Prerequisites cont’d

For technicians and sales managers!

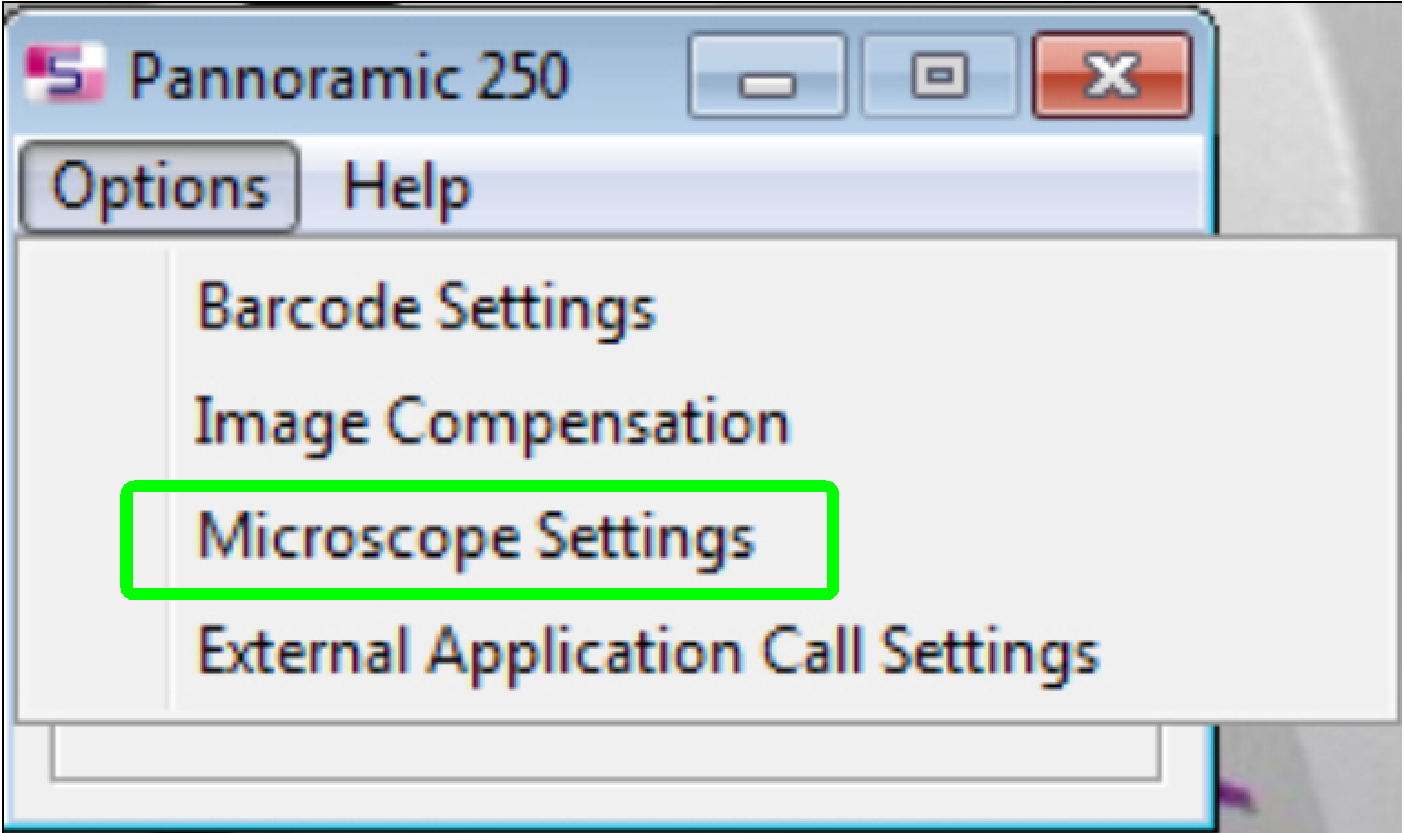

Since the software

version 1.14 usable scan cameras as well as other settings of the scanner are

defined in the dialogue “Microscope settings” in the menu “Options” of the

selector dialogue.

Since the software

version 1.14 usable scan cameras as well as other settings of the scanner are

defined in the dialogue “Microscope settings” in the menu “Options” of the

selector dialogue.

Adimec

Q-12A180 CXP

All cameras with “CL” (Camera Link interface) in the name will be

handled via the SOLIOS or the RADIENT board!

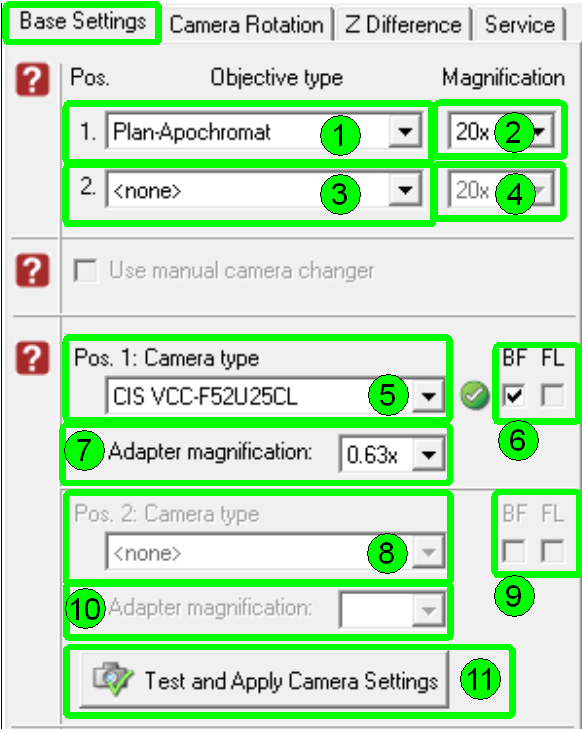

“Base Settings”

All hardware

(camera implementation or exchange) and driver modifications have to be done prior

to starting the program SlideScanner.exe and the dialogue “Base Settings”; the

driver have to be already installed, the camera have to be connected and

powered on!

All hardware

(camera implementation or exchange) and driver modifications have to be done prior

to starting the program SlideScanner.exe and the dialogue “Base Settings”; the

driver have to be already installed, the camera have to be connected and

powered on!

The objective settings should

be done or checked together with the setup of the camera(s); the items (1) to

(4).

![]() “Setup and define

implemented objectives”

“Setup and define

implemented objectives”

Pos.

1: Camera type (FL-camera)

By opening the pull down menu (5) one of the implemented cameras can be

selected. The selected camera type has to be identical with the connected

camera type.

If the Pannoramic

scanner is equipped with a camera changer unit, the fluorescent scan camera has

to be defined here.

If the 90º camera tube

is installed, the brightfield camera has to be

defined here.

![]() “Camera positions on the camera

changer”.

“Camera positions on the camera

changer”.

BF

Check this checkbox (6), (9) if the selected camera should be used for brightfield scan.

FL

Check this checkbox (6), (9) if the selected camera should be used for

fluorescent scan.

Check both checkboxes if the

camera should be used for BF and FL scan operation (if only one camera is

installed or for test purposes).

Adapter

magnification

Select the real value for the camera adapter magnification (7), (10); it

can be found on the

camera adapter itself.

Pos.

2: Camera type (Brightfield camera)

If the Pannoramic scanner is equipped with a

camera changer unit the brightfield camera has to be

defined here. The camera, defined for position 1 will be excluded from the list

of this pull down menu. Furthermore, if the position 1 camera was defined as FL

scan, the position 2 camera can be defined for BF scan only and vice versa (8).

![]() “Camera positions on the camera

changer”.

“Camera positions on the camera

changer”.

Test

and Apply Camera Settings

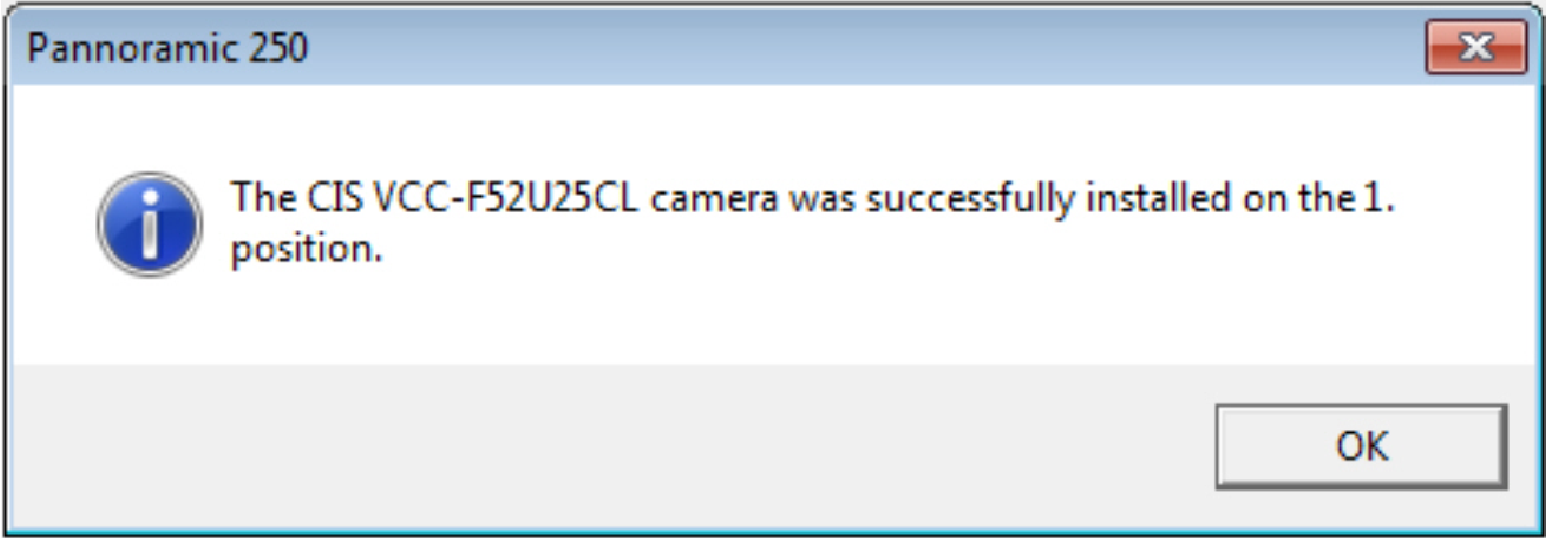

The defined camera

type(s) will be checked for system integrity (11). If the result of the check

is positive, the camera types are accepted and are integrated into the system;

the success is shown with a “

The defined camera

type(s) will be checked for system integrity (11). If the result of the check

is positive, the camera types are accepted and are integrated into the system;

the success is shown with a “![]() ”

mark beside the selected camera type. An information window shows the result of

the check.

”

mark beside the selected camera type. An information window shows the result of

the check.

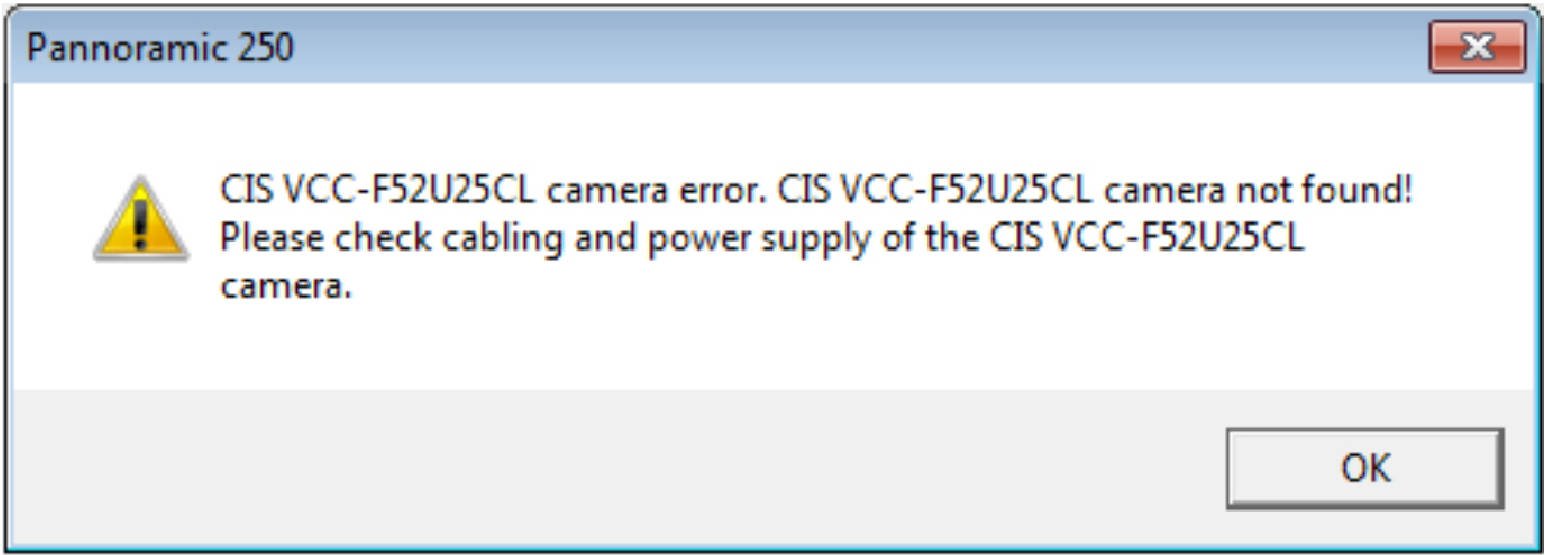

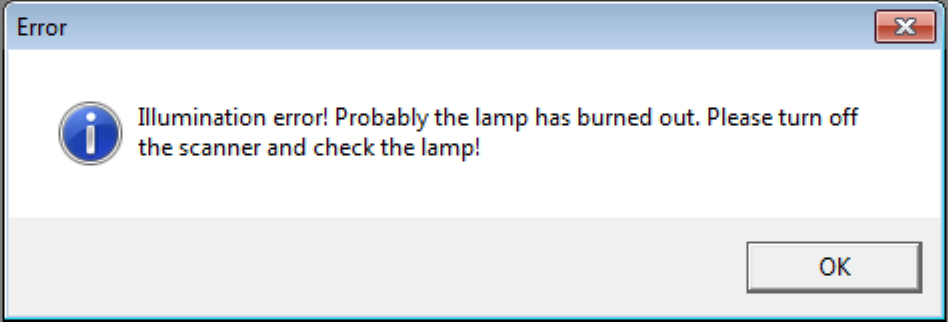

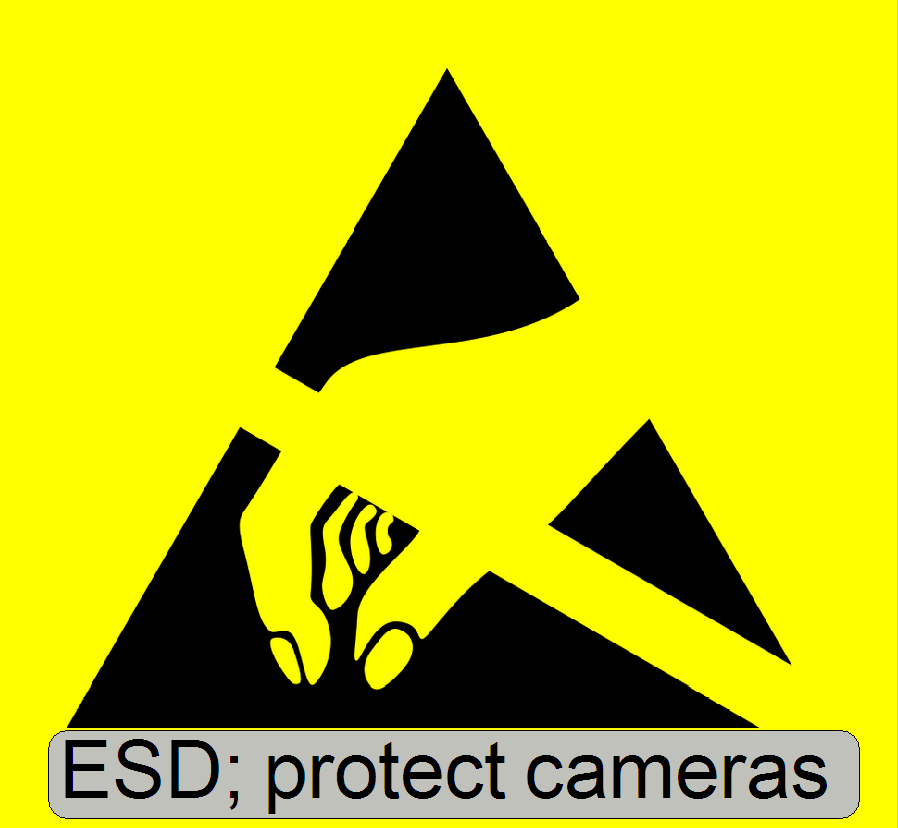

If there is trouble with any

selected camera an error message occurs; the unsuccessful integrity is shown

with a “![]() ”

mark.

”

mark.

![]()

Success of camera integrity check

![]()

