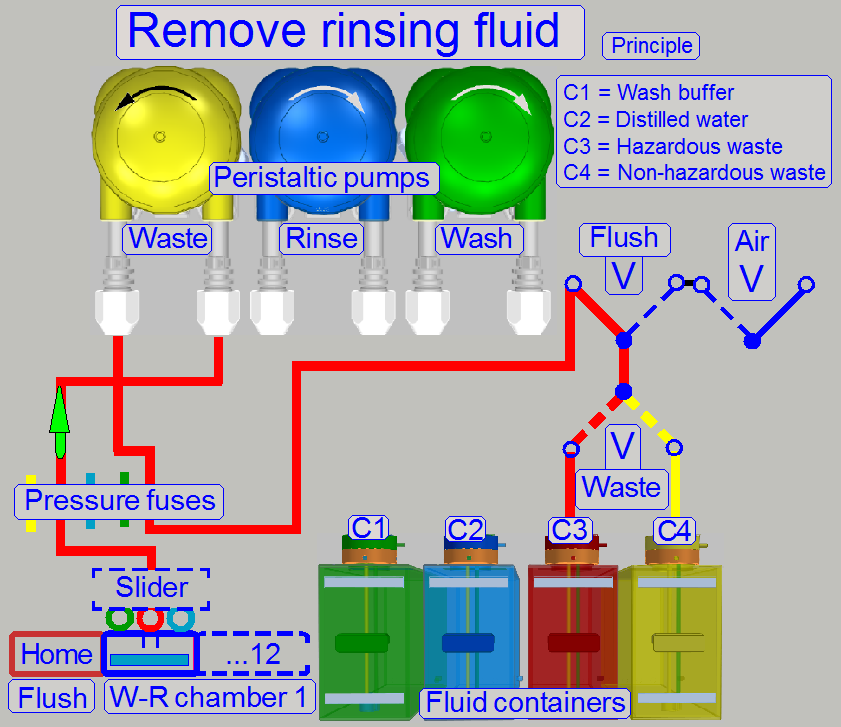

If the incubation time of the washing fluid is over, the fluid will be

moved to a waste container, depending on the stain was hazardous or not.

The washing fluid is removed to the hazardous waste container or to the

non-hazardous waste container!

· If the stain is

hazardous, the washing fluid is moved to the hazardous waste container!

The distilled water is applied to the specimen after

the washing fluid is removed.

· There

is no incubation time of the rinsing fluid.

As the rinsing fluid applied to the specimen, the

slider's position is changed to the waste nozzle and the rinsing fluid is

removed into a waste container (C3 or C4).

· If the reagent

(stain) was hazardous, the rinsing fluid is moved into the hazardous waste

container (C3)!

