For

technicians and partly for sales managers!

Introduction

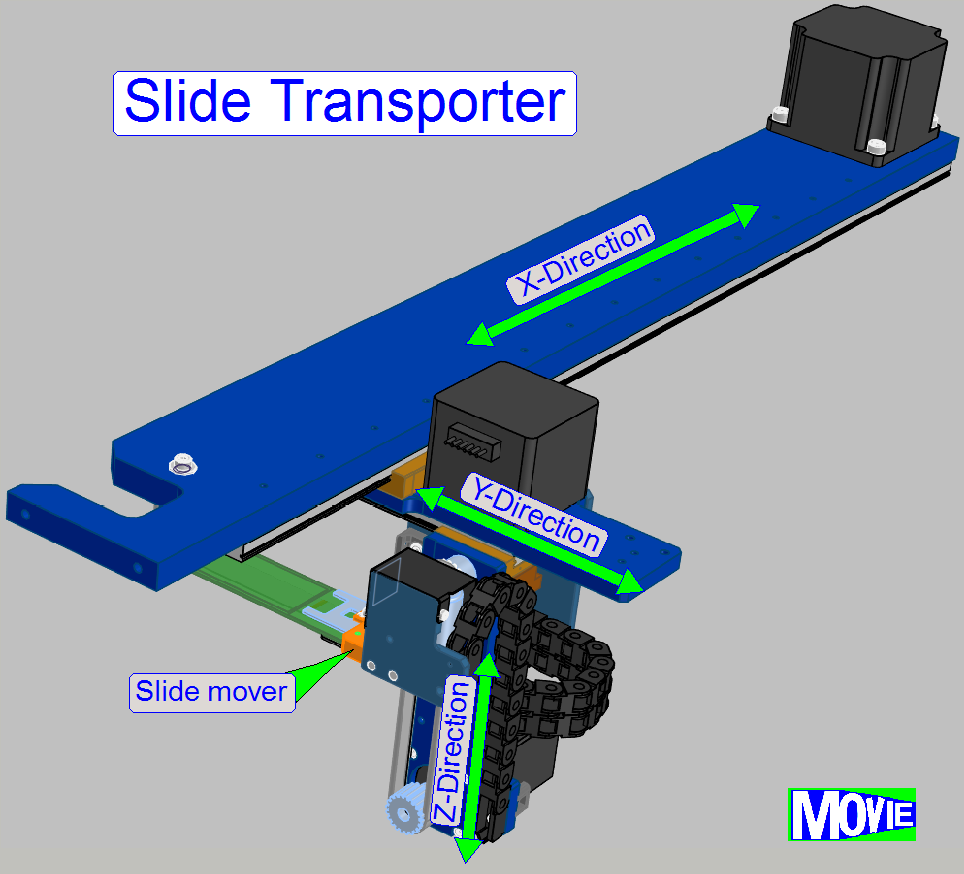

The slide

transporter unit moves the slide into the desired position. Starting from the

origin storage of the slide, the slide is moved to

· Specimen

Preview position

· Staining

position

· Wash

and rinse chamber

· Wiper

position

· Cover

slipping position

· Any

manipulation position

· Slide

tray of the scanner

· From

any position back to the slide’s origin position.

To fulfill this task, the slide mover has to move the

slide along the X-axis, the Y-axis and the Z-axis.

The movement of the slide mover along the axes is

executed by a toothed belt driven mechanics; the belt is driven by a stepper

motor. In relation to a spindle driven solution the accuracy of 1μm is not

required and by using a belt drive, the slide may be moved much faster.

The Slide mover holds the slide with a solenoid

controlled clamp (spoon and fork) on the barcode side, so the slide may be

positioned very precise in the slide bays. The exact position of the slide is

very important during the application procedure of the stain, it has to have

the same position as it had during preview capturing.

