Staining unit; iSaCS

For

technicians and partly for sales managers!

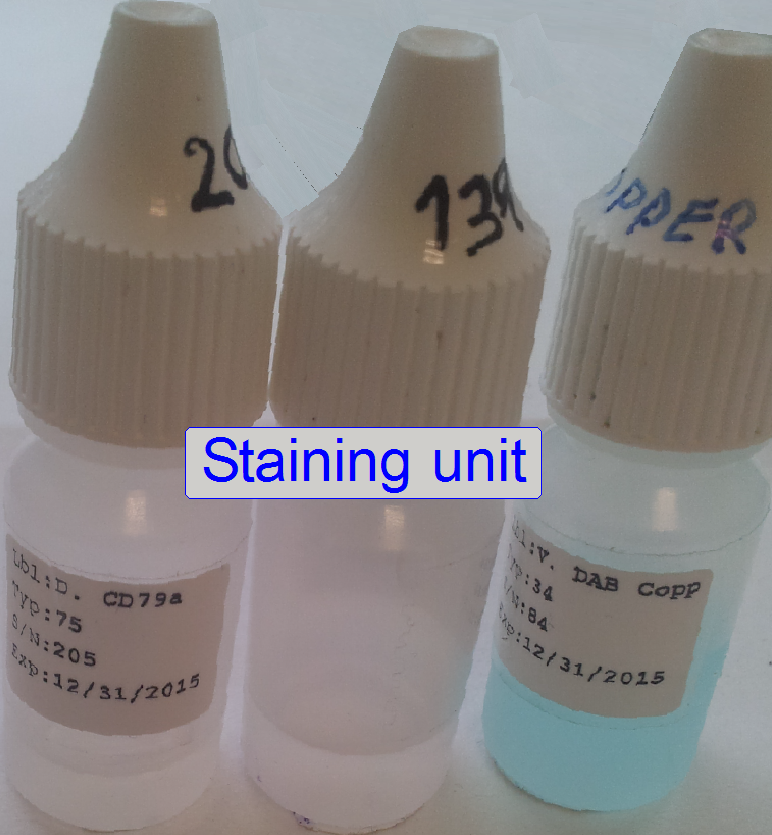

To stain a tissue automatically in the iSaCS, some

information is required. Because there are a lot of reagents in vials, the

identification of the vial (and so, the reagent) is required. Because the size

and the position of the tissue on the slide can vary and the reagents are often

very expensive, the required quantity of stain has to be calculated, and the

area of the specimen on the slide has to be known exactly. Furthermore, it is

important to know, how many reagents has to be used and for which tissues. All

this information is collected and handled by software and based on this

information, the staining process will be controlled.

To stain a tissue automatically in the iSaCS, some

information is required. Because there are a lot of reagents in vials, the

identification of the vial (and so, the reagent) is required. Because the size

and the position of the tissue on the slide can vary and the reagents are often

very expensive, the required quantity of stain has to be calculated, and the

area of the specimen on the slide has to be known exactly. Furthermore, it is

important to know, how many reagents has to be used and for which tissues. All

this information is collected and handled by software and based on this

information, the staining process will be controlled.

Overview

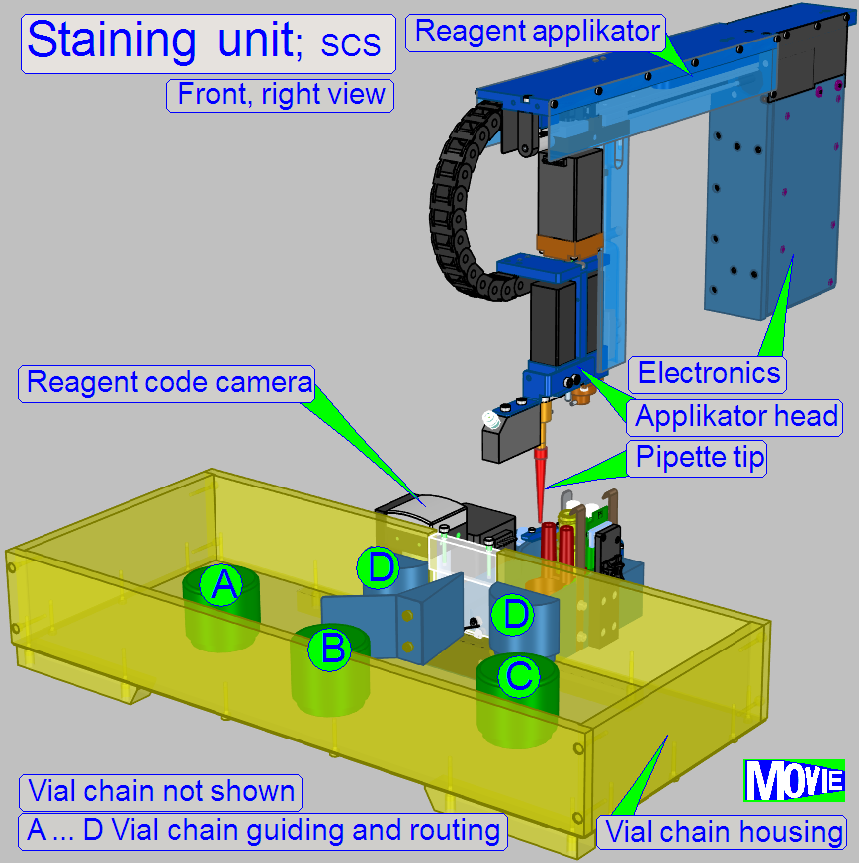

The

staining unit can be divided into three main parts.

The

staining unit can be divided into three main parts.