Camera integrity check failed

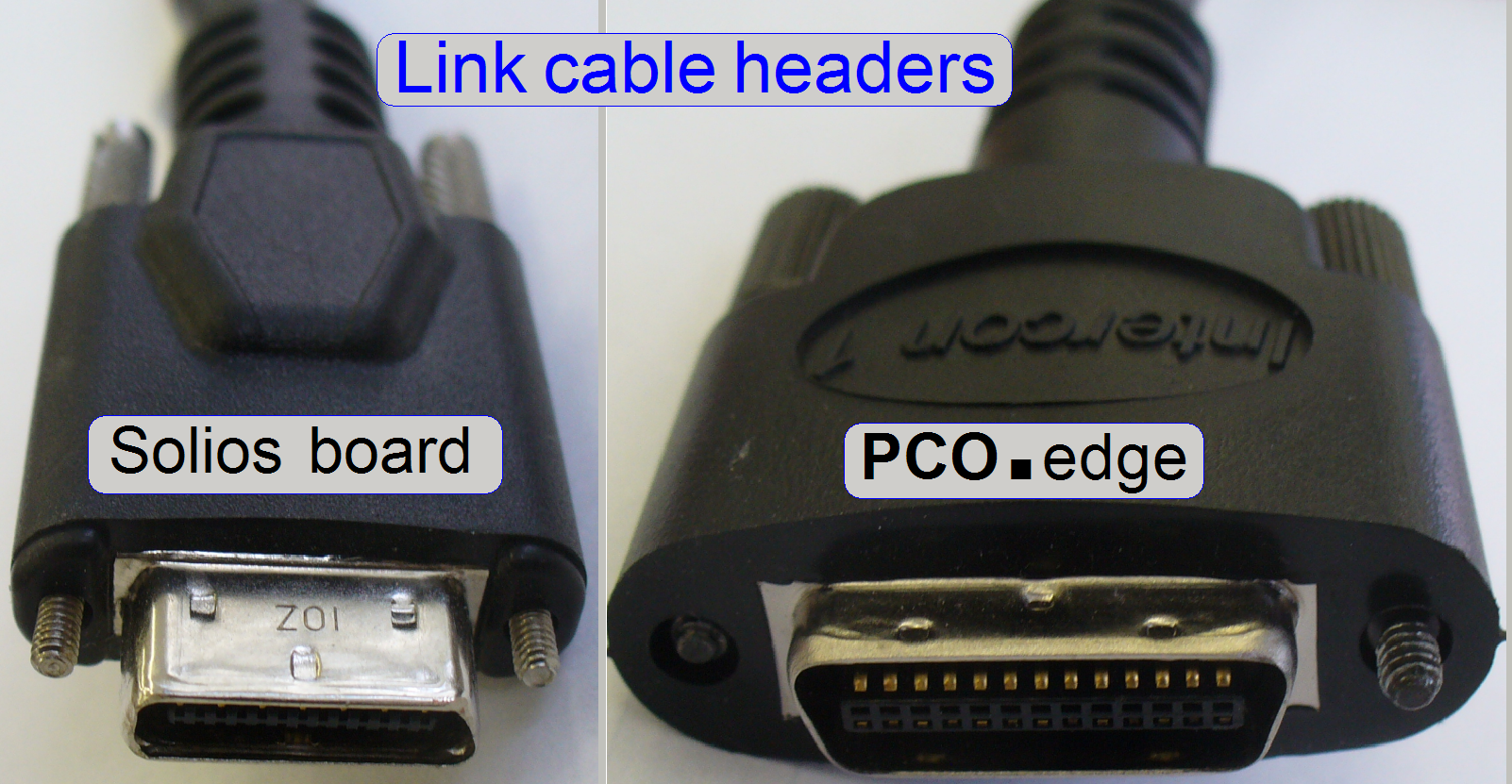

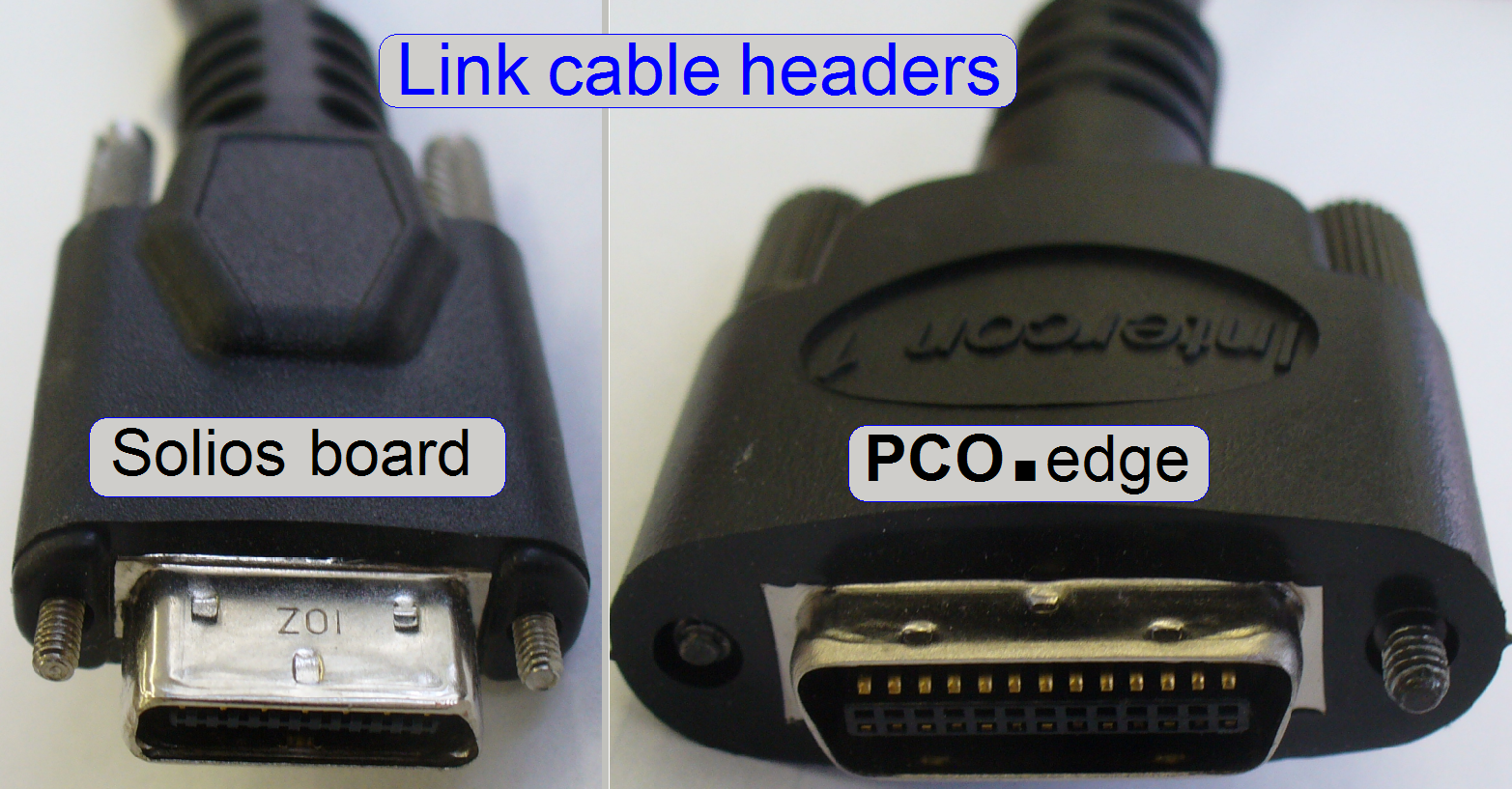

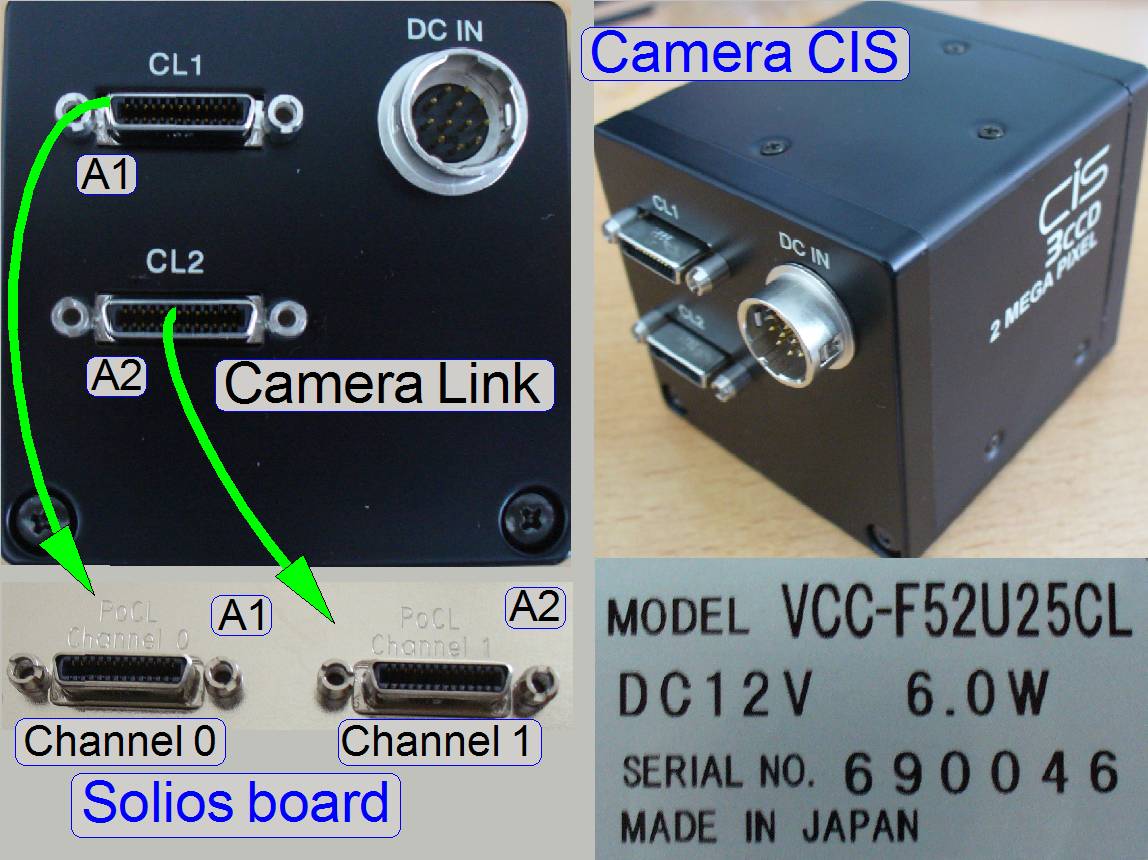

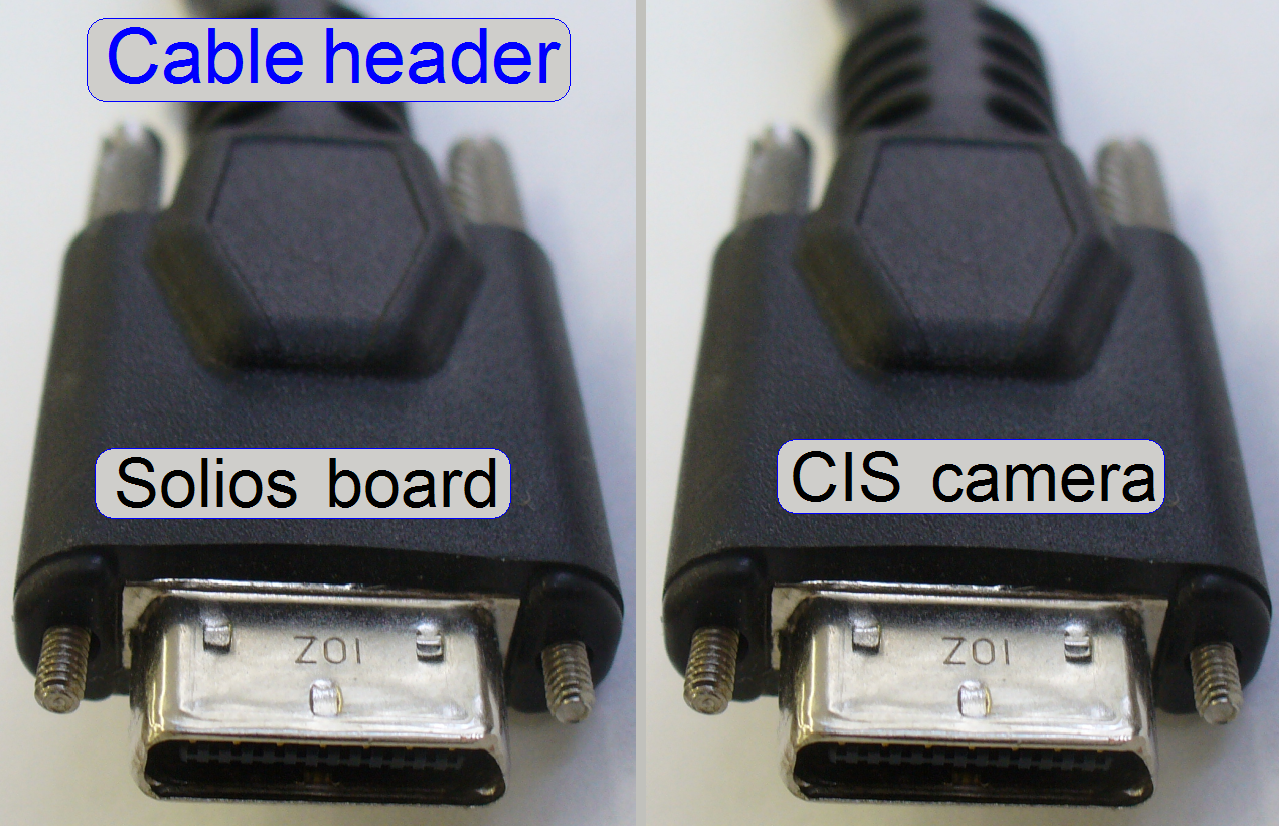

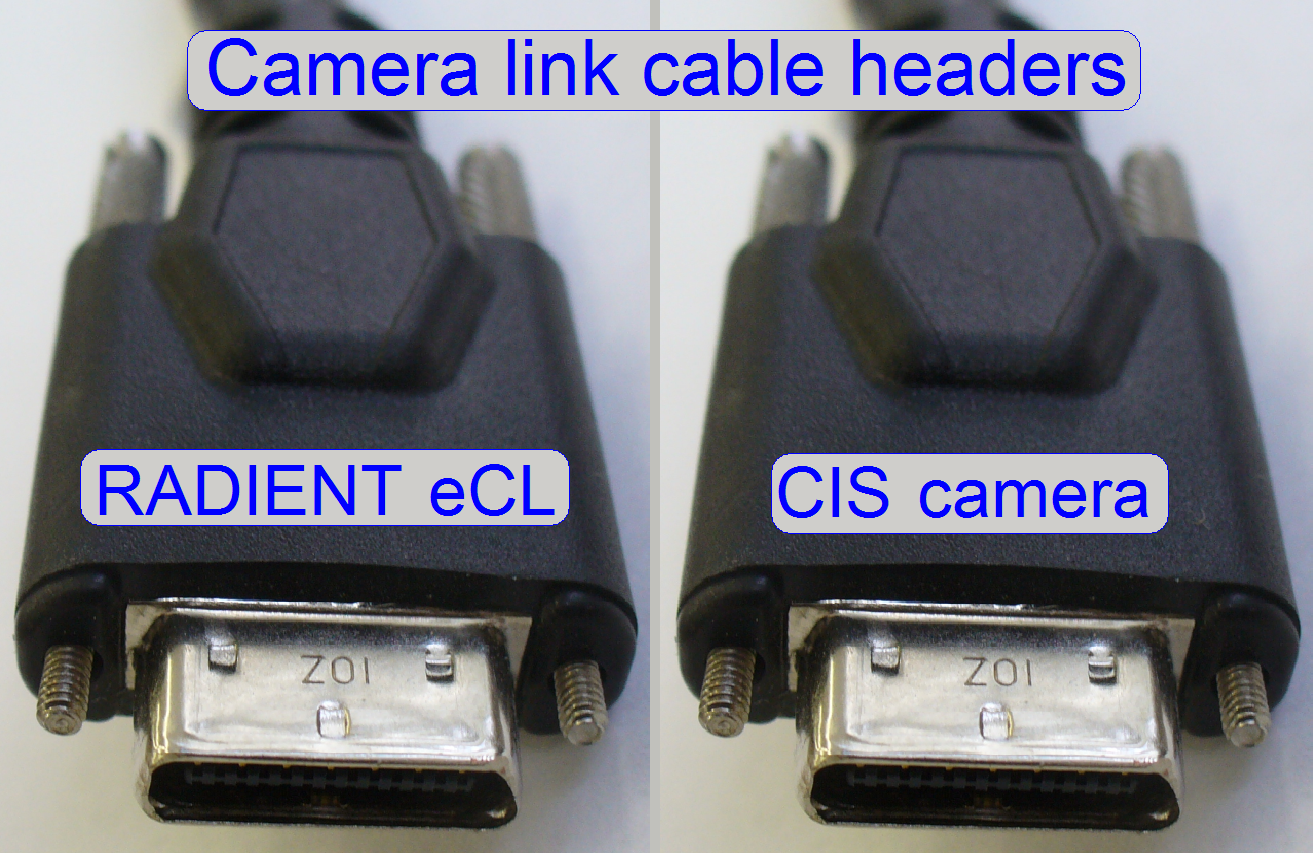

If the camera integrity check has failed

Check the Camera Link connection

between Solios board and camera; the cables should be

connected to the appropriate port (connector) and the lock bolts should be

tightened on all four headers.

Check the Camera Link connection

between Solios board and camera; the cables should be

connected to the appropriate port (connector) and the lock bolts should be

tightened on all four headers.

·

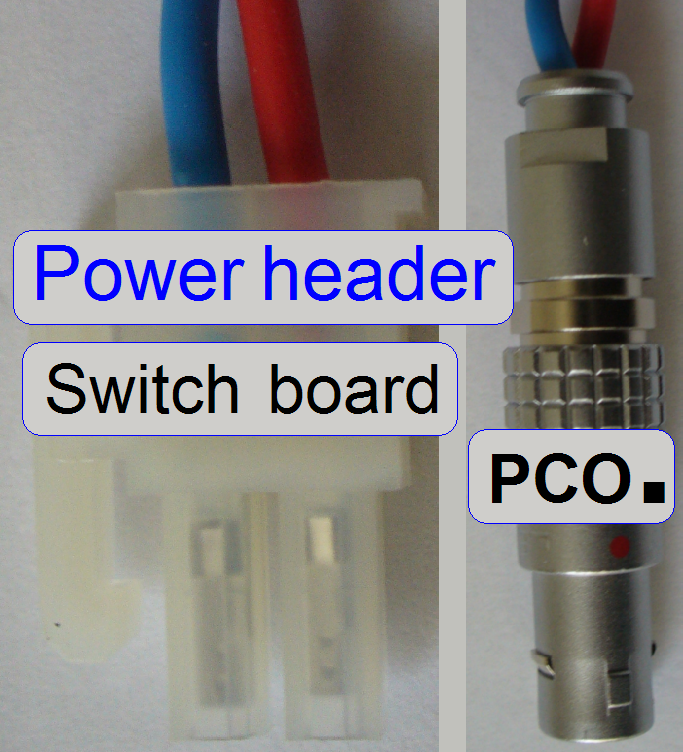

Check the power of the camera; the power connector

should be connected well; the camera should be switched on.

·

Check the enable or disable state of the “Power

distribution and switch board” in the file “MicroscopeConfiguration.ini” or

check the external power supply (if present).

Check the correct power

connector position on the “Power

distribution and switch board”.

·

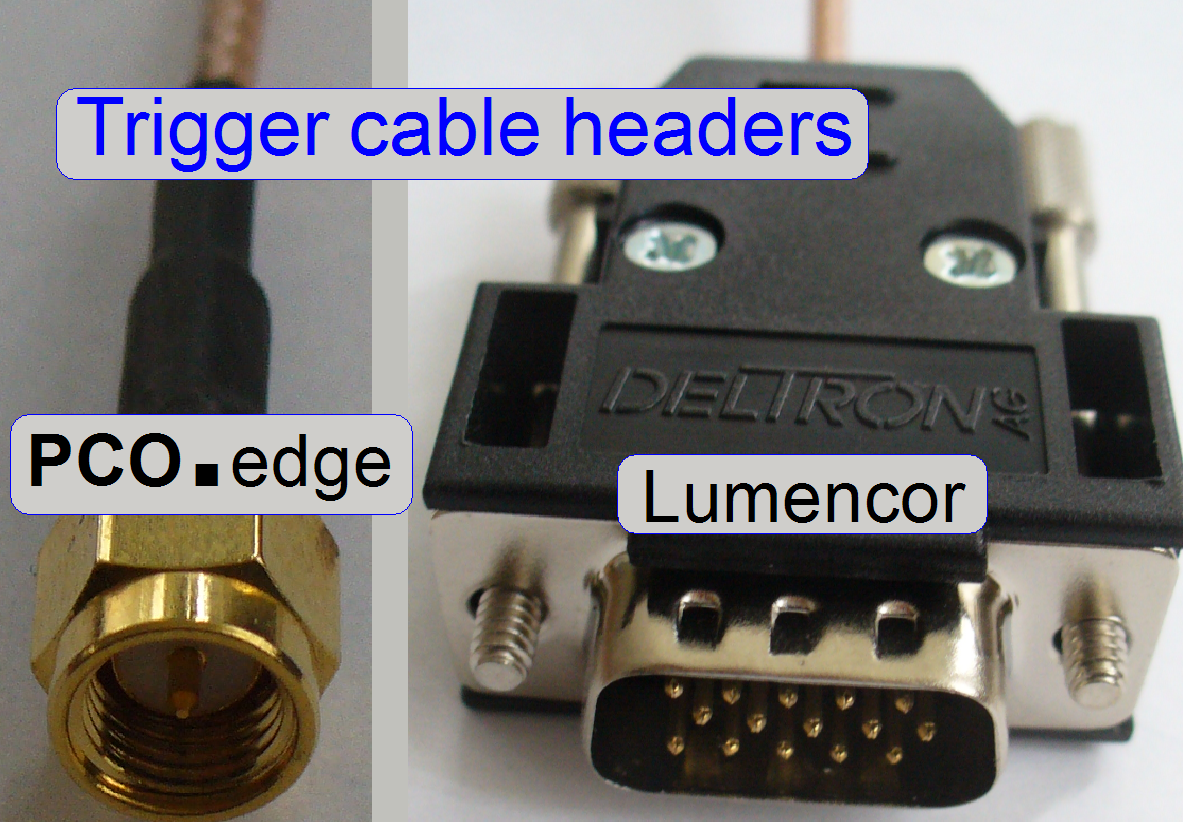

Check the trigger cable and its connection between

camera and “X-Y-Z-ND

motor & flash light control” electronics; the trigger connector should

be connected right.

·

See also: “Camera

CIS-VCC-F52U25CL” and “Camera pco.edge”

respectively

Check the port (cable

connection and power supply) of the failed camera, the installation of the

MIL_9.0 or the driver

installation.

Important

Important

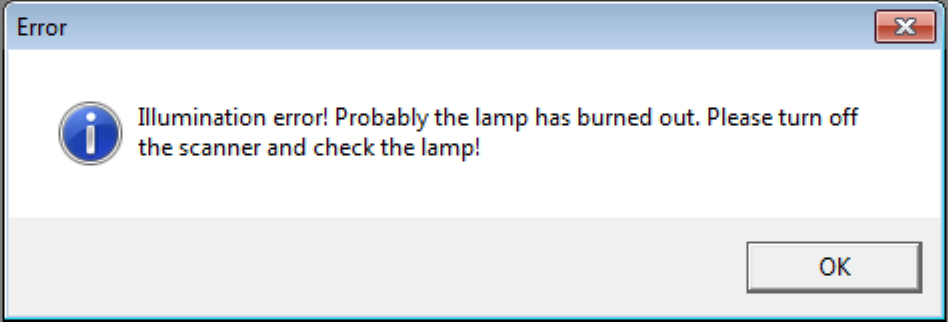

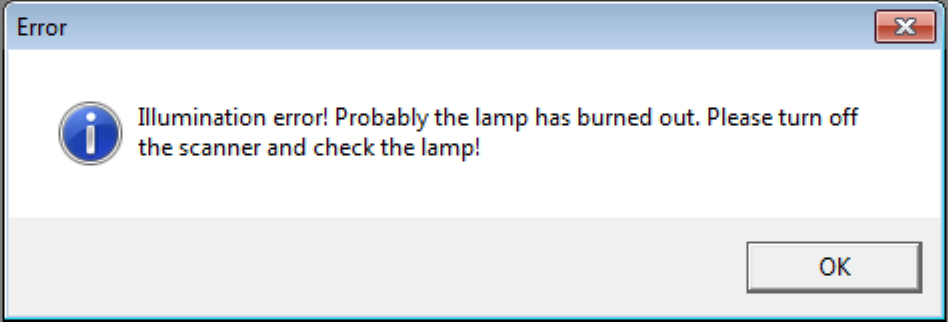

If the switch “TRG” or “Vref” of the flash light

source is not set to “External” the camera installation may be not finished

correctly in the dialog “Microscope settings” or the scan program fails the

camera installation with the error message.

Following tables summarizing parameters of the preview and scan cameras

in optical aspects for scanning purposes.

|

Preview

cameras |

||||

|

Camera |

Effective pixel

array size |

Active pixel

size |

||

|

(H) pixels |

(V) pixels |

(H) µm |

(V) µm |

|

|

2056 |

1544 |

3.2 |

3.2 |

|

|

Used: |

2048 |

1536 |

3.2 |

3.2 |

|

640 |

480 |

5.6 |

5.6 |

|

Preview camera pixel view =

(Preview camera pixel size) * (Preview objective magnification)

Preview objective magnification DFK 21F04 ~ 8.2x

Preview objective magnification VRmagic ~

4.7x

·

Preview camera pixel view DFK 21F04 = 46µm

·

Preview camera pixel view VRmagic

= 15µm

|

Useable magnifications

and resulting resolutions of scan (main) cameras |

|||||||||||

|

Camera |

Pixel array size used ; [Pixels] |

Pixel size [µm] |

Useable Magnification; Resolution [µm] |

||||||||

|

Active |

Valid |

0.63x |

1.0x |

1.6x |

|||||||

|

(H) |

(V) |

(H) |

(V) |

(H or V) |

20x |

40x |

20x |

40x |

20x |

40x |

|

|

2448 |

2048 |

3.45 |

3.45 |

4.87* |

0.39 |

0.19 |

0,24 |

0.12 |

X |

X |

|

|

1380 |

1030 |

4.65 |

4.65 |

6.58* |

0.52 |

0.26 |

0.33 |

0.16 |

X |

X |

|

|

Marlin* 1) |

1368 |

1024 |

4.65 |

4.65 |

6.58* |

0.52 |

0.26 |

0.33 |

0.16 |

X |

X |

|

4096 |

3072 |

5.5 |

5.5 |

7.78* |

X |

X |

X |

X |

0.24 |

0.12 |

|

|

1624 |

1224 |

4.40 |

4.40 |

4.40 |

0.35 |

0.18 |

0.22 |

0.11 |

X |

X |

|

|

2048 |

2048 |

5.5 |

5.5 |

7.78* |

X |

X |

0.39 |

0.19 |

0.24 |

0.12 |

|

|

1360 |

1024 |

4.65 |

4.65 |

4.65 |

0.37 |

0.18 |

0.23 |

0.12 |

X |

X |

|

|

Sony DFW-X710*

1) |

1024 |

768 |

4.65 |

4.65 |

6.58* |

0.52 |

0.26 |

0.33 |

0.16 |

X |

X |

|

Monochrome scan cameras (FL or RGB illuminated) |

|||||||||||

|

2448 |

2048 |

3.45 |

3.45 |

3.45 |

0.27 |

0.14 |

0,17 |

0.08 |

X |

X |

|

|

1388 |

1040 |

6.45 |

6.45 |

6.45 |

X |

X |

0.32 |

0.16 |

X |

X |

|

|

2048 |

2048 |

6.5 |

6.5 |

6.5 |

X |

X |

0.32 |

0.16 |

X |

X |

|

|

PCO-edge 5.5_@

2.5Mp |

1600 |

1600 |

6.5 |

6.5 |

6.5 |

X |

X |

0.32 |

0.16 |

X |

X |

|

PCO-edge 5.5_@

4.0Mp |

1920 |

1920 |

6.5 |

6.5 |

6.5 |

X |

X |

0.32 |

0.16 |

X |

X |

|

PCO-edge 5.5_PCON |

2560 |

2160 |

6.5 |

6.5 |

6.5 |

X |

X |

0.32 |

0.16 |

X |

X |

X)

Not defined, can not be used

* Calculations for

these cameras are done by using the factor sqrt(2)

Resolution [µm] = (Active camera pixel size * sqrt(2) )

/ (objective magnification * camera adapter magnification); used if single chip

camera with Bayer method

· sqrt(2)= required,

because debayering (creation of color information in

single chip cameras with Bayer

method); and generation of JPEG file

If real color camera or monochrome (FL)

camera:

Resolution [µm] = (Active camera pixel size) / (objective

magnification * camera adapter magnification)

1) No longer delivered

2) Useable since SW

version 1.20 only!

3) Useable since SW

version 1.21only!

Used in: P250 FLASH 3, SW-version

1.20 and higher

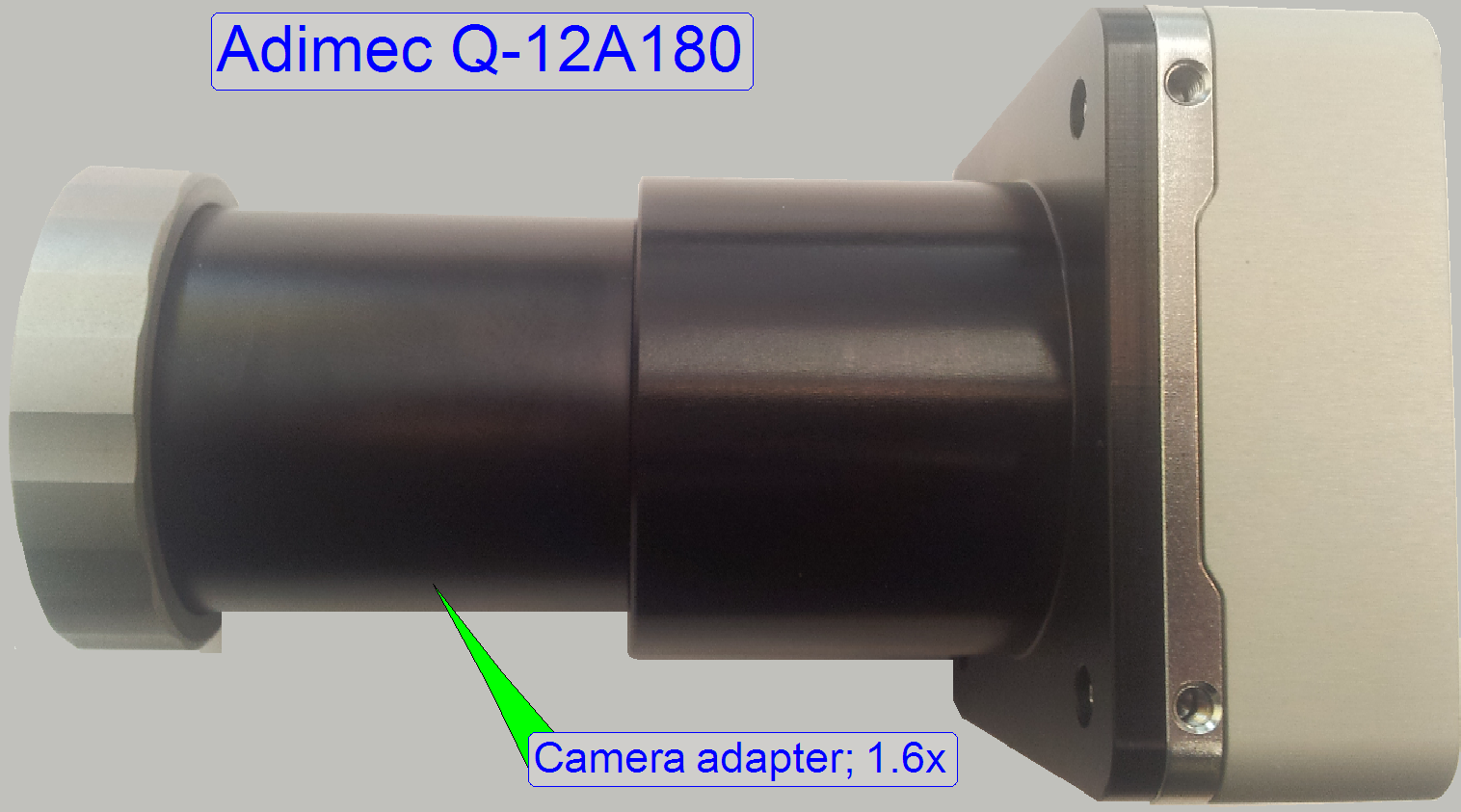

The Adimec

QUARTZ Q-12A180 is a12 Megapixel camera at 187 fps with a maximum of only 9W

power consumption in a small outline; with the highest image quality today and

the QUAD CoaXPress interface.

The Adimec

QUARTZ Q-12A180 is a12 Megapixel camera at 187 fps with a maximum of only 9W

power consumption in a small outline; with the highest image quality today and

the QUAD CoaXPress interface.

Sensor

·  Type: CMV12000

Type: CMV12000

·

Global shutter CMOS

·

A/D conversion 32 channels 8 or 10bit ADC

·

Optical size APS-C

·

Resolution 12MPixels - 4096(H) x 3072(V)

·

Pixel size 5.5 x 5.5 μm

·

Active

pixels 4096

(H) x 3072 (V)

· Frame rate 300 fps (10 bit)

132

fps (12 bit)

·

Chroma Mono, Mono NIR enhanced and

RGB

Triggering Internal or external

Power Input 24Vdc PoCXP

(Power over CXP)

Operating temperature

Operating temperature

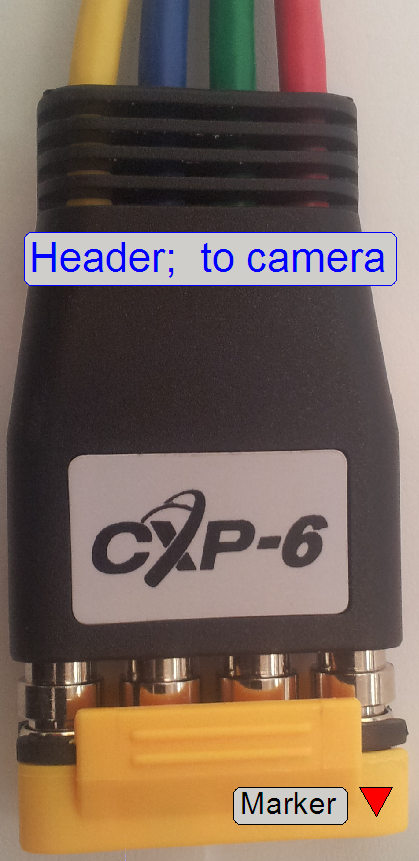

Interface CoaXPress; Configurable 1, 2 or 4 lanes

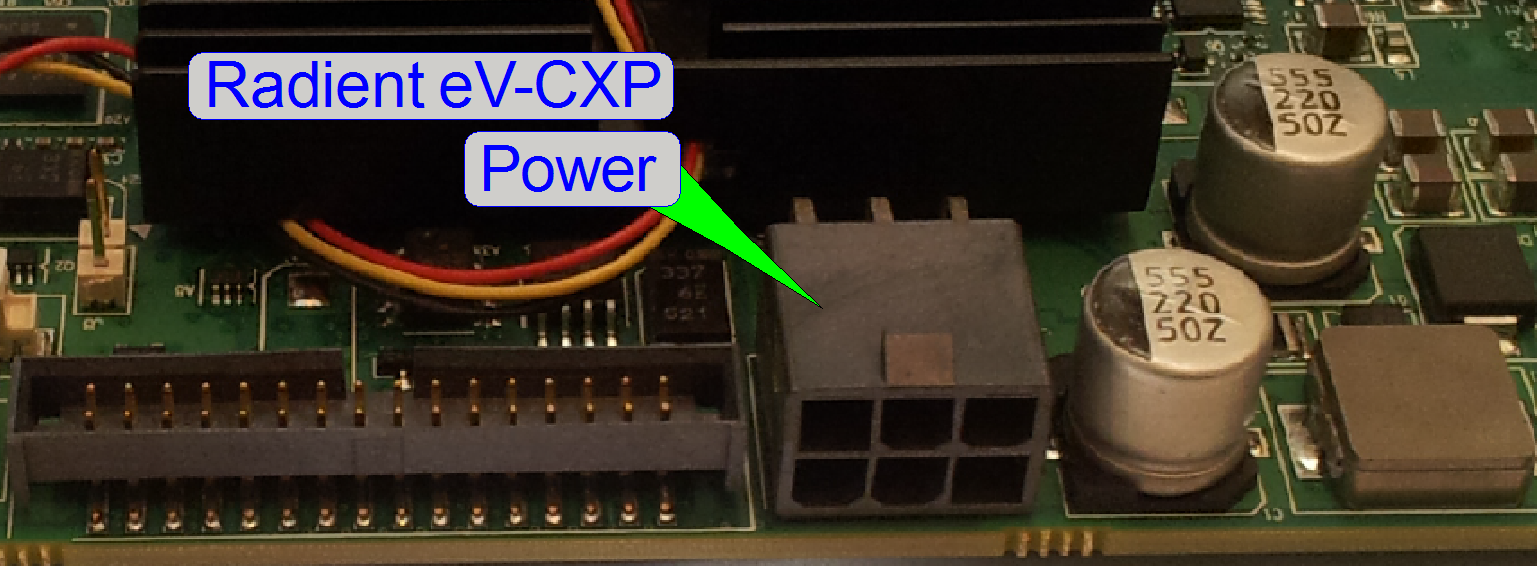

Board: Matrox Radient eV-CXP; PCIe 2.0 x8, PoCXP

![]() ”Specifications”

(stored); “CoaXPress”; “Multyway-connector” (stored); “Matrox_Radient_ev_cxp.pdf”

(stored)

”Specifications”

(stored); “CoaXPress”; “Multyway-connector” (stored); “Matrox_Radient_ev_cxp.pdf”

(stored)

If the LED of any wire is flashing red, then the appropriate line is not

recognized or not connected or the line is not controlled yet by software!

