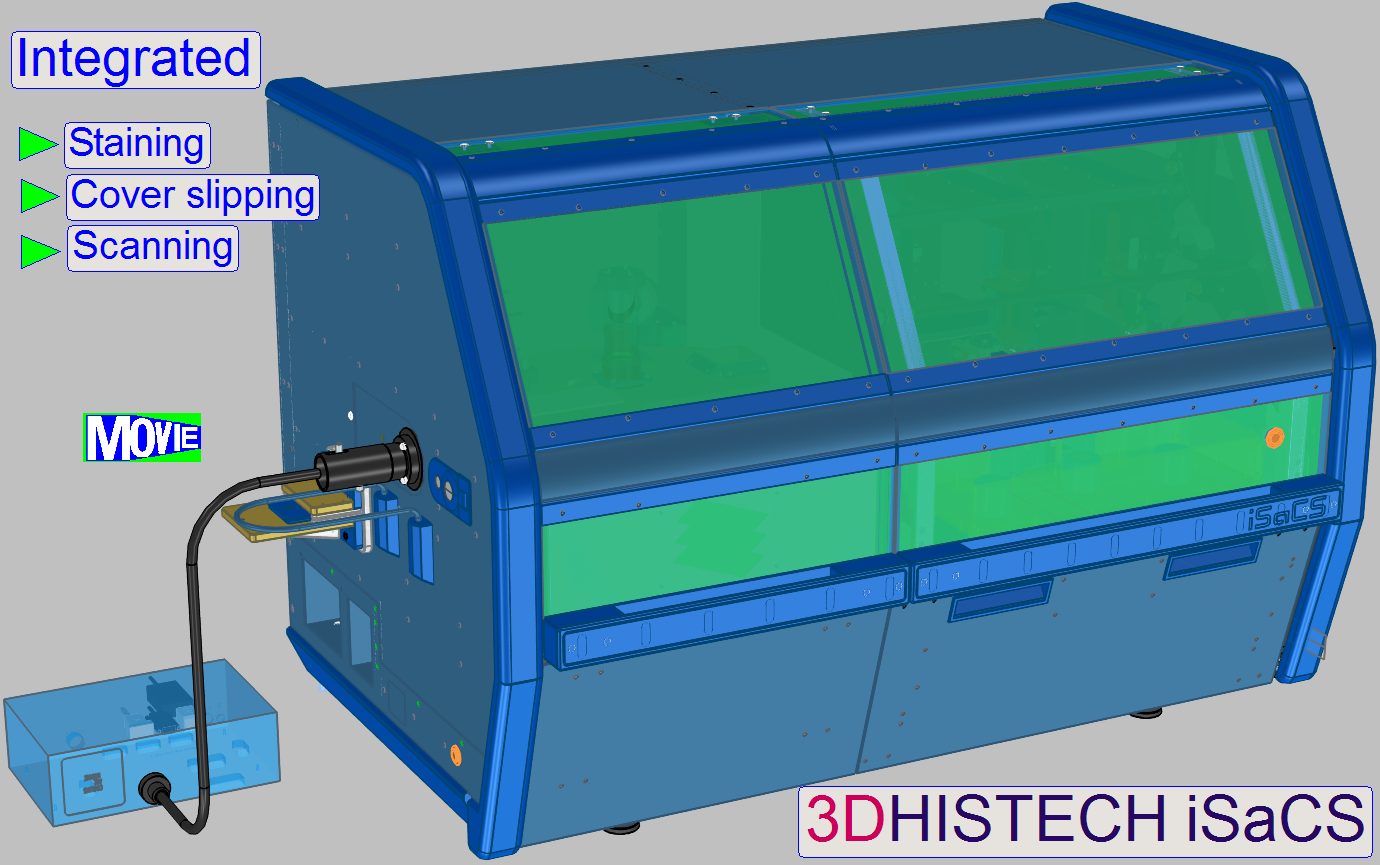

Overview; iSaCS

For

technicians and sales managers

This section describes the tasks, units and components

of the 3DHISTECH Immunohistochemistry Staining automatic Cover slipping and Scanning

equipment (iSaCS).

Features

· Complex and integrated

solution with small footprint

· Handling of 72

slides simultaneously

· The modular

construction allows to execute different tasks concurrently

· Immunohistochemistry

and counterstaining of tissue specimen

· Application of

stain during staining procedure

· Application of

mounting medium during cover slipping

· Automatic scan of

the created specimen in fluorescent (FL) or brightfield (BF) scan mode

· Automatic scan

session performed in 30-120 seconds in brightfield scan mode for 1 specimen

Capacities

·

72 slides with specimen

·

150 cover slips

·

15 ml cover slip mounting medium (for 300 slides)

·

40 reagent vials

·

8 ml vial (for

80 staining procedures)

·

1 x 5l tank for washing fluid (for 200 slides)

·

1 x 5l tank for rinsing fluid (for 200 slides)

·

2 x 5l tanks for waste fluid (for 200 slides)