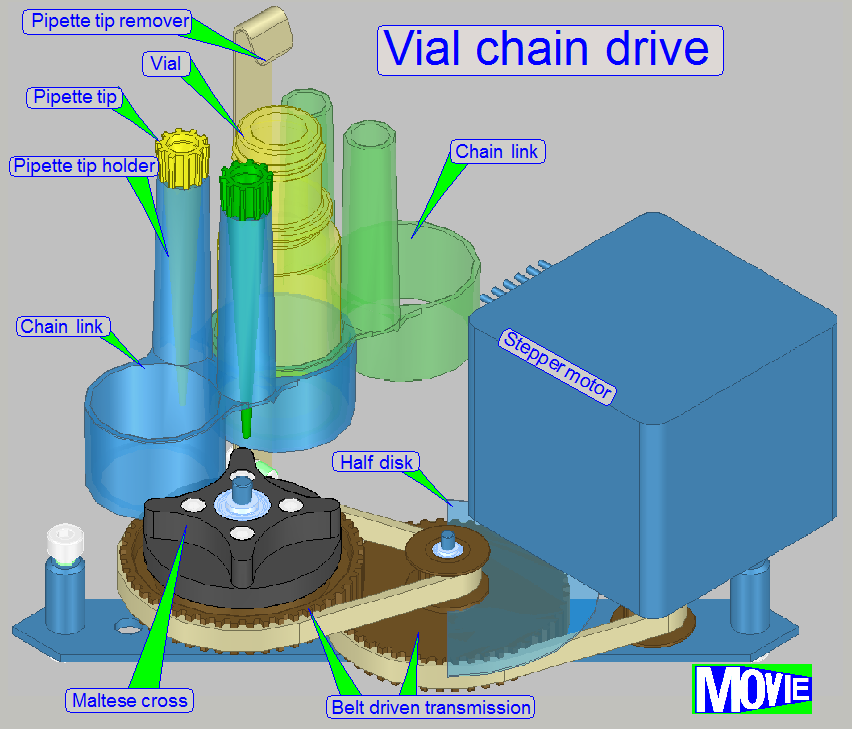

· Vial moving and selection

A stepper motor

driven transmission rotates a Maltese cross. The Maltese cross moves the vial

chain.

· Vial barcode capturing and

To select the required

stain (vial) the position of the vial in the chain is required. Assigning the

stain to the position in the vial chain is performed via the vial’s barcode and

software.

· Application of the stain (reagent)

By filling the

appropriate pipette tip with the assigned reagent and moving it over the sample

area, stain will be applied onto the specimen area.

Reagent vials are inserted into the vial chain manually

when the whole equipment is shut off.

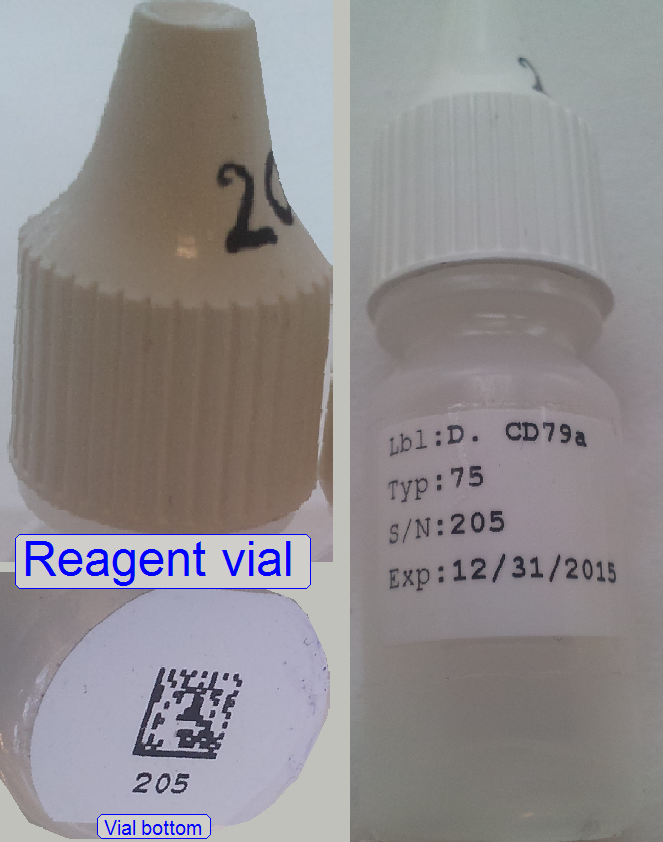

Every vial has a matrix code on the bottom to identify

the actual vial.

The code includes name, quantity, expiry date and

other information.

· Required

parameters and values are collected in the process control table.