Power

The power for the

camera is provided over the CXP cables

The power for the

camera is provided over the CXP cables

Important

To provide power for the camera the internal power connector of the Radient eV-CXP board has to be

connected with the power supply!

Cabling

See the images on the right

If the LED of any wire is flashing red, then the appropriate line is not

recognized or not connected or the line is not controlled yet by software!

Trigger

Camera

adapter

Because the camera Adimedc has a very large

CMOS sensor, the camera is always used with a camera adapter of 1.6x

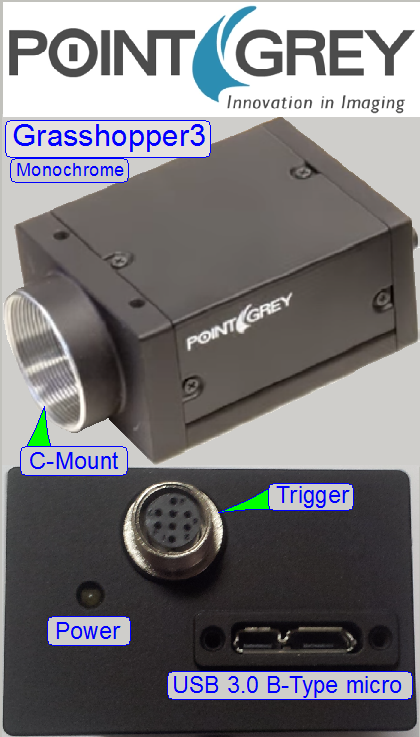

Manufacturer: POINTGREY

Model: GS3-U3-51S5 M-C;

monochrome and

Model: GS3-U3-51S5 M-C;

monochrome and

GS3-U3-51S5

C-C; Color

Monochrome

version used in: delivered S_M_D

type scanners since summer 2016 as BF and FL scan camera or in other scanner

types as FL scan camera

Color version used in: scanner types, delivered before summer 2016,

as BF scan camera

SW Version: 1.21

or higher.

Interface type: USB

3.0

Power: Supplied

over USB 3.0 or external; 4.5W max.

The Grasshopper3 is an USB 3.0 interfaced monochrome scan camera, used

mainly in improved SCAN,

The camera requires the software version 1.21. Because improved S_M_D

type scanners got an RGB brightfield scan

illumination unit, the FOV is captured three times, one time by each

color. The 3 gray scale images, taken by

the Grasshopper3 monochrome camera, define the partial intensity of the

appropriate color. By assembling the raw RGB images and using the software

coloring method, images of a very high quality and color fidelity with improved

resolution can be produced.

The color version of the camera may be used in upgraded Pannoramic type scanners with Halogen lamp BF illumination;

it offers higher pixel resolution and higher image transfer speed.

Improvements

·

Only one camera is required for BF and FL scan

sessions

·

Camera changer unit not required

·

Higher scan quality, faster scan speed

·

Higher pixel resolution

·

10 times faster image transfer over USB3.0 (in

relation to Stingray camera)

|

Features; GS3-U3-51S5 |

|||

|

Parameter |

M-C (mono) |

C-C (color) |

|

|

Resolution (H x V) |

2448 x 2048 |

2448 x 2048 |

|

|

Pixel Size |

3.45 µm |

3.45 µm |

|

|

Megapixels |

5.0 MP |

5.0 MP |

|

|

Chroma |

Mono |

Color |

|

|

Sensor Name |

Sony IMX250 |

Sony IMX250 |

|

|

Sensor Type |

CMOS |

CMOS |

|

|

Readout Method |

Global shutter |

Global shutter |

|

|

Sensor Format |

2/3" |

2/3" |

|

|

Frame Rate |

75 FPS |

75 FPS |

|

|

Lens Mount |

C-mount |

C-mount |

|

|

ADC |

10-bit and 12-bit |

10-bit and 12-bit |

|

|

Interface |

USB 3.0 |

USB 3.0 |

|

![]() POINTGREY

home page

POINTGREY

home page

Getting started manual (stored)

Technical Reference

(stored)

Imaging Performance

(stored)

Data sheet (stored)

Important

Please use always a FRESCO FL 1100 USB 3.0 interface board, type

U3-PCIE1XG211 to interfacing Grasshopper3 type cameras in Pannoramic

Scanners.

·

By using other USB 3.0 interface ports, the camera

might not work.

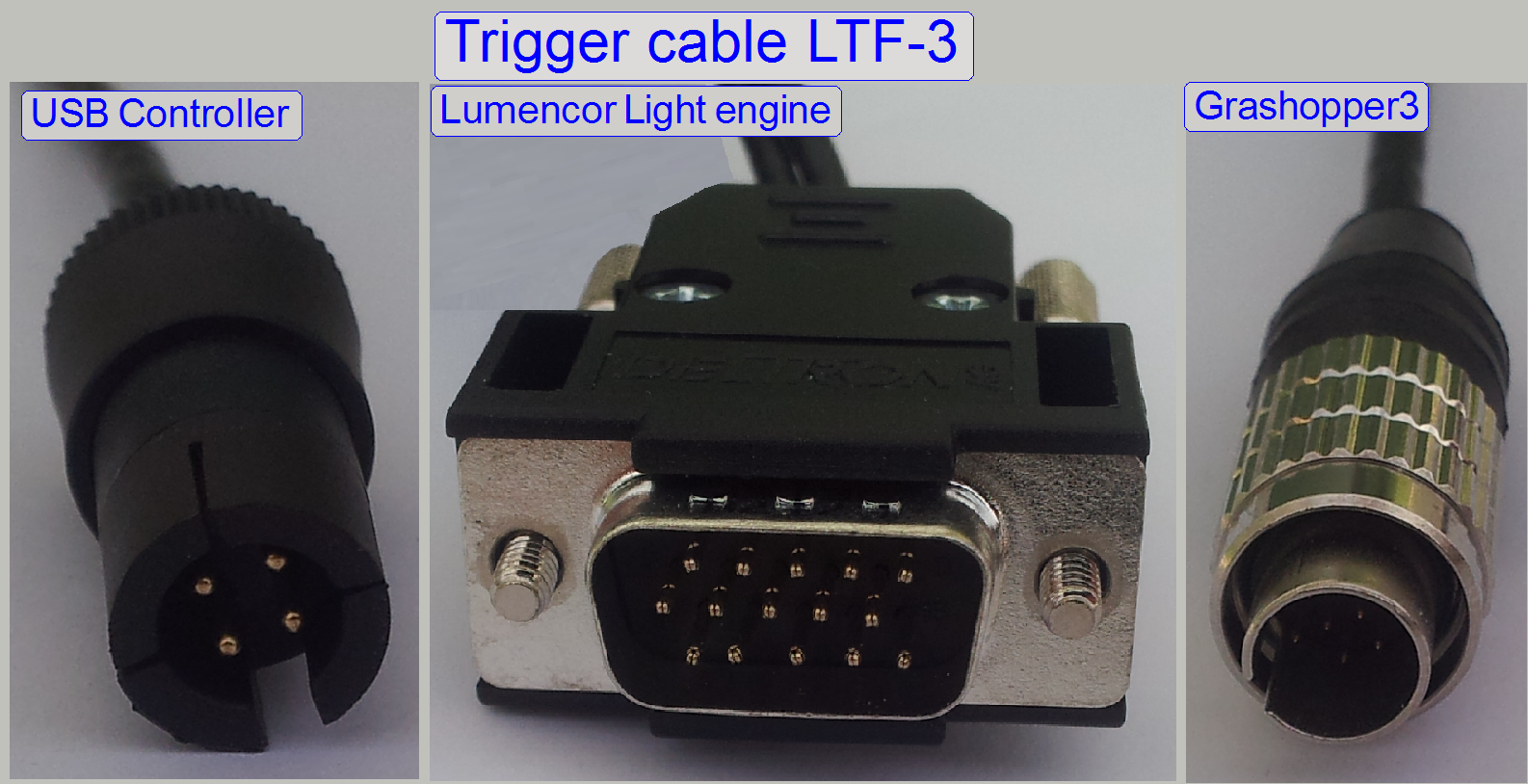

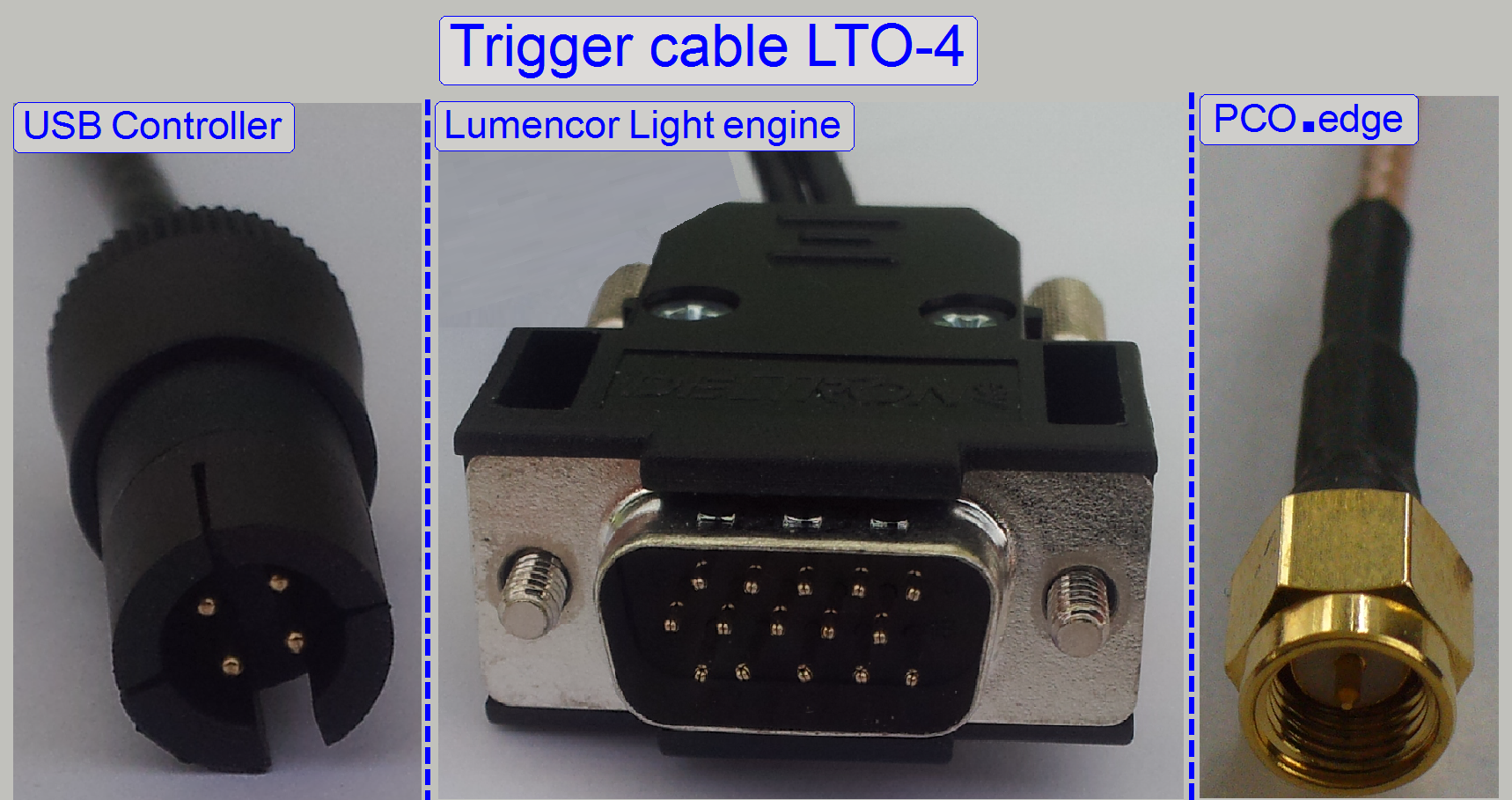

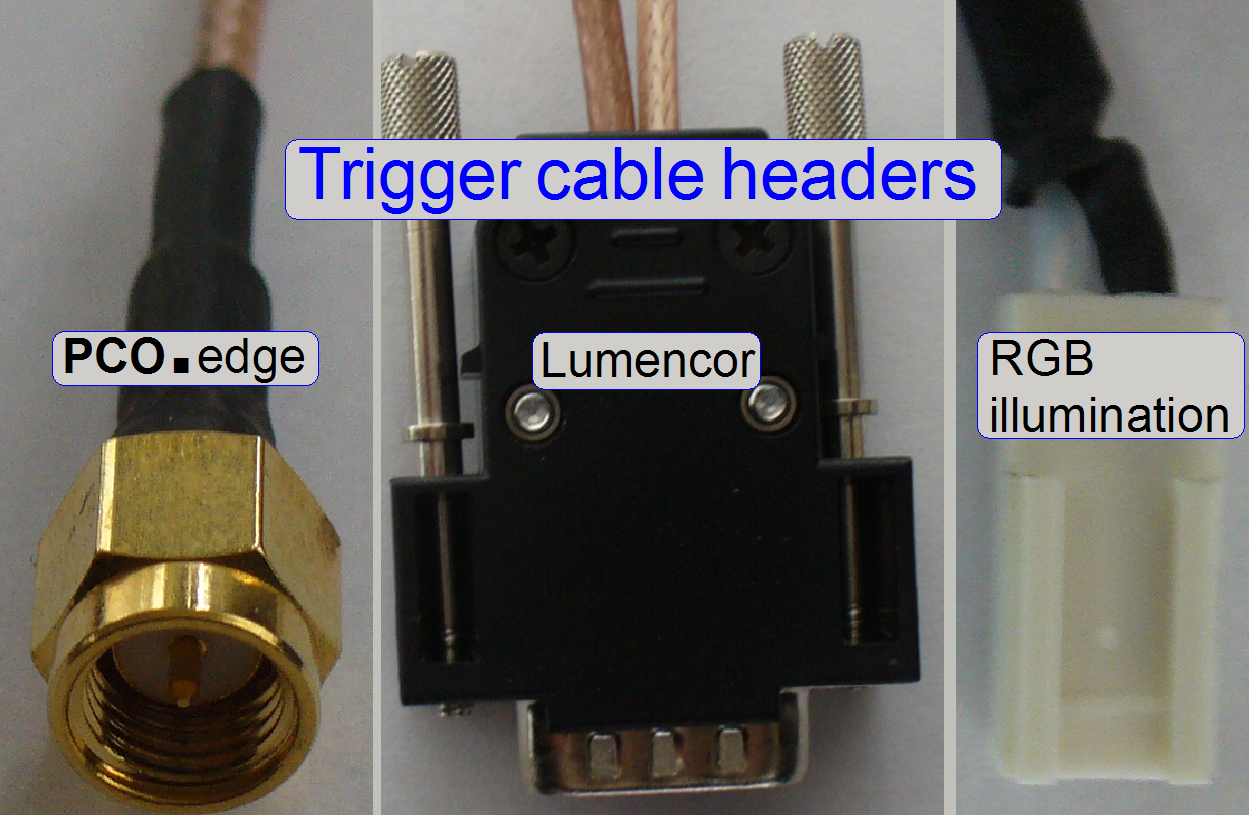

Trigger

HW triggering

If an RGB brightfield illumination unit is used and the camera works

as BF scan camera (S_M_D), the camera will be triggered by the trigger output

of the scanner.

If an RGB brightfield illumination unit is used and the camera works

as BF scan camera (S_M_D), the camera will be triggered by the trigger output

of the scanner.

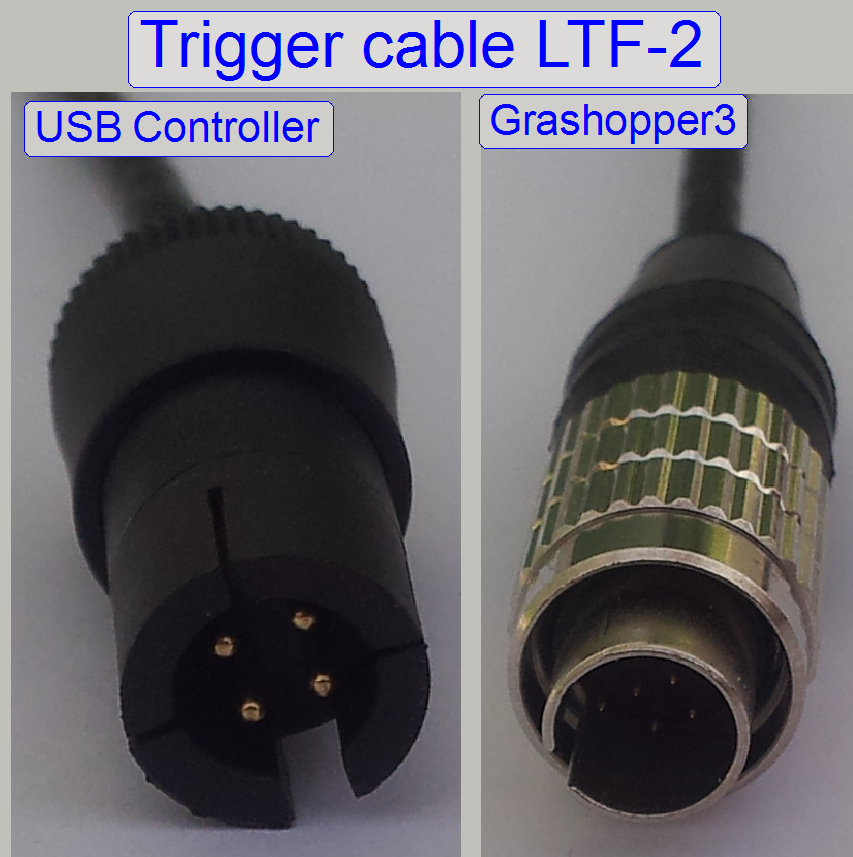

Two types of trigger cable are used:

LTF-2: The scanner’s USB control

electronics triggers the camera

LTF-3: The scanner’s USB control

electronics triggers the camera and the lumencor

spectra light engine©

SW triggering

If the camera works as FL scan camera in scanners with camera changer,

the camera will be triggered by software.

![]() Getting started manual (stored)

Getting started manual (stored)

Driver setup

Used in: P250, SCAN,

The VCC-F52U25CL is a

camera link interfaced, 3CCD high-resolution industrial color video camera

module utilizing a 1/1.8 type PS IT CCD. The 2M pixels CCD image sensor with

on-chip micro-lenses realizes high sensitivity and high resolution. The full

size field of view can be read out within approx. 30fps.

The VCC-F52U25CL is a

camera link interfaced, 3CCD high-resolution industrial color video camera

module utilizing a 1/1.8 type PS IT CCD. The 2M pixels CCD image sensor with

on-chip micro-lenses realizes high sensitivity and high resolution. The full

size field of view can be read out within approx. 30fps.

CIS-

VCC-F52U25CL

Device Type: 1/1.8 type

Interline Transfer Color CCD

CCD: SONY

ICX274AL

Effective Pixel Number: 1628 (H) × 1236 (V)

Unit Cell Size: 4.40μm (H) ×

4.40μm (V)

Chip Size: 8.50mm (H) × 6.80mm

(V)

![]() “Possible scan modes with different cameras and

magnifications in the software version 1.16; 1.17beta and 1.17

“Possible scan modes with different cameras and

magnifications in the software version 1.16; 1.17beta and 1.17

“Useable magnification and resulting

resolution for scan (main) cameras”

Further

information about features, precautions and detailed technical information can

be found in the file “vcc-f52u25cl_en.pdf”.

Power

The camera gets its power of 12V-DC, 6.0W by default from the “Power

distribution and switch board” of the scanner.

The camera interface is a so called “Hot plug interface” so the cable

header may be removed or plugged during the computer is powered on, but wait

until the data transfer between camera and link board is finished (if in

progress).

Nevertheless, the camera should be powered off before any connection

modification is taken.

Unplug the power header of

the camera or switch off the entire scanner.

Make the desired connections

and secure the header connection with the lock bolts.

Switch on the scanner, or plug

the power header.

Check the camera

integrity or implementation with the

dialogue “Microscope Settings”.

Check the camera

integrity or implementation with the

dialogue “Microscope Settings”.

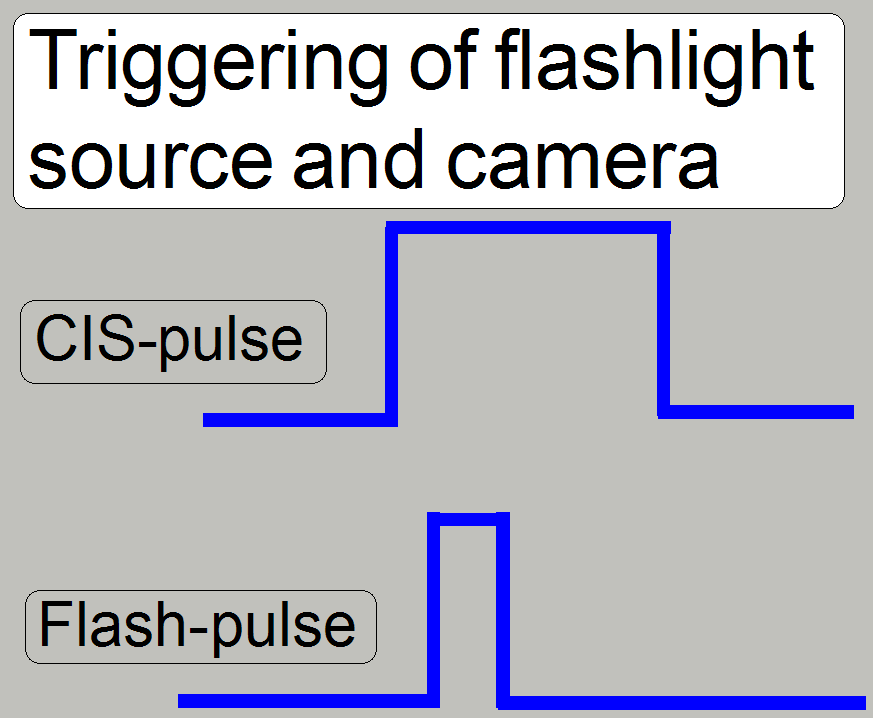

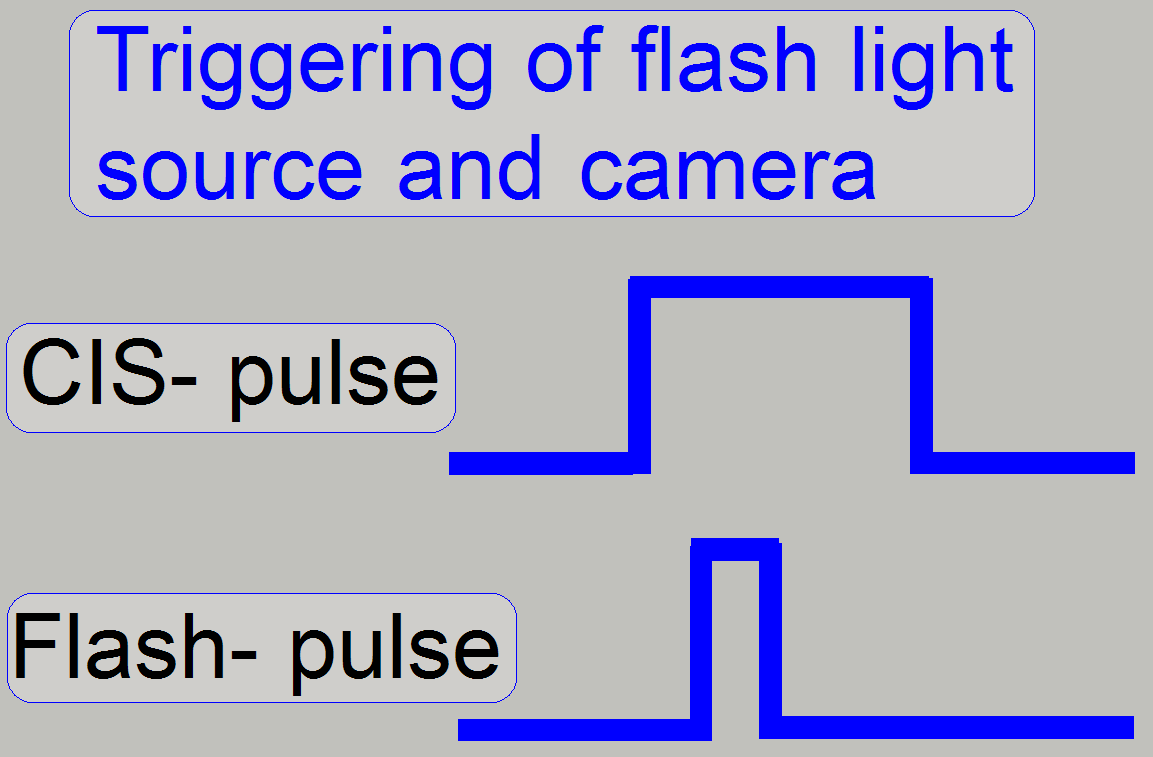

Triggering

The trigger input pulse width of the camera as well as the width of the

trigger pulse of the flash light source is controlled by the firmware. The

trigger cable of the camera is connected to the appropriate connector of the “X-Y-Z-ND motor and flash

light control” electronics.