Main part list

|

Component |

Stepper motor |

Actuator |

Sensor |

Light source |

Camera |

|

|

STA |

Staining module |

4 |

0 |

2 |

0 |

0 |

|

COV |

Cover slipper |

3 |

2 |

3 |

0 |

0 |

|

TRA |

Transporter |

3 |

1 |

1 |

0 |

0 |

|

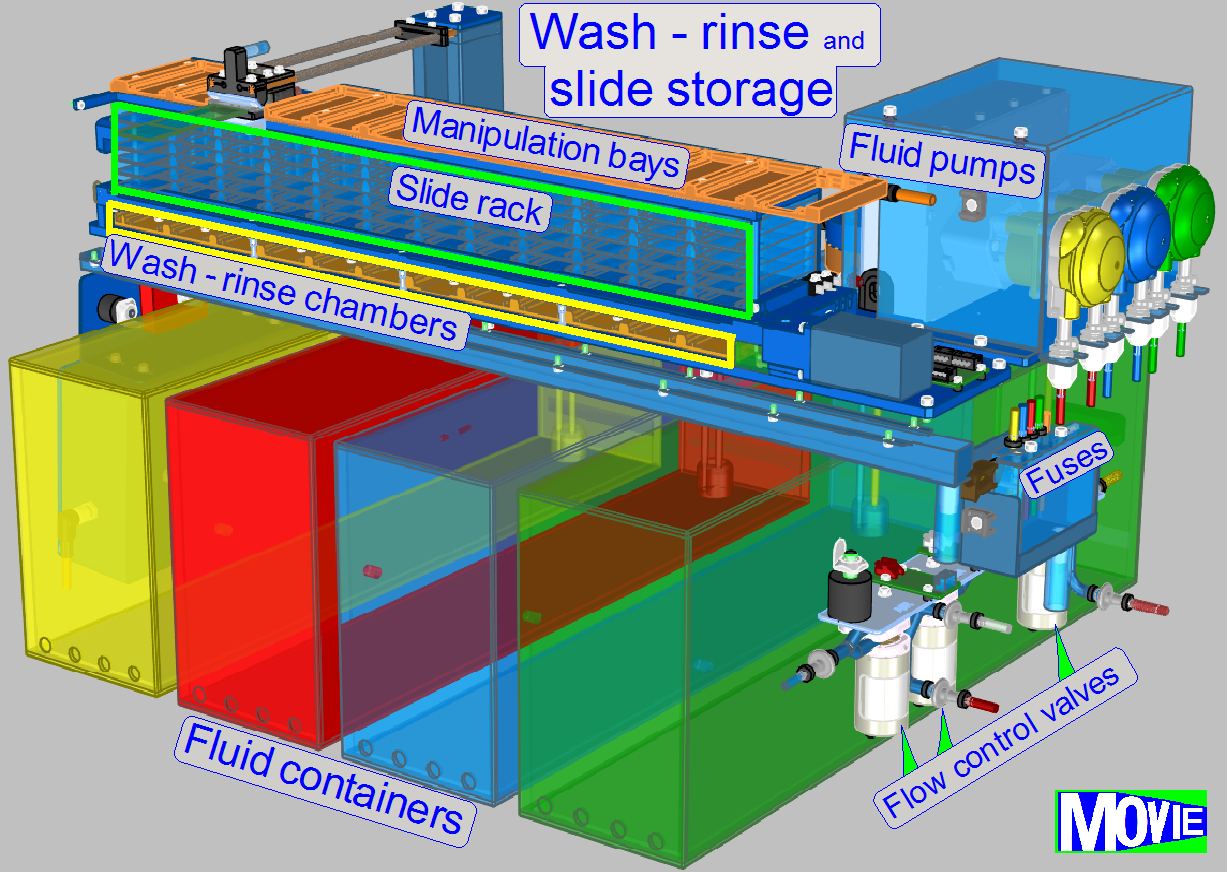

WRU |

Wash - rinse unit |

4 |

2 |

12 |

0 |

0 |

|

REA |

Reagent changer |

1 |

0 |

0 |

1 |

1 |

|

SLI |

Slide image |

0 |

0 |

0 |

2 |

1 |

|

AIR |

Air wiper |

0 |

1 |

0 |

0 |

0 |

|

FRH |

Frame; housing |

0 |

0 |

4 |

1 |

0 |

|

|

Digital scanner |

6 |

0 |

2 |

3 |

2 |

|

Total |

iSaCS |

21 |

6 |

24 |

7 |

4 |

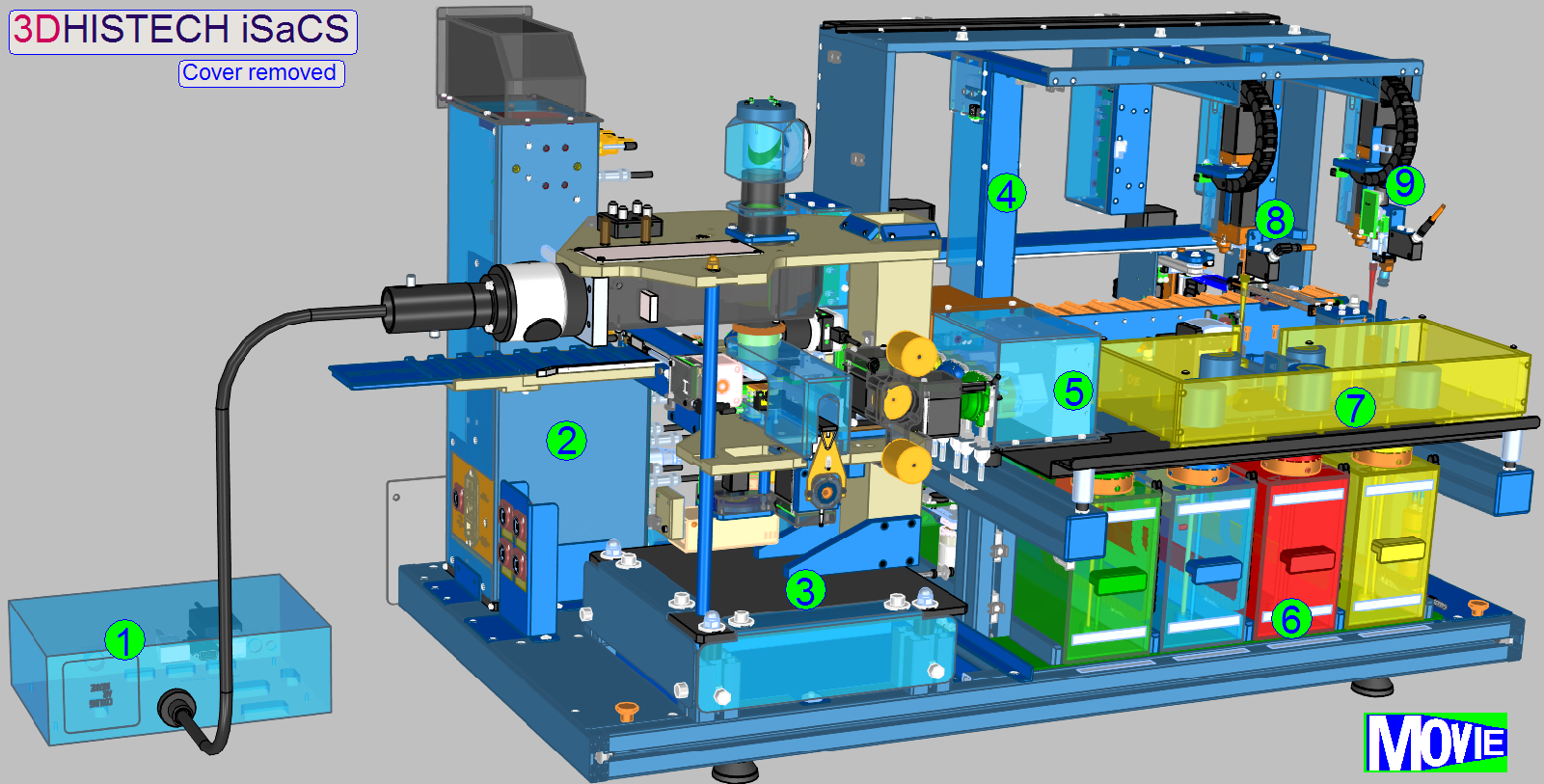

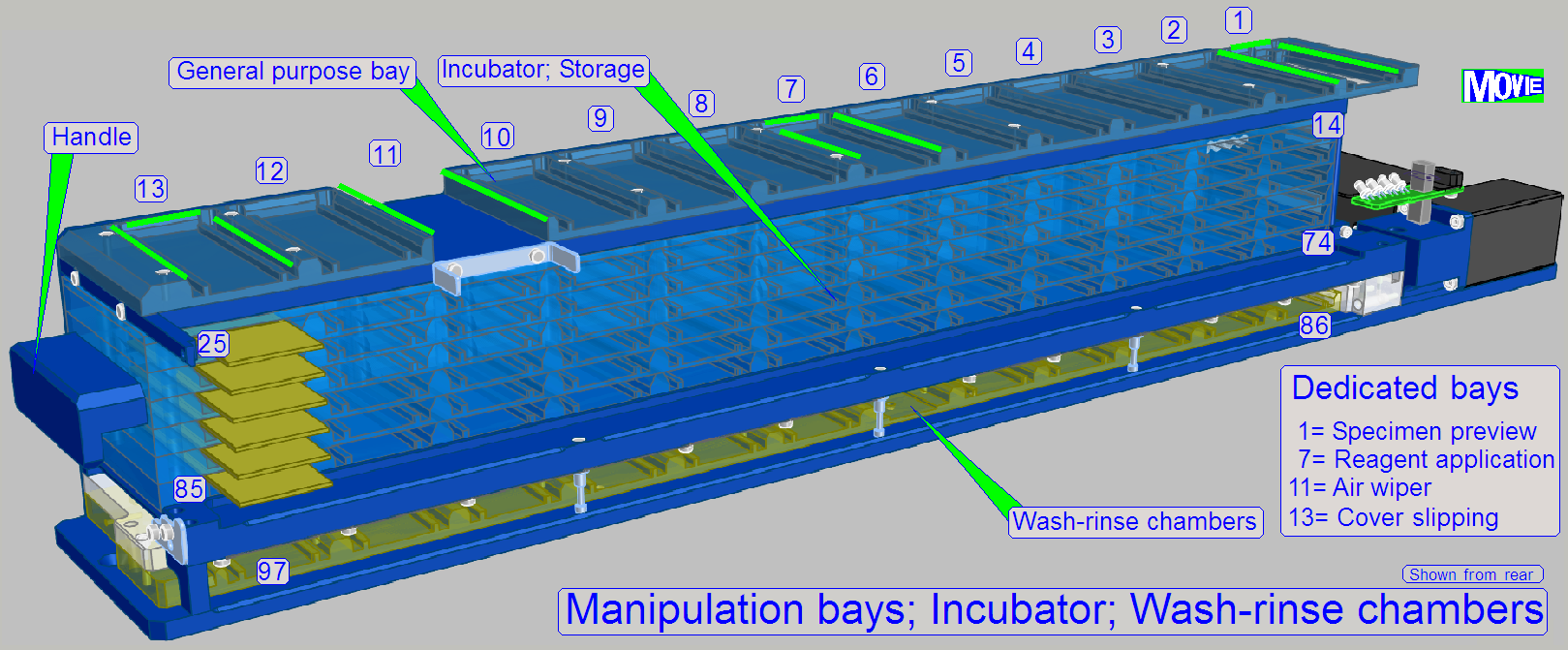

The iSaCS is a complex, small footprint,

integrated solution for the automation of tissue antigen marking. It is

intended to perform IHC (Immunohistochemistry) staining, FISH (Fluorescent In

Situ Hybridization) staining, counterstaining, cover slipping and scanning. The

iSaCS was designed to use a modular construction approach, with the aim of

having numerous modules working simultaneously.