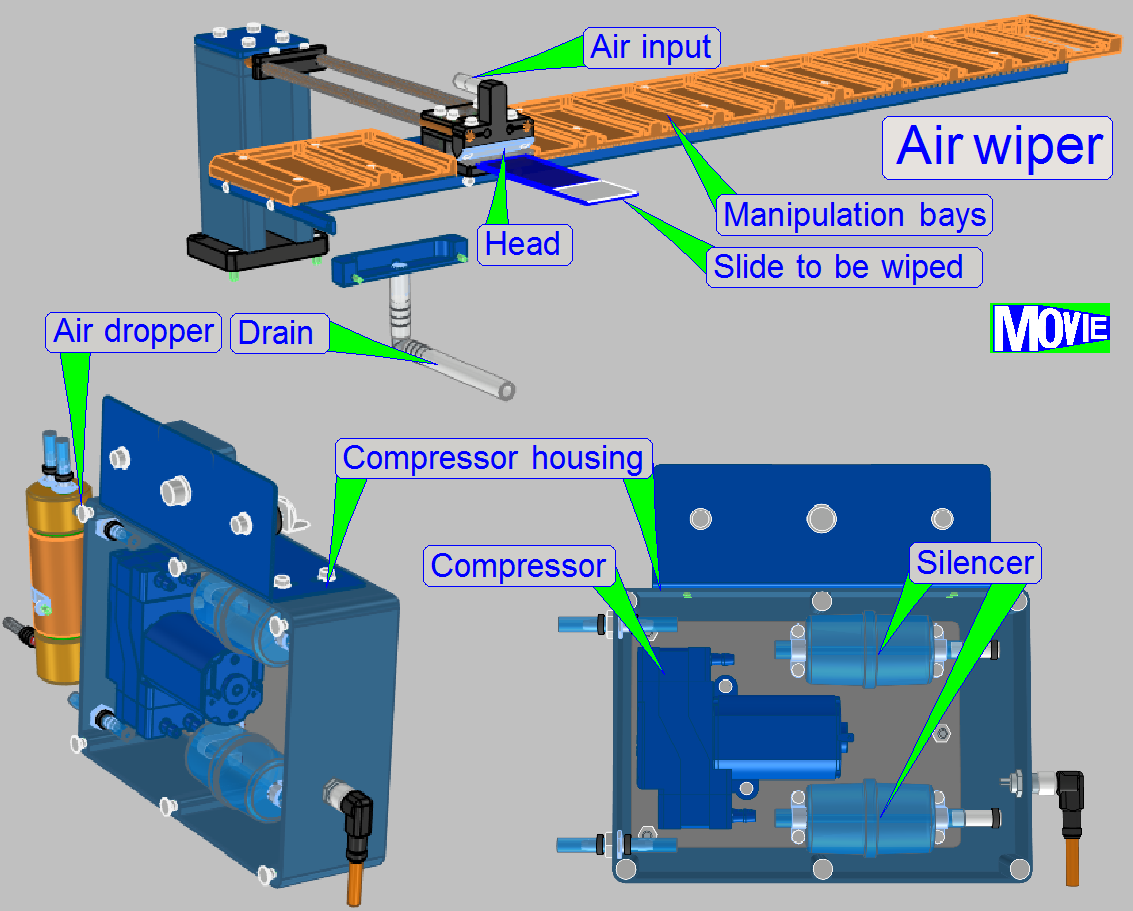

After

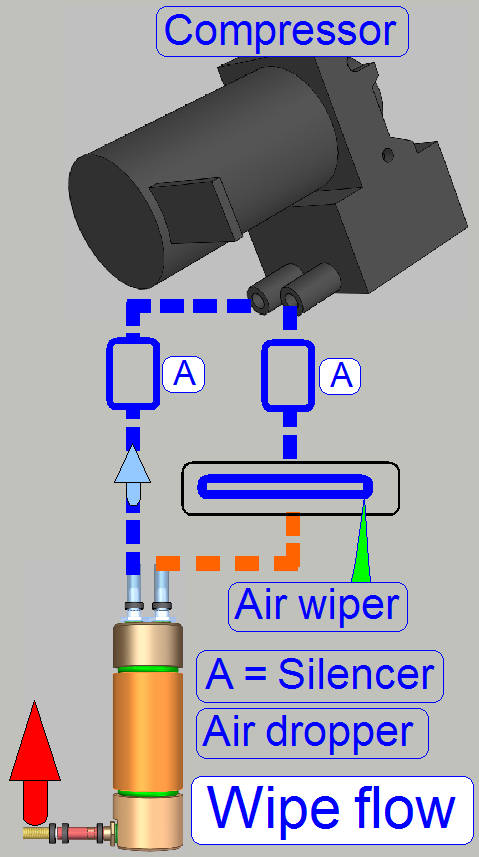

the rinsing process is finished, finest water drops may remaining on the

specimen. Because any extraneous material may affect the specimen’s scan

quality, residues of the specimen staining process have to be removed before

cover slipping.

The specimen must not be heat up for this procedure,

residues are removed by the “Air wiper”.

