Cover slipping unit; iSaCS

For

technicians and partly for sales managers!

The cover slipping unit mounts the cover slip onto the

slide.

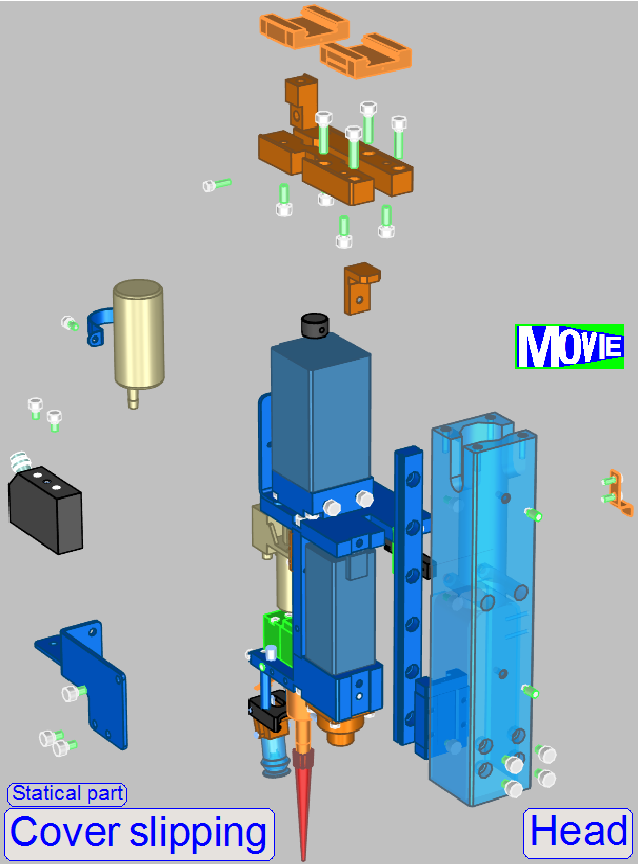

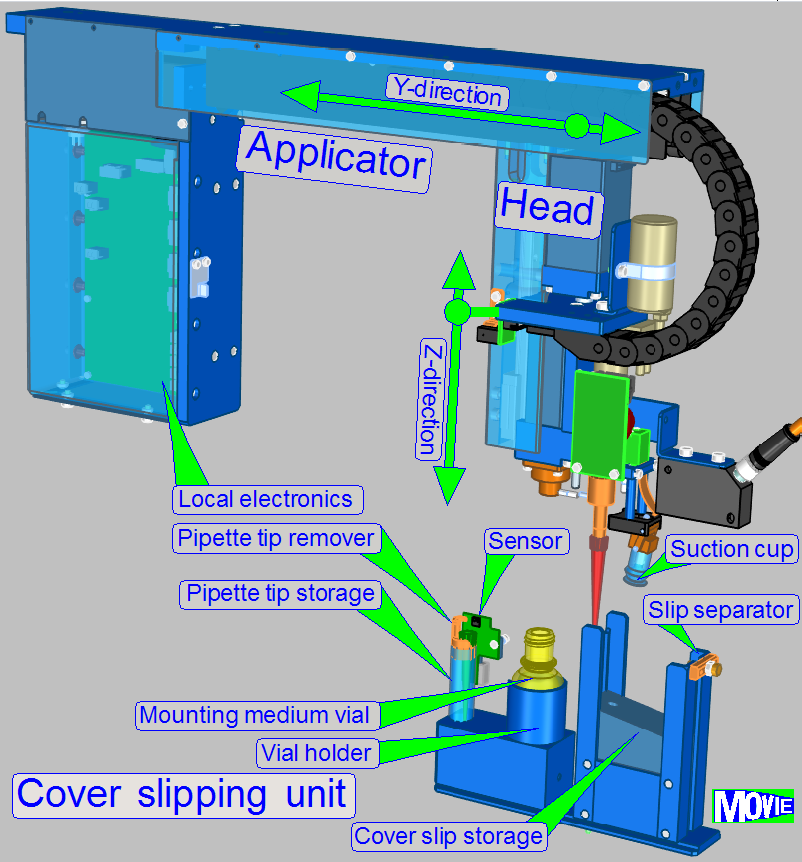

Components of the unit

Cover

slipping unit consists of

Cover

slipping unit consists of

· Cover

slip applicator

· Mounting

medium holder with vial

· Cover

slip store

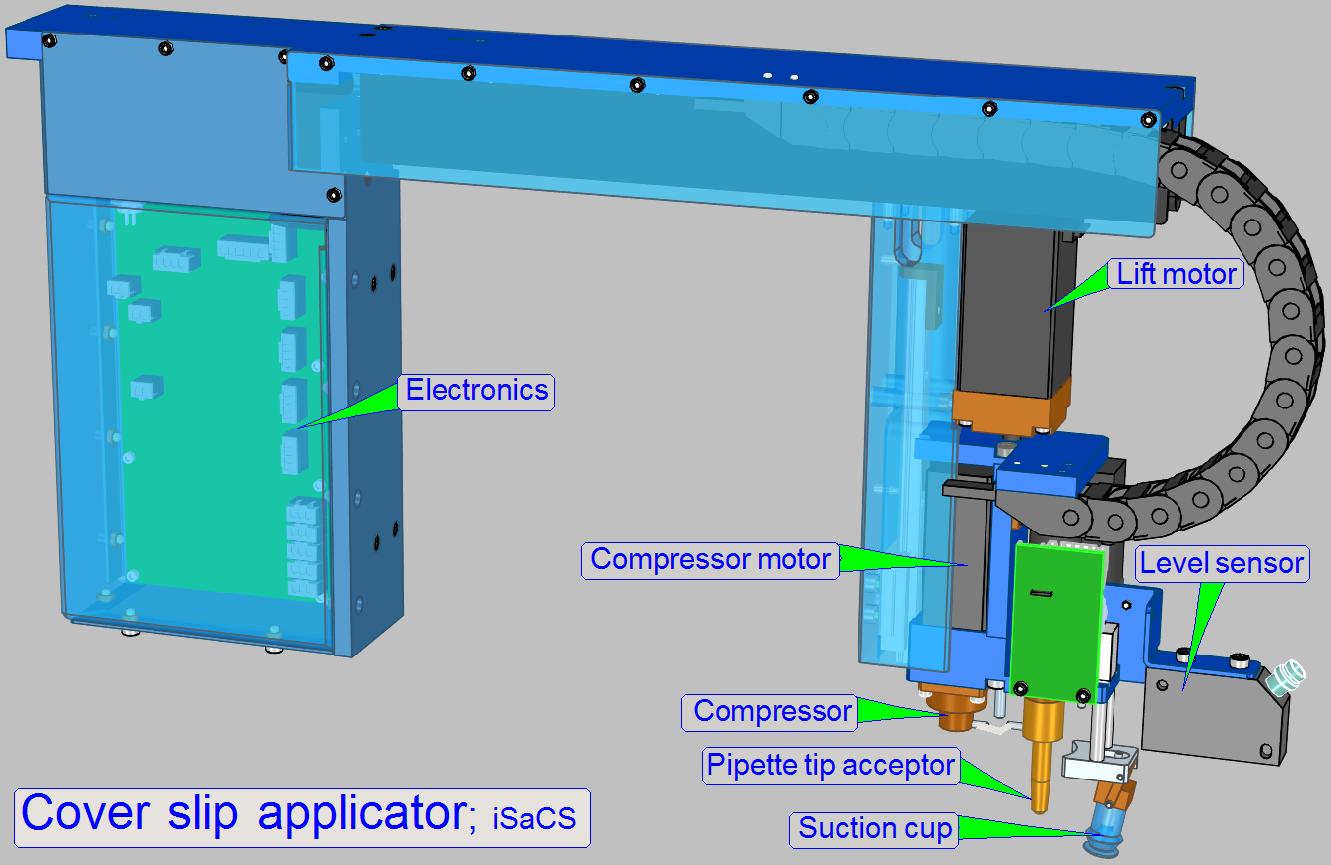

Cover slip applicator consists of

·

Local

electronics

Local

electronics

·

Y-direction movement rail with spindle

·

Cover slipping head with

· Z-movement

motor with rail and spindle

· Air

compressor with silencer

· Pipette

tip holder

· Suction

cup

· Magnet

valve

· Level

sensor

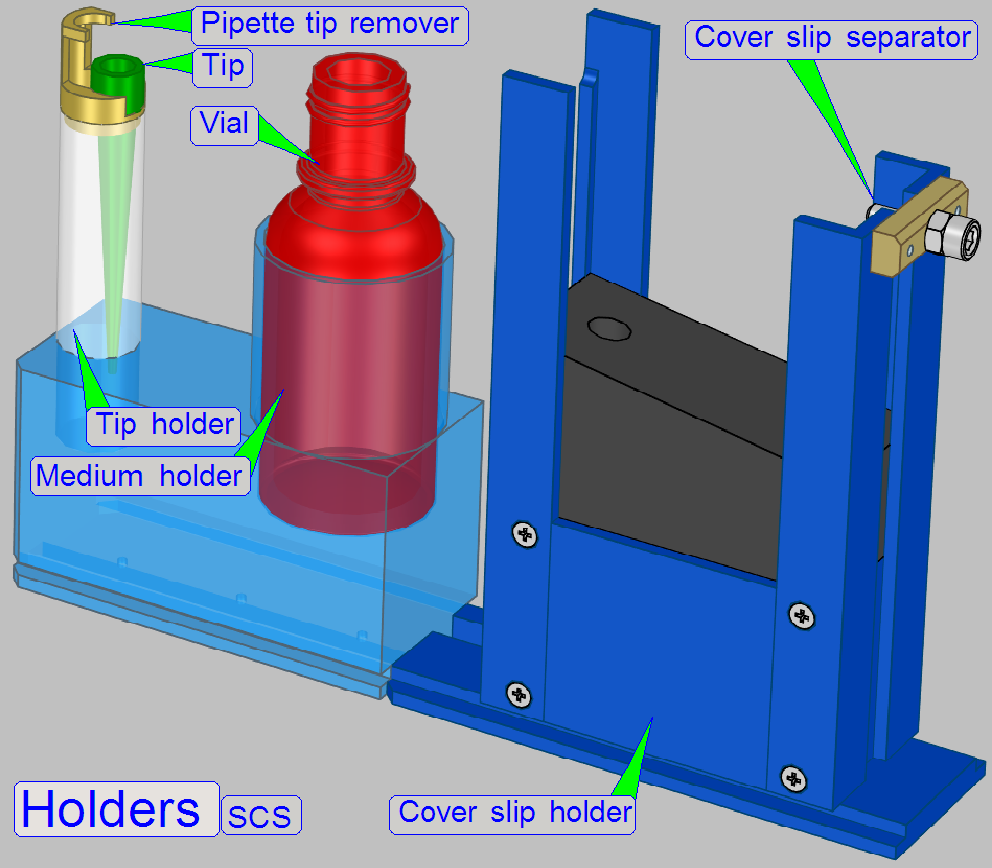

Holder unit consists of

Holder unit consists of

·

Mounting medium holder with vial

·

Pipette tip storage

·

Pipette tip remover

·

Cover slip slope

·

Cover slip separator

Operation

principle

The cover slipping head travels along the Y-direction

on the spindle. The cover slipping lift block moves in Z-direction up and down

according to the desired action.

The spindle and the head are moved by a stepper motor.

1. After

previous operations are finished (staining, washing, rinsing and air wiping),

the slide is ready for cover slipping.