This power supply

is used if the CIS-camera works in SCAN or

This power supply

is used if the CIS-camera works in SCAN or

The timing of the camera’s

shutter in the SCAN or the

Camera Link

connection

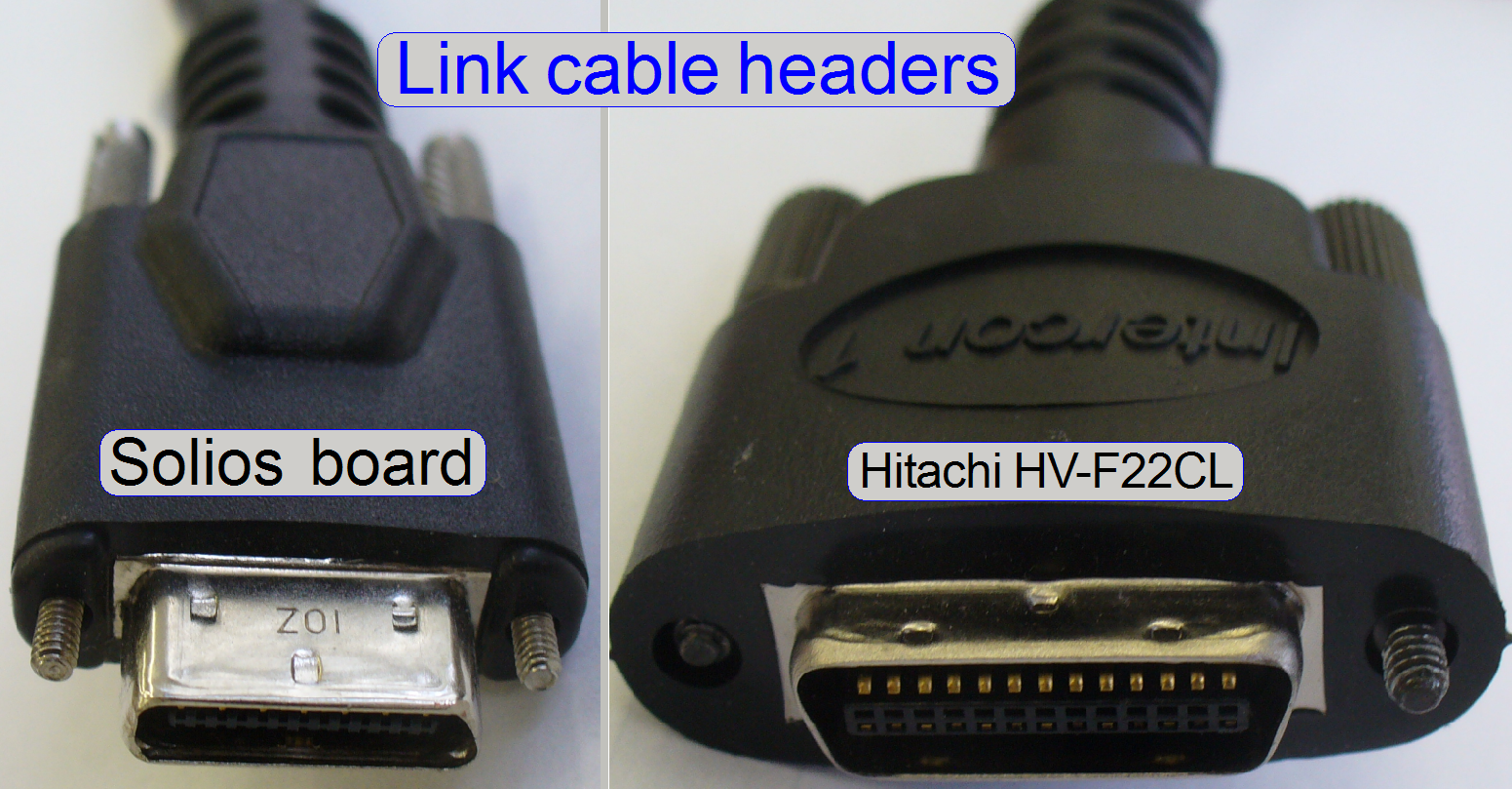

Both camera link

cables are from the same type and the headers are wired 1:1, so any cable

header can be connected to the Solios board or to the

camera as well.

Both camera link

cables are from the same type and the headers are wired 1:1, so any cable

header can be connected to the Solios board or to the

camera as well.

Important

The Camera link cable, connected to the port “CL1” of the camera have to

be connected to the “Channel

If

these conditions are not met, the camera will not be found or recognized by the

software!

Important

If the switch “TRG” or “Vref” of the flash light

source is not set to “External” the camera installation may be not finished

correctly in the dialog “Microscope settings” or the scan program fails the

camera installation with the error message.

Driver

install

The CIS-camera is fully handled by the scan software “SlideScanner.exe”

via the Solios board; therefore, an explicit driver

installation procedure is not required.

![]() “Setup the Matrox Imaging Library version 9.0 (MIL 9.0)”

“Setup the Matrox Imaging Library version 9.0 (MIL 9.0)”

Used in: iSaCS,

P250, SCAN,

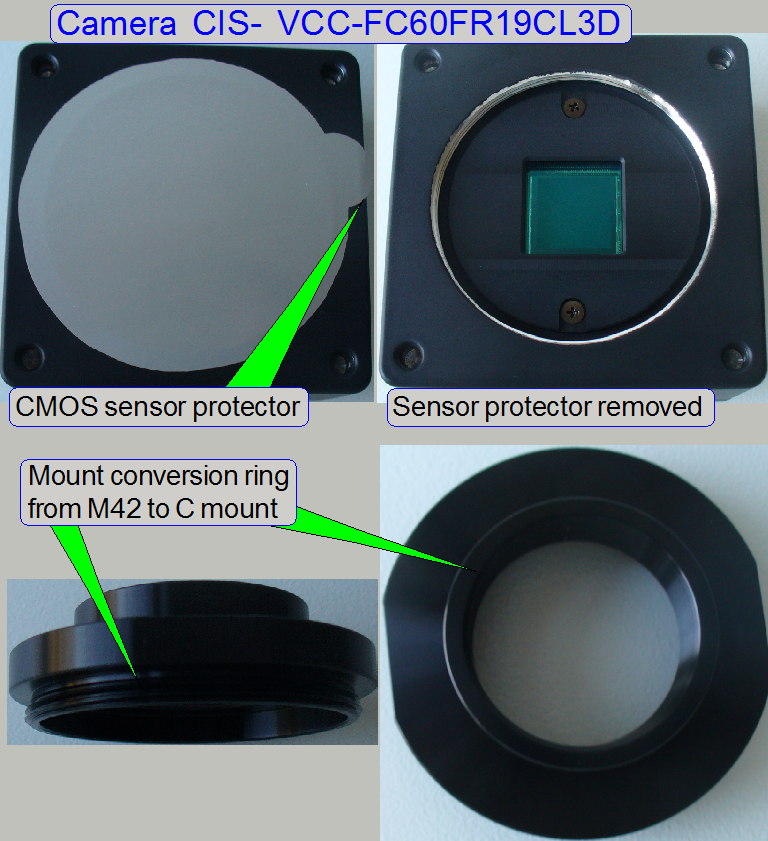

The VCC-FC60FR19CL is a

camera link interfaced, 4Mpixels high-resolution industrial color video camera

module. The 4M pixels global shutter CMOS sensor realizes high sensitivity and

high resolution. The full size field of view can be read out within 135fps,

depending on the configuration.

VCC-FC60FR19CL

Diagonal length: 15.930mm

Shutter type: Global

Effective pixel number: 2048 (H) x 2048 (V)

Cell size: 5.5μm (H) x

5.5μm (V)

Frame rate: 68 to 135fps;

depending on configuration

![]() “Possible scan modes with different cameras and

magnifications in the software version 1.16; 1.17beta and 1.17

“Possible scan modes with different cameras and

magnifications in the software version 1.16; 1.17beta and 1.17

“Useable magnification and resulting

resolution for scan (main) cameras”

Further information about

features, precautions and detailed technical information can be found in the

Product Specification and Operational Manual “Spec_VCC-FC60FR19CL.pdf

”.

CL: In this position the power is supplied

via the “Power & trigger” connector (DC IN).

PoCL: The power is supplied via the

camera link interface (PoCL= Power over Camera Link).

Set the switch into the

position “CL” and use the power and trigger connector!

Remove

the CMOS sensor protector and mount the conversion ring.

Remove

the CMOS sensor protector and mount the conversion ring.

Power;

P250

The camera gets its power of 12V-DC, 3.0W by default from the “Power

distribution and switch board” of the scanner.

The camera interface is a so called “Hot plug interface” so the cable

header may be removed or plugged during the computer is powered on.

Nevertheless, the camera should be powered off before any connection

modification is taken.

Unplug the power header of

the camera or switch off the entire scanner.

Make the desired connections and

secure the header connection with the lock bolts.

Switch on the scanner, or

plug the power header.

Check the

camera migration with the

dialogue “Microscope Settings”.

Power;

S_M_D

Please refer to

“External power supply”

Triggering

The trigger input pulse width of the camera as well as the width of the

trigger pulse of the flash light source is controlled by the firmware. The

trigger cable of the camera is connected to the appropriate connector of the “X-Y-Z-ND motor & flash

light control” electronics.

Camera Link connection

Both camera link cables

are from the same type and the headers are wired 1:1, so any cable header can

be connected to the grabber card RADIENT eCL (or to

the Solios board, if only 1 camera is used in the

scanner) or to the camera as well.

Both camera link cables

are from the same type and the headers are wired 1:1, so any cable header can

be connected to the grabber card RADIENT eCL (or to

the Solios board, if only 1 camera is used in the

scanner) or to the camera as well.

Important

The Camera link cable, connected to the port “CL1” of the camera have to

be connected to the “Channel

If

these conditions are not met, the camera will not be found or recognized by the

software!

Important

If the switch

“TRG” or “Vref” of the flash light

source is not set to “External” the camera installation may be not finished

correctly in the dialog “Microscope settings” or the scan program fails the

camera installation with the error message.

If the switch

“TRG” or “Vref” of the flash light

source is not set to “External” the camera installation may be not finished

correctly in the dialog “Microscope settings” or the scan program fails the

camera installation with the error message.

Driver

install

The camera CIS is fully handled by the scan software “SlideScanner.exe”

via the RADIENT eCL board;

therefore, an explicit driver installation procedure is not required.

![]() “Setup the Matrox Imaging Library version 9.0 (MIL 9.0) Radient eCL”

“Setup the Matrox Imaging Library version 9.0 (MIL 9.0) Radient eCL”

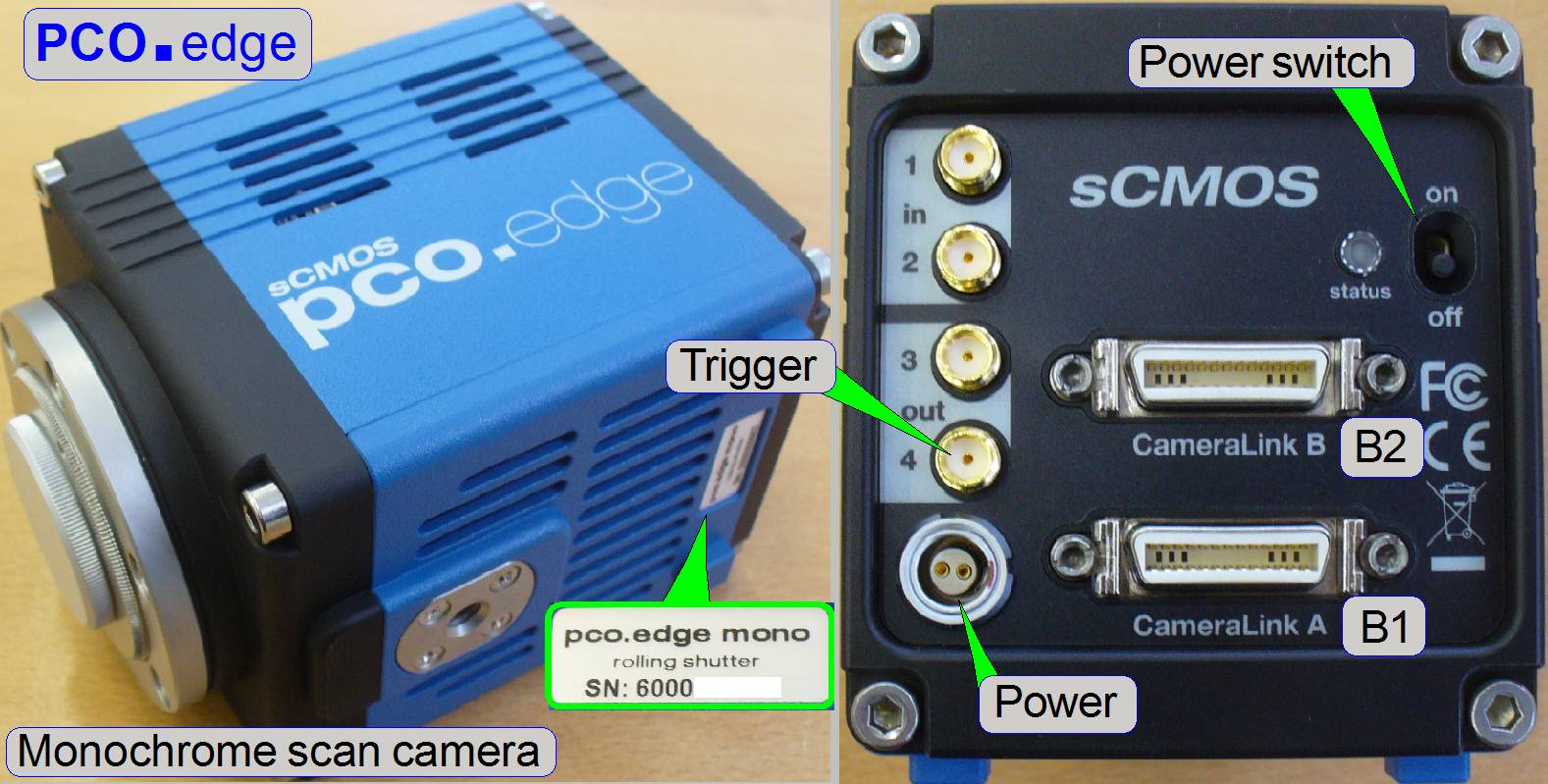

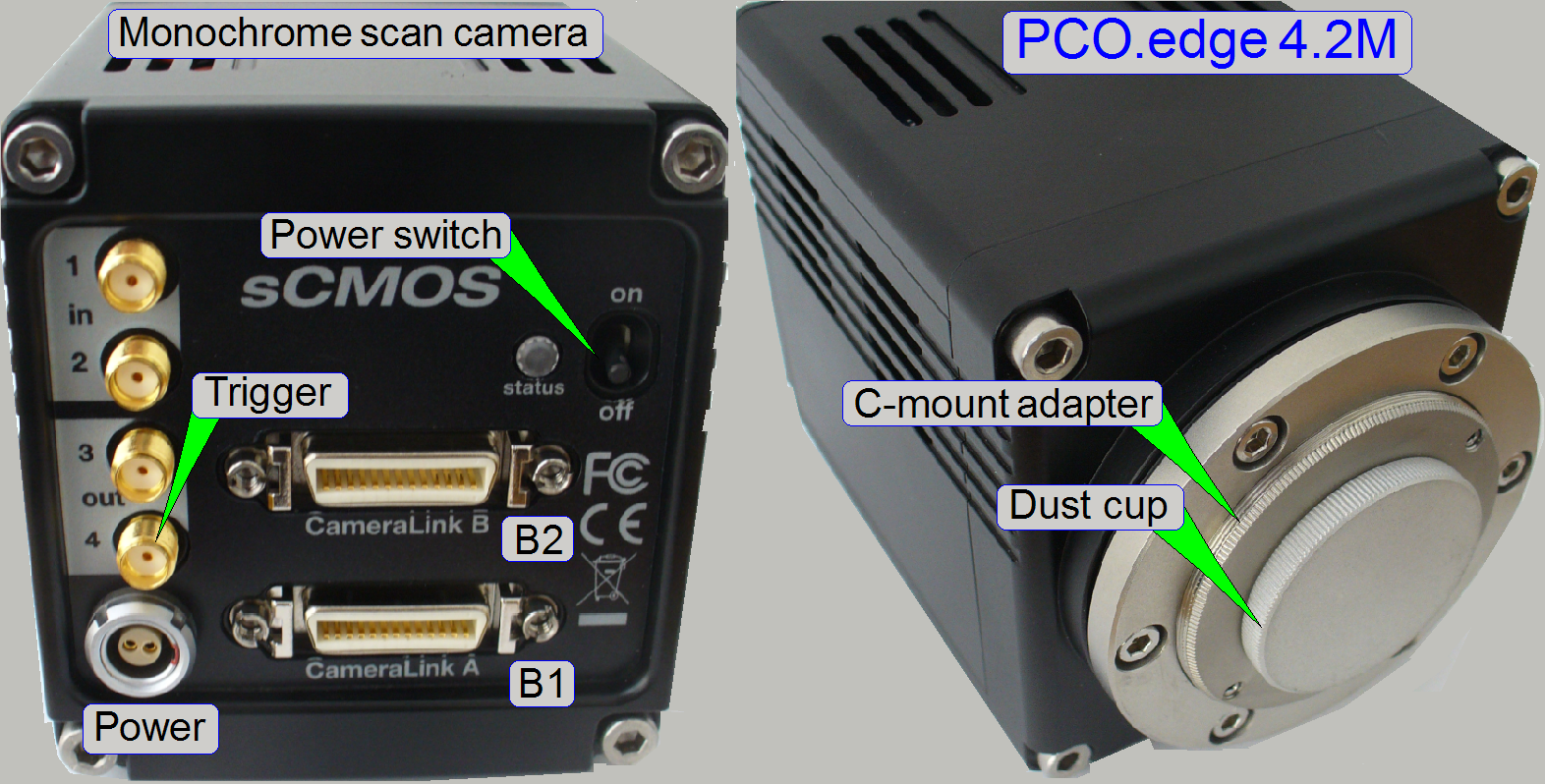

Camera

PCO-edge 5.5MP

Used in: PCON, P250, SCAN and

The pco.edge is a camera link interfaced, monochrome camera and

is used for scanning of stained tissues in the fluorescent scan mode. In the

scanner type “PCON” all scan modes are handled with this camera. The color

(wave length of the light) is defined by the used filter block and the gray

scale image, taken by the pco.edge camera, defines

the partial intensity. By using the software coloring method, images of a very

high quality and color fidelity can be produced.

The pco.edge is a camera link interfaced, monochrome camera and

is used for scanning of stained tissues in the fluorescent scan mode. In the

scanner type “PCON” all scan modes are handled with this camera. The color

(wave length of the light) is defined by the used filter block and the gray

scale image, taken by the pco.edge camera, defines

the partial intensity. By using the software coloring method, images of a very

high quality and color fidelity can be produced.

Resolution: 5.5Mpixels

Pixel array: 2560 (H) x 2160 (V)

Pixel size (h x v): 6.5 µm x 6.5 µm

Transfer rate: 100fps (full size)

Power

requirements

Input: 12 … 24 VDC

(+/- 10 %)

Power consumption:

20W max. (typ. 10 W @

Remark

This camera is used in some configurations with a smaller sensor size, the size is reduced by software.

In these cases, the camera is named as

· PCO-edge_5.5_@2.5MP and

More information about sensor

size and resolutions can be found on the shown links.

![]() “Possible scan modes with different cameras and

magnifications in the software version 1.16; 1.17beta and 1.17

“Possible scan modes with different cameras and

magnifications in the software version 1.16; 1.17beta and 1.17

“Useable magnification and resulting

resolution for scan (main) cameras”

“Useable magnification and resulting

resolution for scan (main) cameras”

Information about

features, precautions and others can be found in the file: “pco_edge_20110527.pdf”

or

further, detailed technical information: “pco_edge_manual_V1-01.pdf”

(stored).

Camera Link connection

The data transfer between camera

and Solios board is realized with two Camera link

cables.

Both camera link cables are

from the same type and the headers are wired 1:1.

The cable header on the Solios board side is a “Camera link HDR26” (CL mini) type

connector during on the camera side a “Camera link (CL) original” type cable

header is used.

Important

The Camera link cable, connected to the port “CameraLink

A” of the camera have to be connected to the “Channel

If

these conditions are not met, the camera will not be found or recognized by the

software!

Driver

install

The camera PCO.edge is fully handled by the

scan software “SlideScanner.exe” via the Solios board(s);

therefore, an explicit driver installation procedure is not required.

See also: “Setup the Matrox Imaging Library version 9.0 (MIL 9.0)”

Power;

P250

The camera gets its

power of 12V- DC 15W by default from the “Power

distribution and switch board” of the scanner; in exceptions or special

conditions an external power supply may be used (e.g. SCAN,

The camera gets its

power of 12V- DC 15W by default from the “Power

distribution and switch board” of the scanner; in exceptions or special

conditions an external power supply may be used (e.g. SCAN,

The camera interface is a so called “Hot plug interface” so the cable

header may be removed or plugged during the computer is powered on, but wait

until the data transfer between camera and link board is finished (if in

progress).

Nevertheless, the camera should be powered off before any connection

modifications are done.

Switch of the camera or

unplug the power header or switch off the entire scanner.

Make the desired connections

and secure the header connection with the lock bolts.

Switch on the scanner, the

camera or plug the power header.

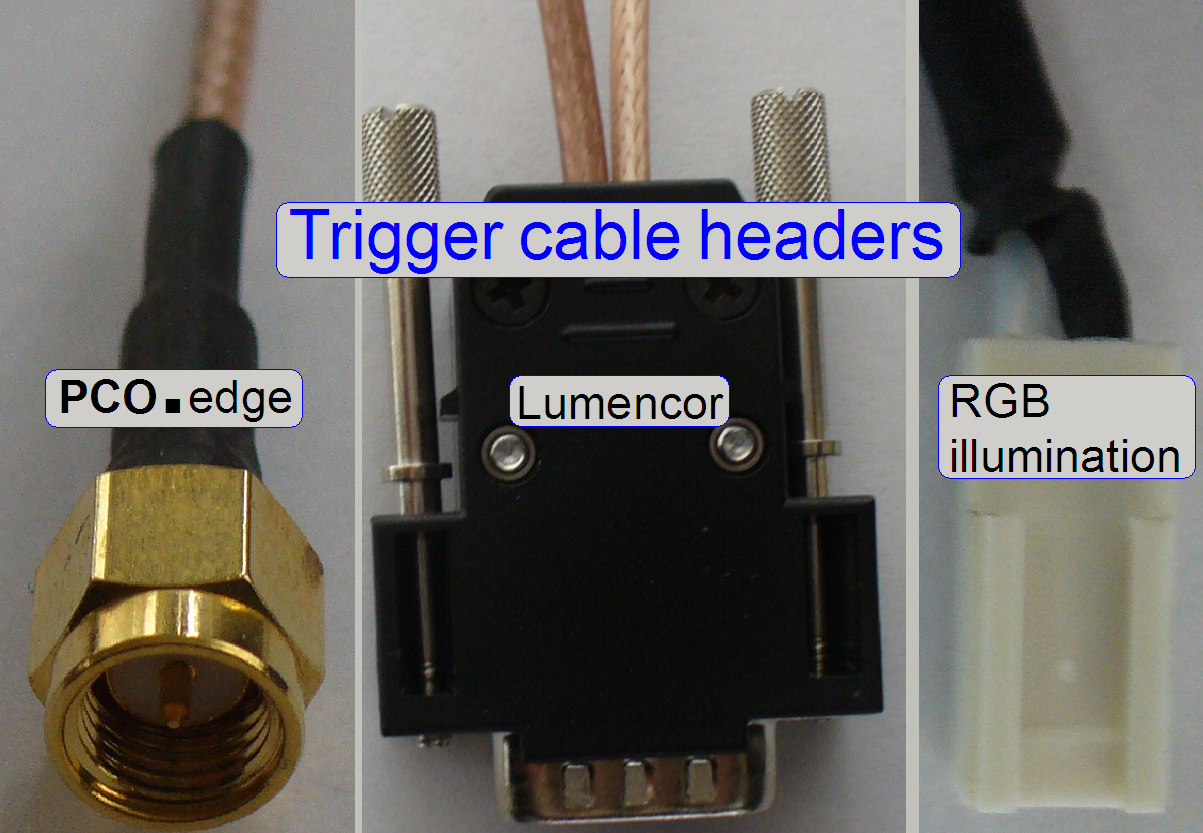

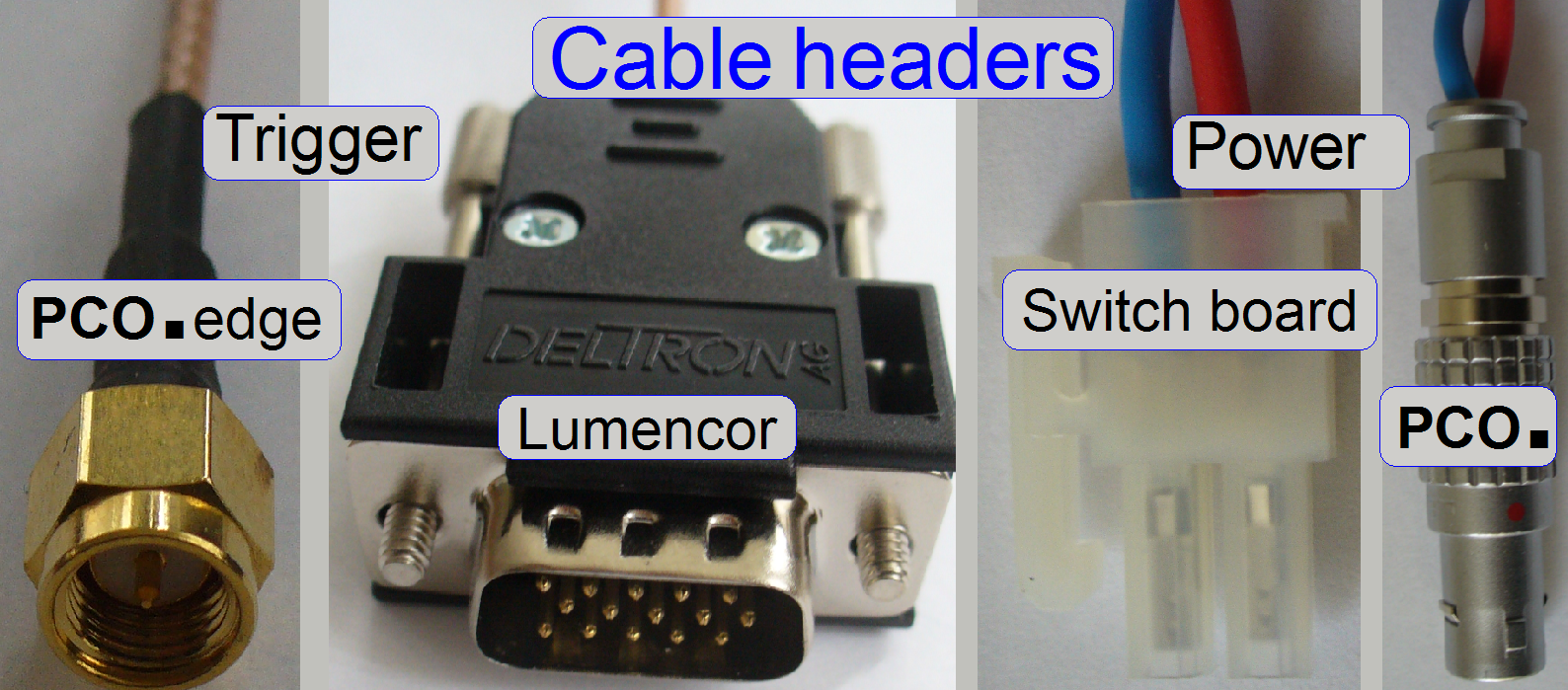

Triggering

Triggering

The trigger output 4 of the camera is used to trigger the Lumencor

SPECTRA light engine.