As included in the name, the residues of the creation

process will be removed by blowing air over the prepared specimen and so,

finest water drops and other residues of the creation process are removed.

Principle

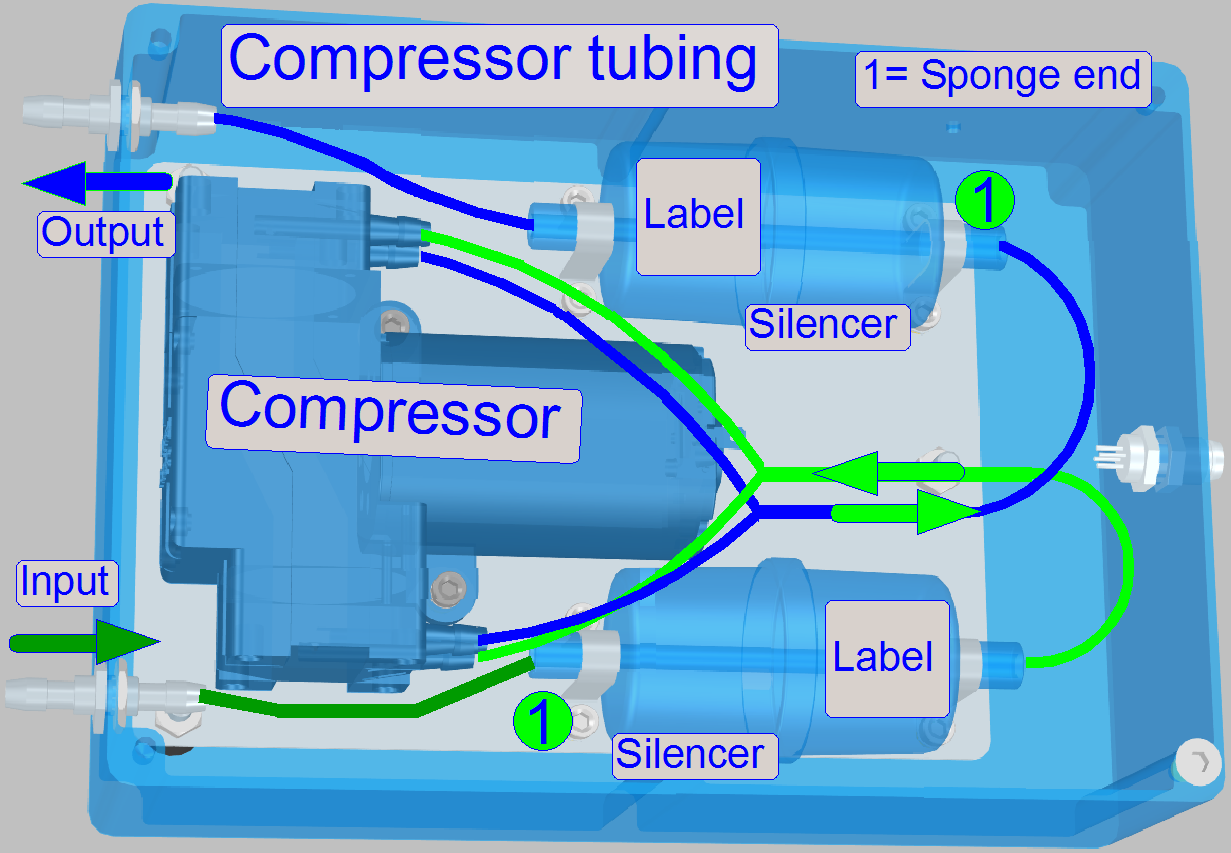

If the real wiping process starts, the compressor will be

switched on. The compressed air arrives to the nozzle of the “Air wiper” in an

angle of 45º by crossing the silencer (A). The nozzle of the air wiper is

a bit larger than the width of the slide, so the entire surface of the slide

will be blown with compressed air. The removed fluid will be sucked into the

droplet separator (air dropper), where the fluid will be separated from the

air. After crossing a second silencer (A), the droplet separator's output is

connected to the vacuum input of the compressor and the air loop is closed.