For basics about fluorescent scan techniques, staining, fluorophores and

others

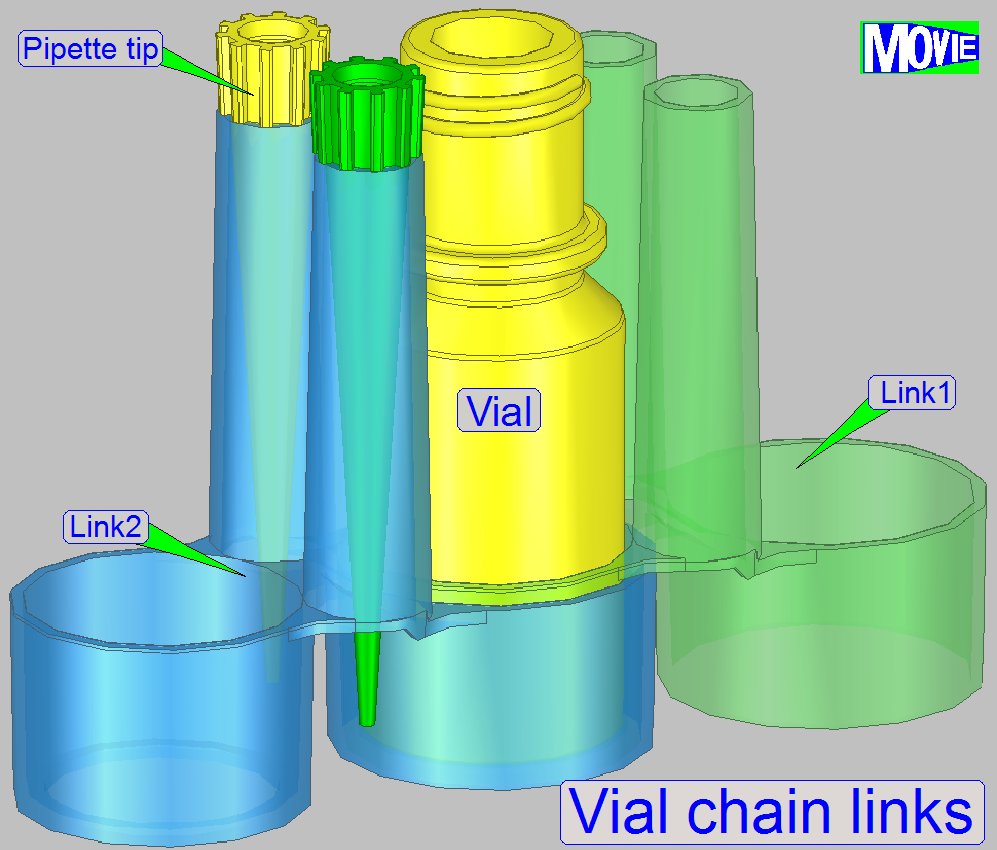

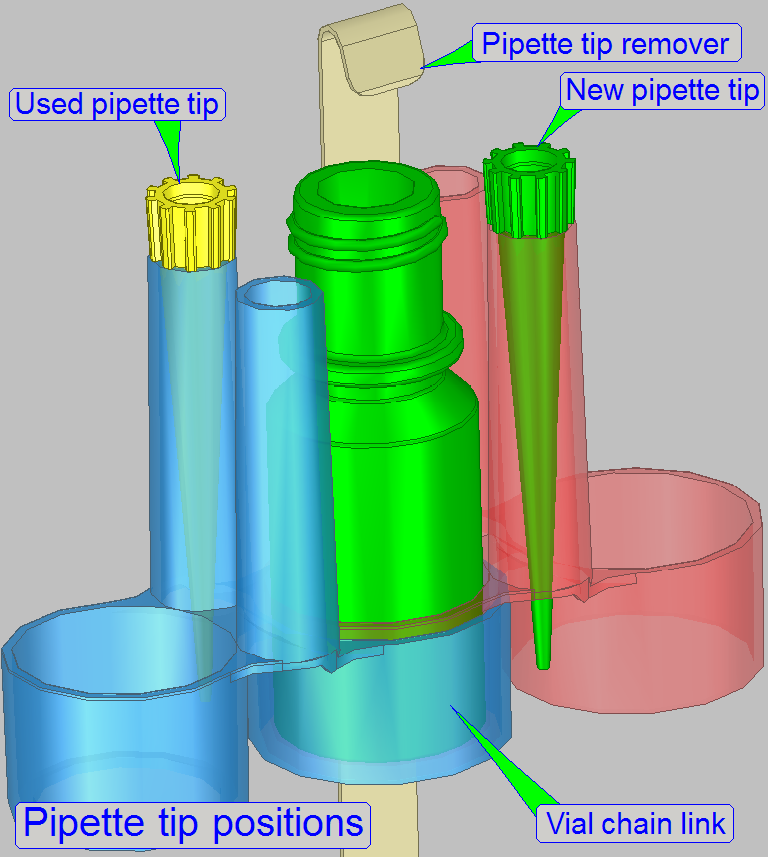

A chain link contains two pipette tip holder and two vial

acceptor shapes, different in diameters; so shapes of two vial acceptors are

fitting each other.

Pipette

tip

The system is able to differentiate between 2 pipette tips;

the used pipette tip and the new pipette tip.

The system is able to differentiate between 2 pipette tips;

the used pipette tip and the new pipette tip.

If the reagent vial was exchanged with a new vial of

the same reagent or by a different reagent vial, the pipette has to be placed

into the position of the “New pipette tip” as shown.

· The

pipette tip acceptor takes the tip at first time from this position.

· After

the stain applying process is finished, the pipette tip will be stored in the

position ‘Used pipette tip’.

By

implementing of links into the vial chain, the number of available reagent

vials may be increased.

By

implementing of links into the vial chain, the number of available reagent

vials may be increased.

· Maximal

number of vials in the chain: 40

By dismounting of chain links from the vial chain, the

number of available reagent vials may be decreased.

· Minimal

number of vials in the chain: 17

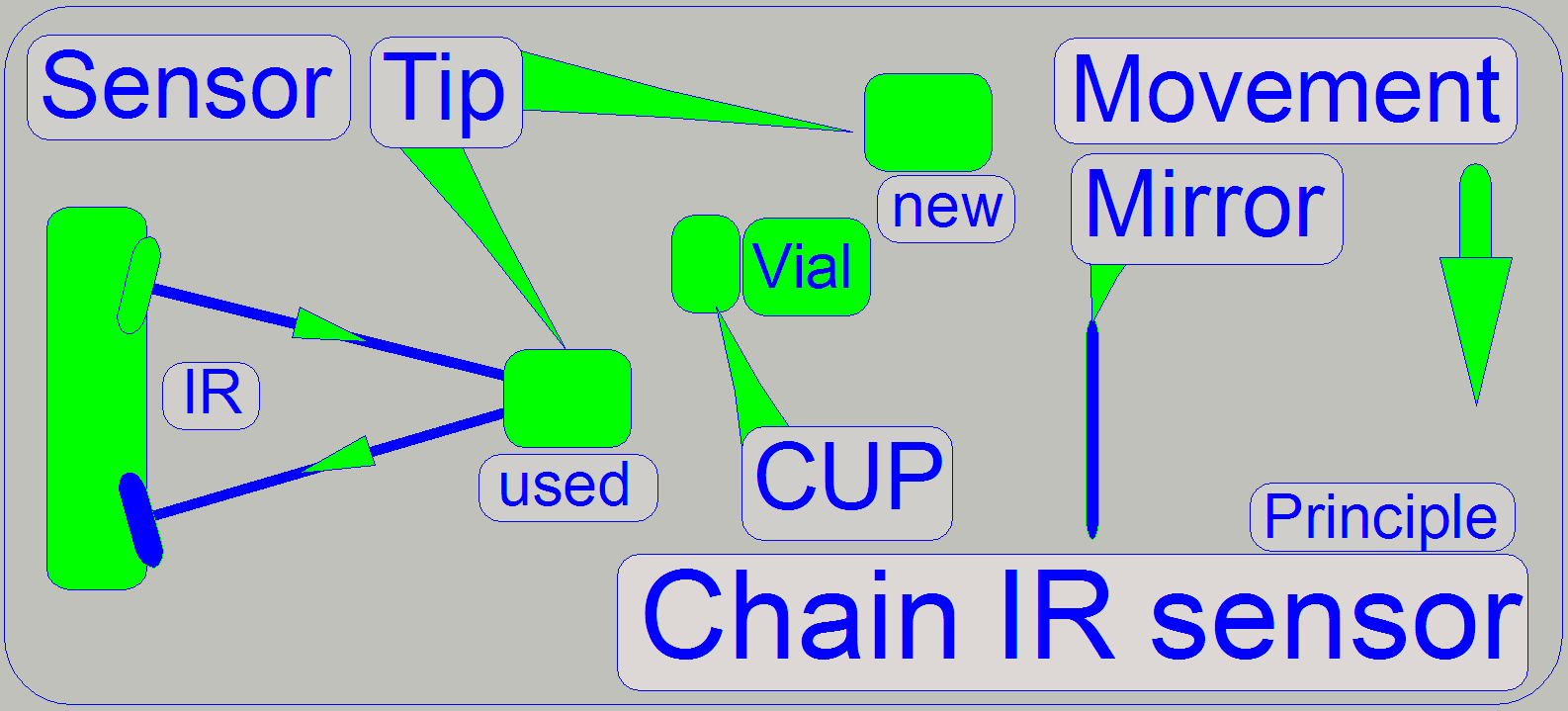

Sensor

The IR-sensor

beside the pipette tip is used to detect

· Presence

of a used pipette tip

· Presence

of a new pipette tip

· Presence

of the vial cup

· Presence

of the vial

The components are moving in front of the sensor. The

IR beam of the sensor will be reflected on the components with different

intensity, depending on the distance between the particular component and the

sensor. By calibrating expected distances, the presence of expected parts can

be distinguished.

As the vial chain moves, the different components pass

the sensor. The nearest passing component is the used pipette tip, then the

vial (with or without cap) and the farthest is the new pipette tip.