The iSaCS is a complex, small footprint,

integrated solution for the automation of tissue antigen marking. It is

intended to perform IHC (Immunohistochemistry) staining, FISH (Fluorescent In

Situ Hybridization) staining, counterstaining, cover slipping and scanning. The

iSaCS was designed to use a modular construction approach, with the aim of

having numerous modules working simultaneously.

- Lumencor SPECTRA

- Power tower

- Slide

scanner

- Specimen

image

- Peristaltic pumps

- Fluid containers

- Reagent

changer

- Reagent

applicator

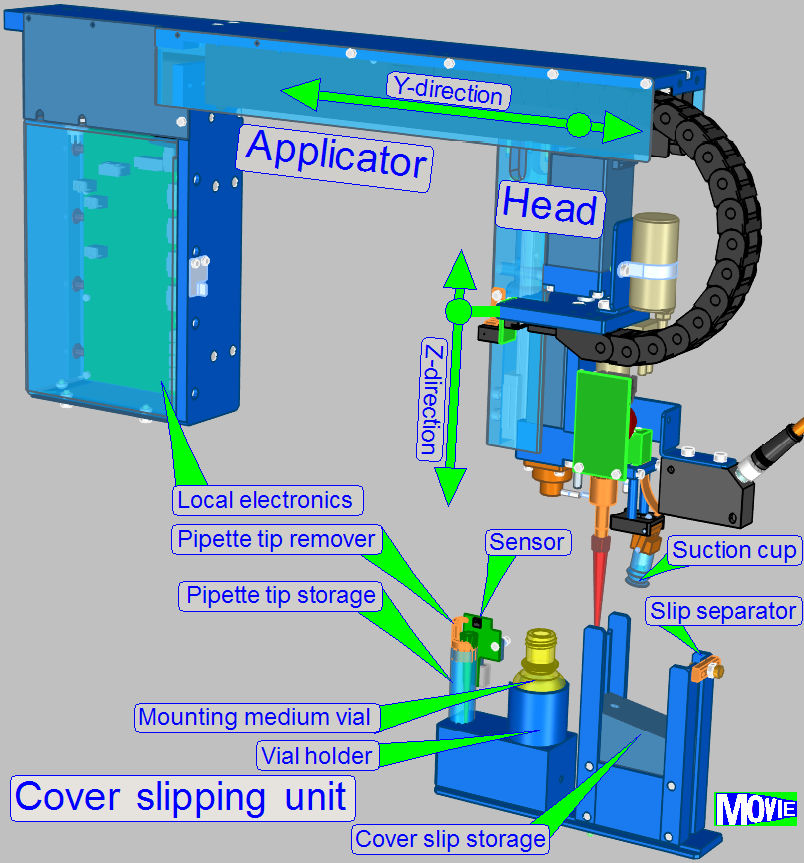

- Cover slipping unit

The Lumencor SPECTRA Light Engine is an external light source that

illuminates the field of view at fluorescent scanning procedure. It is connected

to the iSaCS through the left side service door of the equipment with a light

cable. The Lumencor has its own power cable through which it receives the

necessary power.

![]() Lumencor SPECTRA light

engine®

Lumencor SPECTRA light

engine®

Power

tower

The main electronics of the iSaCS are stored in the power tower. It is

located behind the scanner module in the equipment.

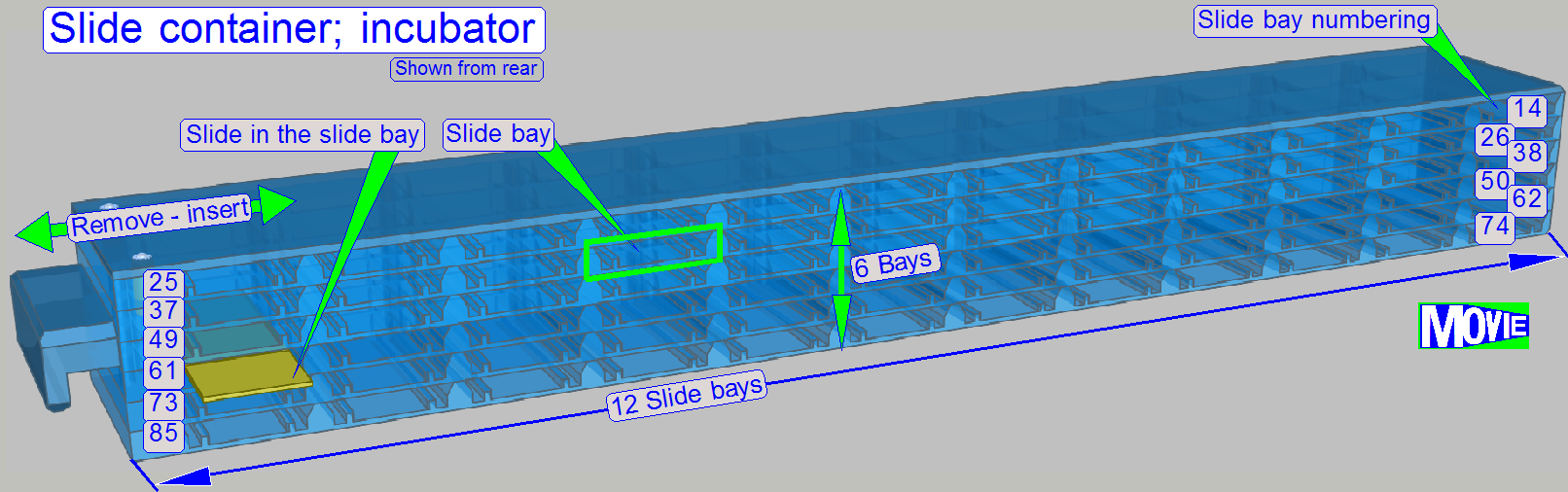

Slide storage

The user fills the

slide rack (incubator) with slides containing the specimen.

The user fills the

slide rack (incubator) with slides containing the specimen.

For this purpose, 72 (12x6) slide bays are arranged in the rack.

To fulfill the tasks, dedicated slide bays are defined; always in these

positions the named task will be executed; general purpose bays are used e.g.

for sorting tasks.