In SCAN_II and MIDI_II type scanners the trigger cable LTO-4 is used.

This power supply

is used if the PCO.edge camera works in SCAN or

This power supply

is used if the PCO.edge camera works in SCAN or

PCON

The principle of triggering is the same as for the P250 but cable

headers are modified!

The trigger output 4 of the camera is used to trigger the Lumencor

SPECTRA light engine and the RGB illumination

unit.

![]() Control,

cables and connections

Control,

cables and connections

Used in: P250, SCAN,

The pco.edge 2.4M is a camera link interfaced, monochrome

camera and is used for scanning of stained tissues in the fluorescent scan

mode. The color (wave length of the light) is defined by the used filter block,

the wavelength of the exciting light beam and the gray scale image, taken by

the pco.edge camera defines the partial intensity. By

using the software coloring method, images of a very high quality and color

fidelity can be produced.

The pco.edge 2.4M is a camera link interfaced, monochrome

camera and is used for scanning of stained tissues in the fluorescent scan

mode. The color (wave length of the light) is defined by the used filter block,

the wavelength of the exciting light beam and the gray scale image, taken by

the pco.edge camera defines the partial intensity. By

using the software coloring method, images of a very high quality and color

fidelity can be produced.

Resolution: 4.2Mpixels

Pixel array: 2048 (H) x 2048 (V)

Pixel size (h x v): 6.5 µm x 6.5 µm

Transfer rate: 100fps (full size)

Power

requirements

Input: 12 … 24 VDC

(+/- 10 %)

Power

consumption: 20W max. (typ. 10 W

@

Power

consumption: 20W max. (typ. 10 W

@

![]() “Possible scan modes with different cameras and

magnifications in the software version 1.16; 1.17beta and 1.17

“Possible scan modes with different cameras and

magnifications in the software version 1.16; 1.17beta and 1.17

“Useable magnification and resulting

resolution for scan (main) cameras”

Information

about features, precautions and others can be found in the file: “BR_pco_edge42_105_online.pdf”

or further, detailed technical information: “pco_edge_manual_V1-01.pdf”.

Camera Link connection

The data transfer between camera

and Solios board is realized with two Camera link

cables.

Both camera link cables are

from the same type and the headers are wired 1:1.

The cable header on the Solios board side is a “Camera link HDR26” (CL mini) type

connector during on the camera side a “Camera link (CL) original” type cable

header is used.

Important

The Camera link cable, connected to the port “CameraLink

A” of the camera have to be connected to the “Channel

If

these conditions are not met, the camera will not be found or recognized by the

software!

Power;

P250

The camera gets

its power of 12V- DC 15W by default from the “Power

distribution and switch board” of the scanner; in exceptions or special

conditions an external power supply may be used (e.g. SCAN,

The camera gets

its power of 12V- DC 15W by default from the “Power

distribution and switch board” of the scanner; in exceptions or special

conditions an external power supply may be used (e.g. SCAN,

The camera interface is a so called “Hot plug interface” so the cable

header may be removed or plugged during the computer is powered on, but wait

until the data transfer between camera and link board is finished (if in

progress).

Nevertheless, the camera should be powered off before any connection

modifications are done.

Switch of the camera or

unplug the power header or switch off the entire scanner.

Make the desired connections

and secure the header connection with the lock bolts.

Switch on the scanner, the

camera or plug the power header.

Power;

SCAN and

Triggering

The trigger output 4 of the camera is used to trigger the Lumencor SPECTRA

light engine.

Driver

install

The camera PCO.edge 4.2Mp is fully handled by

the scan software “SlideScanner.exe” via the Solios

board(s); therefore, an explicit driver installation procedure is not required.

![]() “Setup the Matrox Imaging Library version 9.0 (MIL 9.0)” and “Solios

board”

“Setup the Matrox Imaging Library version 9.0 (MIL 9.0)” and “Solios

board”

Camera

AxioCam MRm REV.3

Used in: P250, SCAN and

The AxioCam MRm Rev.3 camera is a 12

bit monochrome camera especially used for fluorescent scan. The color (wave

length of the light) is defined by the used fluorescent filter and the gray

scale image, taken by the AxioCam camera defines the

intensity. By using the software coloring method, images of a very high quality

and color fidelity can be produced.

The AxioCam MRm Rev.3 camera is a 12

bit monochrome camera especially used for fluorescent scan. The color (wave

length of the light) is defined by the used fluorescent filter and the gray

scale image, taken by the AxioCam camera defines the

intensity. By using the software coloring method, images of a very high quality

and color fidelity can be produced.

CARL ZEISS Monochrome camera for fluorescent scan

Frame rate:

MAX. 13 FPS

Effective pixels: 1388 x 1040 (1.4 Mega pixels)

Cell size: 6.45 x 6.45 μm

Pixel resolution (with 20x objective and C-mount

adapter 1x): 0.33μm

Interface type: IEEE 1394a

More information about features, precautions and others can be found in

the file “AxioCam MRm Rev.3”

![]() “Useable

magnification and resulting resolution for scan (main) cameras”

“Useable

magnification and resulting resolution for scan (main) cameras”

FireWire IEEE 1394 “a” header type controller (card)

FireWire IEEE 1394 “a” header type controller (card)

FireWire IEEE

1394 “a” to “a” header type cable

Install and driver CD for Pannoramic scanners, “AxioCam.inf”

Cables

and connections

The camera cable connection is

realized with an IEEE 1394 “a” type header and the

cable is connected to the inserted controller board with a FireWire IEEE 1394 “a” type or “b” screw lock type header.

The camera needs a FireWire port of the

extension card. The camera has a FireWire input port (connected to the

computer) and a link port (connected to the next camera; not used in Pannoramic scanners). If the camera is not recognized after

driver installing, please try with the other port connector of the camera.

The camera cable connection is

realized with an IEEE 1394 “a” type header and the

cable is connected to the inserted controller board with a FireWire IEEE 1394 “a” type or “b” screw lock type header.

The camera needs a FireWire port of the

extension card. The camera has a FireWire input port (connected to the

computer) and a link port (connected to the next camera; not used in Pannoramic scanners). If the camera is not recognized after

driver installing, please try with the other port connector of the camera.

![]() “FireWire interface”, “Precautions” and “Connect the camera”

“FireWire interface”, “Precautions” and “Connect the camera”

Driver

install

· Windows®

7x64bit Setup the driver for the

camera “Carl Zeiss AxioCam MRm R3”

· Windows®

XP Setup the XP driver

for the camera “Carl Zeiss AxioCam

MRm R3”

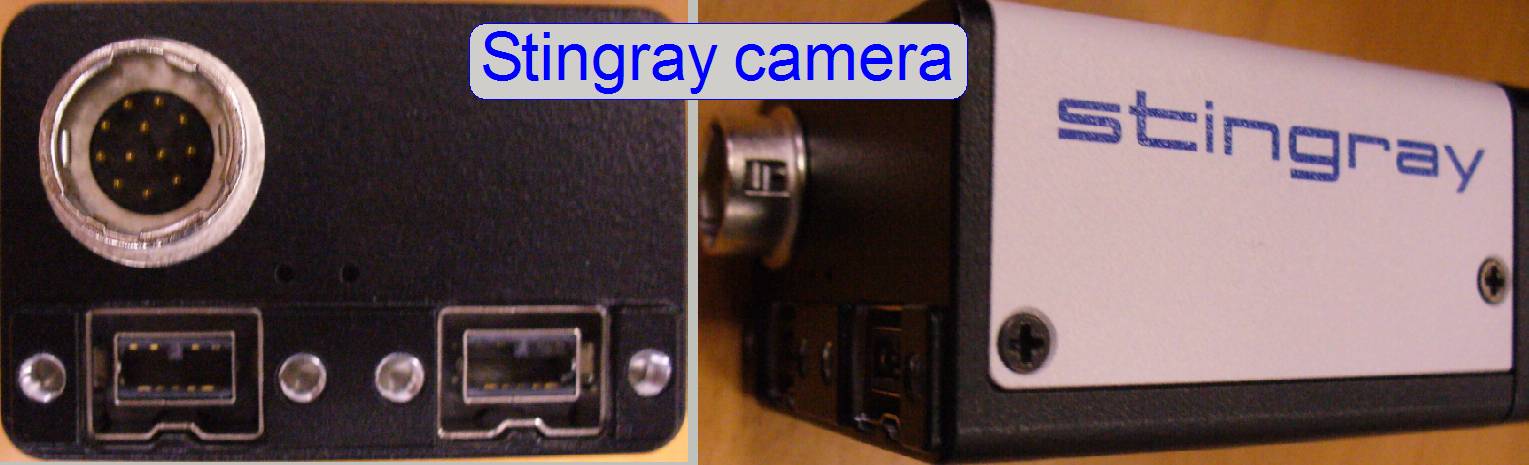

Stingray F-

Used in: SCAN,

The camera uses a single chip CCD and

produces pictures of a good quality, and is used for brightfield

and fluorescent scan likewise. Because the sensitivity of this camera is very

high and the RGB logic contains a hardware equalizer, the color fidelity is

also high.

The camera uses a single chip CCD and

produces pictures of a good quality, and is used for brightfield

and fluorescent scan likewise. Because the sensitivity of this camera is very

high and the RGB logic contains a hardware equalizer, the color fidelity is

also high.

Further information about “Single

chip CCD color capturing” and

‘Single chip CCD” Wikipedia

AVT Stingray color camera Fire

Wire 1/2" type progressive SCAN IT CCD

Video data output: 8/14 bit

Frame rate: ~15 FPS

Effective pixels: 1388 x 1038 (1.44 Megapixels)

Cell size: 4.65 x 4.65μm

Pixel resolution (with 20x objective and C-mount adapter

1x): 0.23 μm

Interface type: IEEE 1394b, screw lock

Interface type: IEEE 1394b, screw lock

![]() “Useable magnification and resulting

resolution for scan (main) cameras”

“Useable magnification and resulting

resolution for scan (main) cameras”

“Stingray_DataSheet_F-146_V4.0.1_en.pdf”,

“”

Fire wire IEEE

1394 “b” screw lock type controller board

Fire wire IEEE

1394 “b” screw lock type cable

Install and driver CD for Pannoramic scanners AVT Fire package

Cables

and connections

The camera cable connection is

realized with an IEEE 1394 “b” screw lock type header

and the cable is connected to the inserted controller board with a FireWire IEEE 1394 “a” type or “b” screw lock type header.

The camera needs a FireWire port of the

extension card. Because the AVT fire package uses the entire controller of the

board, no other type cameras (like the DFK21F04) can be connected to this

controller (card). The camera has a FireWire input port (connected to the

computer) and a link port (connected to the next camera; not used in Pannoramic scanners). If the camera is not recognized after

driver installing, please try with the other port connector of the camera also.

The camera cable connection is

realized with an IEEE 1394 “b” screw lock type header

and the cable is connected to the inserted controller board with a FireWire IEEE 1394 “a” type or “b” screw lock type header.

The camera needs a FireWire port of the

extension card. Because the AVT fire package uses the entire controller of the

board, no other type cameras (like the DFK21F04) can be connected to this

controller (card). The camera has a FireWire input port (connected to the

computer) and a link port (connected to the next camera; not used in Pannoramic scanners). If the camera is not recognized after

driver installing, please try with the other port connector of the camera also.

![]() “FireWire interface”, “Precautions” and “Connect the camera”

“FireWire interface”, “Precautions” and “Connect the camera”

Check or set the following entries of the file

“MicroscopeConfiguration.ini” (until SW version 1.14):

[Microscope]

ScanCameraType= AVT Stingray F146C

[ScanCamera]; the

following parameter values are for information only!

Gain=0

Shutter=1000

Gamma=0

Saturation=128

WhiteBalance_U=81

WhiteBalance_V=45

Sharpness=0

Brightness=0

TriggerTimeout=5000

AutoCalibrate=TRUE

Check / set the following entries of the file

“MicroscopeSettings.ini”:

[ReflectorTurret]

CameraName = Stingray F146C

Driver

install

· Since

the software version 1.16 Setup_AVT_cam_Driver

Windows® 7x64bit

· Until

the software version 1.14 Setup AVT_XP_FirePackage Windows® XP x 32bit

Marlin F-

Used in: SCAN,

The camera uses a single chip CCD and

produces color pictures of a good quality; it is used for brightfield

and fluorescent scan likewise. Because the sensitivity of this camera is very

high and the RGB logic does not contain a hardware equalizer, the illumination

of the FOV must be adjusted very well, otherwise the color fidelity is reduced.

This is the reason why in newer systems this camera is replaced by the camera

“Stingray F-

The camera uses a single chip CCD and

produces color pictures of a good quality; it is used for brightfield

and fluorescent scan likewise. Because the sensitivity of this camera is very

high and the RGB logic does not contain a hardware equalizer, the illumination

of the FOV must be adjusted very well, otherwise the color fidelity is reduced.

This is the reason why in newer systems this camera is replaced by the camera

“Stingray F-

Resolution: 1392 x 1040

Data rate: 400 Mbit/s max.

Speed: 17 fps max.

Interface type: IEEE 1394a

![]() “Useable magnification and resulting resolution

for scan (main) cameras”

“Useable magnification and resulting resolution

for scan (main) cameras”

“Marlin_DataSheet_F-146_V4.0.0_en.pdf”” and ”Sngle chip CCD color capturing”

Fire wire IEEE 1394

“a” type controller card

Fire wire IEEE

1394 “a” type cable

Install and driver CD for Pannoramic scanners; AVT Fire package

Cables

and connections

The camera is connected to the

inserted controller board with a FireWire IEEE 1394

“a” type cable. The camera needs a FireWire

port of the extension card. Because the AVT fire package uses the entire

controller of the board, no other type cameras (like the DFK 21F04) can be

connected to this controller.

The camera is connected to the

inserted controller board with a FireWire IEEE 1394

“a” type cable. The camera needs a FireWire

port of the extension card. Because the AVT fire package uses the entire

controller of the board, no other type cameras (like the DFK 21F04) can be

connected to this controller.

![]() “FireWire interface”, “Precautions” and “Connect the camera”

“FireWire interface”, “Precautions” and “Connect the camera”

Driver

install

· Since

the software version 1.16 Setup_AVT_cam_Driver Windows® 7x64bit

· Until

the software version 1.14 Setup AVT_XP_FirePackage Windows® XP x 32bit

Used in: SCAN,

The camera contains for the colors red green and

blue a separate CCD; it is a “Three CCD camera”.

Each CCD uses a 10 bit A/D converter so the color fidelity is very high.

Because the camera uses an own interface board and own interface cables

(Data-Link interface), the transfer rate is very high as well. Primarily the

camera is advised for brightfield scan procedures but

there can be produced fluorescent scans with a high quality as well.

The camera contains for the colors red green and

blue a separate CCD; it is a “Three CCD camera”.

Each CCD uses a 10 bit A/D converter so the color fidelity is very high.

Because the camera uses an own interface board and own interface cables

(Data-Link interface), the transfer rate is very high as well. Primarily the

camera is advised for brightfield scan procedures but

there can be produced fluorescent scans with a high quality as well.

Hitachi HV-F22CL 3CCD progressive

scan color camera

Video Data output: 3 x 10 bit

Frame rate: ~15 FPS

Effective pixels: 1360 x 1024 (1.4 Megapixels)

Pixel resolution (with 20x objective and C-mount

adapter 1x): 0.23 μm

![]() “Useable

magnification and resulting resolution for scan (main) cameras”

“Useable

magnification and resulting resolution for scan (main) cameras”

“HV-F22CL Specifications”,

“Operation_Manual”,

Technical_information”

Requirements

The Matrox Solios XCL controller board; delivered

with the camera

The Matrox Solios XCL controller board; delivered

with the camera

Interface cables;

delivered with the camera

Power supply; delivered with the camera

Matrox Imaging Library MIL 8.0

or MIL

9.0; to install the hardware

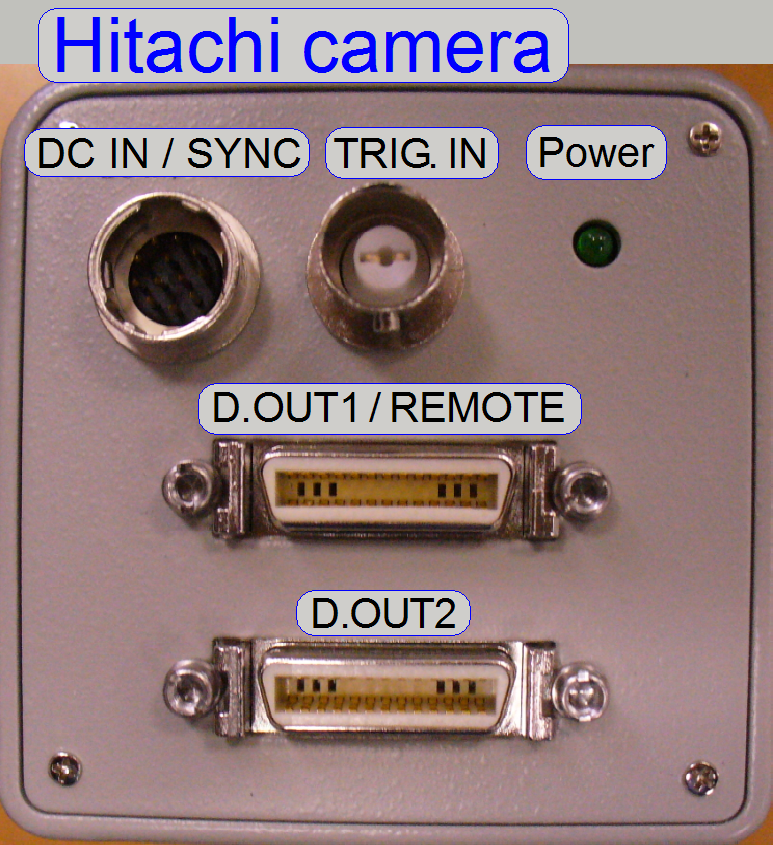

Cables

and connections

The Matrox Solios XCL controller

board should be inserted into a PCI slot with 64bit /66MHz

or higher (in software versions until 1.14)!. The camera is

connected to the computer with the D.OUT1 and D.OUT2 data link cables to the

appropriate connectors of the Solios board. The

delivered power supply is connected to the DCIN / SYNC input of the camera.

The Matrox Solios XCL controller

board should be inserted into a PCI slot with 64bit /66MHz

or higher (in software versions until 1.14)!. The camera is

connected to the computer with the D.OUT1 and D.OUT2 data link cables to the

appropriate connectors of the Solios board. The

delivered power supply is connected to the DCIN / SYNC input of the camera.

The installation

of the board and the driver installation procedures are suggested to be done by

a qualified system administrator.

Important

The Solios board should be inserted into a slot PCI-E

generation 1 (PCI-Express x8 gen.1); otherwise, if a PCI-E generation 2 slot is

used, the system may freeze during boot (in software versions until 1.14)!

Detailed information about hardware install and software setup

procedures can be found on the Install CD for Pannoramic

scanners in the files:

<CD ROM>:Drivers\Matrox Imaging Library\

Matrox Imaging Library Installation Guide MIL

8.0 or MIL9.0

respectively

And

<CD ROM>:Drivers\Matrox Imaging

Library\Hitachi HV-F22CL (Original CD)\Doc\ English \Operation_Manual

Check or set the following entries of the file

“MicroscopeConfiguration.ini” (until SW version 1.14):

[Microscope]

ScanCameraType=Hitachi_HV_F22CL

[ScanCamera]; until

SW version 1.14; the following parameter values are for information only!

Gain=0

Shutter=1000

Gamma=0

Saturation=128

WhiteBalance_U=86

WhiteBalance_V=44

Sharpness=0

Brightness=0

TriggerTimeout=5000

AutoCalibrate=TRUE

Check or set the following entries of the file

“MicroscopeSettings.ini”:

[ReflectorTurret]

CameraName =

Hitachi_HV_F22CL

To install the camera driver for the camera Hitachi

HV-F22CL

Please refer to the file:

<CD ROM>\Drivers\Matrox Imaging Library\

Matrox Imaging Library Installation Guide.doc

Used in: MIRAX SCAN and MIRAX

DESK

The Sony camera uses a single chip CCD and

was used in early SCAN,

The Sony camera uses a single chip CCD and

was used in early SCAN,

Progressive scan CCD

Frame rate: 15 fps max.

Resolution: 1024 x 768

Cell size: 4.65 x

4.65μm

Transfer speed: 400/200 Mbps

(400 with external triggering)

Interface type: IEEE 1394a

![]() “Useable magnification and resulting

resolution for scan (main) cameras”

“Useable magnification and resulting

resolution for scan (main) cameras”

Manuals: DFW_SX910_X710_s, dfw-sx910-x710_data

Further information can be found in the

chapter “Sony_DFW_X710_cam_and_driver”

Lumencor SPECTRA light engine®

The Lumencor SPECTRA Light Engine® is a light source, used to

illuminate the field of view of fluorescent stained tissues; the required light

wavelengths are created by light modules. The light modules are switched on or

off separately, as required for the excitation wavelength to be used.

The Lumencor SPECTRA Light Engine® is a light source, used to

illuminate the field of view of fluorescent stained tissues; the required light

wavelengths are created by light modules. The light modules are switched on or

off separately, as required for the excitation wavelength to be used.

·

The Lumencor SPECTRA Light

Engine® is delivered together with the PCO.edge FL

scan camera.

·

The following chapter is true for the

PSCAN and the PMIDI also.

·

The use of a separate

light module for each excitation wavelength allows the precise creation of the

required light wavelength.

The use of a separate

light module for each excitation wavelength allows the precise creation of the

required light wavelength.

·

The light sources are switched separately and

electronically, software controlled.

·

The exchange of the excitation wavelength is done very

quickly.

·

The use of multiple band filters is possible.

·

Minimizing of mechanical movements (of the filter

wheel) saves scan time.

·

Bleaching of the fluorescent tissue is minimized,

because the exciting light is switched on only during the shutter time of the camera

(hardware triggering).

·

Low heat emission.

·

Low power consumption.

·

The scan process of the virtual tissue in the

fluorescent scan mode speeds up.