If any component is not present, the mirror is used to

reflect the IR beam and so the software knows in conjunction with the position

of the vial chain, which component is missed.

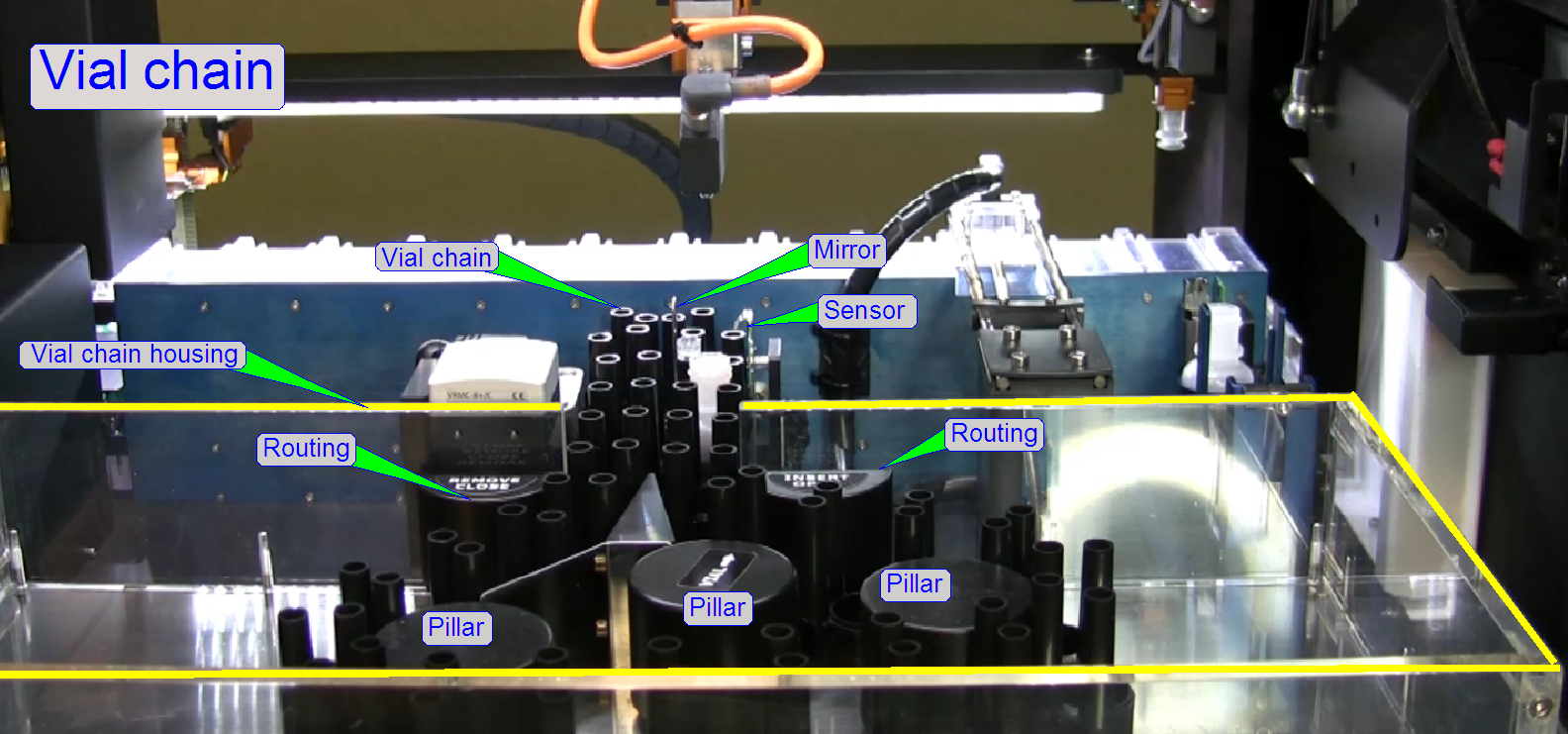

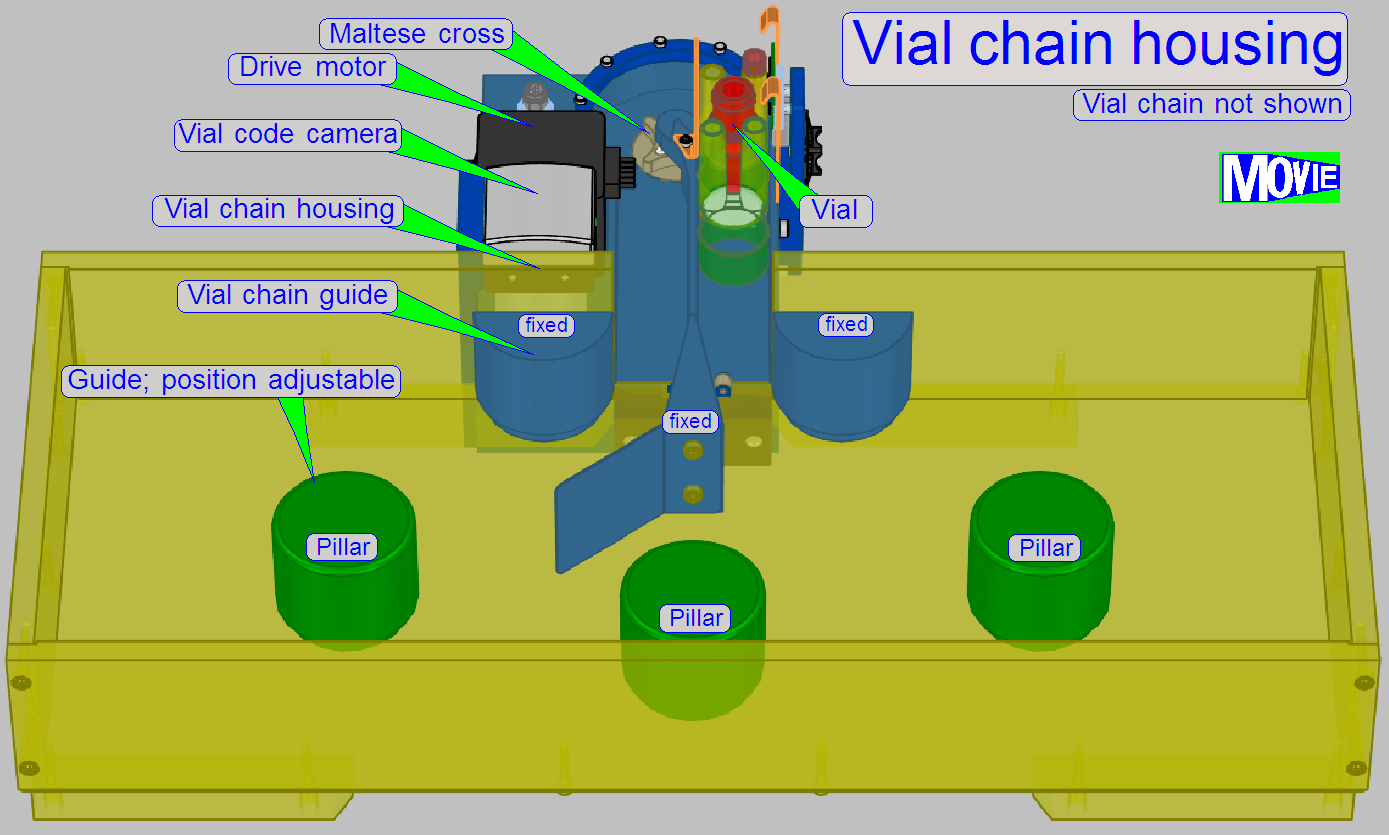

Vial

chain housing

The housing covers the vial chain and protects

the reagents from dust.