If the real wiping process starts, the compressor will be

switched on. The compressed air arrives to the nozzle of the “Air wiper” in an

angle of 45º by crossing the silencer (A). The nozzle of the air wiper is

a bit larger than the width of the slide, so the entire surface of the slide

will be blown with compressed air. The removed fluid will be sucked into the

droplet separator (air dropper), where the fluid will be separated from the

air. After crossing a second silencer (A), the droplet separator's output is

connected to the vacuum input of the compressor and the air loop is closed.

· The

water reservoir of the droplet separator will be drained in defined intervals,

if the software will be shut down and the slider of the wash-rinse unit stays

in the flush position.

Components

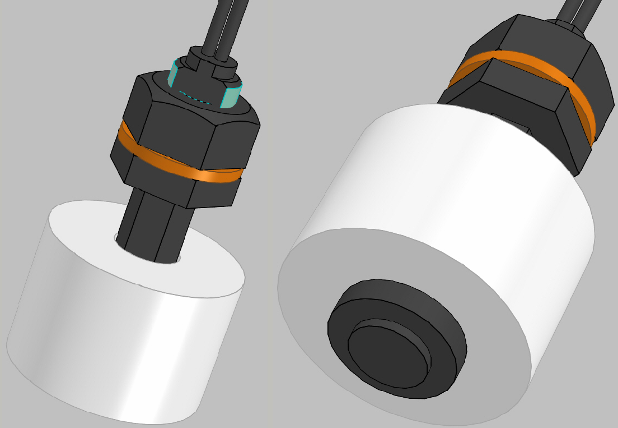

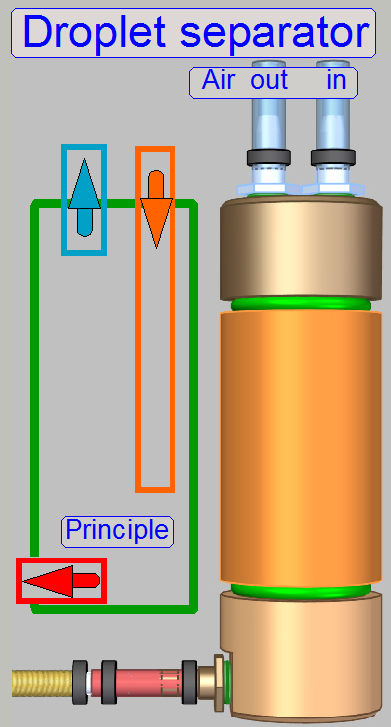

Droplet separator

The air,

arriving from the air wiper is contaminated with finest droplets as a result of

the wiping procedure.

These droplets are separated from the air by gravity and

are collected in the lower part of the device. During shut down the software,

the droplet separator will be emptied via the valve “Air” and the “Flush” part

of the sliders home position.

These droplets are separated from the air by gravity and

are collected in the lower part of the device. During shut down the software,

the droplet separator will be emptied via the valve “Air” and the “Flush” part

of the sliders home position.

If the device does not contain anymore water, the

tubes of the waste fluid path are filled with air via the "Air input"

of the device.

See also: “Shut down software”