Contents

Y-Z-Unit

Z-Unit

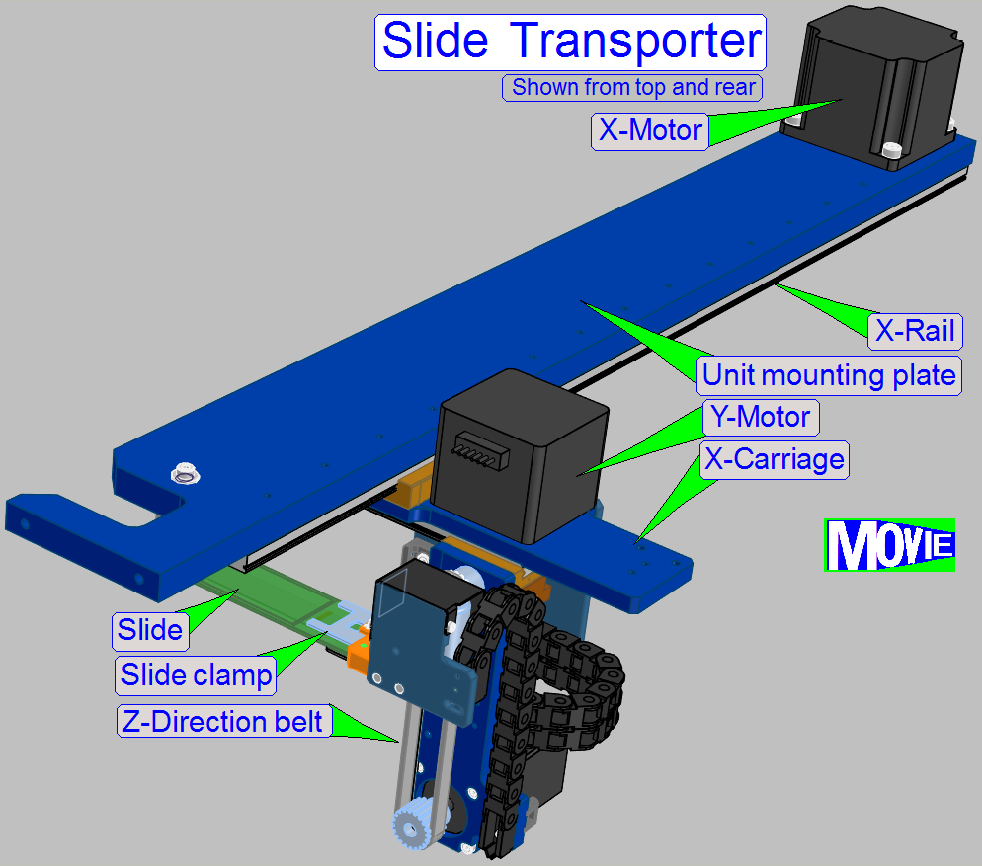

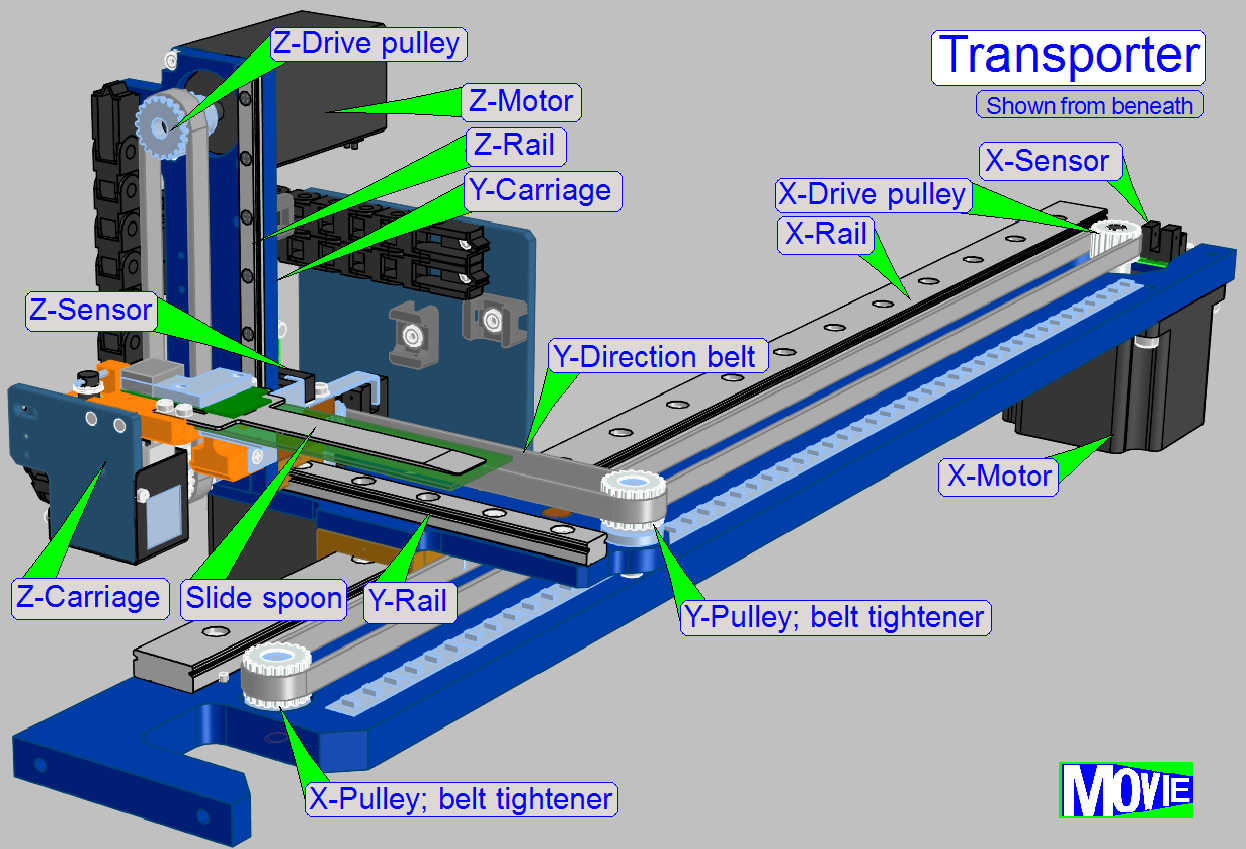

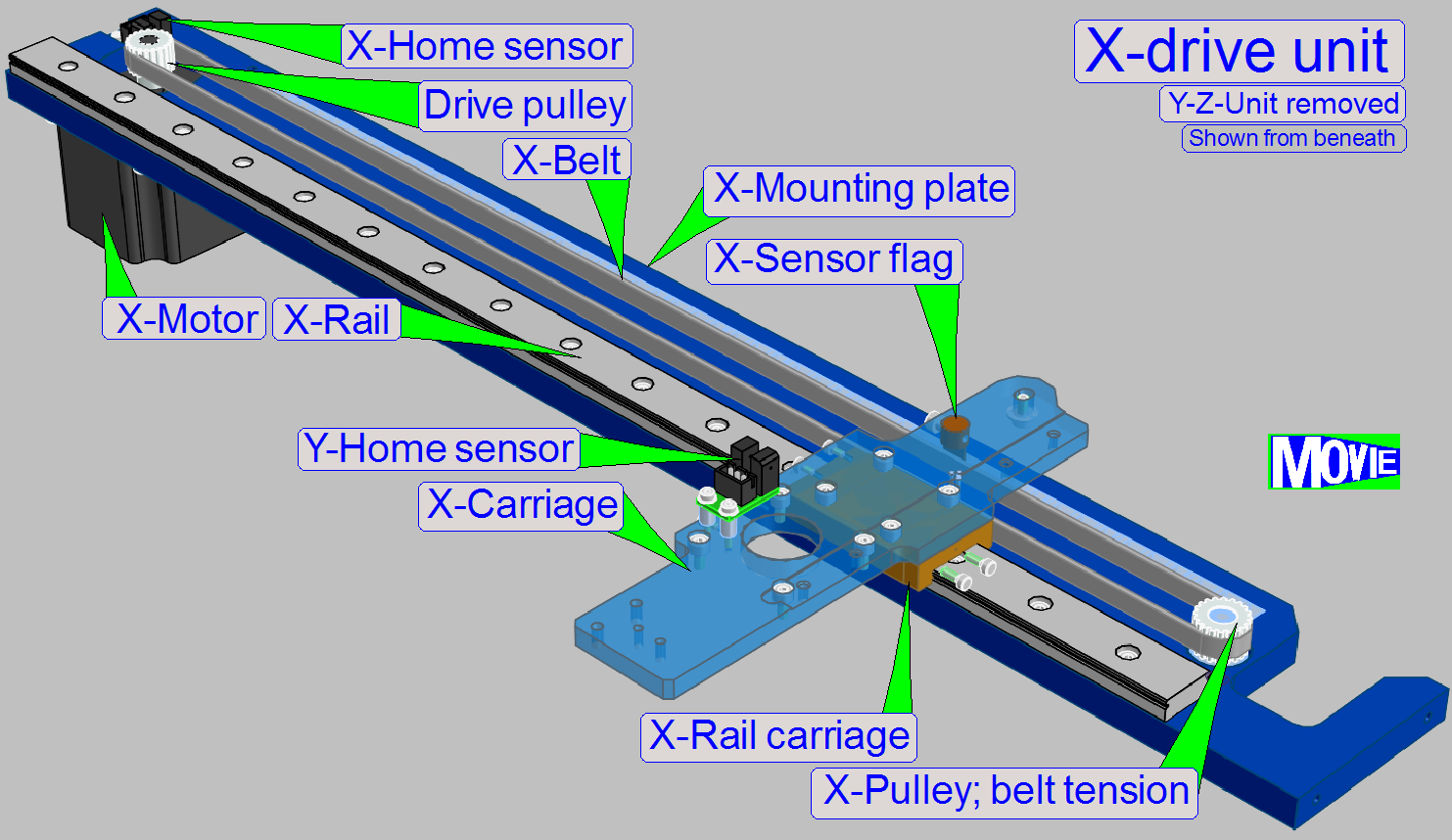

The

statically part of the X-drive unit (and so the entirely construction) is

mounted onto the X-Mounting plate; components are:

The

statically part of the X-drive unit (and so the entirely construction) is

mounted onto the X-Mounting plate; components are:

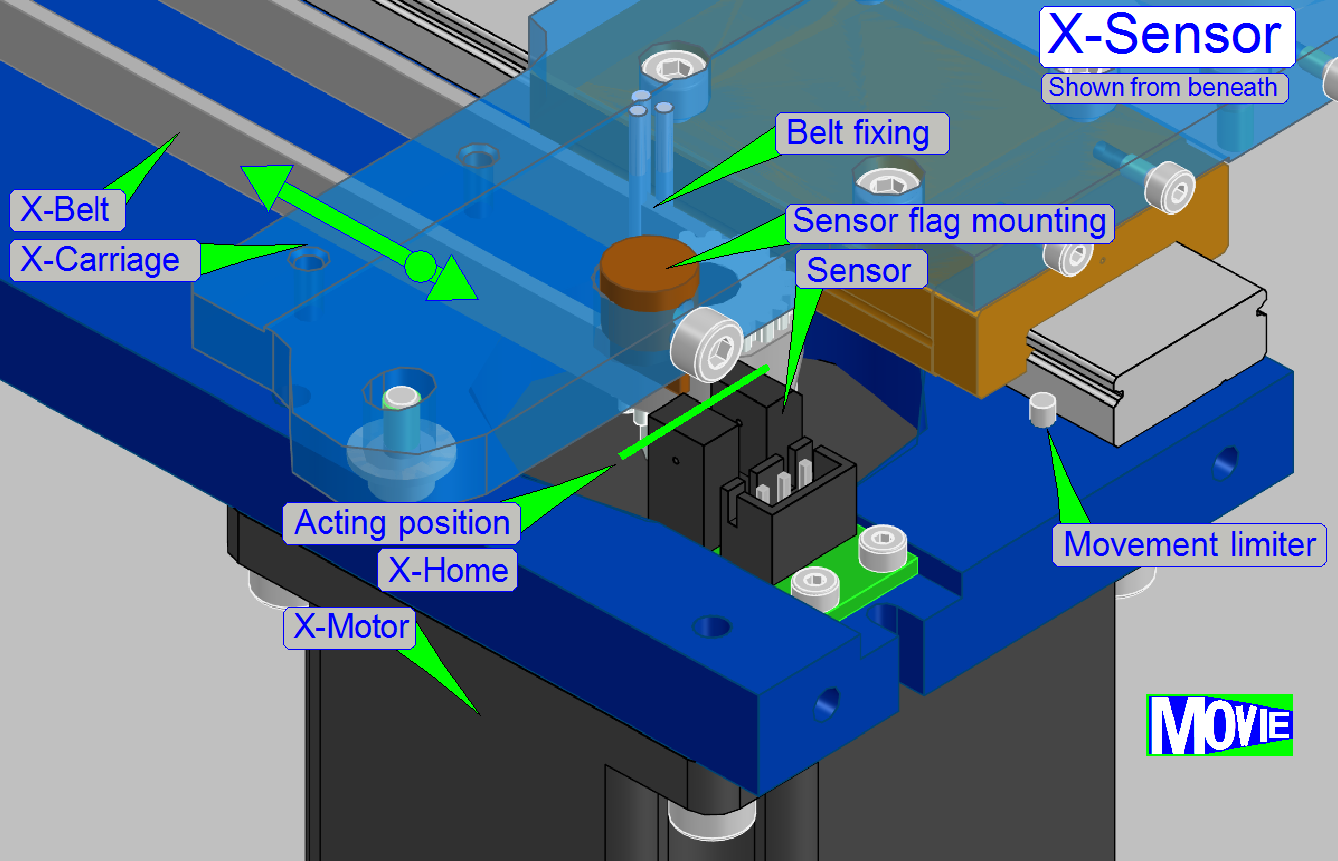

· X-Motor

· X-rail

· X-Sensor

· Toothed

belt pulley with belt tension adjustment

Dynamically part

· Rotor

axle with toothed drive pulley

· Toothed

belt

· Belt fixing to drive the carriage

· Carriage

(contains the X-sensor flag and the entire Y and Z-unit)

Each

carriage has a Sensor to define the Home position of the entire moveable,

mechanical construction. From the X-Home position steps are counted in positive

or negative direction. The Home position is not the limit of the moveable

construction; the absolute limit is defined by the Movement limiter.

Each

carriage has a Sensor to define the Home position of the entire moveable,

mechanical construction. From the X-Home position steps are counted in positive

or negative direction. The Home position is not the limit of the moveable

construction; the absolute limit is defined by the Movement limiter.

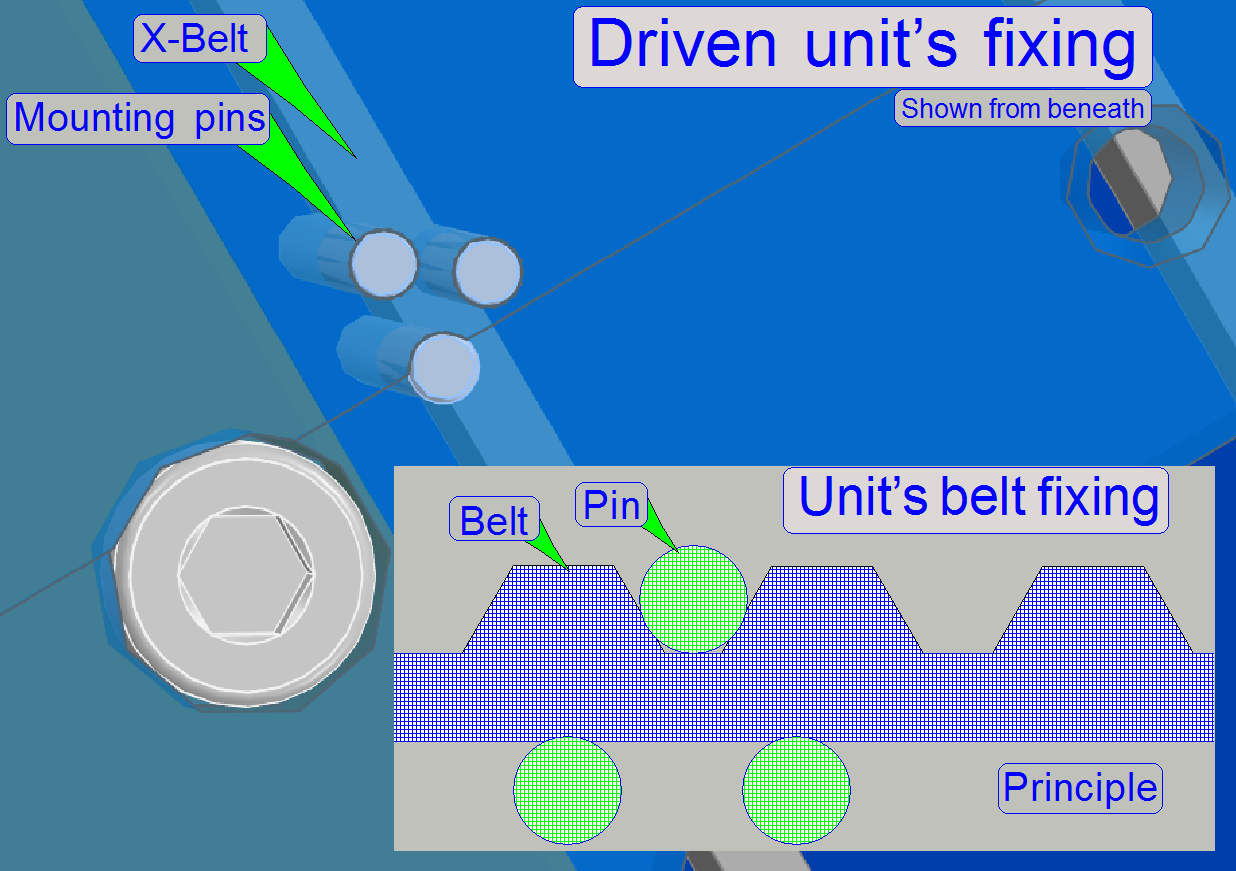

The

belt is shifted into the space, defined by the three pins as shown. With this

solution a slippage free connection between belt and carriage is realized.

The

belt is shifted into the space, defined by the three pins as shown. With this

solution a slippage free connection between belt and carriage is realized.

The dimension and position of the pins to each other and

so the space for the belt was defined so, that the surface of the belt will not

be damaged but by using a little pressure, a movement of the belt in relation

to the pins is impossible.