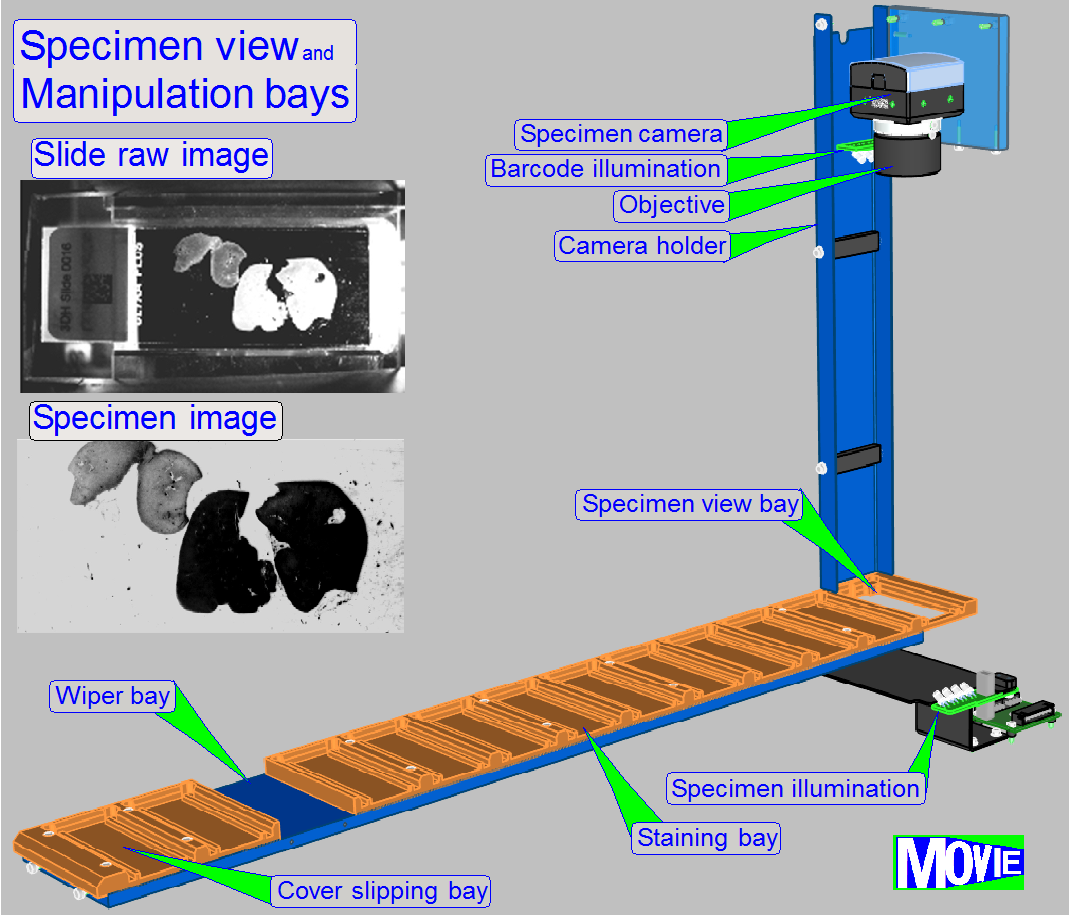

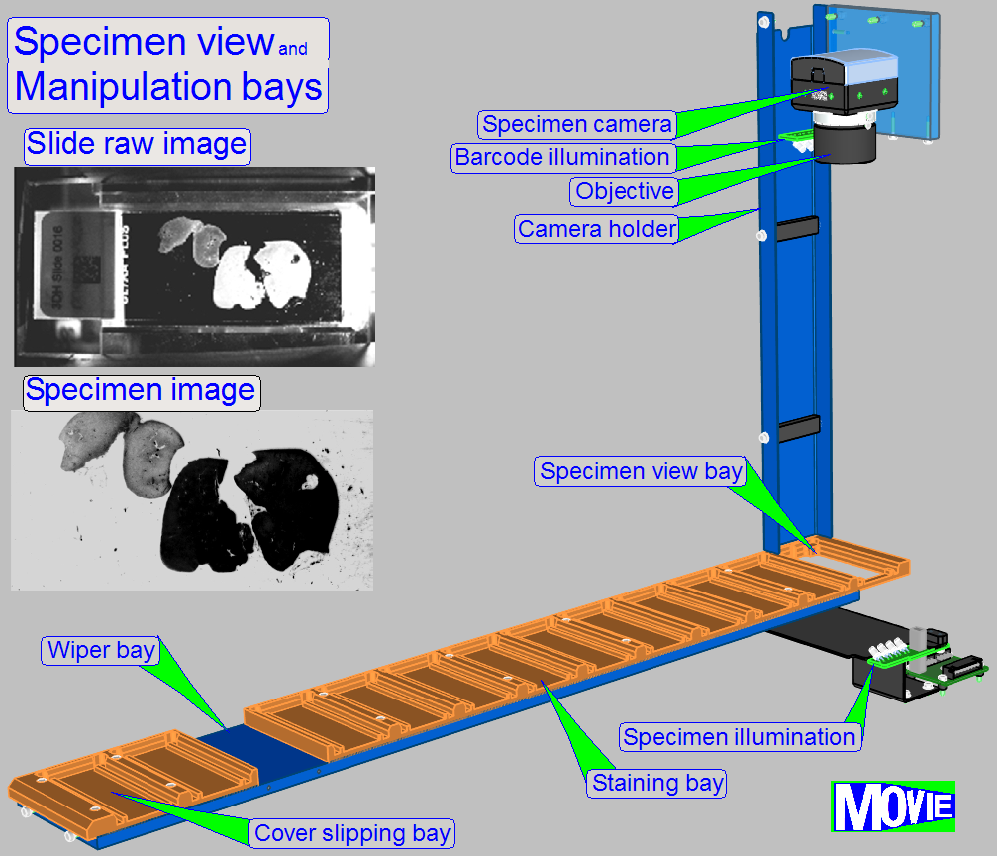

· 1= Specimen Image; barcode capturing

· 7= Reagent application

· 11= Air wiper

· 13= Cover slipping

12

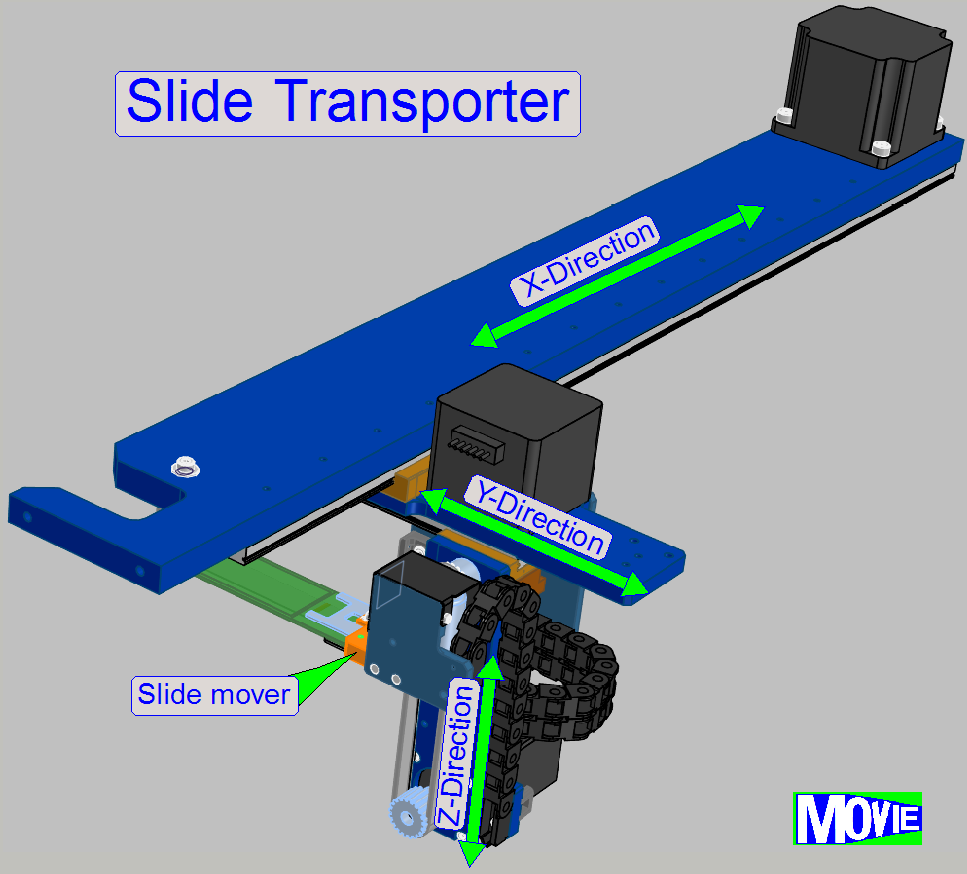

·

localization of tissue specimen on the slide

localization of tissue specimen on the slide

·

slide identification

through DataMatrix barcode label

· special

illumination for tissue specimen with low contrast

·

fast positioning (approx. 5 s) of slides anywhere inside the slide

storage and staining-cover-slipping unit

· dedicated motion

schemes for different movement types

The transporter moves the slide from the slide rack position to

- preview unit

- staining unit

- wash and

rinse chambers

- Air wiper

position

- cover

slipping unit

- any possible

position

- finally to

the slide scanner and return to its origin position