The housing covers the vial chain and protects

the reagents from dust.

· In the

housing, the vial chain will be routed.

To increase or decrease the number of links in the

chain three position-able vial chain guide pillars are situated. By adjusting

their position, a smooth movement of the chain links can be reached.

The

stepper motor drives a belt driven transmission

The

stepper motor drives a belt driven transmission

· On

the first transmission wheel the “Half disc” for home detection is mounted.

· On the

second transmission wheel the Maltese cross is mounted.

· By moving

the stepper motor's rotor a defined number of steps, the vial is changed by

exactly 1 position

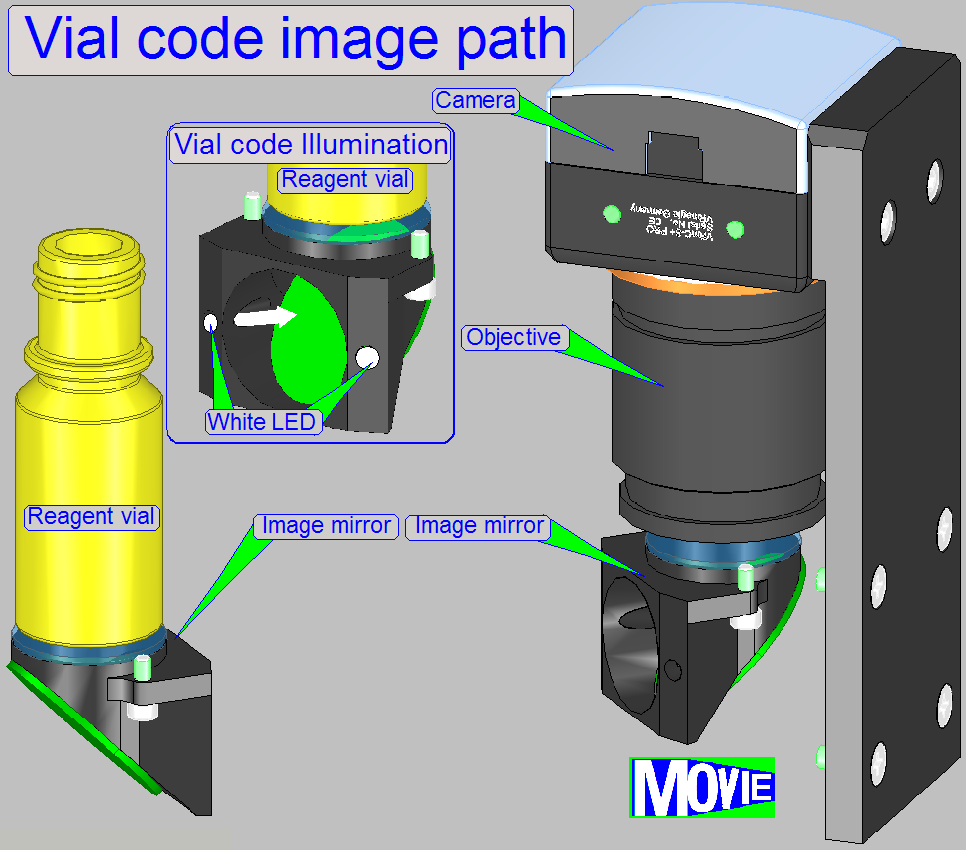

Vial

code capturing

Main components are

· Barcode

on vial’s bottom

· Illumination

of the vial’s bottom

· Mirrors,

to reflect the image path to the objective

· Objective

· Camera

By illuminating the vial’s bottom by 2 white LEDs the

code of the vial is visible.

· If the

correct vial position is reached, the camera makes an image of the vial bottom;

the image is send to the barcode analyzing software.

The barcode is used to find the vials position inside

the chain and to identify the reagent, so the reagent’s parameters are known.

· The

sequence of the vials in the chain is stored in the vials chain table.

Reagent code camera

The camera makes an image of the vial’s bottom

The camera makes an image of the vial’s bottom

· By

analyzing the barcode, the reagent name and it’s parameters are known

· The position

of the reagent in sequence inside the chain is recognized and an item in the

reagent position table is updated.

Reagent code objective

·

Tamron M118FM25 (for vial

barcode)

The barcode view objective is a Tamron M118FM25 Megapixel Fixed-focal

Industrial Lens (25mm).

·

Delivers optimum performance in the center and in the

edges

·

Anti-vibration construction

Specifications

|

Tamron M118FM25 |

|

|

Parameter |

Value |

|

Imager Size |

1/1.8" |

|

|

C |

|

Focal Length |

25mm |

|

Aperture |

1.6-16 |

|

Angle of View (HxV) |

1/1.8":

16.6 x 12.5° |

|

1/2":

14.6 x 11° |

|

|

1/3":