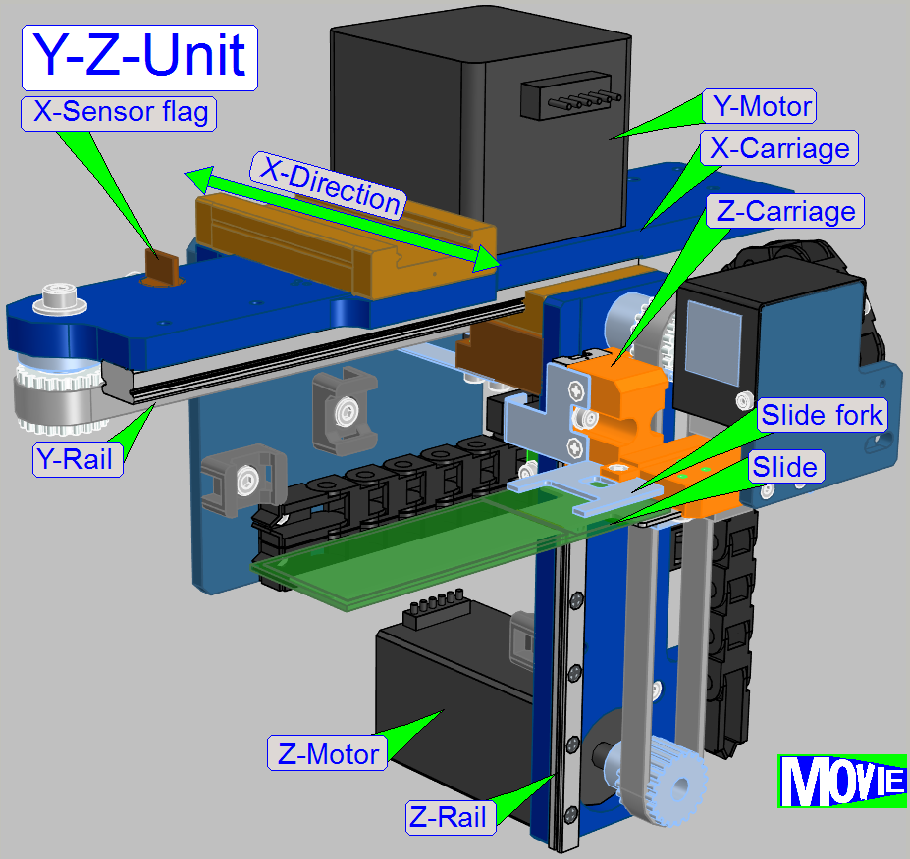

The Y-drive unit

is used to move the Z-unit along the Y-axis.

The Y-drive unit

is used to move the Z-unit along the Y-axis.

· The

moveable part of the Y-drive unit contains the entire Z-unit.

For construction details please refer to the X-drive unit.