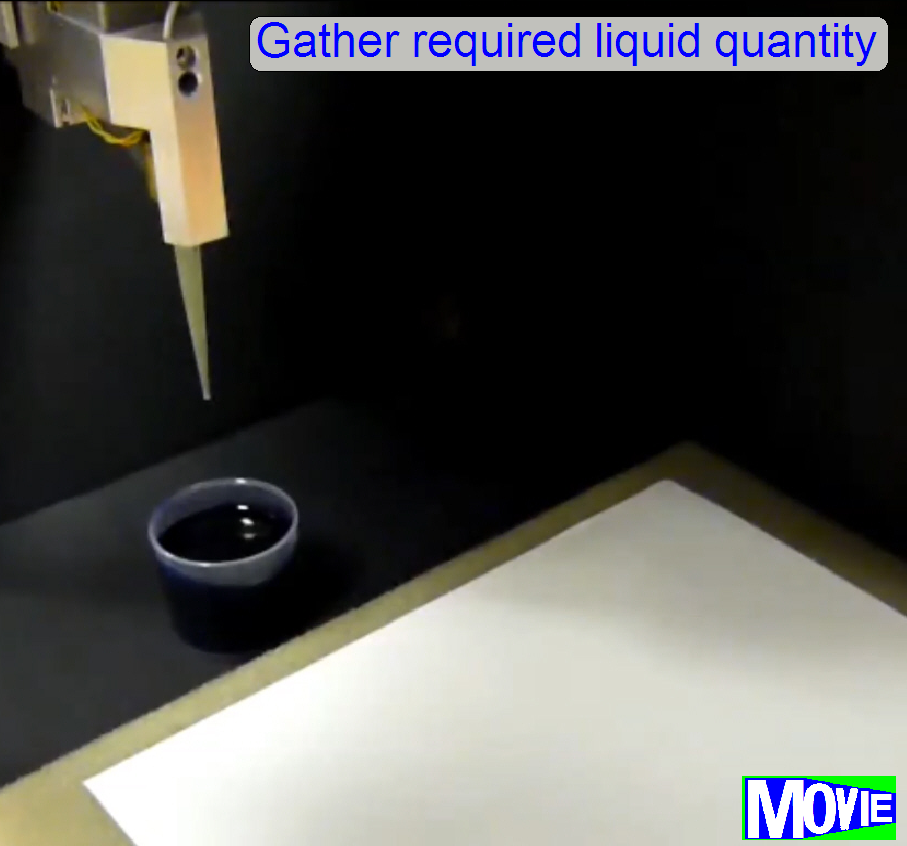

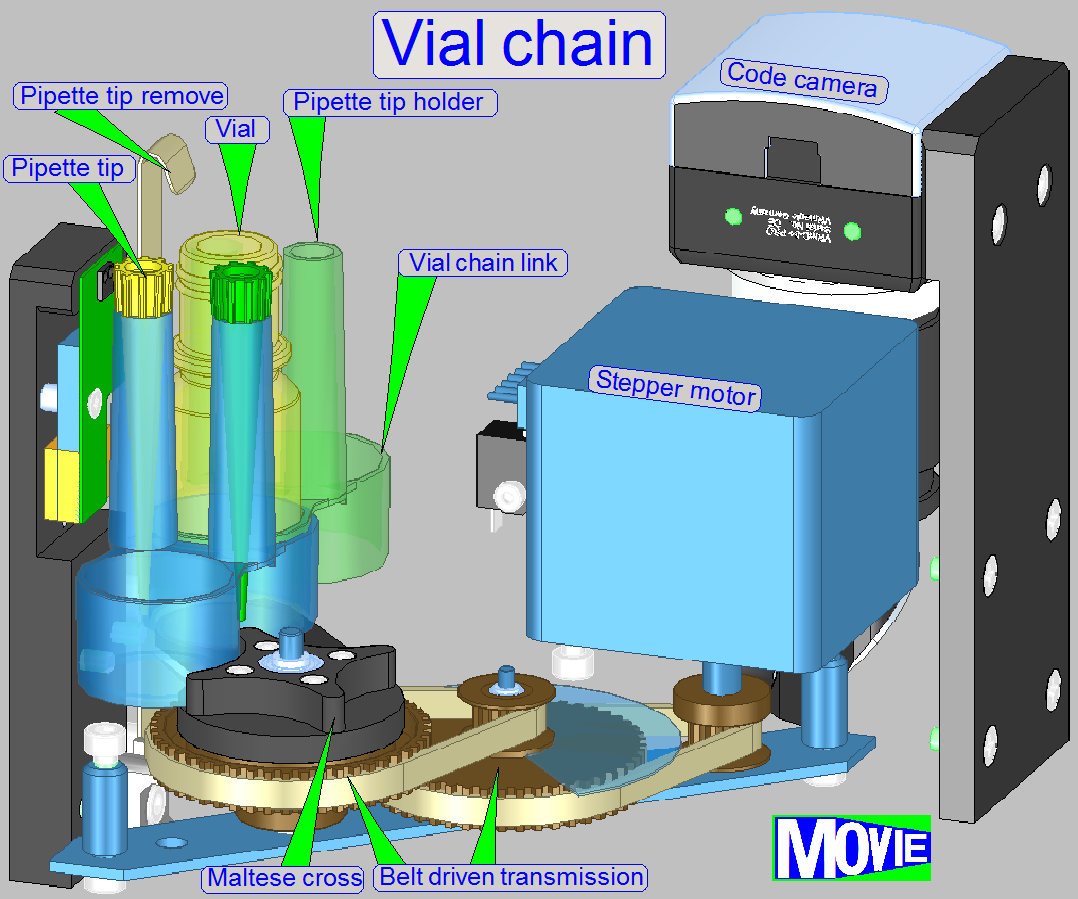

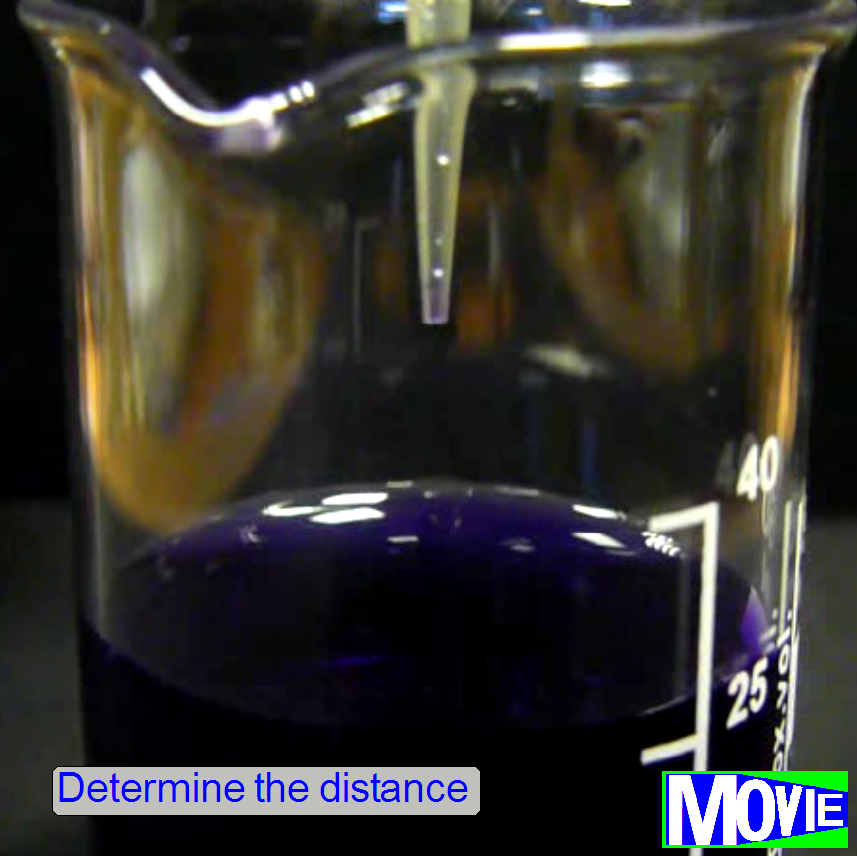

To determine the quantity of

required liquid exactly, an “acoustic fluid level detector” is implemented. The

distance of the liquid surface to the pipette tip has to be known. If the

distance is known exactly, the immersion depth of the pipette to gather the

required liquid quantity for the process can be calculated, because the

diameter of the vials is known.

To determine the quantity of

required liquid exactly, an “acoustic fluid level detector” is implemented. The

distance of the liquid surface to the pipette tip has to be known. If the

distance is known exactly, the immersion depth of the pipette to gather the

required liquid quantity for the process can be calculated, because the

diameter of the vials is known.