11 x 8.2° |

|

|

Distortion |

TV

Distortion: Less than -0.2% |

|

Minimum Object Distance (M.O.D.) |

0.1m ~ ∞

|

|

Focus Operation |

Manual

with lock |

|

Iris Operation |

Manual

with lock |

|

Filter Size |

M25.5

P=0.5mm |

|

Back Focus |

(in air) |

|

Operating Temperature |

14 - |

|

Dimensions (Diam. x L) |

1.1 x

1.4" (29 x 24mm) |

|

Weight |

|

|

Suitable for |

FA

(Factory Automation) and Machine

Vision application |

|

Immersion depth |

4.6mm |

|

Resolution |

2.23 MPix |

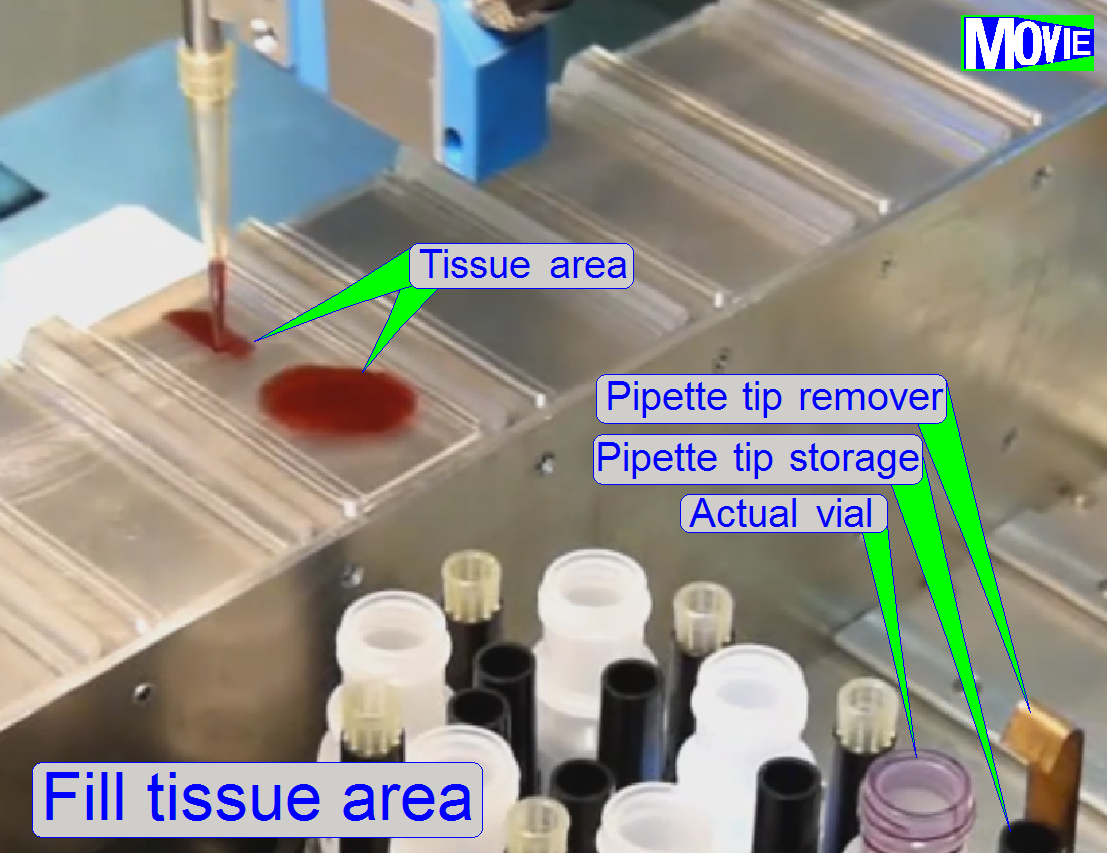

Introduction

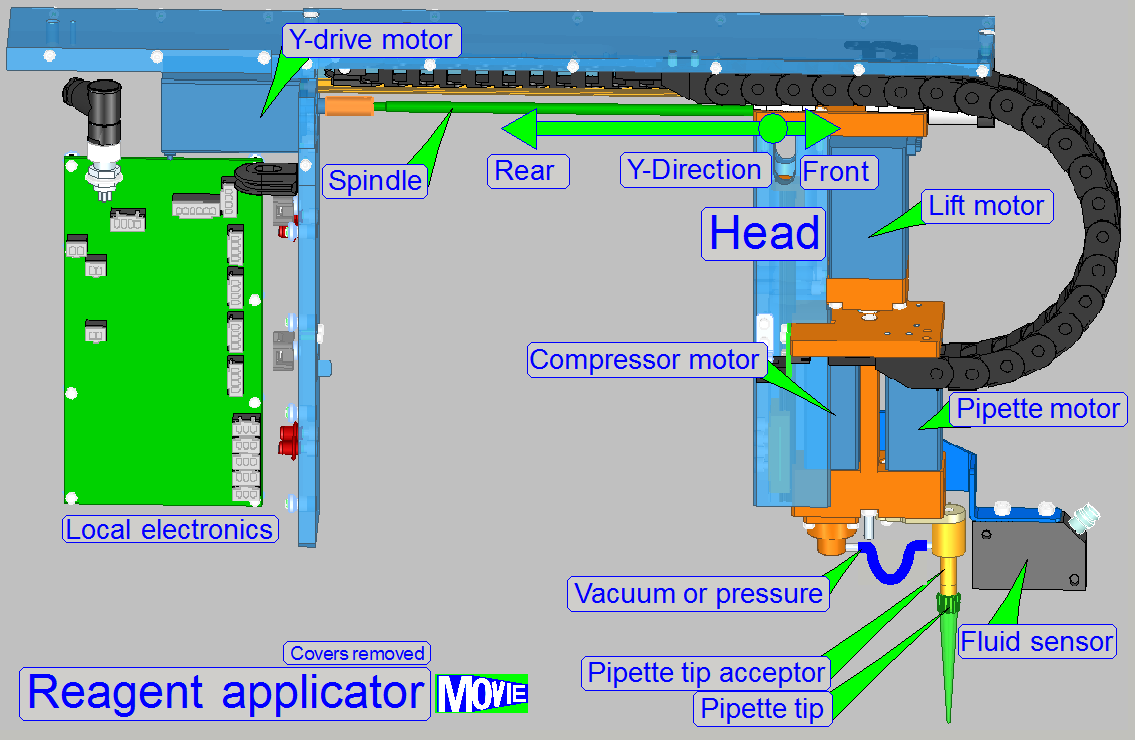

In reality, the real reagent applicator is the pipette

tip itself.

The unit, named as “Reagent applicator” is used to

control the pipette tip’s movement and actions.