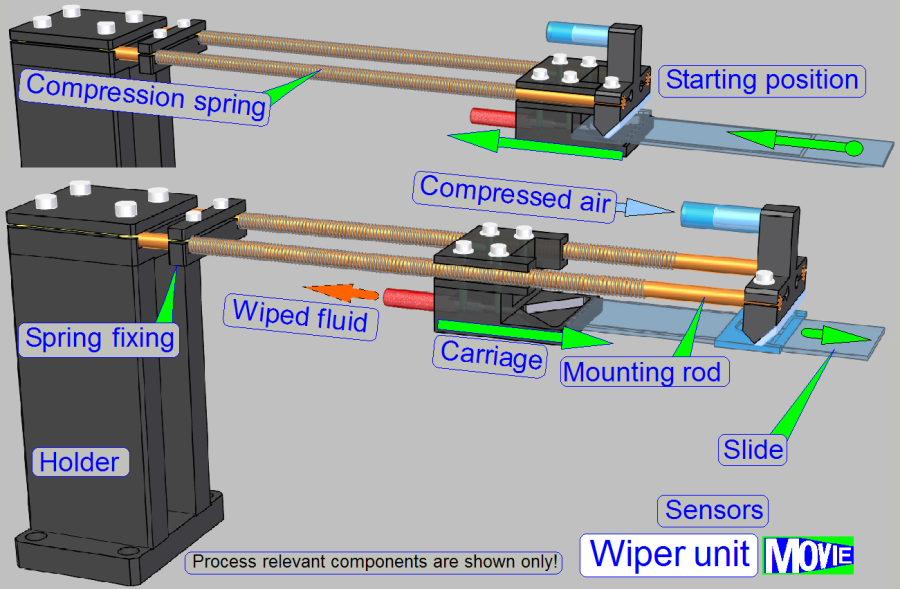

Working

·  If

the slide will be inserted into the wiper position by the slide mover, the

carriage moves in direction to the holder and the compression springs will be

stressed.

If

the slide will be inserted into the wiper position by the slide mover, the

carriage moves in direction to the holder and the compression springs will be

stressed.

· If the

slide is inserted by about 60mm, the compressor is switched on and the

compressed air arrives onto the sample surface of the scan area in an angle of

45º and the wiped fluid will be moved into the air dropper.

· Now,

the slide mover moves the slide slowly backward, out of the wiper position and

the liquid on the slide surface will be moved to the inner edge of the slide.

· The

compression springs pushing the carriage always against the slide inner edge

and the wiped fluid can be moved away.

· If the

starting position is arrived again, the wipe procedure is finished and the

compressor will be switched off.

Remark

The working principle of the “compression spring” is

not shown correctly!