· The distance of

the liquid surface to the pipette tip is determined acoustically.

It is important to

gather the required quantity of the appropriate liquid very precise. At the end of the fluid application process,

the pipette has to be empty! If the quantity of fluid in the pipette is too

less, the process result becomes poor, otherwise, if fluid remains in the

pipette, the level in the pipette will increase more and more and a waste of

(often very expensive) fluid occurs. Furthermore, if the lfluid will dry in the

pipette, waste process results are produced.

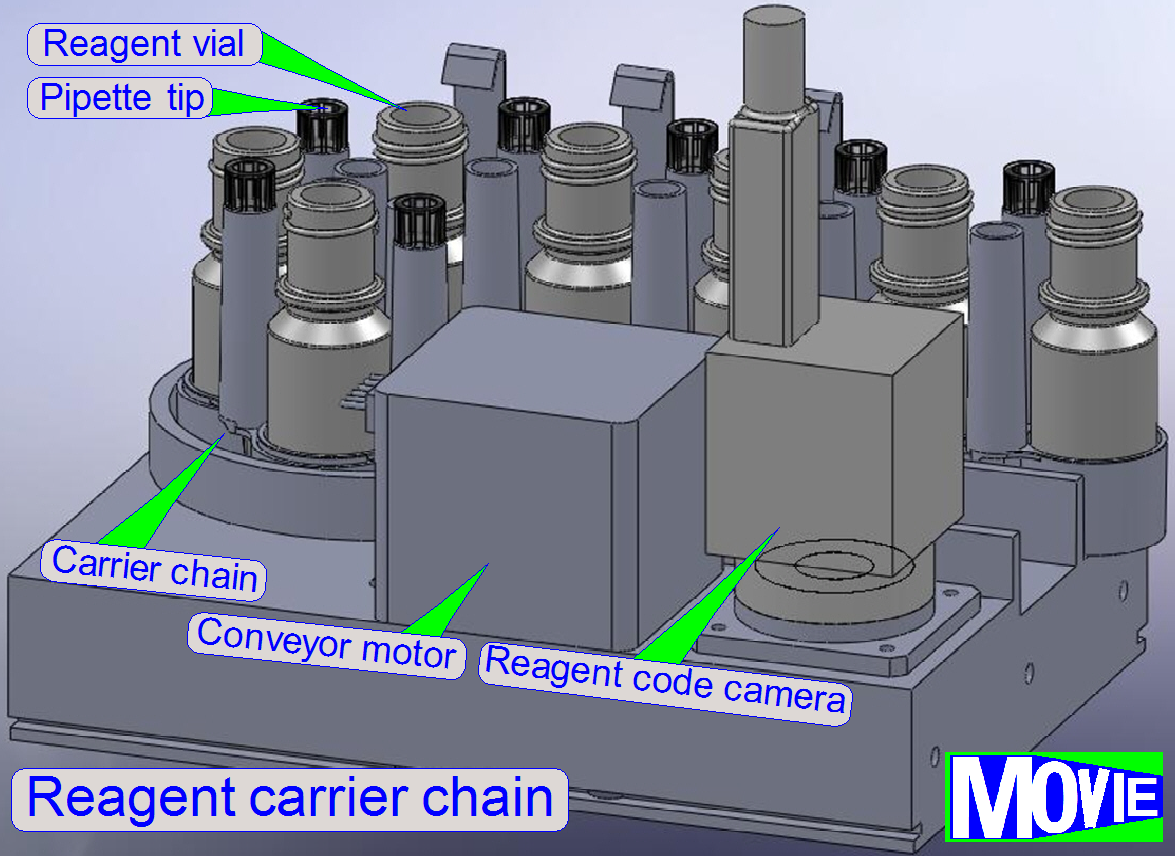

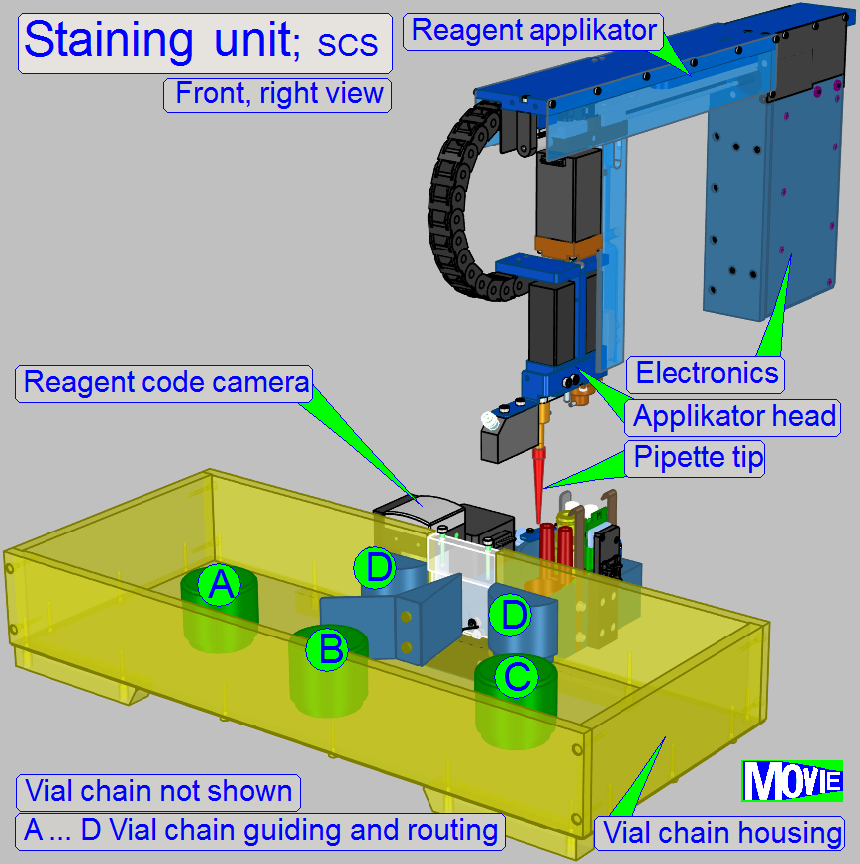

·

freely variable number (up to 40

pcs.) of 8 ml reagent vials

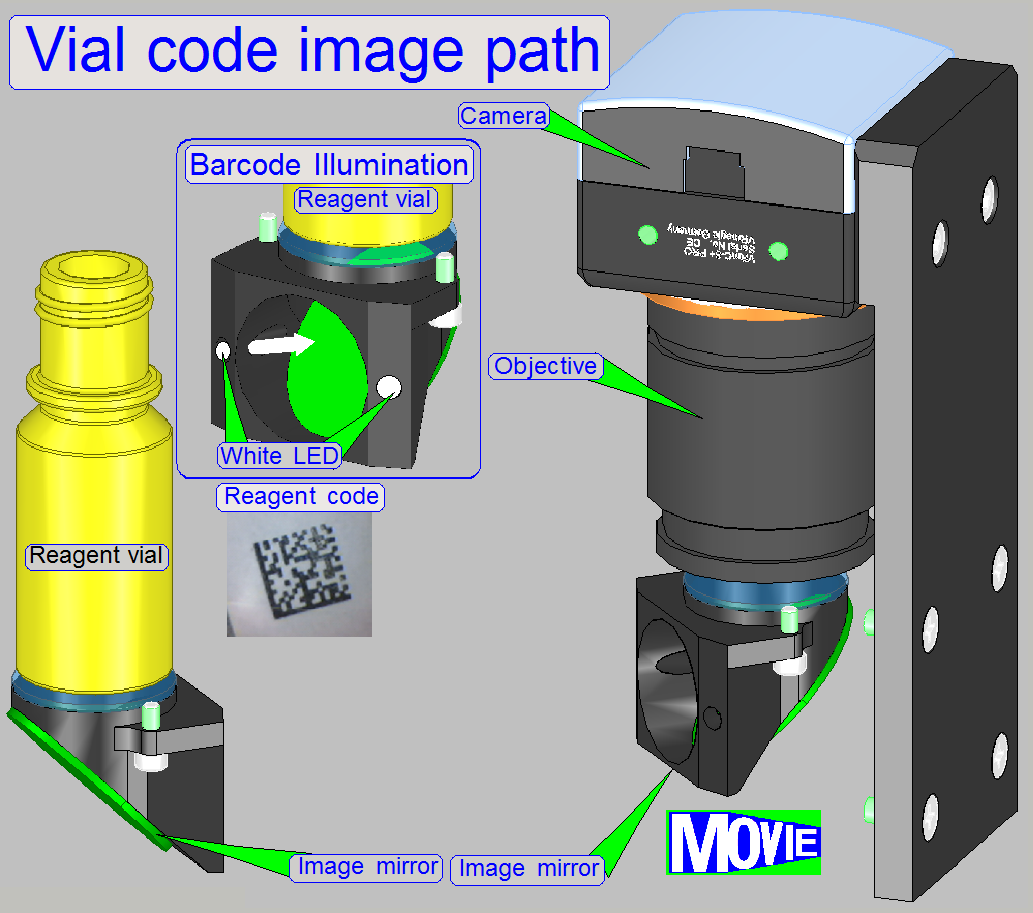

· vial identification

through barcode Data Matrix labels

·

disposable

pipette tips (200 μl) dedicated to each reagent

·

reagent

level measurement with 100 μl precision

·

reagent

dispensing along any arbitrary trajectory

· precise covering of the specimen surface

exclusively, using the lowest possible amount of reagent

·

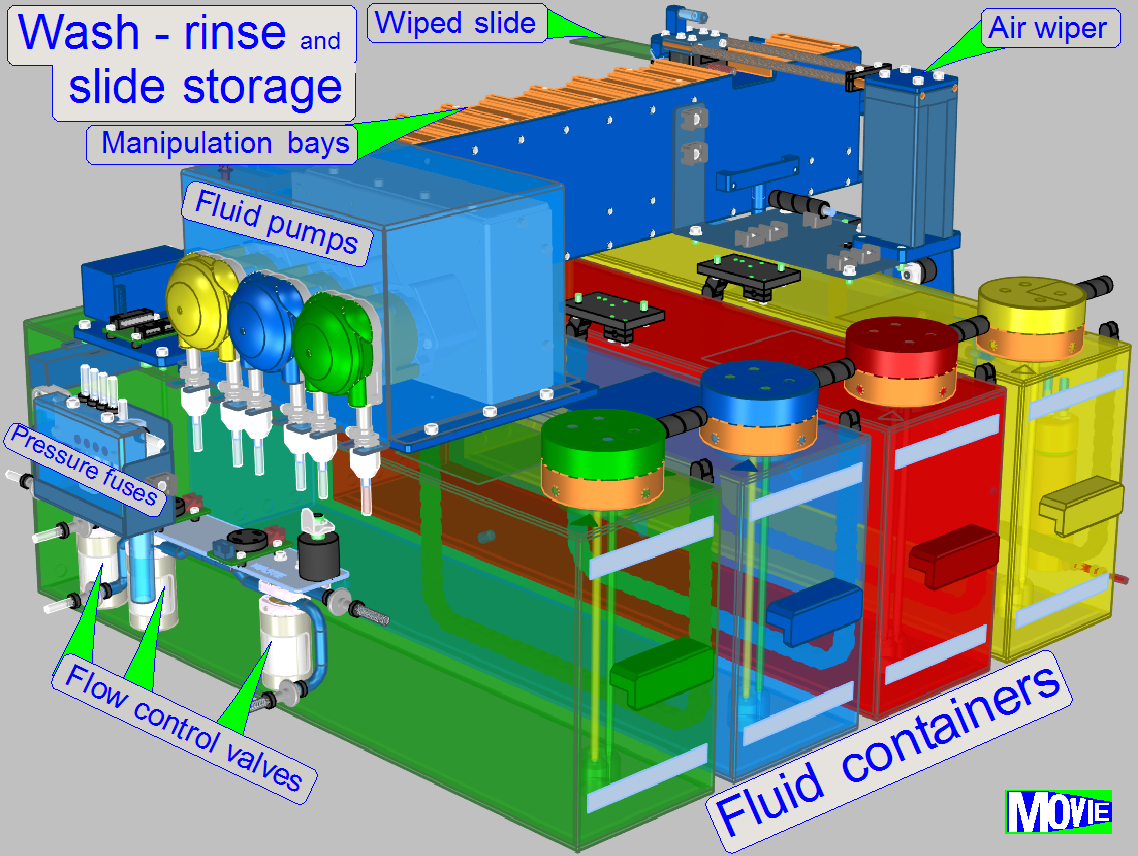

Washing and rinsing is done by the help of dedicated peristaltic pumps

for distilled water, wash buffer and fluid waste.