·

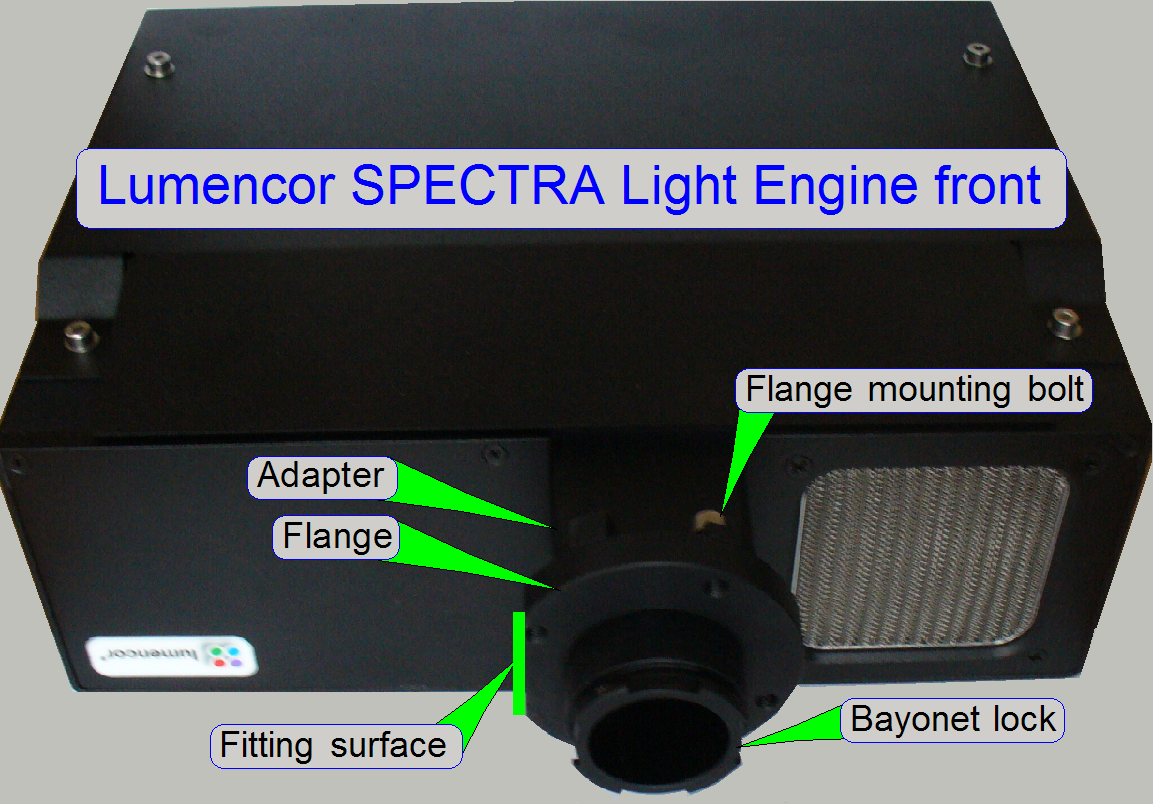

The Lumencor SPECTRA Light Engine® (shown in its working position;

upside down)

The Lumencor SPECTRA Light Engine® (shown in its working position;

upside down)

·

The adapter; with heat barrier filter and concentrator

lens

·

The flange with bayonet lock mechanism (the Lumencor light source adapter)

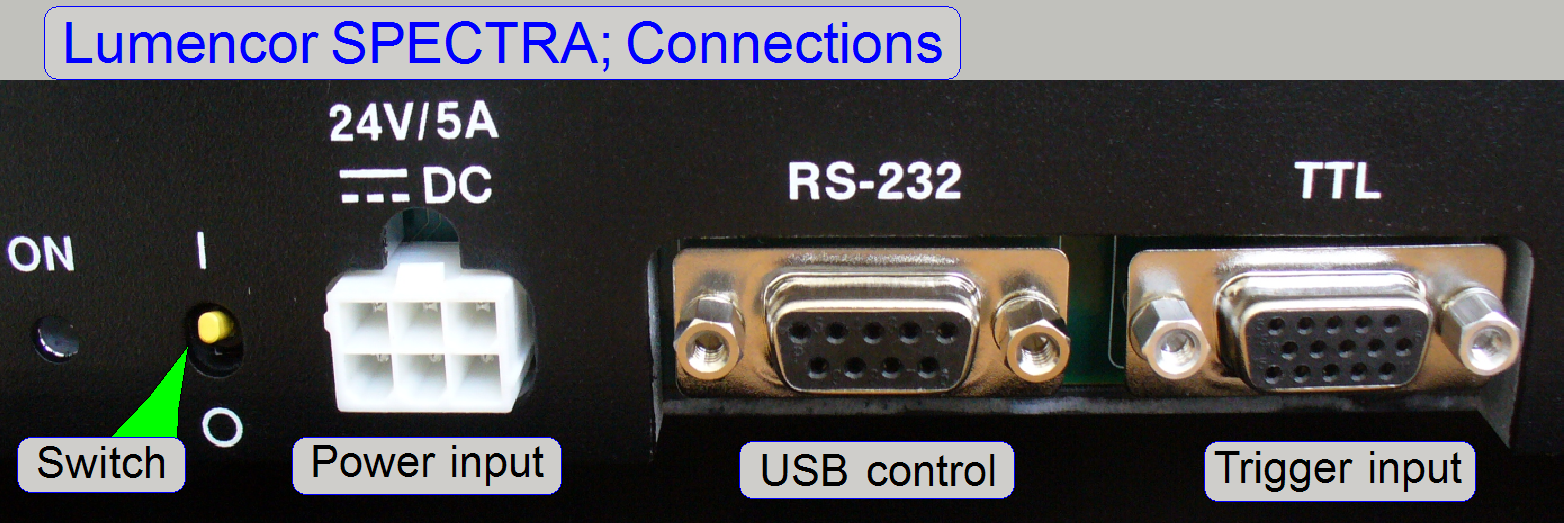

On

the rear

Power connector, power switch

and power LED

Trigger input (TTL)

Control input of the light

engine (RS-232)

Detailed information

about features, precautions, warnings and technical data can be found in the

file “Lumencor_Spectra_LE_User_Manual.pdf”

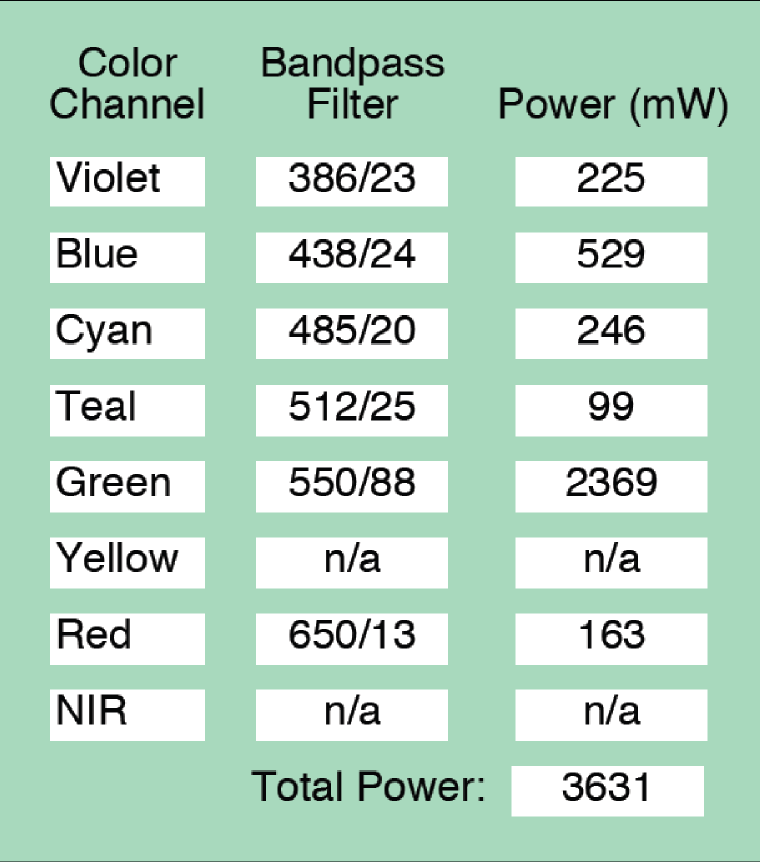

The light modules in the lumencor

SPECTRA light engine, delivered by 3DHISTECH, creating the excitation lights with

the wavelengths as shown on the right.

The light modules in the lumencor

SPECTRA light engine, delivered by 3DHISTECH, creating the excitation lights with

the wavelengths as shown on the right.

To excite the fluorophore of the tissue, the

light wavelength, selected in the Lumencor SPECTRA,

the characteristic of the quad band filter (or the single band filter) and the

exciting wavelength of the fluorophore must meet each

other, otherwise, the fluorophore will not be

excited, the exposure time rise up and the quality of the scanned tissue

becomes bad.

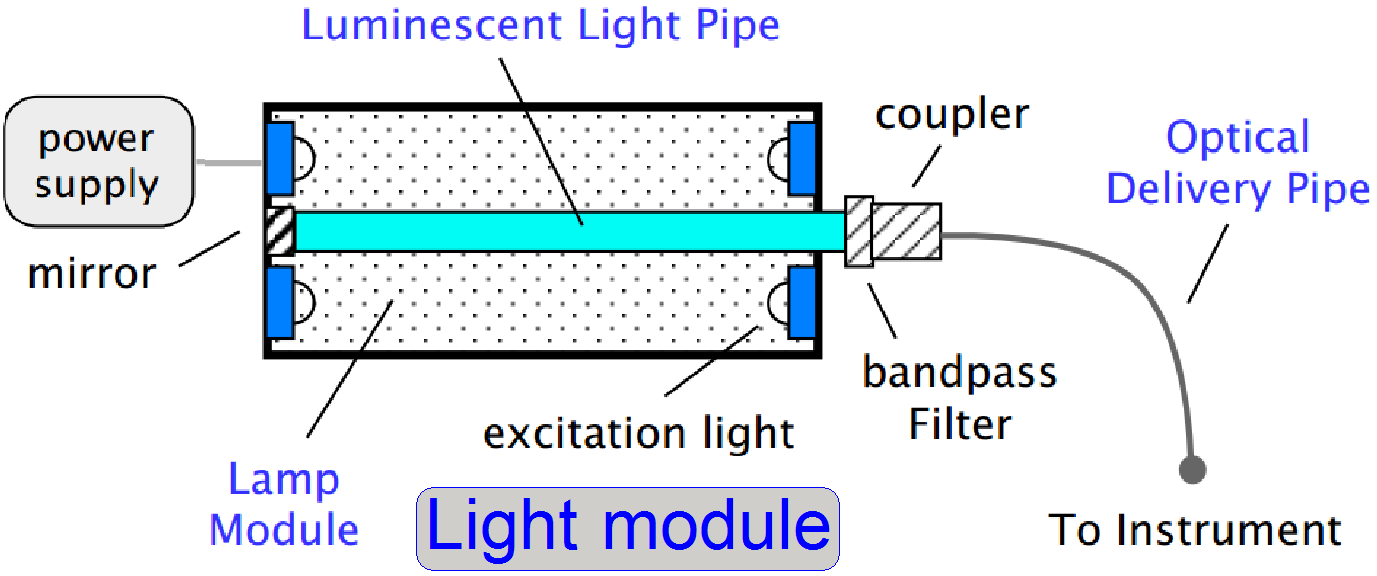

Light

Engine Subsystem

Each light engine consists

of a lamp and delivery optics. The lamp subsystem embodies multiple modules

optimized to each produce a precise set of wavelengths. One such module is

shown on the right. Here Lumencor’s light pipe

technology is the source. Light is generated by a luminescent light pipe which

is driven by an e-beam, LEDs or UV lamps. The pipe,

which may consist of any of a variety of luminescent materials (e.g. rare earth

doped glass, organic doped plastic, single crystal fiber)

is tailored to emit light in the UV through the NIR. In the case of the rare

earths, emission is inherently narrow due to their atomic-like energy

structure. Any unwanted light is removed by a simple bandpass

filter. The light output from the pipe is fed into an optical delivery pipe and

into the instrument. The fast luminescence decay results in rapid switching

with no appreciable warm up time.

Each light engine consists

of a lamp and delivery optics. The lamp subsystem embodies multiple modules

optimized to each produce a precise set of wavelengths. One such module is

shown on the right. Here Lumencor’s light pipe

technology is the source. Light is generated by a luminescent light pipe which

is driven by an e-beam, LEDs or UV lamps. The pipe,

which may consist of any of a variety of luminescent materials (e.g. rare earth

doped glass, organic doped plastic, single crystal fiber)

is tailored to emit light in the UV through the NIR. In the case of the rare

earths, emission is inherently narrow due to their atomic-like energy

structure. Any unwanted light is removed by a simple bandpass

filter. The light output from the pipe is fed into an optical delivery pipe and

into the instrument. The fast luminescence decay results in rapid switching

with no appreciable warm up time.

The light pipe geometry integrates a significant fraction of the light

leading to high external efficiencies.

These efficiencies are optimized by the innovative design of the lamp

module including the excitation source and the unique geometric shape of the

pipe. Increased power levels, exceeding those typical for lasers in these

applications, can readily be obtained by scaling the light pipe and associated

excitation.

Source: Lumencor-White-Paper.pdf

(stored)

Watch slide show: Lumencor

SPECTRA light engine

· The Lumencor SPECTRA creates the excitation light by using

light modules; each module creates the light in the specified wavelength and

the excitation beams are routed by the use of dichroic

mirrors.

The modules are switched on

or off separately, controlled by the scan program via the control input of the

light engine, so the required light wavelength to excite the appropriate fluorophore of the tissue can be created and selected.

Dichroic mirror

A dichroic mirror reflects the lower

wavelength of the light while the higher wavelength passes thru it. The edge

wavelength keeps the border between lower wavelengths and higher wavelengths.

![]() Dichroic beam splitter (Semrock)

Dichroic beam splitter (Semrock)

P250

The lumencor SPECTRA get its power of 24V- 5A DC from the

internal power supply tdk-Lambda of the scanner P250.

The lumencor SPECTRA get its power of 24V- 5A DC from the

internal power supply tdk-Lambda of the scanner P250.

Because the relays of the power distribution and switch board can not

handle the required current of 5A DC, a Power amplifier is

used; it is situated in the common housing of the power supply and the switch

board.

The real working position of the Lumencor

SPECTRA Light Engine® is upside down!

If the Lumencor SPECTRA Light Engine is used together with the PSCAN

or the PMIDI, the shown external power supply is used.

If the Lumencor SPECTRA Light Engine is used together with the PSCAN

or the PMIDI, the shown external power supply is used.

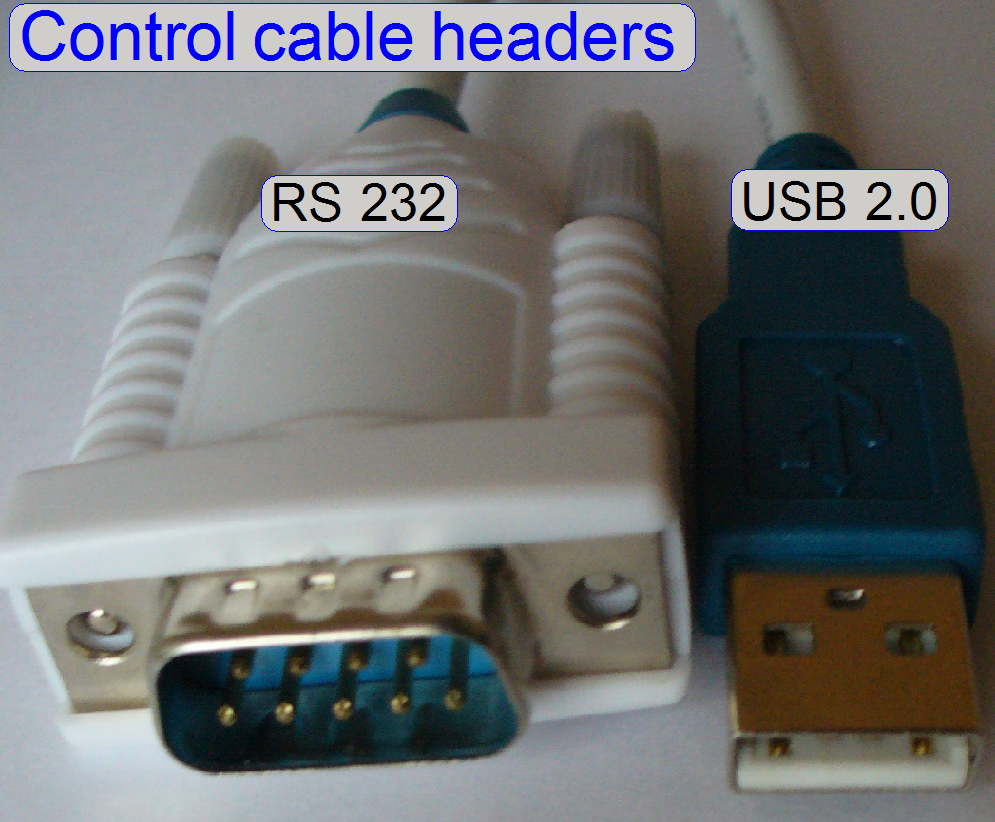

The control of the

light engine is realized via the RS-232 input; on the other end of the cable an

USB 2.0 A-type header is connected.

The control of the

light engine is realized via the RS-232 input; on the other end of the cable an

USB 2.0 A-type header is connected.

The control and selecting of the appropriate light wavelength is

realized via an USB-port.

The cable header RS-232

contains the converter logic to convert the interfaces from USB2.0 to RS-232

and vice versa.

· If the control cable was

exchanged or another USB 2.0 port (on the computer) is used, the USB port

address has to be checked and probably updated.

![]() Check and update the

USB port address.

Check and update the

USB port address.

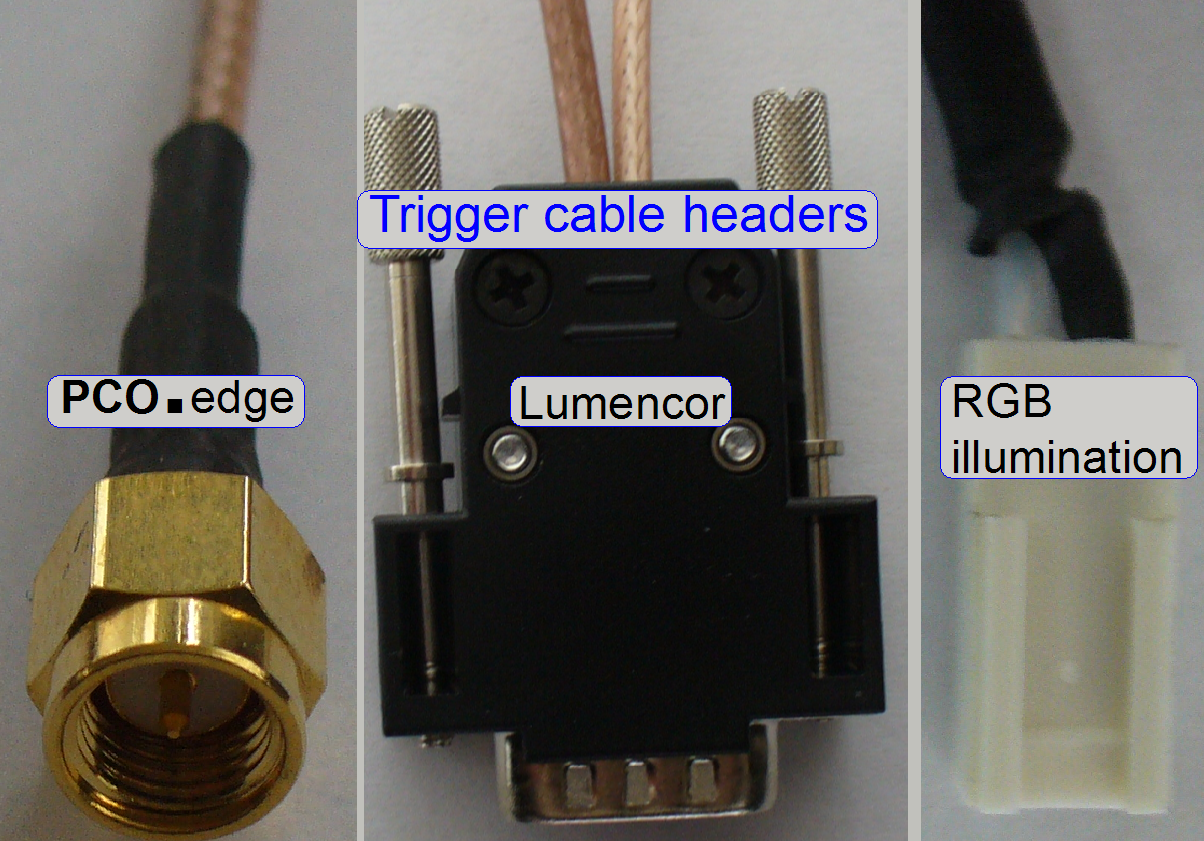

The trigger cable

is connected to the TTL port of the lumencor SPECTRA.

The trigger cable

is connected to the TTL port of the lumencor SPECTRA.

If the shutter of the PCO camera is open, the selected light module

(selected via the USB port) will be switched on.

Remark

The extension to the RGB BF illumination unit is used in the PCON only!

PCON

The principle

of triggering is the same as for the P250 but cable headers are modified!

The trigger output 4 of the camera is used to trigger the RGB illumination

unit also.

![]() Control,

cables and connections

Control,

cables and connections

Check and update

the USB port address

Because the

control of the light engine is done via an USB 2.0 port of the computer, the

scan software has to know the port address.

Because the

control of the light engine is done via an USB 2.0 port of the computer, the

scan software has to know the port address.

The port address is defined in the section [Lumencor]

of the file “MicroscopeConfiguration.ini”.

If the control cable was

exchanged or another USB 2.0 port (on the computer) is used, the USB port

address has to be checked and updated.

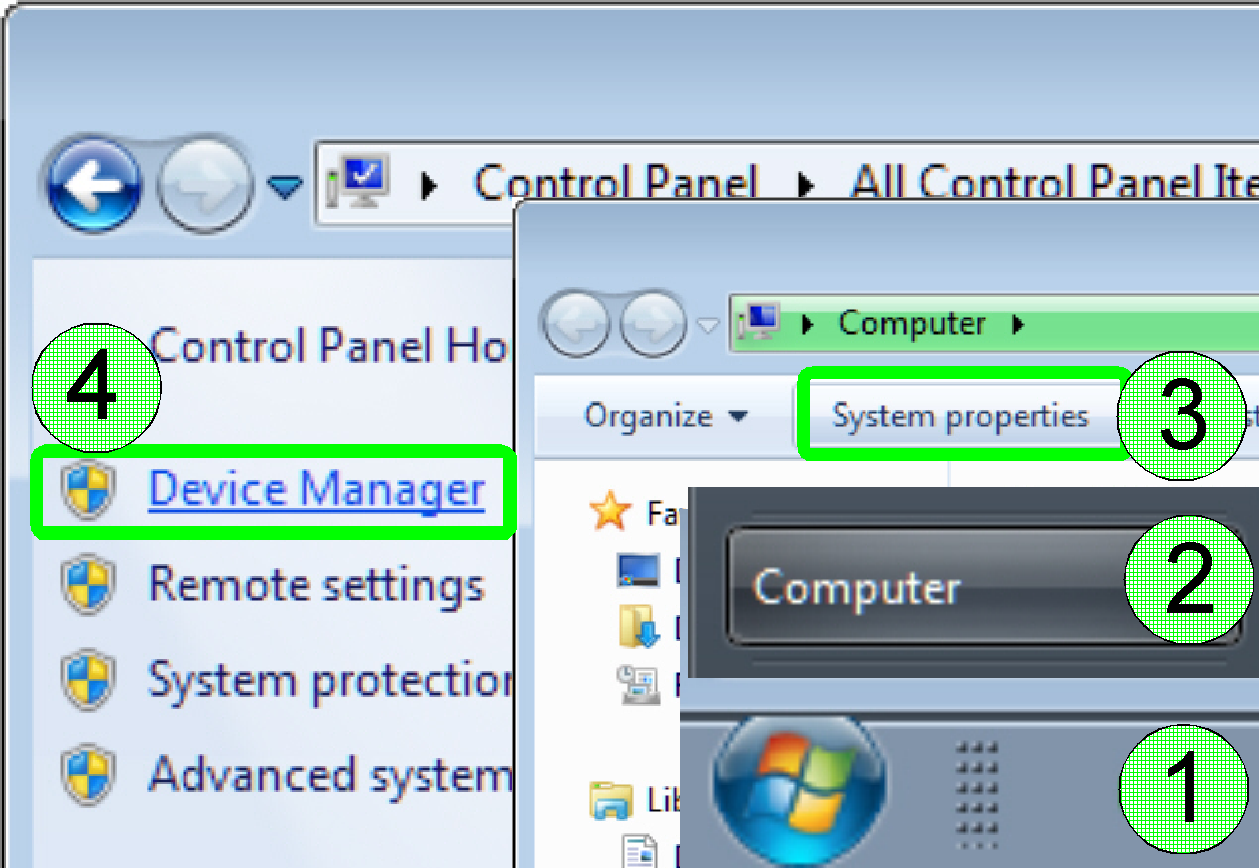

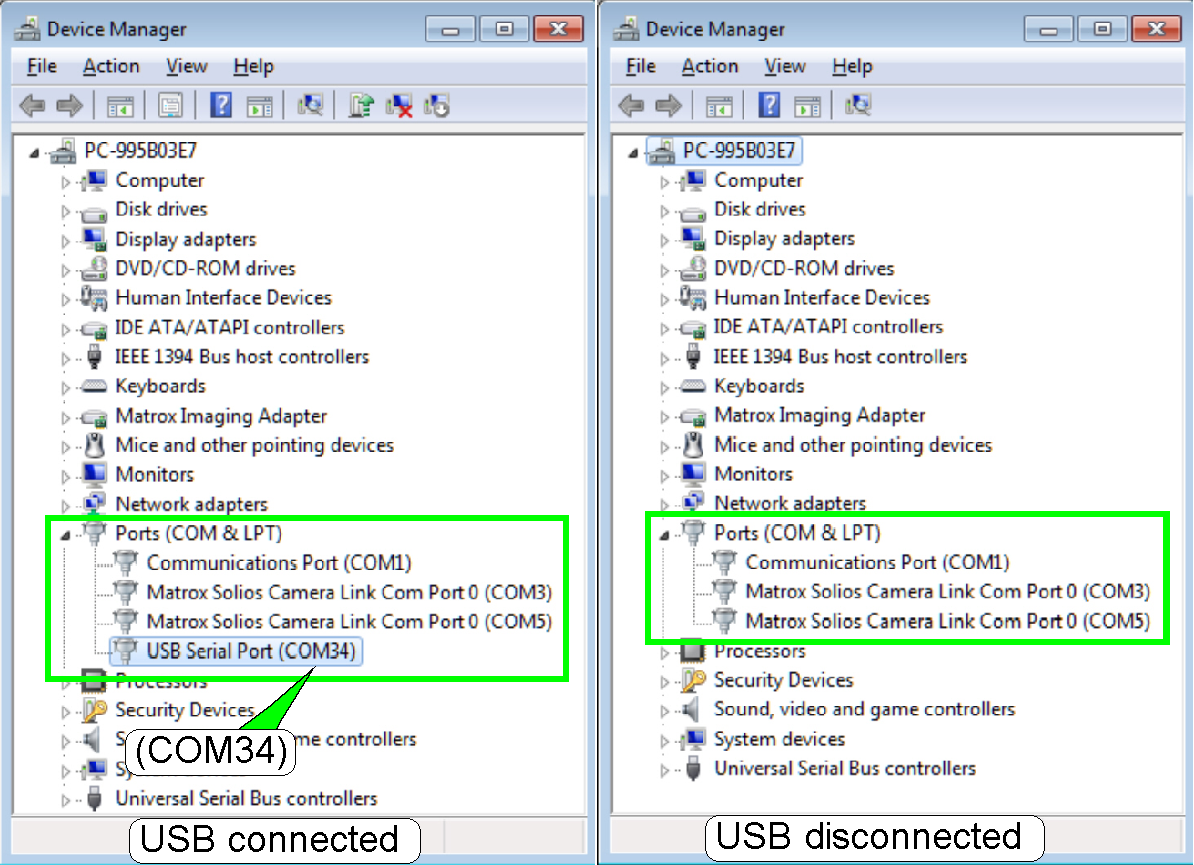

Start

the “Device manager”

· Press “Start”(1), “Computer”(2), “System properties”(3),and “Device

Manager”(4).