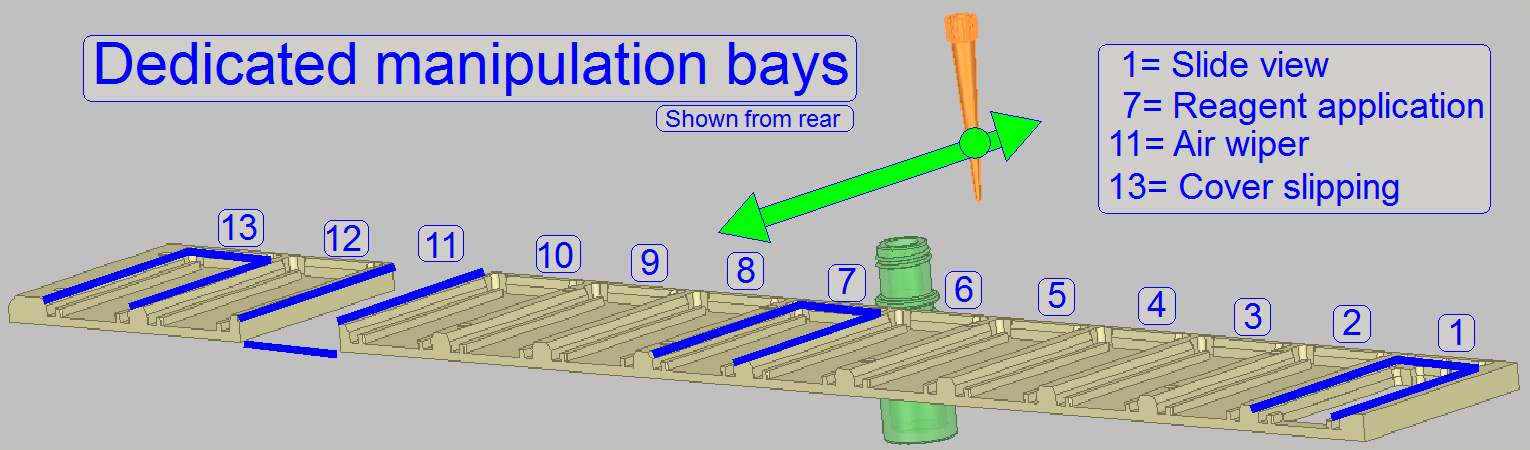

We assume,

the slide is already placed in the manipulation bay 7

We assume,

the slide is already placed in the manipulation bay 7

The quantity of reagent for the tissue is known

Pipette tip actions in sequence

· Move the

pipette tip acceptor to the pipette tip store position and take the pipette

tip.

· Move

the pipette tip over the actual reagent vial.

· Define

the immersing deepness of the pipette tip, depending on the required quantity

of reagent.

· Insert

the pipette tip into the vial.

· Filling

the pipette tip with the required quantity of reagent; create a defined vacuum.

· Move

the pipette tip out of the vial.

· Move

the pipette tip over the manipulation bay 7.

· Move

the pipette tip to the start point of the tissue.

· Fill

the sample area with stain; hereby defined pressure will be created onto the

liquid in the pipette tip. The pipette tip moves on a meandering course.

· If the

slide contains several sample areas, each area will be filled separately.

· If the

sample fill process is finished, move the pipette tip to its storage position.

· Remove

the pipette tip and place it in its store

·  The dedicated application bay for staining is the bay 7.

The dedicated application bay for staining is the bay 7.

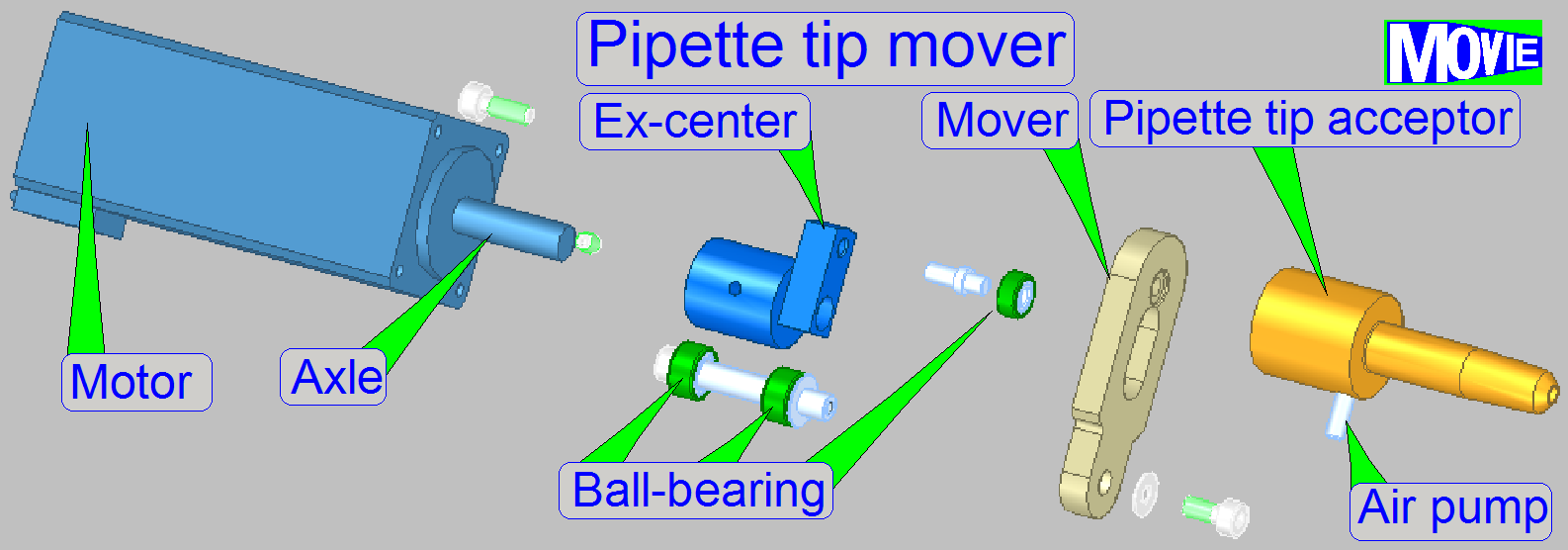

The movements of the pipette tip are executed with the

“Reagent applicator”

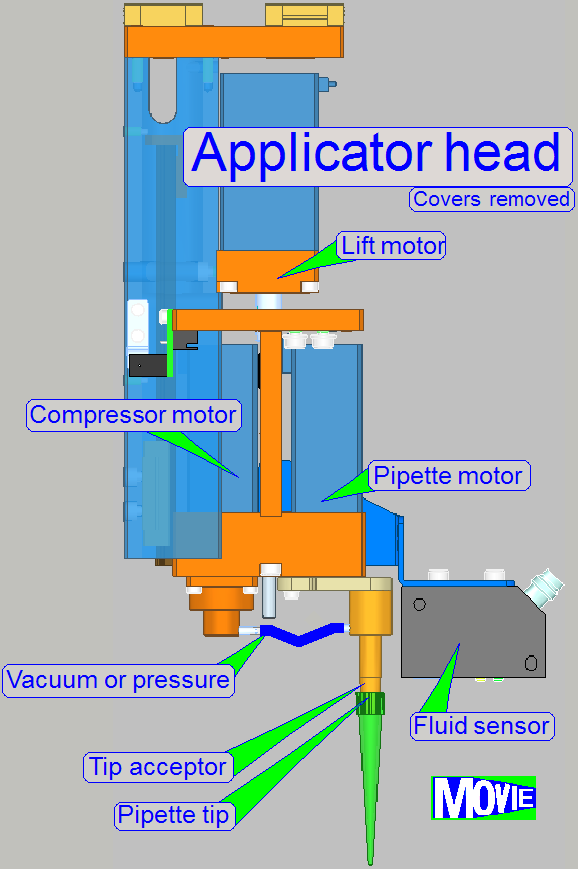

The applicator head controls the pipette tip; main

components are

· Lift

motor; the moveable part of the applicator head and so, the pipette tip, is

moved in Z-direction

· Pipette tip mover with tip acceptor;

moves the pipette tip on the width of the slide, in the X-direction.