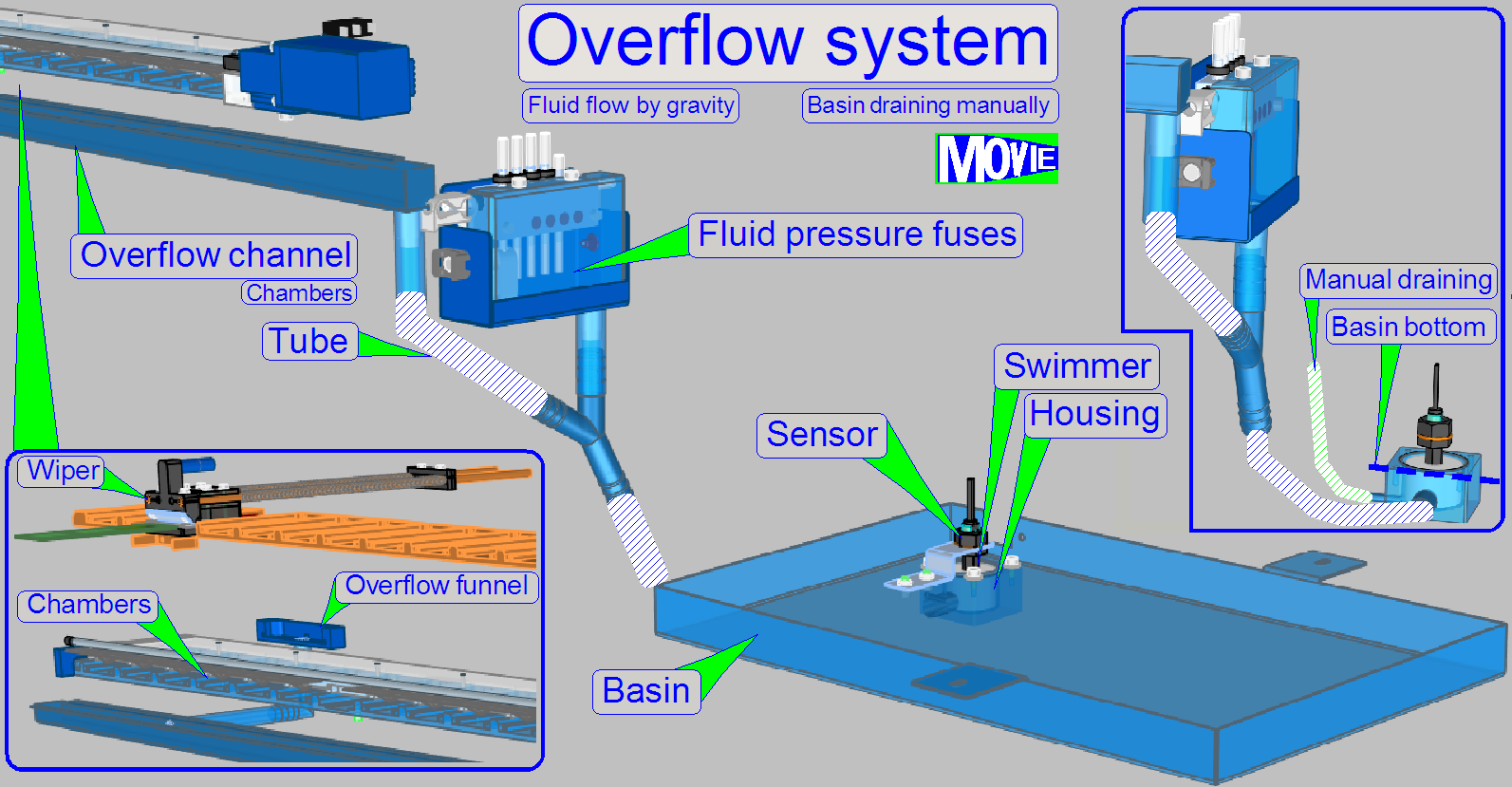

In emergency conditions

fluid may flow out of its dedicated path. To protect the equipment from damage

by partially aggressive fluid, an overflow draining system is realized.

Source

of overflow may be

· Any chamber of the

wash – rinse unit

· The rear of the

wiper bay

· Any fluid pressure

fuse

· Flush unit

The fluid is collected by the “Overflow funnel” (Wiper rear), the “Overflow

channel” (any wash – rinse chamber and flush unit) and the fuse housing; the

flow is realized by gravity.

The overflow fluid is drained to the basin below the slide scanner; a

swimmer driven sensor is used to indicate to the software that fluid is present

in the basin.

At the lowest point of the swimmer housing, the fluid can be drained

manually to an external pot by the help of a syringe and should be disposed as

hazardous waste fluid.

· To drain the

basin, remove the overflow drain tube from its holder and connect a syringe

with a capacity of 50ml and suck out the fluid.

See also: “Truss”