Find

the USB control port address

By connecting or

disconnecting the USB connector, the state of the item “USB serial port (COMxx)” is changed.

By connecting or

disconnecting the USB connector, the state of the item “USB serial port (COMxx)” is changed.

It is shown in the section “Ports (COM & LPT)” of the device

manager; in this example the COM port address 34 is found.

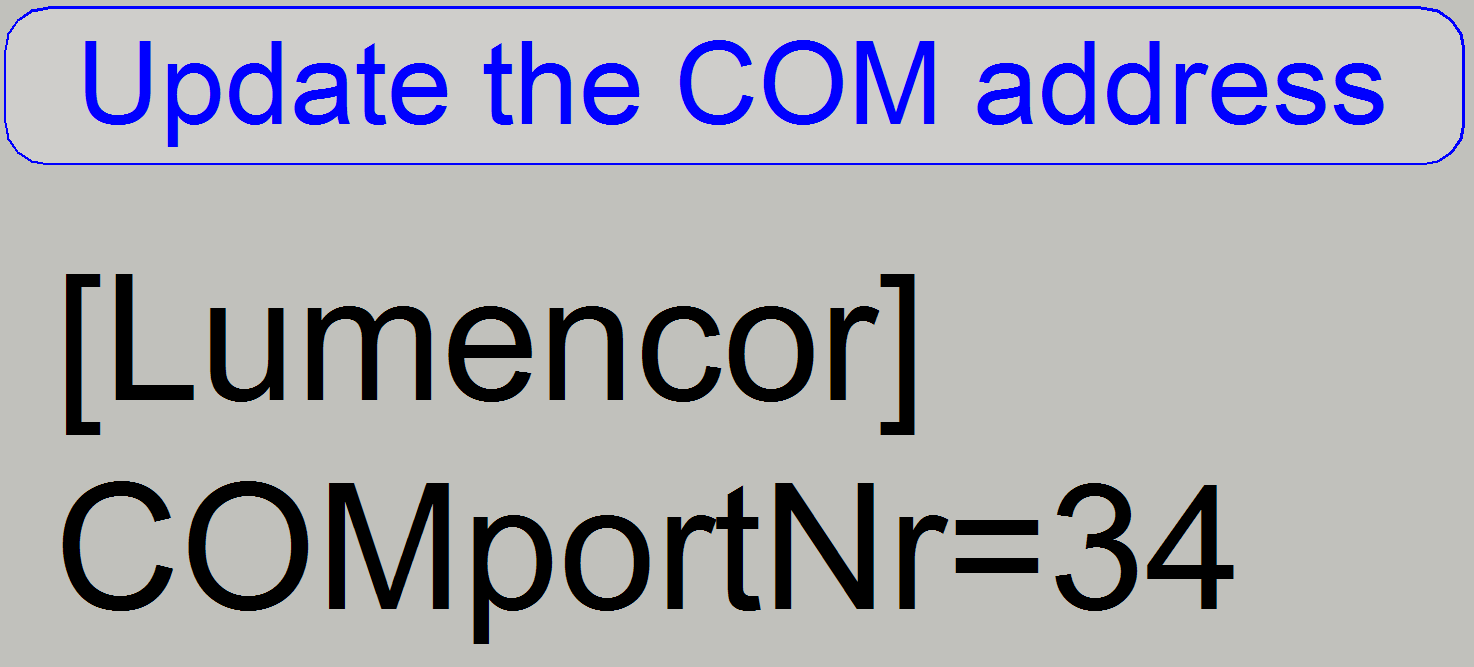

Update the

section [Lumencor] of the file

MicroscopeConfiguration.ini with the found address:

C:\ProgramData\3DHISTECH\SlideScanner\MicroscopeConfiguration.ini

If the section [Lumencor] does not exist in the file

MicroscopeConfiguration.ini (e.g. the Lumencor SPECTRA

light engine is implemented later or implemented as a result of upgrade) please

create this section.

If

the section [Lumencor] is missed

Please

implement the following two lines at the end of the file

“MicroscopeConfiguration.ini” with a text editor, like “Notepad”:

Please

implement the following two lines at the end of the file

“MicroscopeConfiguration.ini” with a text editor, like “Notepad”:

[Lumencor]

COMportNr=xx

Save the file “MicroscopeConfiguration.ini”

without any formatting information, as a *.txt-type file (text only)!

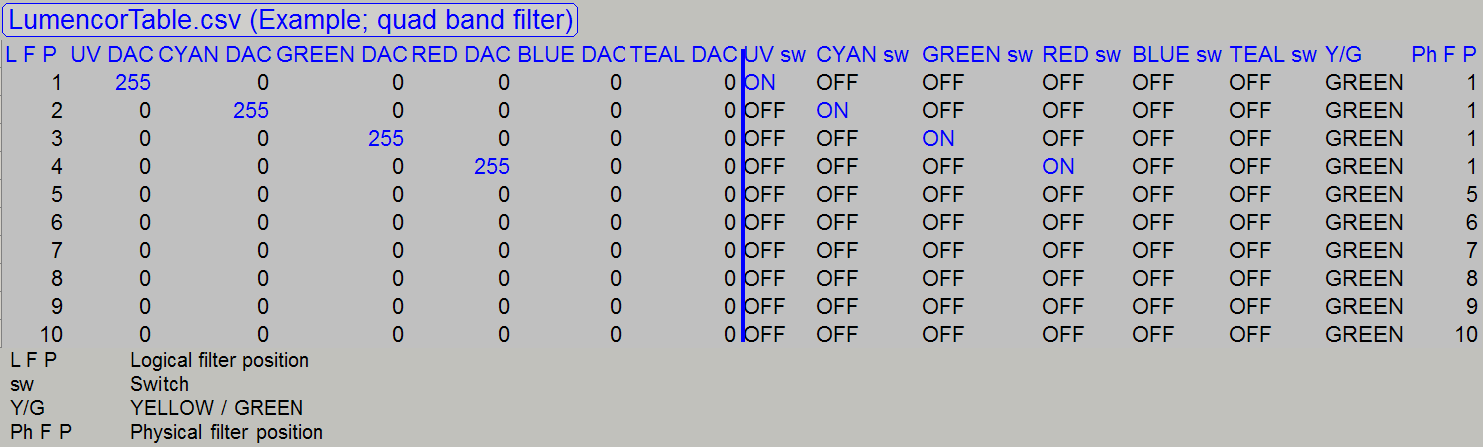

C:\ProgramData\3DHISTECH\SlideScanner\LumencorTable.csv

The lumencor table is used in the software

version 1.15 only to assign exciting light wavelengths to the logical and physical

filter positions. The logical filter position means a color channel while the

physical filter position defines the position of the filter in the filter wheel

of the turret unit.

In the example, only

1 filter block is inserted in the filter wheel position 1.

If a quad band

filter is inserted (as shown), it has four color channels; therefore, the

logical filter positions from 1 to 4 are used.

In this

construction, each color channel occupies a physical filter position also, but

the filter wheel stays always in the position 1; so the filter wheel will not

move.

The next filter

block may be inserted in the filter position 5 of the filter wheel, if

required.

Important

·

If modifications are done in the file “LumencorTable.csv” the file content has to be saved as

txt-type file, without formatting information!

Setup sequence

of the Lumencor SPECTRA

Mount the lumencor

SPECTRA light engine (see also the Lumencor light source adapter).

Connect the cables (Trigger,

RS-232 and power) and switch on the light engine.

Check and update the USB 2.0 port address

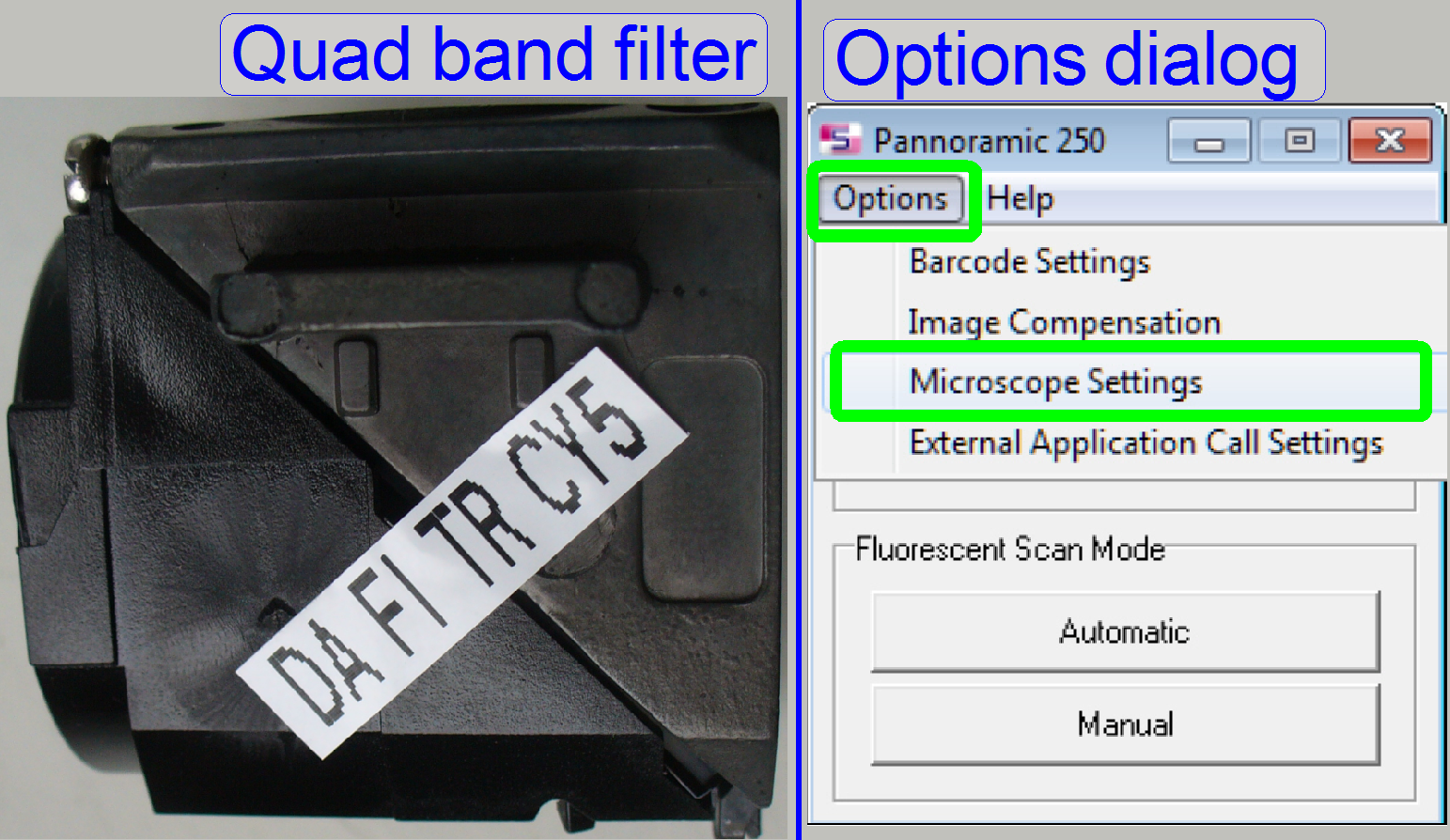

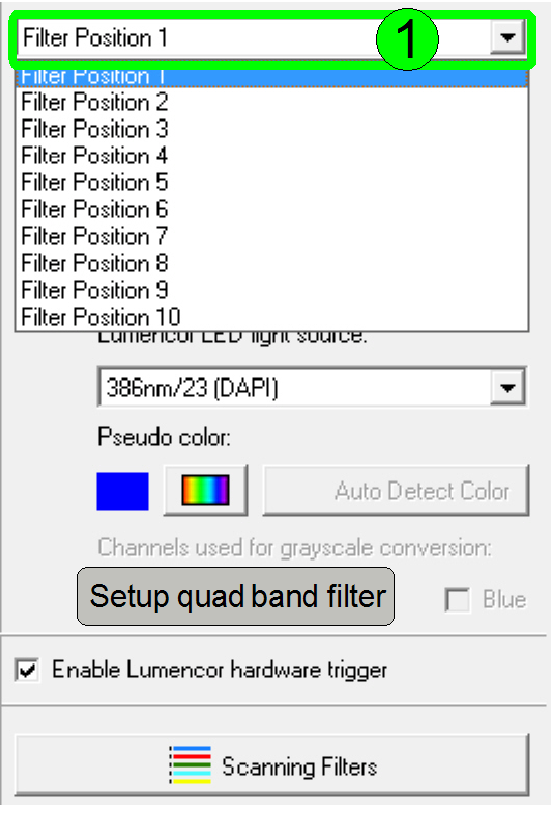

For technicians, sales managers and users

In this chapter, the settings are shown for a quad

band filter and the software version 1.16 or higher.

·

This chapter is true for P250, SCAN and

Start the scan program SlideScanner.exe

In the selector

menu, open the option “Microscope Settings”.

The wavelengths

of the filter are shown on the label.

DA= DAPI; FI= FITC;

TR= TRITC and CY5 = CY5.

For

filter sets, filter blocks and filter characteristics, see also: (Links refer to P250)

![]() “Filter block”, “Introduction

to fluorescent filters”, “Filter block assembling”,

“Cleaning

optical filters” (Semrock), “Staining”, “Virtual tissue” and “Fluorescence

microscopy”.

“Filter block”, “Introduction

to fluorescent filters”, “Filter block assembling”,

“Cleaning

optical filters” (Semrock), “Staining”, “Virtual tissue” and “Fluorescence

microscopy”.

“Matching

Fluorescent Probes with Nikon Fluorescence Filter Blocks”; interactive

“Matching

Fluorescent Probes with Nikon Fluorescence Filter Blocks”; interactive

Assign colors, color channels,

and filter positions

In

the software version 1.15

Because the quad band filter allows the use of 4

colors (color channels) in one physical filter position, the next 3 filter

positions, until position 4 can not be equipped with a filter; they are empty

positions. In other words, one quad band filter occupies 4 physical positions

of the filter wheel.

The next filter block can be inserted in the position

5.

See also: Lumencor

table

In

the software version 1.16 or higher

The

quad band filter allows the use of 4 colors in one physical filter position,

but in opposite to the software version 1.15 every physical filter position may

be equipped with a filter.

The

quad band filter allows the use of 4 colors in one physical filter position,

but in opposite to the software version 1.15 every physical filter position may

be equipped with a filter.

You can insert

multiple band filters and single band filters likewise into the filter wheel,

so theoretically more 10 color channels are be possible, but the software

handles only nine color channels in 1 session.

If other colors are

required, then these can be defined and selected; see also the item (21).

Remark

· The Lumencor

SPECTRA light engine® is

able to create 6 exciting wavelengths so maximal 6 color channels can be created

this time; the use of multiple band filters is possible and recommended.

· By

using traditional light sources like X-Cite®

Series 120 or equivalent types (white light is created), 9 or more light

channels are possible; but only single band filters are used.

Example

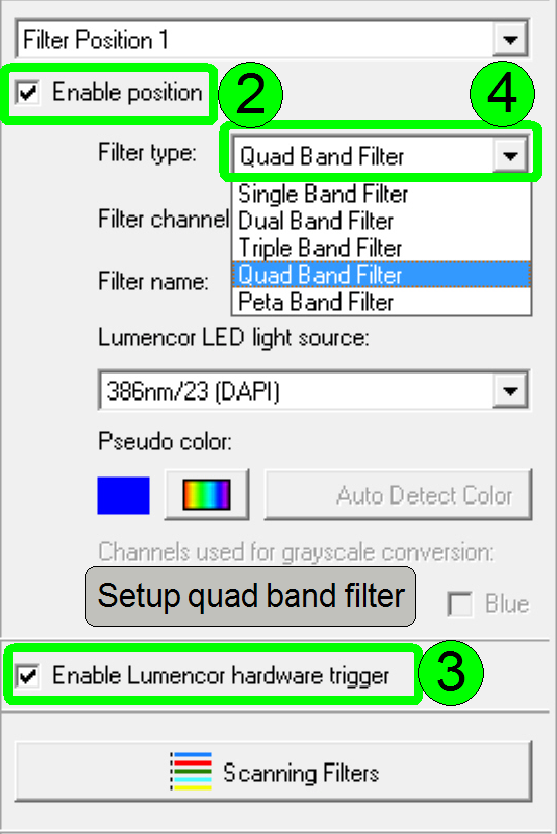

Define the Quad band filter in the “Position

Select the “Position

Check the checkbox “Enable position” (2)

Check the checkbox “Enable Lumencor

hardware trigger” (3)

In the P250 and

the use of the PCO.edge camera, this checkbox should

be checked.

If a fluorescent

camera is used in the scanner that is unable to deliver a trigger pulse for the

Lumencor SPECTRA Light Engine, this checkbox should

be unchecked; the selected wavelength will light continuously until the color

will be changed.

Select the Filter type “Quad band filter” (4)

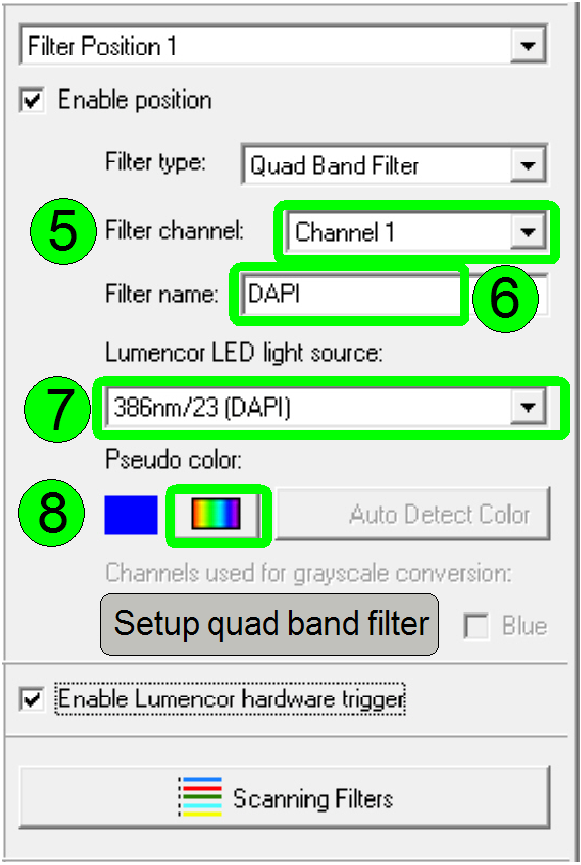

Select channel 1; (5)

Type in the filter name “DAPI” (6)

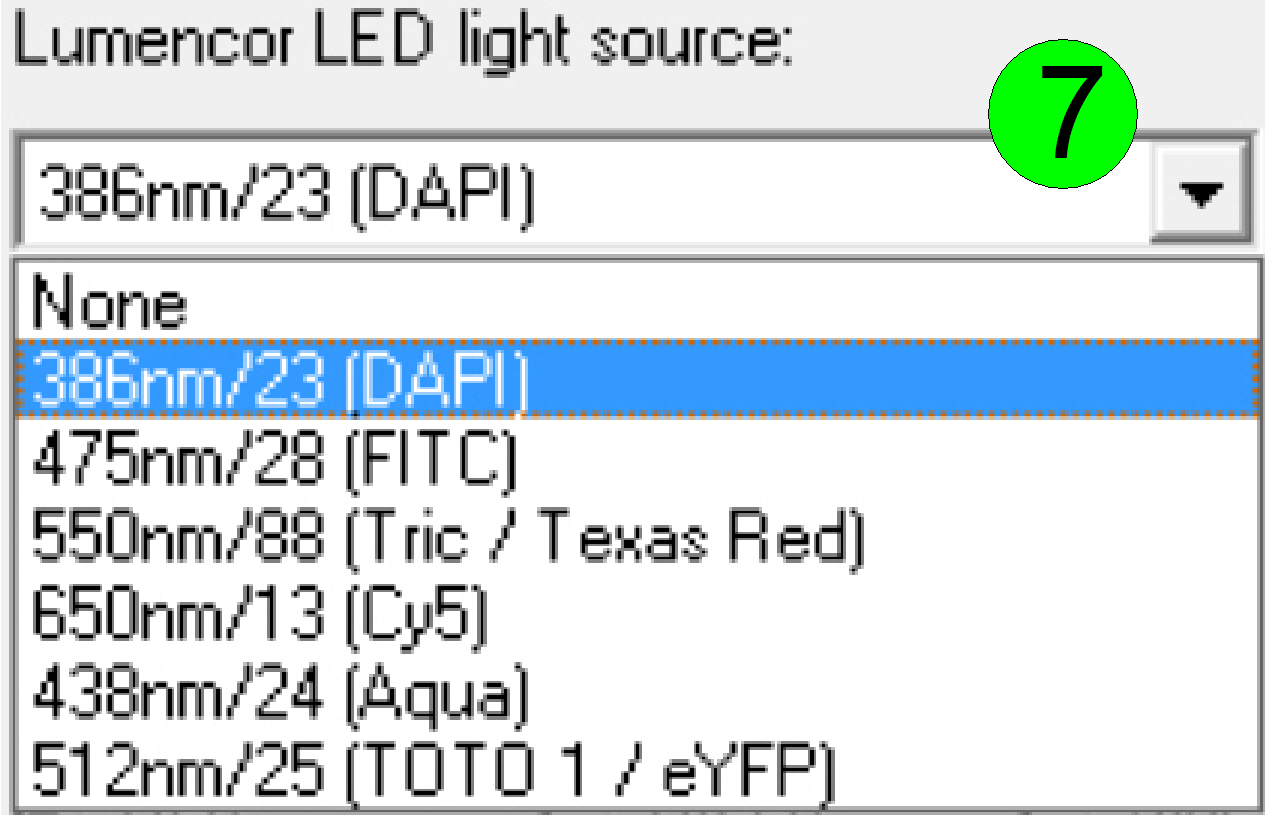

Select the assigned exciting wavelength; (7)

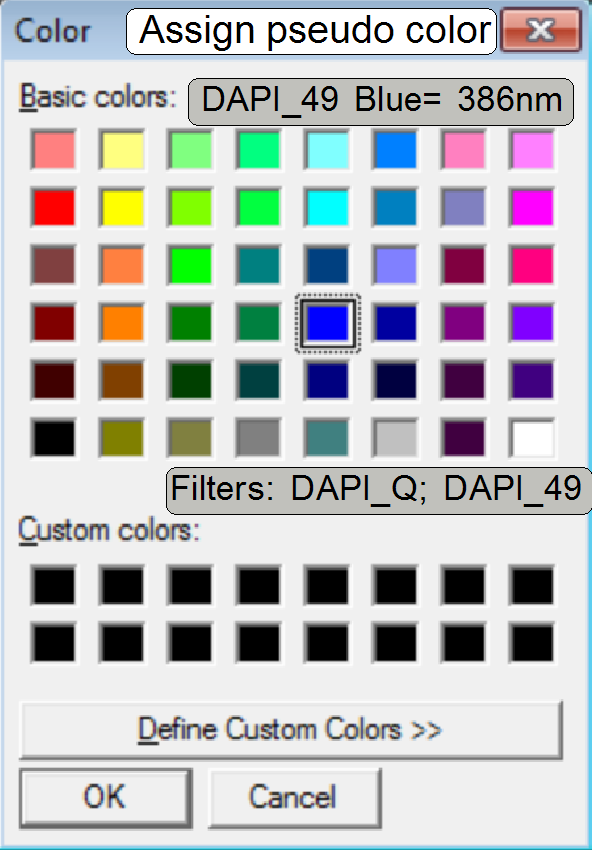

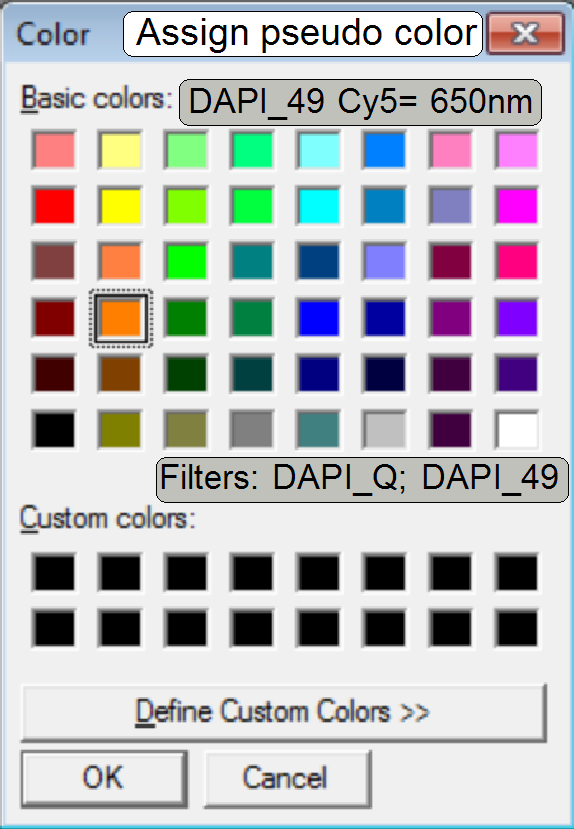

Assign the color to the wavelength; (8)

The here assigned

color will affect the color, seen in the Pannoramic

viewer.