· bubble detection

in the tubing, priming of pumps with opto-tube sensors

·

simultaneous

use of multiple wash-and-rinse chambers possible, capacity: 12 slides

·

precisely

controlled flooding and draining of chambers, wash-and-rinse volume: 1-3 ml

·

residual fluid amount on slide surface: less than 10 μl

·

small volume of

single-slide incubation chambers minimizes evaporation

· incubation

chambers in compact, small footprint arrangement, capacity: 72 slides

·

control

of relative humidity and temperature

·

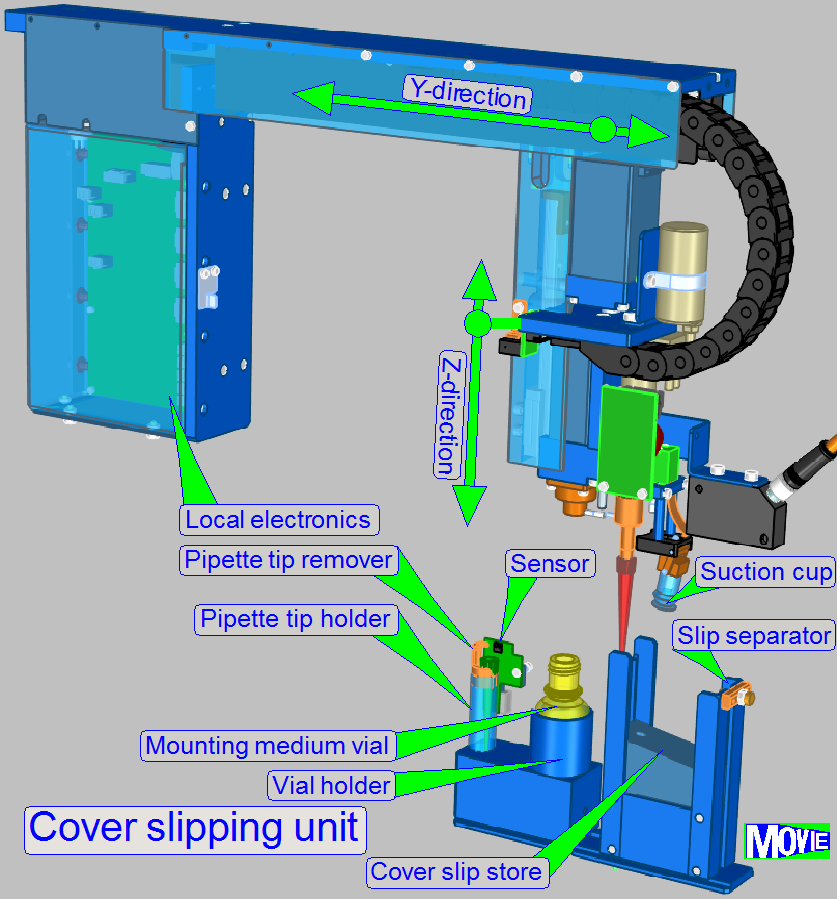

Conventional glass

cover slips of different sizes, capacity: 200

pcs.

· Verification of

the number of available cover slips with +/- 1 pc. precision

·

separation

of multiple adhered cover slips

·

aqueous

mounting medium, capacity: 10 ml

·

disposable

pipette tip (200 μl) for mounting medium

· mounting medium level measurement

with 100 μl precision

·

pick-and-place

cover slipping procedure using suction cup

·

pressure

monitoring in the vacuum system

·

controlled and precise placement of cover-slip onto

the sample

Workflow

The sample to be stained is placed on a glass

slide together with its barcode and this will be inserted into the iSaCS.