|

Image(s) |

Component |

Manufacturer |

Remark |

|

|

|||

|

|

|

|

Air dropper |

|

|

|||

|

|

|

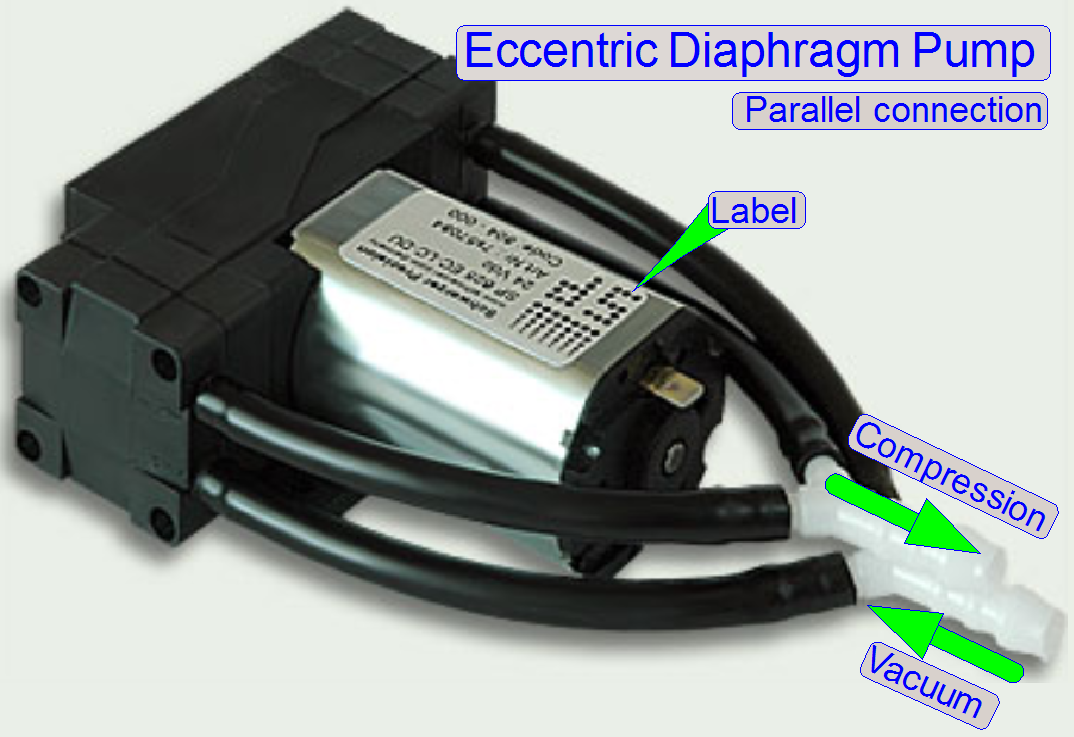

KNF NMP-05-B |

Vacuum

pump (compressor) -pdf- |

|

|

|||

|

|

|

BUS0009 |

Distance

measuring sensor |

|

|

|||

|

|

|

59630 |

Float sensor

|

|

|

|||

|

|

|

WPX1-X1-8FA2-WM4 |

Peristaltic

pump Color Yellow,

green, blue |

|

|

|||

|

|

Used with solenoid operated products |

||

|

|

|

Bondex ID3.0-OD4.0-01549 ID3.0-OD5.0-00072 ID4.0-OD6.0-00078 Saint-Gobain |

Fluid pipe Two 6-inch section of tubing

supplied with valve. Fluid pipe -pdf- Fluid pipe -pdf- |

|

|

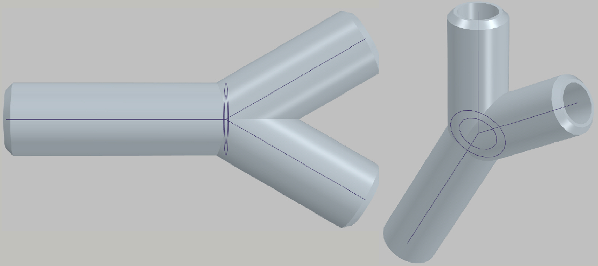

|

Y-splitter Two 6-inch section of tubing

supplied with valve joined by a "Y" connector. |

|

|

|

|||

|

|

|

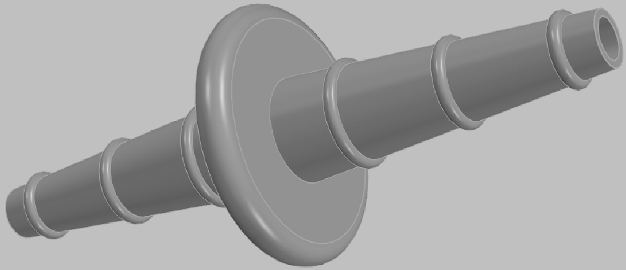

Bovimex K510 |

Tube

joiner |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|