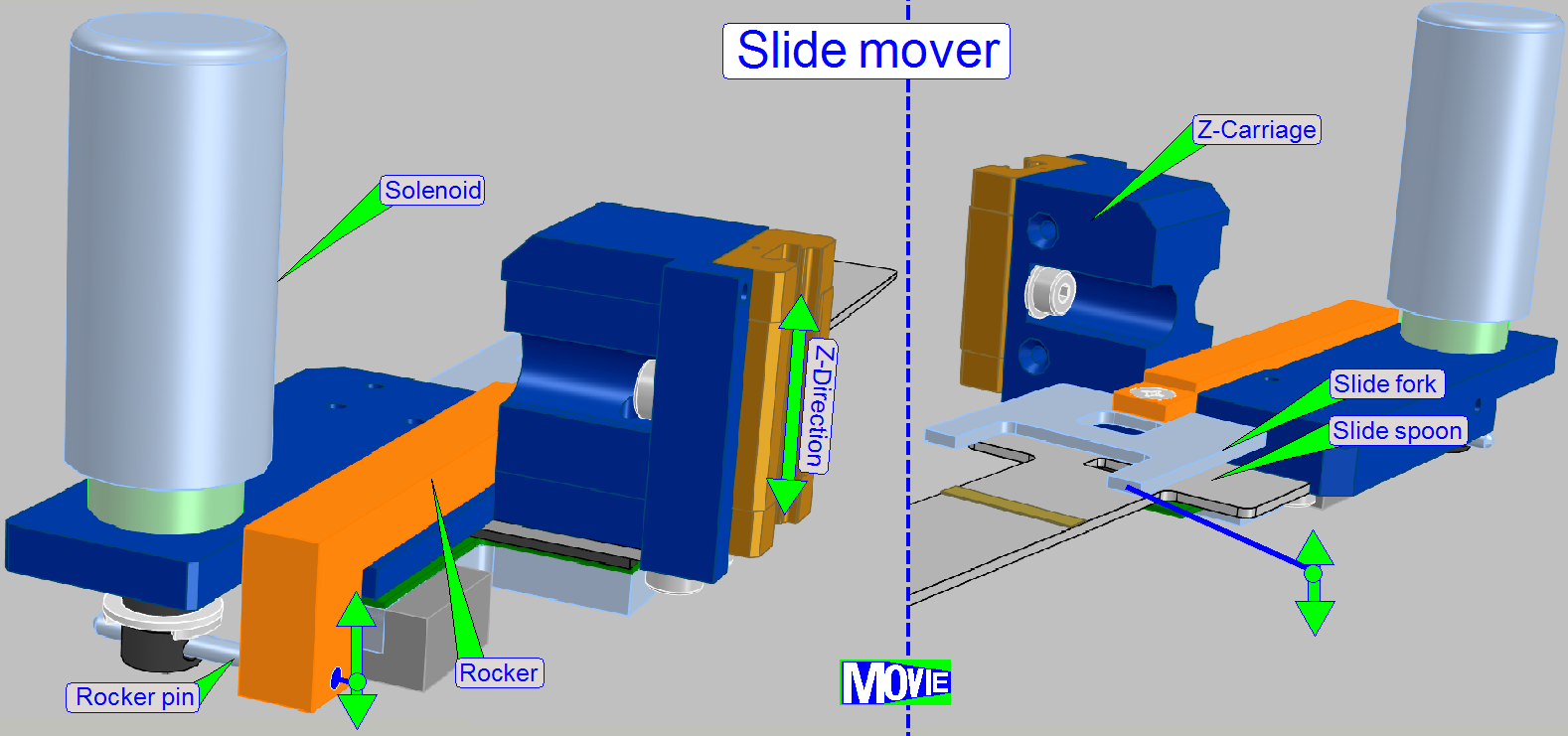

The Z-unit unit

is used to move the Z-carriage in Z-direction.

The Z-unit unit

is used to move the Z-carriage in Z-direction.

· The

Z-carriage is used to move the slide spoon as well as the slide fork along the

Z-axis.

For construction details of the mechanically drive

please refer to the X-drive

unit.