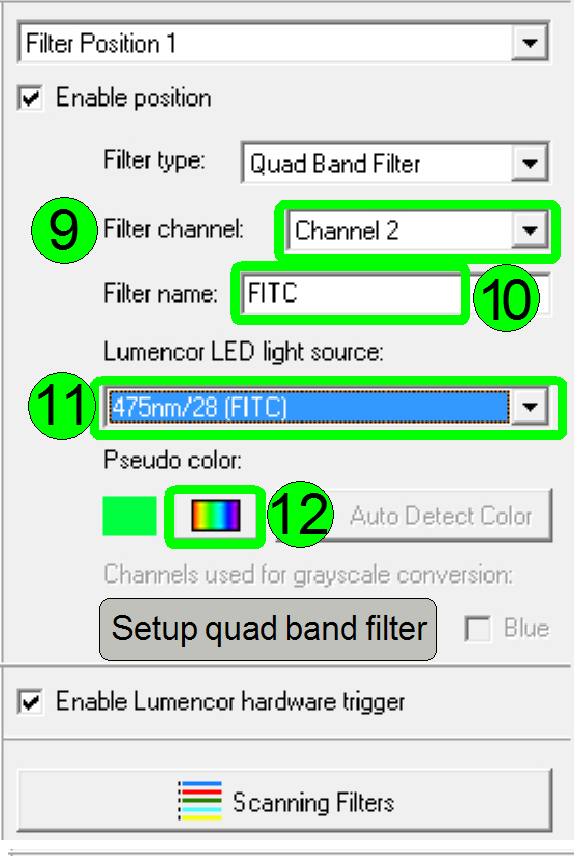

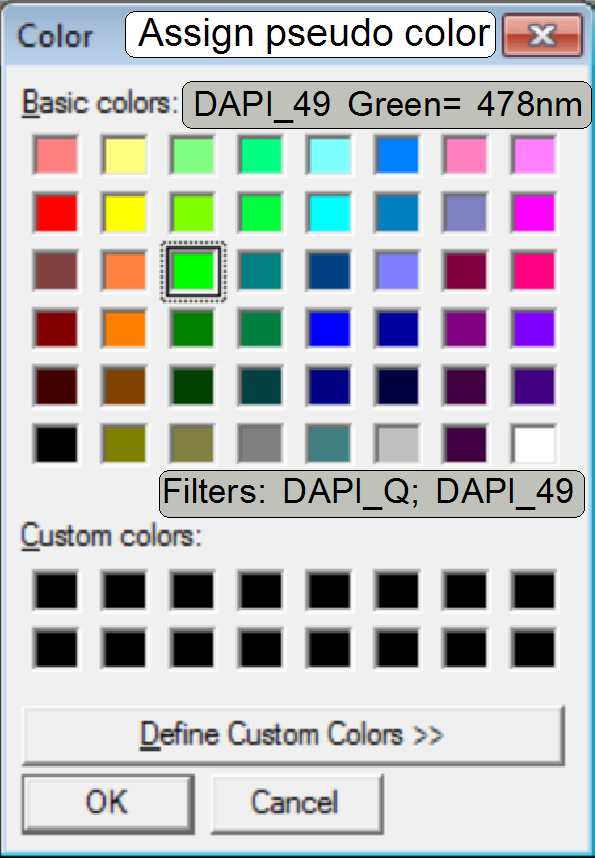

Select channel 2; (9)

Type in the filter name “FITC” (10)

Select the assigned wavelength; (11)

Assign the color to the wavelength; (12)

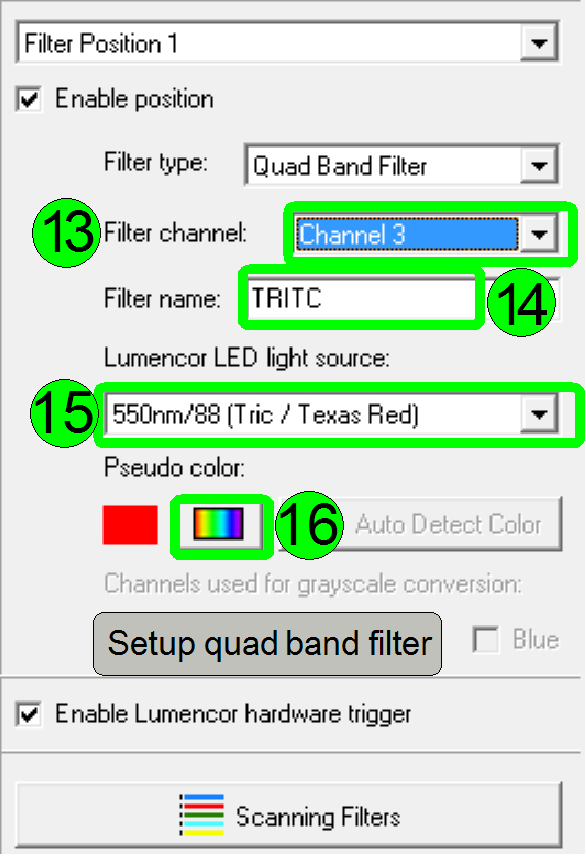

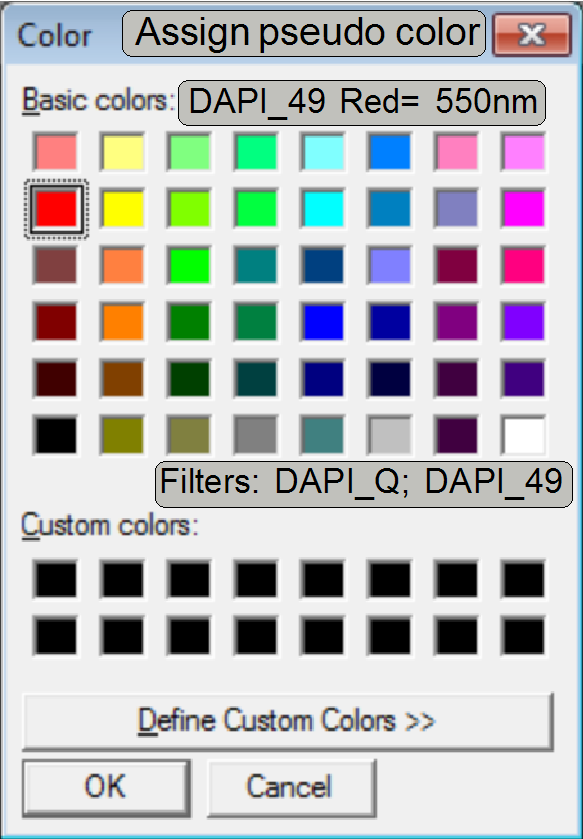

Select channel 3; (13)

Type in the filter name “TRITC” (14)

Select the assigned wavelength; (15)

Assign the color to the wavelength; (16)

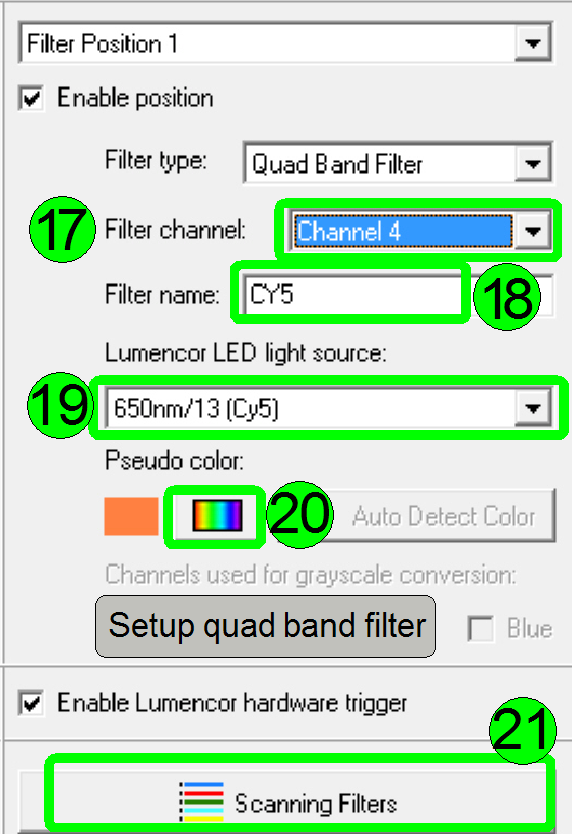

Select channel 4; (17)

Type in the filter name “CY5” (18)

Select the assigned wavelength; (19)

Assign the color to the wavelength; (20)

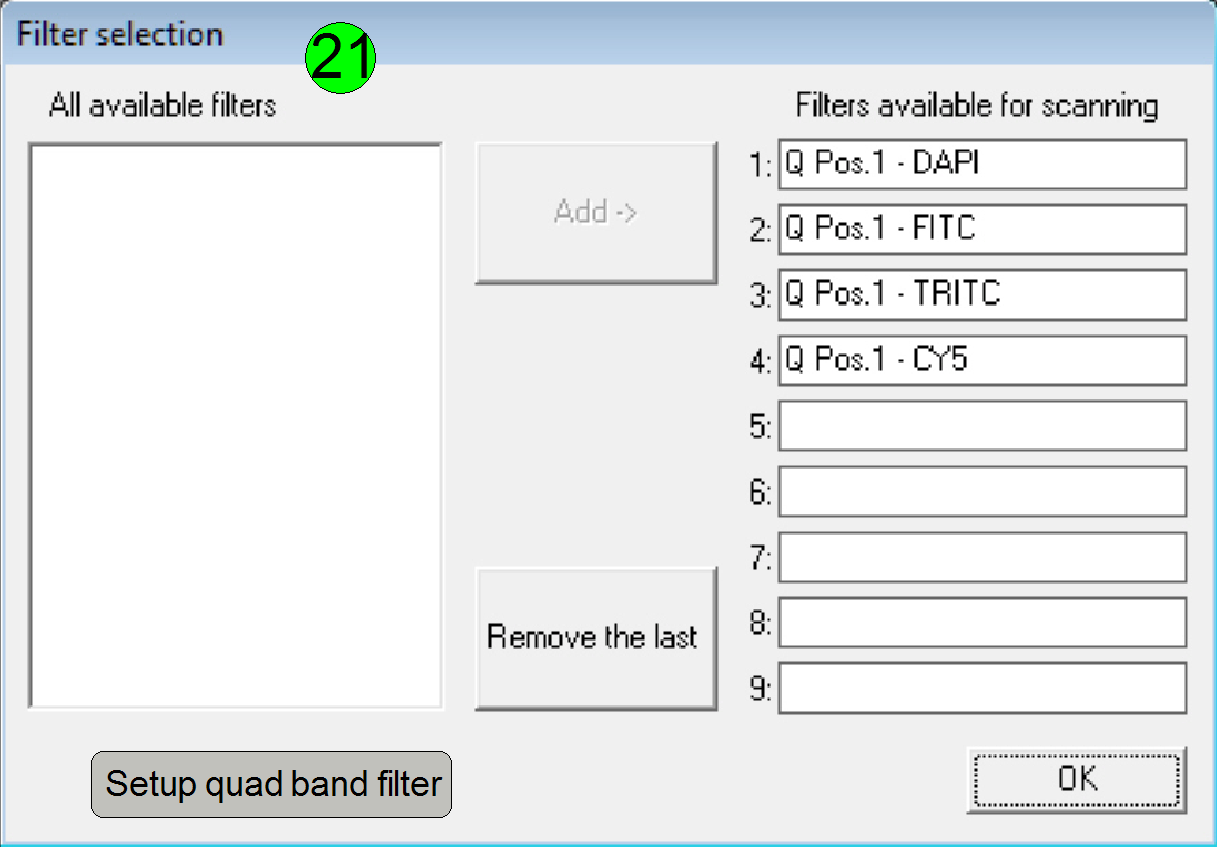

Press “Scanning Filters” and check; (21).

Check

the assigned positions and color channels (21).

Here,

the defined colors can be arranged for the actual scan session

Here,

the defined colors can be arranged for the actual scan session

If all settings are correct, the quad band filter

setup is finished; now the next filter may be inserted and defined or the

fluorescent scan procedure may be started; see also the user’s manual “Pannoramic_250_FLASH_1.16_User's_Guide_EN_Rev1.pdf”;

page 77ff; “4.5 Using

Fluorescent Manual Mode”.

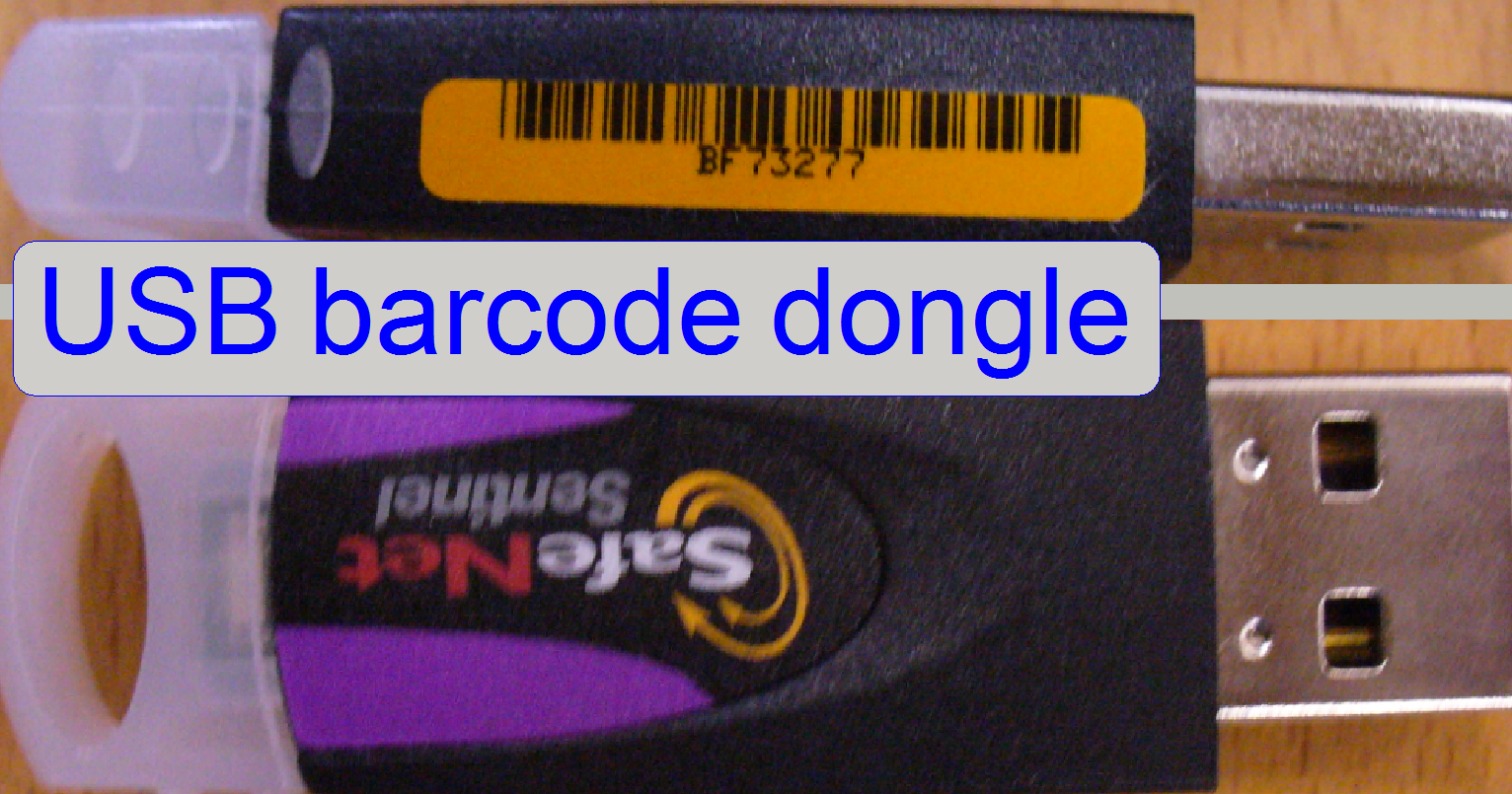

The dongle is a hardware unit, connected to any specified port of the computer

to protect software against unauthorized use. It contains mostly a programmable

logic array or a flash memory area with a protecting data pattern. This data

pattern is compared with the pattern in the software and often analyzed by a

mathematical algorithm or function also. If the result does not produce an

error, the software is ready for use, otherwise the software will not start and

an error message occurs or dongle protected parts of the software can not be

used.

The Matrox USB barcode dongle is used for barcode reading and

protects the option “Barcode reading” of the Matrox

Imaging Library against unauthorized use.

The Matrox USB barcode dongle is used for barcode reading and

protects the option “Barcode reading” of the Matrox

Imaging Library against unauthorized use.

Furthermore, a flag in the Pannoramic scanner

or viewer dongle is used to allow the barcode reading feature of the program

“Slide Scanner”.

If the barcode dongle is missed or not recognized, the message “Barcode dongle not found” will be issued.

If the license for barcode reading is not valid, the message “Barcode reading not licensed” will

be issued.

·

In the Pannoramic DESK, barcode reading is an option and has to be

declared explicitly during ordering the system. If barcode reading is not

allowed in the Pannoramic scanner or viewer dongle,

barcode reading will not work; nevertheless, the barcode dongle is connected.

Further information can be

found in the chapter “Setup

the Matrox Imaging Library version 9.0 (MIL 9.0)”

Further information can be

found in the chapter “Setup

the Matrox Imaging Library version 9.0 (MIL 9.0)”

For software versions with the operating system Windows XP please refer

also to “Setup xP Barcode dongle”

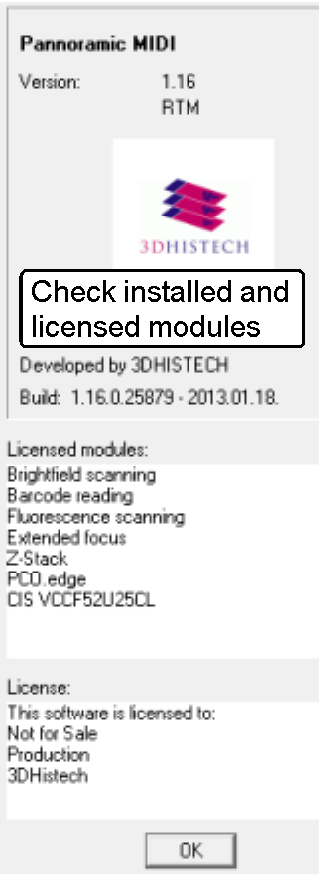

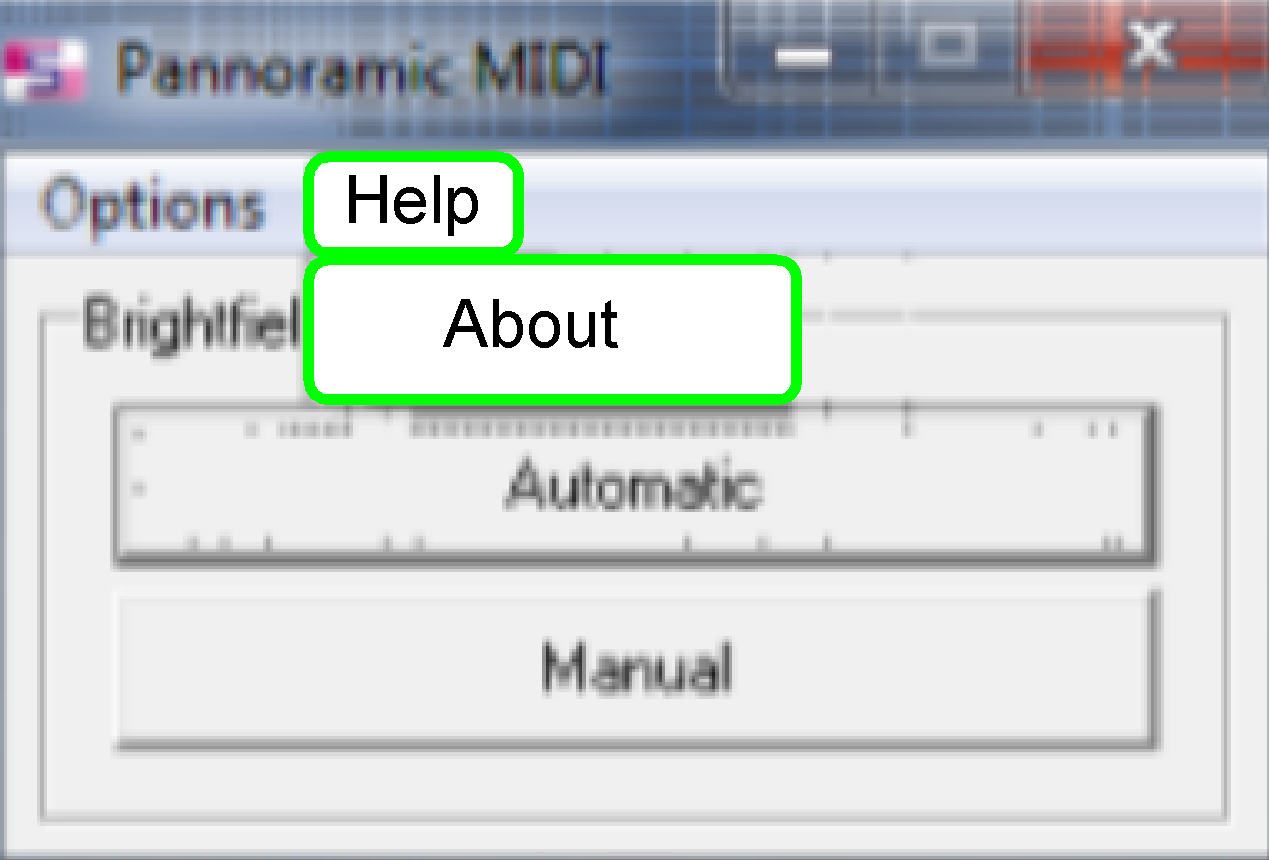

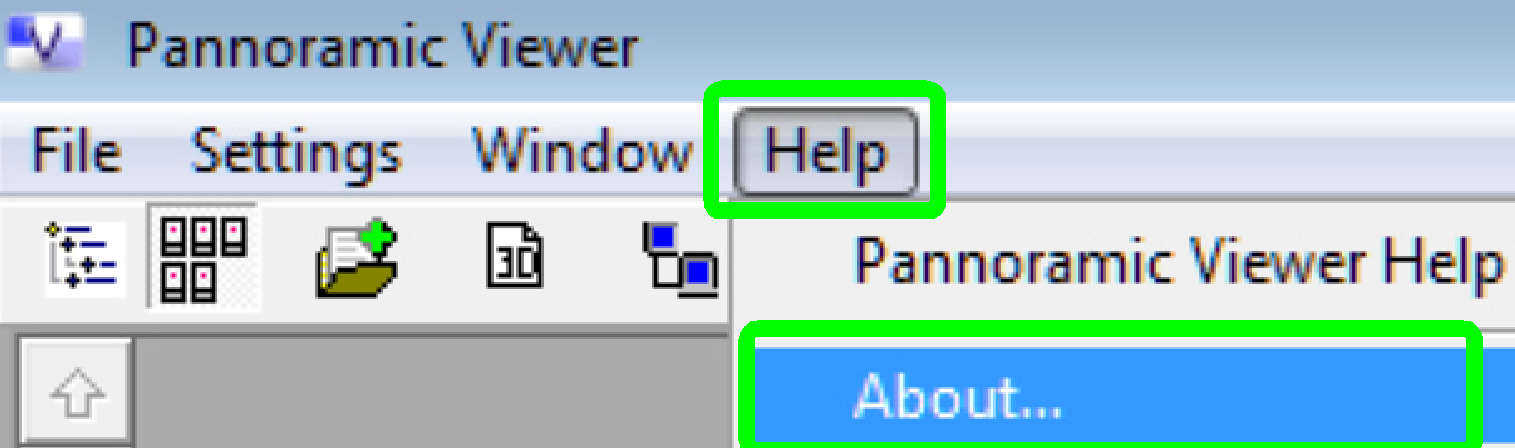

Dongles for Pannoramic scanners

Important

Install

and setup the Pannoramic scan, Pannoramic

viewer and Pannoramic server software without

connected dongle! If the dongle(s) are connected after installation of the

software, these should not be disconnected until the next installation

procedure is done.

Install

and setup the Pannoramic scan, Pannoramic

viewer and Pannoramic server software without

connected dongle! If the dongle(s) are connected after installation of the

software, these should not be disconnected until the next installation

procedure is done.

Newer software versions

are able to accept older dongle protections in the same way, as used for the

older software versions.

Until software version 1.8

To protect the Pannoramic scanner (MIRAX)

configuration, the Pannoramic (MIRAX) scan and the Pannoramic (MIRAX) viewer software, two additional, USB

dongles are required. The Pannoramic viewer basic

software is not dongle protected.

Scanner software

dongle

Requirements

Requirements

Dongle for the Pannoramic

scanner configuration and software protection or License file

Dongle protected scanner parts and options

Installed scan camera

Extended focus

Fluorescent scan

AVTMarlinF146C

Since software version 1.9

To protect the Pannoramic scanner

configuration, the Pannoramic scan and the Pannoramic viewer software since Software version 1.11 only

one USB dongle is required. The Pannoramic viewer

basic software is not dongle protected. Furthermore, if dongle protected parts

of the Pannoramic viewer are ordered, an additional

dongle will be delivered.

Dongle protected parts

·

Barcode reading enabled

·

The installed scan camera(s)

·

Extended focus

·

Fluorescent scan

The AVTMarlinF146C; since SW version 1.10

supported as ICC1 also

The Zeiss

ICC1 camera; since SW

version 1.10 supported

The AVTStingrayF146C; since SW version 1.12 supported, the same flag as the marlin camera

The AVTPikeF421C; not delivered to user

The AxioCam_MRm_Rev3; supported since SW version 1.10

The Hitachi_HV_F22CL; supported since SW version 1.11

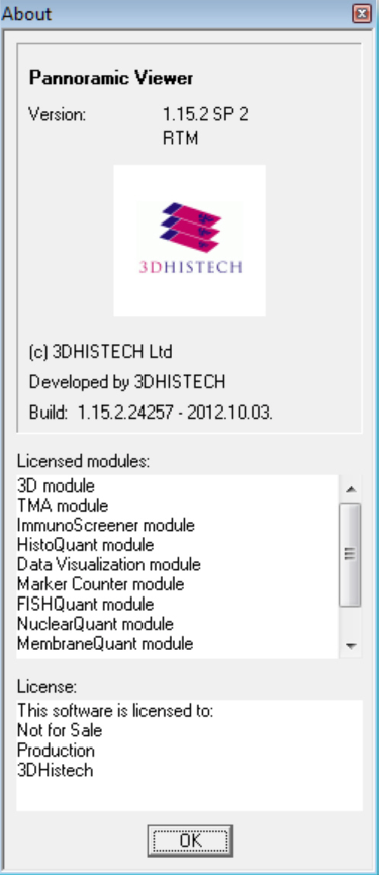

Viewer software dongle

Requirements

Dongle for the Pannoramic

Viewer software protection or License file

Dongle protected viewer

parts and options

Dongle protected viewer

parts and options

3D

OnlineTeleconsultation; since SW version 1.11 this item is

freeware

BookmarkExport

Dongle protected viewer

parts and options

Dongle protected viewer

parts and options

3D

OnlineTeleconsultation; since SW version 1.11 this item is freeware

·

TMA

·

FLViewer supported since SW version

1.10; since 1.11 this item is freeware

BookmarkExport supported since SW version

1.10

IHLab supported

since SW version 1.11; until version 1.14; the new name is “TumorBoard”

·

HistoQuant supported since SW version 1.11

·

DataVisualisation supported since SW version 1.11

·

MarkerCounter supported since SW version 1.11

·

CytoFISHQuant supported since SW version 1.12

NuclearQuant supported since SW version

1.12

MembraneQuant supported since SW version 1.12

TumorBoard

Relevant description of the

module can be found in User's

guide

The most recent description of the licensed module can be found

on the scan computer.

The path is:

C:\Program Files

(x86)\3DHISTECH\Viewer\Users Guides\*.*