Allowed slide dimensions are defined as:

Length: 75.00

to 76.00 mm

Width: 25.00

to 26.00 mm

Thickness: 00.95

to 01.05 mm

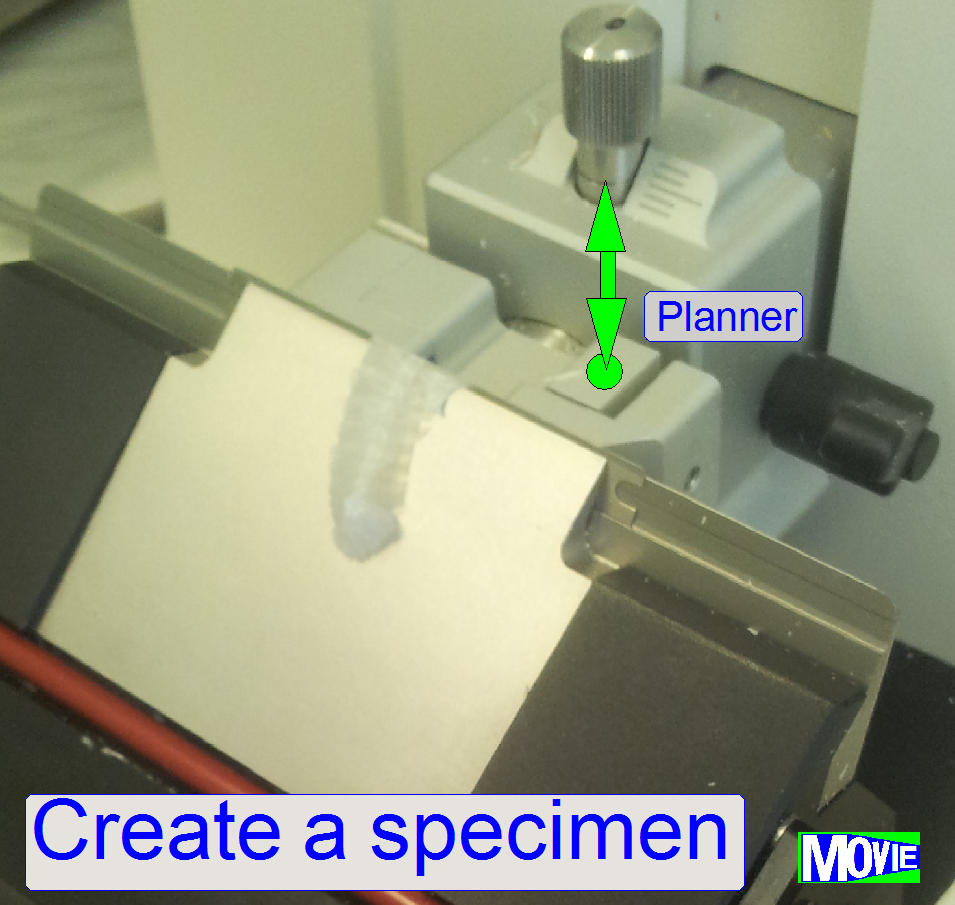

Specimen (sample)

creation process

This process is done to create the specimen and

finally, it will be placed onto the glass slide

·

The creation of the specimen is done before the slide

will be inserted into the slide rack of the iSaSC.

More, detailed information about the sample

creation process can be found in

Introduction

to specimen preparation and

An

animated guide to immunohistochemistry (IHS)

Place slides

The user can fill slides in any bay of the slide

rack; a special sequence is not required.

·

Insert the slide

container

While the process starts, the slide mover senses

3 slide bays for the presence of the slide by using a special algorithm. If a

slide is found, this will be moved to the slide image unit.

If the image of the specimen (and barcode

capturing of the slide) is made, the slide will be returned to its origin place.

The unit makes an

image of the

·

slide’s scan area and the

·

Barcode area.

This way, the position and the size of the sample

is recognized and the staining procedure will be executed with the entire

tissue. On the other side, because the staining materials are very expensive,

redundant areas of the slide will not be coated with staining fluid.

The barcode of the specimen contains information

about the specimen creation process, dyes, staining and about the scan process

also; how to handle the specimen

The user can define the

· Number of

different dyes for the sample

· Type of each dye

and sequence

· quantity (area) of

the appropriate dye

· residence time of

the dye

After the

residence time of the appropriate dye is passed, the unnecessary dye will be removed

from the sample by washing and rinsing it and drying it up.

If the incubation time is over, the staining

with the next dye follows or, if the staining process is finished, the slide

moves to the cover slipping unit.

Before the reagent vial is placed into the vial

chain, the reagent code, containing the name, staining time and other process relevant

parameters has to be affixed onto the bottom of the vial.

The software, during the startup procedure reads

the code of each vial and stores process relevant information. Tis way, the

position in the chain is defined also.

Before the staining procedure starts, the

required vial is moved to the vial using position and the pipette tip immerges

into the reagent and gathers the required quantity.

The sample will be stained by dropping dye onto

it.

If the rinsing and wiping process of the

specimen is finished, the glass slip will cover the specimen.

With a pipette paraffin will be spend to cover

the specimen and by fitting the cover slip, the paraffin works as an adhesive

bonding mean.

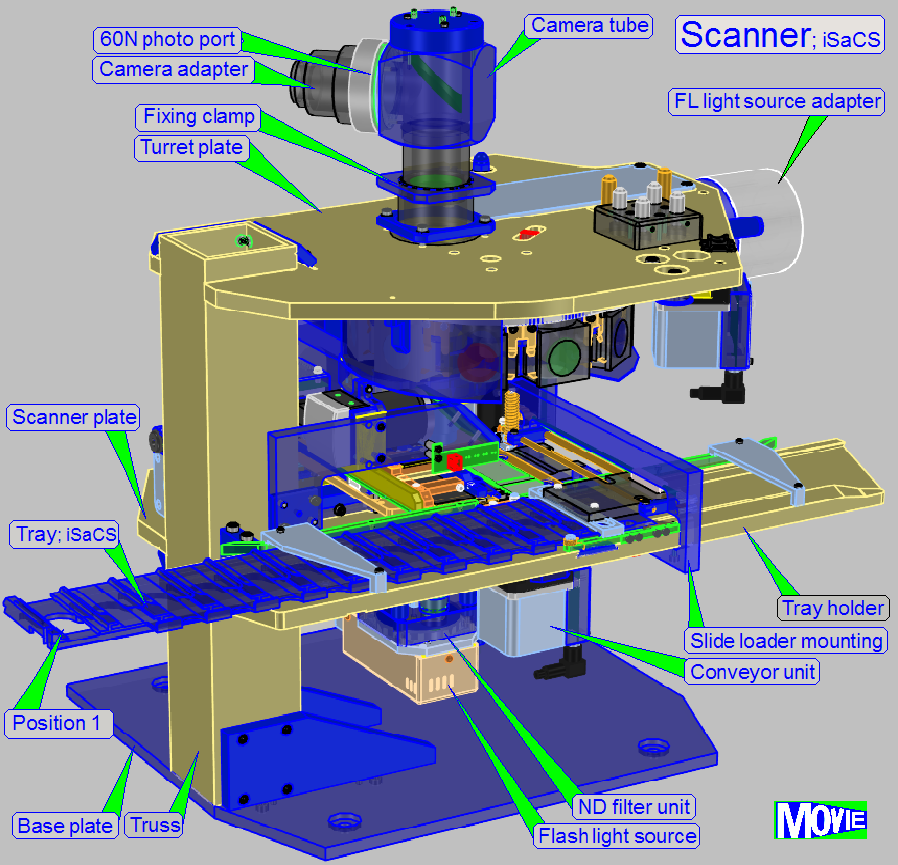

After the specimen

creation process the content of the slide will be scanned.

The scanning procedure in the 3DHISTECH iSaCS is

as follows:

· The slides are

inserted into the scanner and removed automatically via a slide holder tray.

· The slide bays in

the slide holder tray allowing an autonomic work of the scanner.

· Designed for

brightfield scan sessions and fluorescent scan sessions.

· The scanner part

is based on a modular

· An automatic scan

session is performed in 30 … 60 seconds for 1 specimen in BF scan mode.