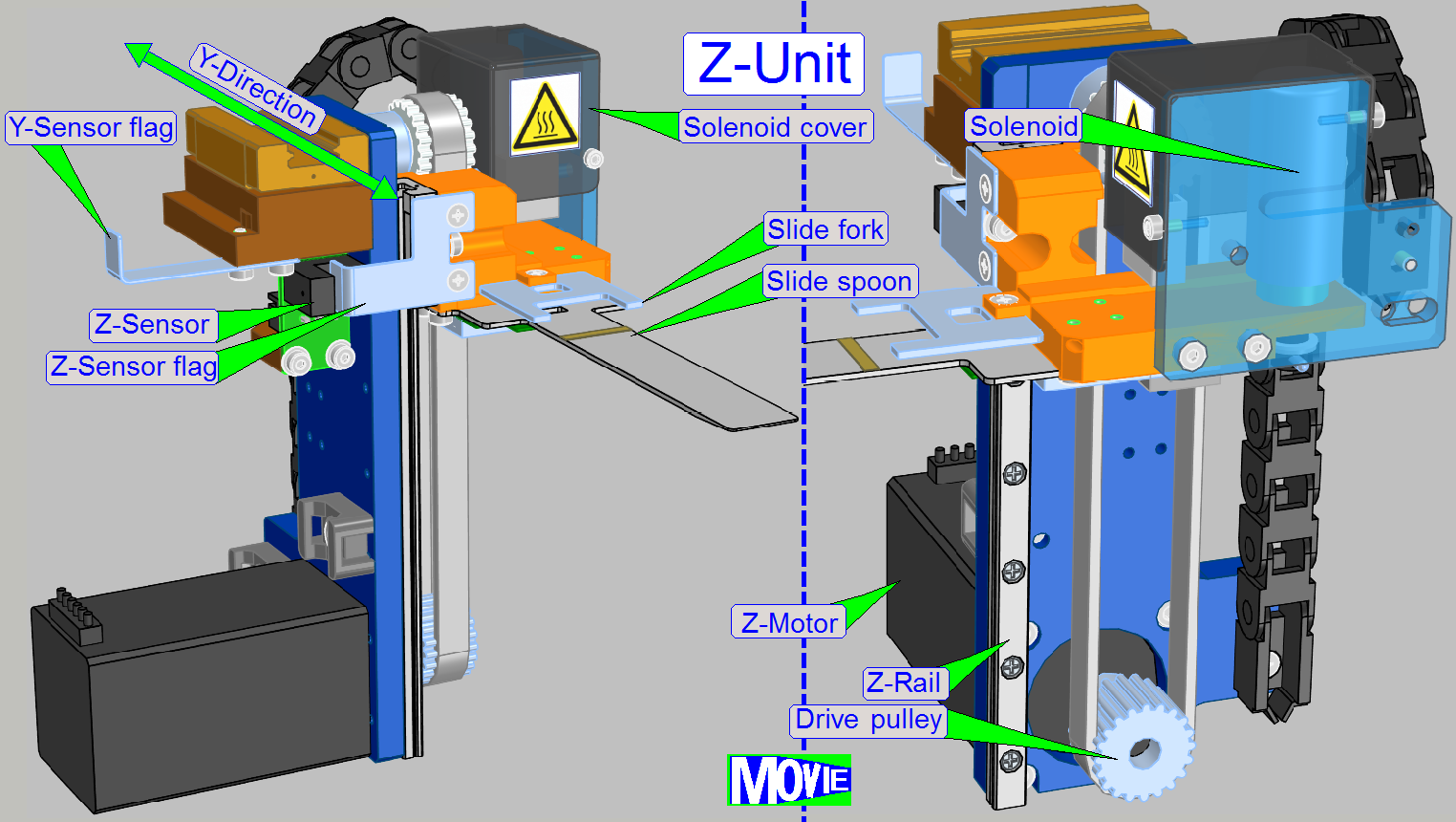

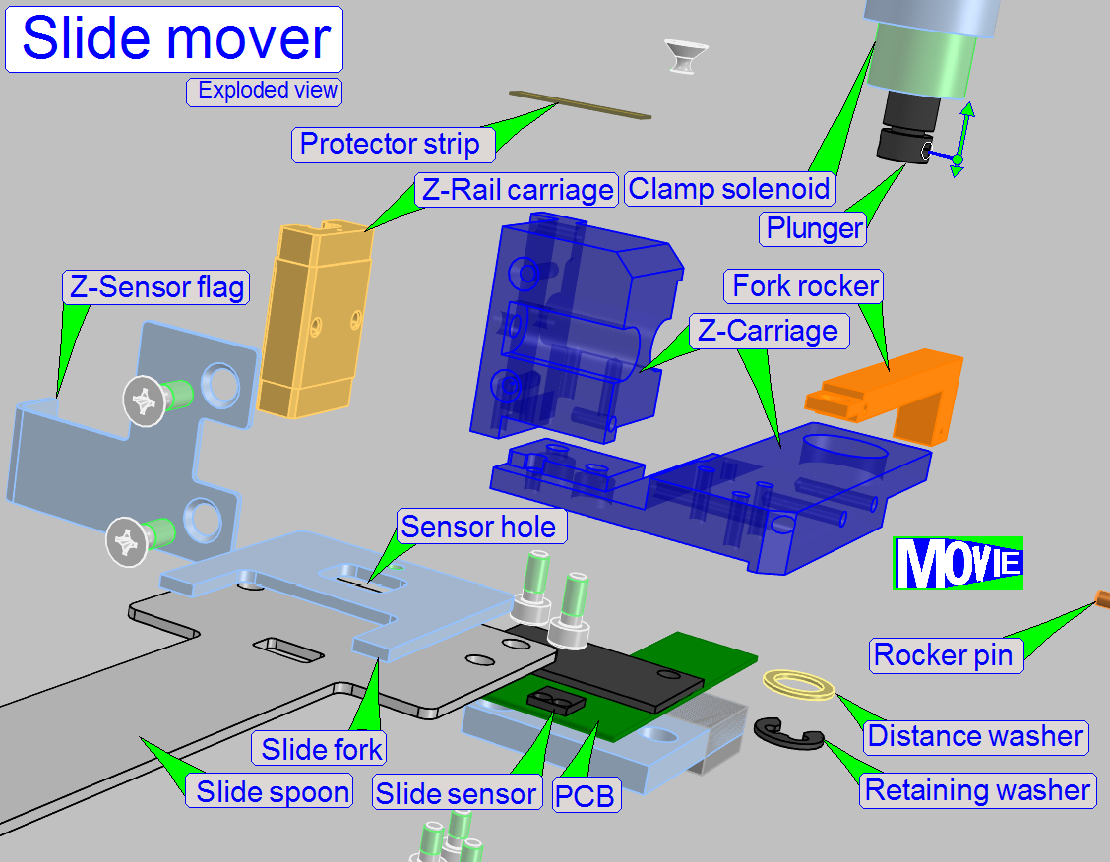

The main

component of the slide mover is the slide spoon with the solenoid controlled

slide fork (clamp).

The main

component of the slide mover is the slide spoon with the solenoid controlled

slide fork (clamp).

The slide mover

(Slide spoon and slide fork) is mounted on the Z-carriage of the transporter.

The slide spoon is mounted fixed, while the Slide fork is mounted moveable. The

movement of the fork is realized with a solenoid driven rocker.

The slide mover

(Slide spoon and slide fork) is mounted on the Z-carriage of the transporter.

The slide spoon is mounted fixed, while the Slide fork is mounted moveable. The

movement of the fork is realized with a solenoid driven rocker.

The produced force onto the slide is limited by the

Distance washer on the solenoid plunger. By using a protector strip on the

slide spoon not the entire bottom of the slide will contact the spoon.

The force, produced to the slide holding mechanics was

dimensioned so, that the slide may be moved in relation to the spoon and fork

if excessive force is used sideward but during real slide movements of the

slide mover, the slide position will not change.