2. To do

this, the transporter moves the slide from its actual position (slide rack or

from the wiper) to the manipulation bay 13; the cover slipping position.

3. The

cover slipping head is moved over the pipette tip storage so the pipette tip

holder is right above the pipette tip.

4. The

cover slipping head is moved downwards and presses so the pipette tip onto the

tip acceptor.

5. The

attached tip is taken out of the tip storage and moved above the mounting

medium vial.

6. The

cover slipping head is moved downwards so the pipette tip is dipped in to the

mounting medium; the deepness is defined by the known medium quantity for the

procedure.

7. The

appropriate amount of mounting medium is sucked up into the pipette tip.

8. Now,

the cover slipping head is moved over the slide with the filled pipette tip.

9. The

mounting medium is applied onto the surface of the slide. As the cover slipping

head moves longitudinal over the slide, the mounting medium is spread in the

middle of the slide’s surface. The pipette tip will be emptied fully.

10. Now

the cover slipping head is moved by software to the pipette tip’s storage.

11. After

the head is moved downwards and a bit sideward, the pipette tip’s remover acts

and removes the pipette tip from its acceptor.

12. Now,

the cover slip w be mounted

13. The

suction cup of the cover slipping head is moved above the cover slip pile in

the cover slip holder.

14. The

cover slips are manually pre-loaded into the cover slip storage.

15. The

head is moved downwards until the suction cup touches the top cover slip in the

pile.

16. The

compressor is started and creates a vacuum in the suction cup, so the cover

slip is hold by the suction cup.

17. The

suction cup is moved upwards until the cover slip touches the cover slip

separator. During the upward movement of the cover slip, the cover slip

separator is slightly touched. As the cover slip is very thin, the cover slip

is a bit bent on the cover slip separator. If there was taken two cover slips,

the second cover slip is bent less, a space is created between both cover slips

and the second cover slip can fall back to the storage place.

18. If the

suction cup with the cover slip arrived over the slide, the cover slip is

placed on the slide surface and is slightly pushed mechanically onto the slide;

the mounting medium is evenly spreading.

19. After

the mounting medium is spread evenly, the compressor pumps air into the suction

cup and this releases so the cover slip. The head is moved to its home position

and waits here for the next cover slipping action.