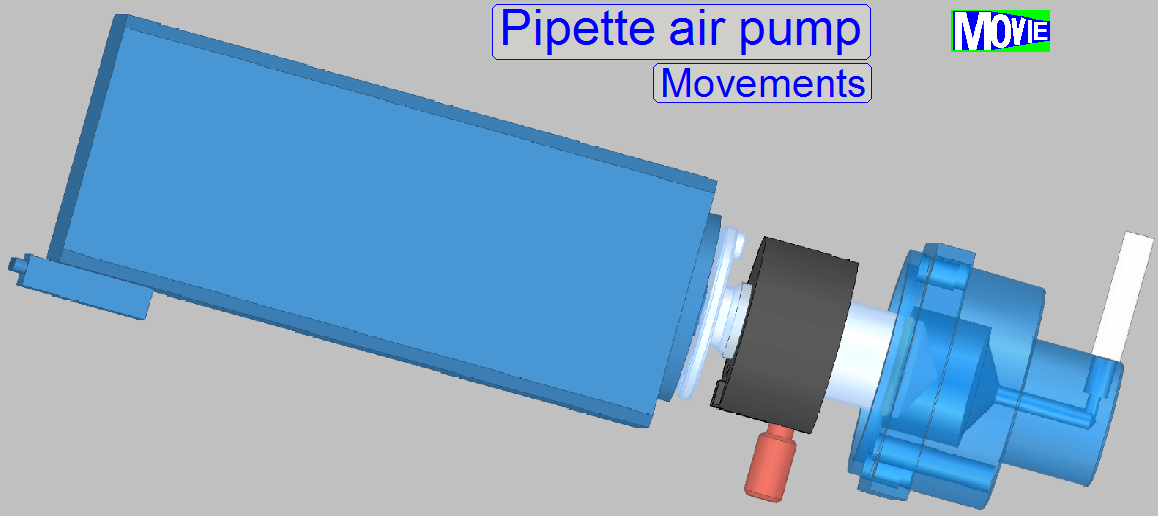

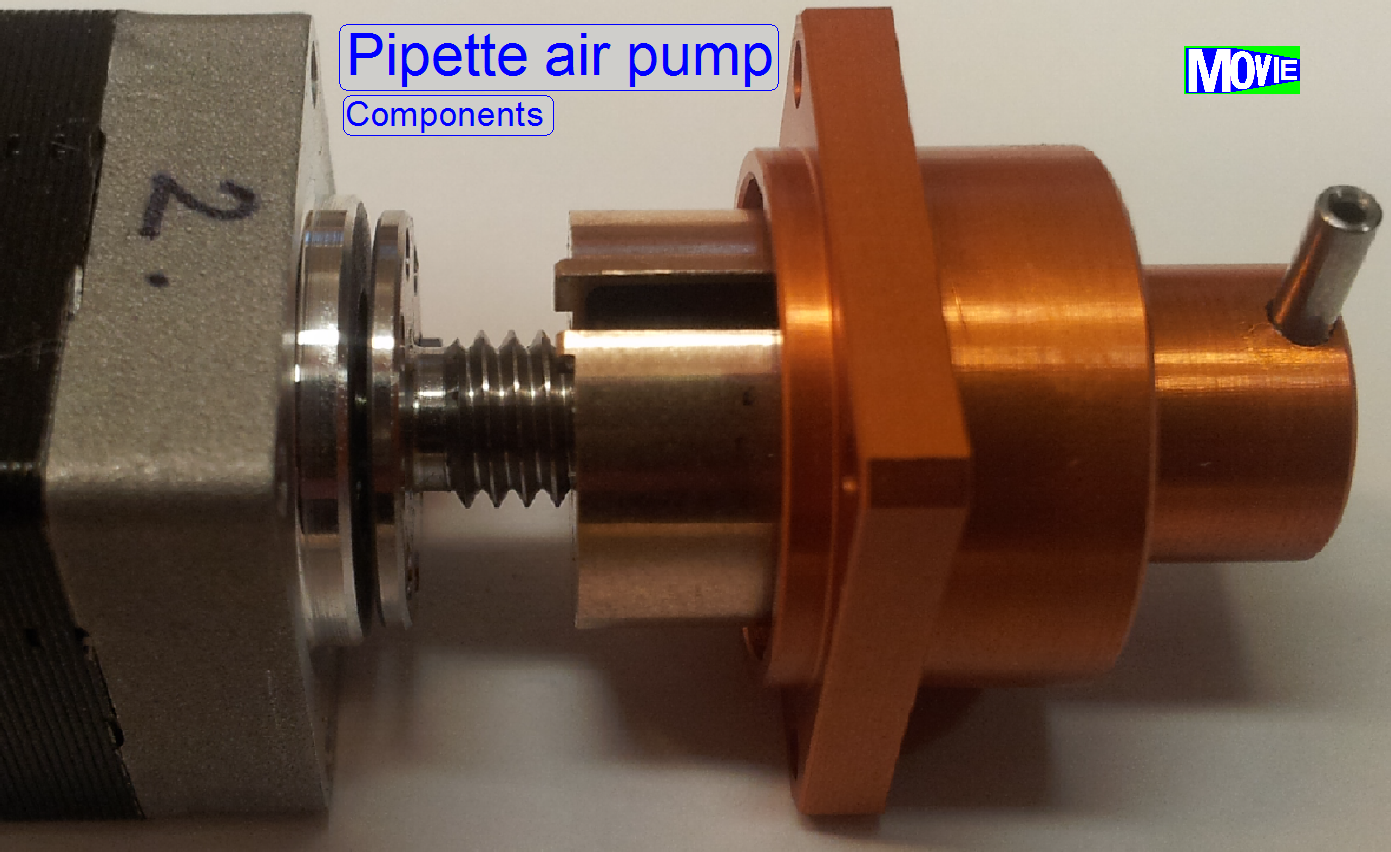

· Compressor

with motor; the ‘Air pump’

· Fluid

level sensor

· Pipette

tip; exchangeable

· The

air pump creates a defined vacuum to fill the pipette tip with reagent and

· Creates

a defined pressure onto the reagent in the pipette tip to apply the stain.

The

“Pipette tip mover“ executes the movement of the pipette tip in the

mathematical X-direction (the width of the slide; nominal 26mm).

The

“Pipette tip mover“ executes the movement of the pipette tip in the

mathematical X-direction (the width of the slide; nominal 26mm).

· The mover

reaches also the new and used tip storage position to accept and release the

pipette tip.