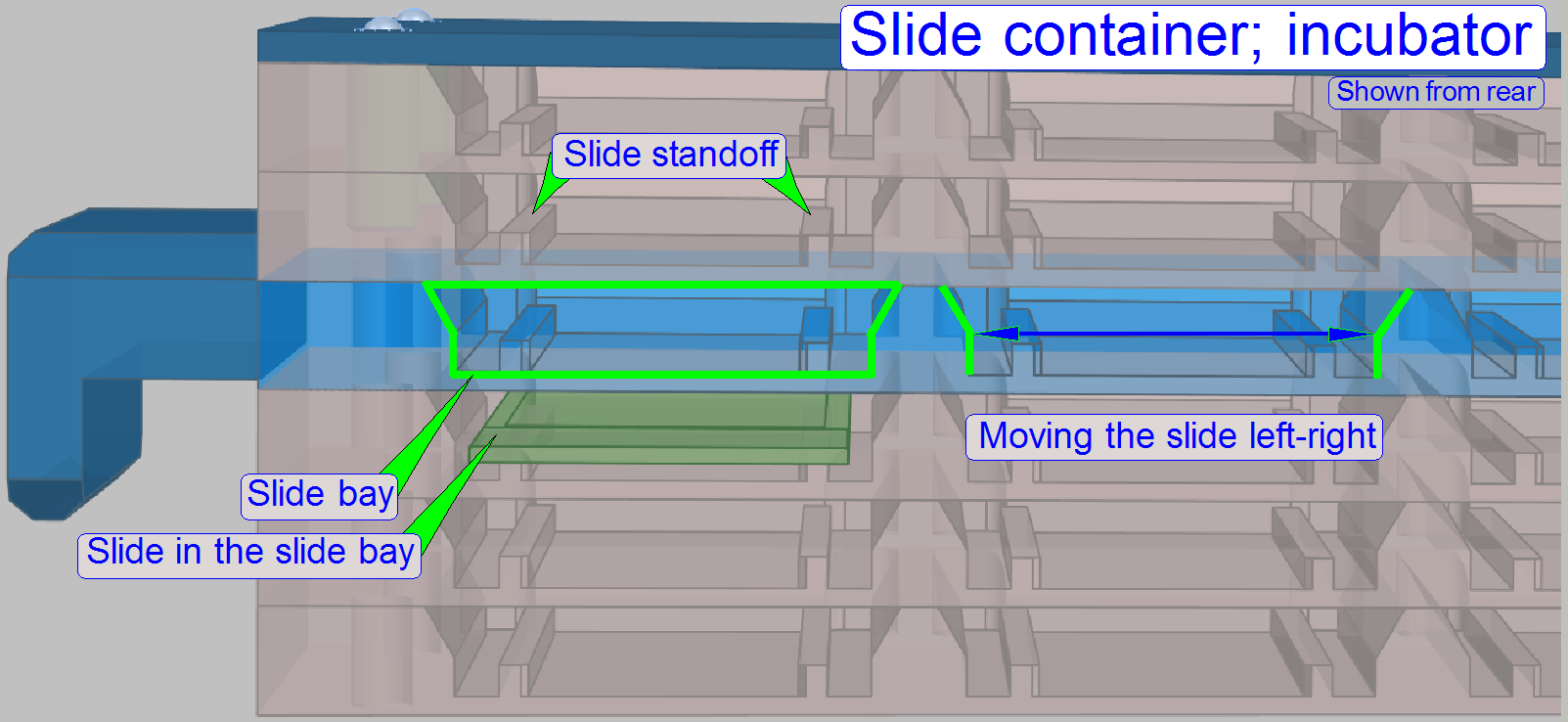

By using the sideward movement in the slide bay, the

slide can be positioned exactly on the spoon before the slide will be picked up

or released in the slide bay.

This is very important during the staining procedure;

the slide has to have the same position in the staining bay as the slide had in

the preview bay! Only so the start point of the preview will meet the start

point for the staining procedure.

This is very important during applying the stain onto

the specimen, otherwise the start point of the sample will not be matched and

parts of the specimen will be left out during applying the stain and partially

only glass will be filled.

Therefore, the software uses always this algorithm to

center the slide on the spoon, regardless the slide is moved into the staining

bay or not.

Remark

Because

the slides has tolerances in width (Slide width defined as 25.00mm – 26.00mm)

the center of the slide is not always met, but by using the left-right movement

routine of the spoon, the position of the slide on the spoon is always exact

the same if the slide will be placed or picked up in any slide bay.

Because

the slides has tolerances in width (Slide width defined as 25.00mm – 26.00mm)

the center of the slide is not always met, but by using the left-right movement

routine of the spoon, the position of the slide on the spoon is always exact

the same if the slide will be placed or picked up in any slide bay.

By using always the left-right movement routine of the

spoon, accumulation of placement deviations is eliminated.

· The

spoon is always positioned centered in relation to the standoffs of the slide

before picking up or releasing the slide!

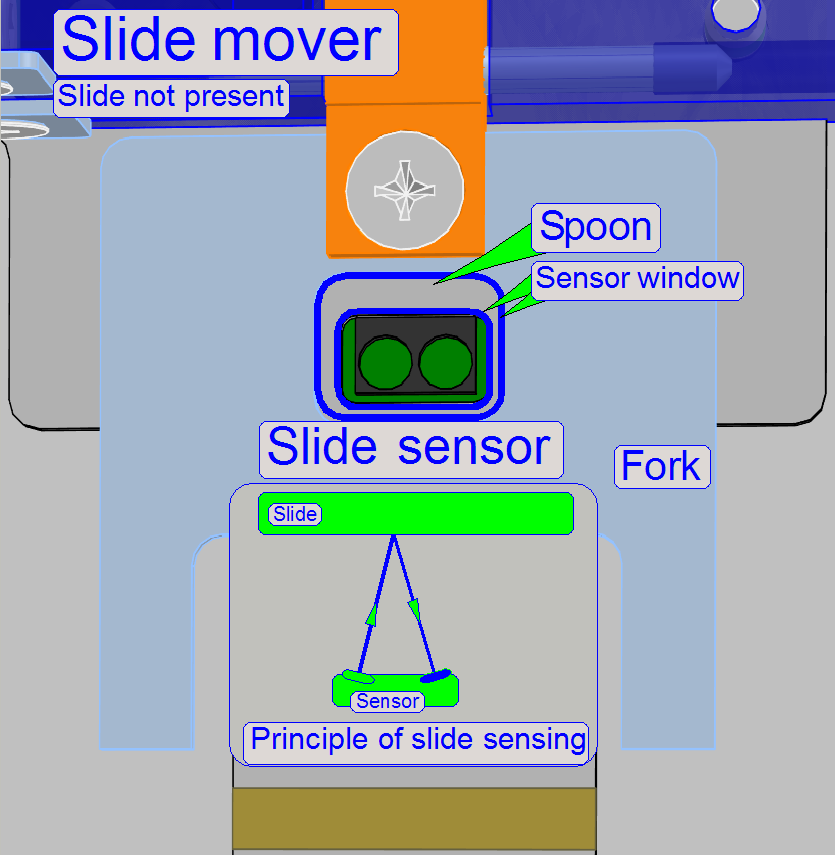

To

optimizing slide mover movements, the software has to know whether a slide is

present or not. For this purpose, the slide in the slide mover is sensed via an

optical sensor.

To

optimizing slide mover movements, the software has to know whether a slide is

present or not. For this purpose, the slide in the slide mover is sensed via an

optical sensor.

· If the

slide is present in the slide mover, the emitted IR light beam will be

reflected return to the sensor by the slide; otherwise the beam will not be

reflected.

To avoid reflecting the beam by the slide fork, the

fork got also a sensor window!